Fuse 1+ 30W

Truly Rapid SLS 3D Printing, From Print To Finish

The #1 SLS 3D Printing Platform, Chosen by More Than Half the SLS Users in the World

Same-Day Parts

A typical print job takes just seven hours and 95% of fully packed print jobs can be completed within 14 hours.

Industrial-Grade Materials & Open Mode

Unlock high-performance SLS 3D printing with a broad range of industry-standard materials that meet the challenges of functional prototyping and production, or print with any 1064 nm powder with Open Material Mode.

Streamlined, Automated Ecosystem

Our complete SLS ecosystem is the only solution that offers an end-to-end streamlined workflow from setup to finished parts.

Meet the Fuse 1+ 30W SLS Printer

FROM DESIGN TO FINISHED PART

An Innovative Workflow, Intuitive From Start To Finish

PreForm

Efficient Print Packing for Optimal Part Density

Use our free print preparation software, PreForm, to import STL, OBJ, or 3MF files, orient models, estimate print times, and pack parts for optimized density, reducing print time and limiting waste.

Fast, Simple

Optimize Prints in One Click

Use our free print preparation software, PreForm, to import 3MF, STL, or OBJ files, orient models, estimate print times and material usage, and monitor prints.

PreForm’s powerful 3D packing algorithm automatically arranges models to increase throughput and reduce material waste by optimizing the packing density.

Manageable

Monitor and Manage Your Printer From Anywhere

Take control of your production across multiple locations and machines. Monitor the live video feed from the comfort of your desk and track print jobs and material flow with our cloud-based tools to ensure minimum downtime and maximum output.

Powder Recovery

Consistent Results and Complete Design Freedom

Unsintered powder supports your parts during printing so you can create complex, interconnecting designs with no need for support structures.

Fine-tuned settings and Formlabs’ patent-pending Surface Armor technology enable mechanical properties and surface quality and ensure professional, consistent results every time.

Consistent

Ready-to-Use Parts in 15 Minutes

Go from printed to professionally finished parts in as little as 15 minutes with a fully automated workflow.

Extract your parts from the unsintered powder in only 5 minutes with Fuse Sift, our all-in-one SLS powder management station, and reuse up to 80% used powder in your next print to minimize cost and eliminate waste.

Fuse Blast, our fully automated cleaning and polishing solution, delivers consumer-grade parts in as little as 10 minutes thanks to the pre-programmed routines.

Nonstop Throughput

Designed for 24/7 Uptime

Achieve faster-than-ever printing speeds to deliver prototypes and small series of end-use parts in under 24 hours.

Industry-leading rapid cooldown times allow you to start a new print within 75 minutes of your previous print job.

Enable continuous throughput by adding a second, removable build chamber and relying on the streamlined, automated post-processing workflow.

Compare SLS Powders

A Material That Does It All

Balancing strength and detail, Nylon 12 Powder is a highly capable material for both functional prototyping and end-use production of complex assemblies and durable parts with high environmental stability.

Ductile, Dimensionally Accurate, and Accessible Parts

Best-in-class refresh rate among Nylon powders, high ductility, and great dimensional accuracy across the build chamber. Choose Nylon 12 Tough Powder to print more durable parts for prototyping and small batch production that have reduced warpage without sacrificing strength.

Versatile, Customizable, Customer-Facing Parts

All of the great qualities of Nylon 12 Powder with the customizability of white parts. Choose Nylon 12 White Powder to create functional prototypes and end-use customer-facing parts that can be easily dyed to match brand aesthetics as well as medical devices and models with high contrast and detail.

Highly Ductile, Impact-Resistant Parts

For highly ductile, robust parts, Nylon 11 Powder is our higher-performance nylon material for functional prototyping and small batch production. Compared to Nylon 12 Powder, our Nylon 11 Powder is more flexible, less brittle, and better at printing thin walls.

Tough Elastomer for Resilient, Skin-Safe Products

Balancing high elongation at break and superior tear strength, TPU 90A Powder enables you to 3D print flexible, skin-safe prototypes and end-use parts that withstand the demands of everyday use – all at a low cost per part thanks to a 20% refresh rate.

Stiff, Stable, Functional Parts

A glass-filled material with enhanced stiffness and thermal stability for demanding industrial environments. Choose Nylon 12 GF Powder to produce stiff functional prototypes or end-use parts for applications where structural rigidity and thermal stability are critical.

Carbon Fiber SLS, for Strong and Lightweight Parts

Get the best of nylon and carbon fiber with this highly stable, high-performance material, perfect for end-use applications that require both high stiffness and superior strength. Choose Nylon 11 CF Powder to produce lightweight rigid parts that can withstand repeated impact and remain stable over time, even at high temperatures.

Print With Any 1064 nm Powder

Unlock the possibility to print with any 1064 nm powder on Fuse Series SLS 3D printers, empowering researchers and expert users to experiment with an advanced printing tool. Optional purchase, one-time lifetime license fee per printer.

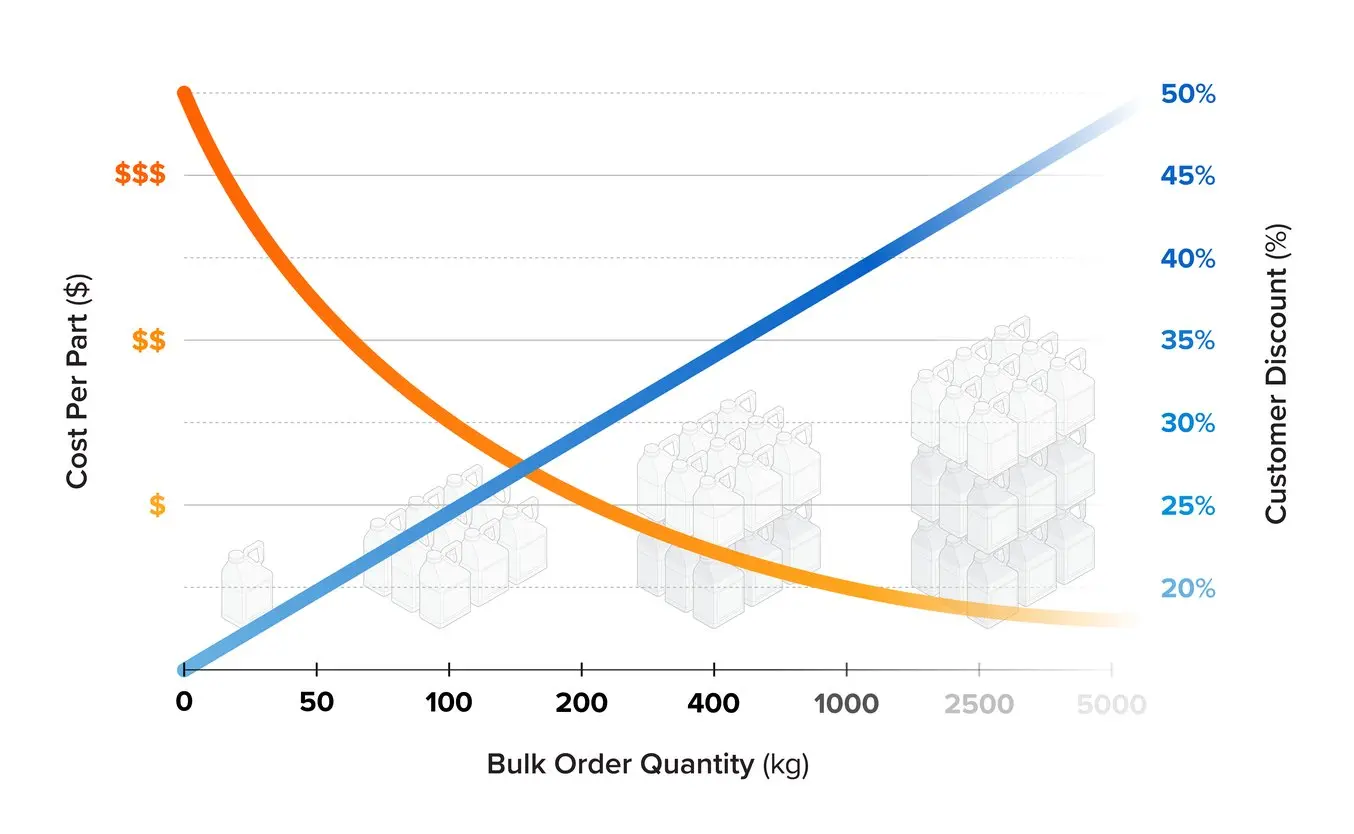

Bulk Powder Pricing for Your Lowest Cost Per Part

3D printing is now cost-effective even at higher volumes thanks to substantial volume discounts for our SLS Powders. Discounts start at 20% for customers purchasing 50 kg of powder in bulk and prices can reach as low as $45 per kilogram.

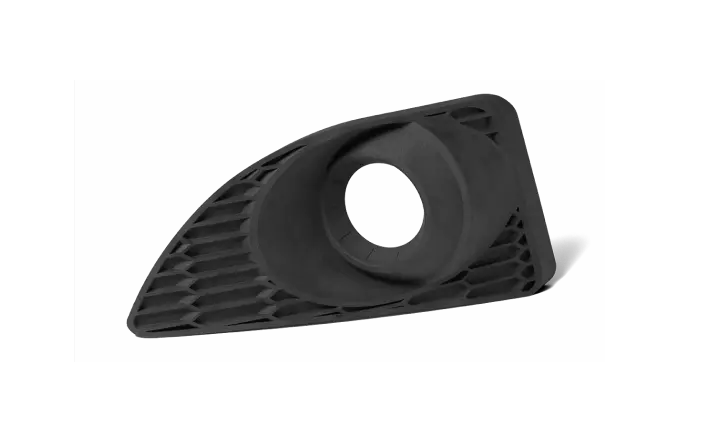

Make Anything With Fuse Series SLS 3D Printers

Bring production in-house and reduce cost per part with a proven, scalable, and accessible SLS ecosystem.

Bring production in-house and reduce cost per part with a proven, scalable, and accessible SLS ecosystem.

Explore SLS Webinars: User Stories, Tutorials, and More

Compare Fuse Series Printers

Fuse 1+ 30W

High-Performance Benchtop SLS 3D Printer

Laser Type

30 Watt Fiber Laser

Throughput

2X Faster for Same-Day Part Delivery

Typical print jobs complete in 7 hours and 95% of fully packed print jobs can be completed in 14 hours

Material Compatibility

Seven Materials

Nylon 12, Nylon 12 Tough, Nylon 12 White, Nylon 11, Nylon 12 GF, Nylon 11 CF, and TPU 90A Powders, or any 1064 nm powder with Open Material Mode

Print Environment Options

Inert Gas and Air

Enhanced material performance and material recyclability

Efficiency

Zero Waste Printing

Enabled by high print density and material recyclability

Fuse 1

Accessible Benchtop SLS 3D Printer

Laser Type

10 Watt Fiber Laser

Throughput

Next-Day Part Delivery

Deliver parts <24 hours

Material Compatibility

Four Materials

Nylon 12, Nylon 11, Nylon 12 GF, and TPU 90A Powders, or any 1064 nm powder with Open Material Mode

Print Environment Options

Air

One option, easy setup

Efficiency

Low Waste Printing

Enabled by high print density

Explore the Fuse Series

A New Wave of Independent Manufacturing Starts Now

Rethink product development and take control of your own manufacturing. Configure your Fuse Series setup today.