Low-Volume Rapid Thermoforming With 3D Printed Molds

Accelerate product development, reduce costs and lead times, and create custom or low volume products with ease by combining 3D printed rapid tooling and thermoforming.

An Efficient and Affordable Means for Rapid Tooling

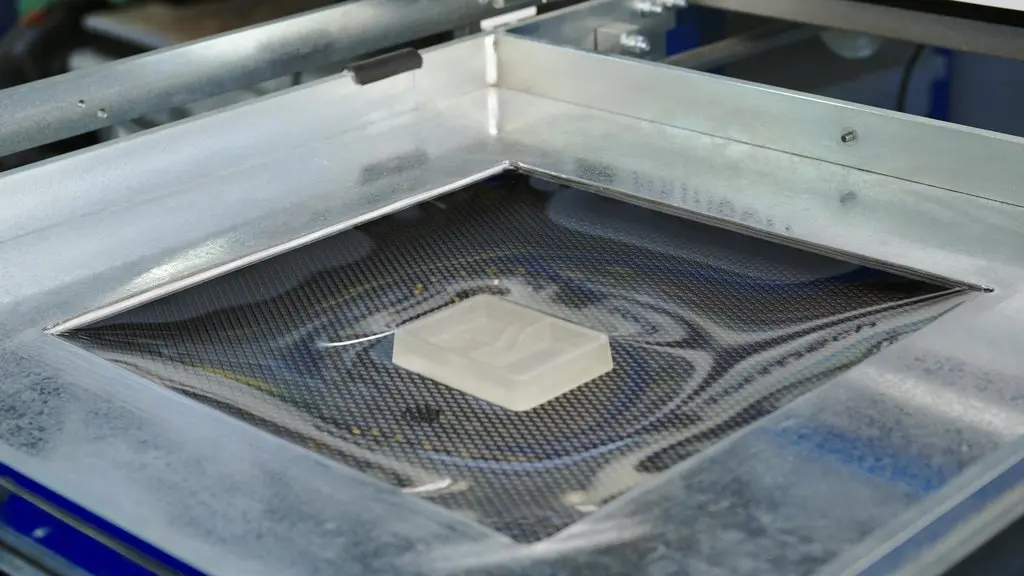

Use 3D printed thermoforming molds with both benchtop and industrial machines to efficiently and affordably produce dozens of functional prototypes, parts for pilot production, or custom and low volumes of end-use parts.

Prototyping Packaging With Vacuum Forming and 3D Printed Molds

How Lush Cosmetics Take Ideas From Concept to Reality in Under 24 Hours with 3D Printing

Read the Story

Digital Orthodontics at Scale: Lessons From the UK’s Largest Ortho Lab

Read the StoryIntegrate Into Any Thermoforming Workflow

Formlabs complete, easy-to-use ecosystem can seamlessly be integrated into any thermoforming workflow. Save time and money on custom and low-volume thermoforming projects by leveraging the benefits of 3D printed molds to quickly and affordably produce dozens to hundreds of parts in traditional thermoplastics.

Mold Design

Mold 3D Printing

Mold Assembly

Sheet Clamping

Heating

Forming

Cooling

Demolding and Trimming

Works With Both Desktop and Industrial Thermoforming Machines

Thermoforming molds fabricated with Formlabs 3D printers have been tested with both desktop and industrial thermoforming machines using a wide range of pressures, temperatures, and materials, using both thin and thick-gauge sheets.

A Complete Desktop Ecosystem

With a Formlabs 3D printer and desktop vacuum forming or pressure forming machine, it’s easy to get started in-house. Quickly test, validate, and iterate prototypes, or manufacture custom and low volumes of end-use parts with limited equipment and training.

Production on the Factory Floor

Grow your business and take on more small volume jobs by leveraging 3D printing to produce thermoforming molds. Whether you outsource low-volume tooling or machine it in house, 3D printing can be used on the factory floor to affordably and efficiently fabricate molds while allocating skilled resources elsewhere. The Form 3L enables the fabrication of large-scale molds for floor standing and fully automatic production machines.

Tools to Get Started 3D Printing Thermoforming Molds

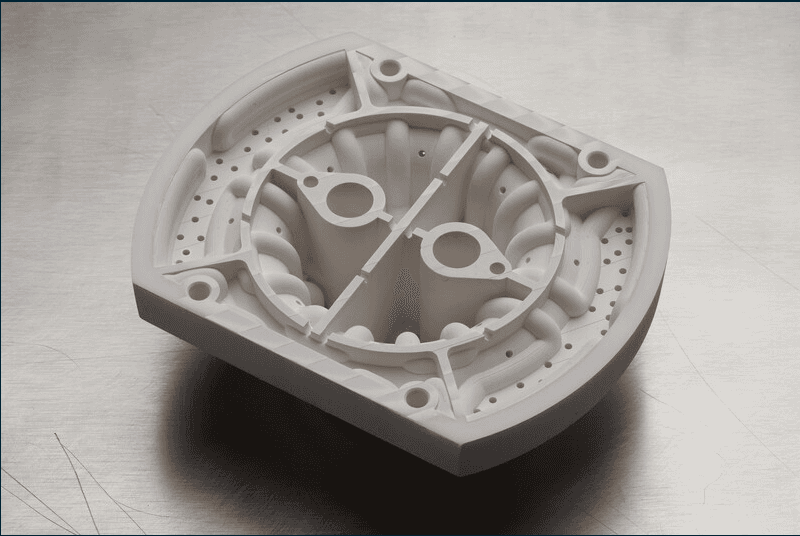

Formlabs ecosystem of accessible 3D printers and high-performance materials can be used to fabricate strong, smooth, highly detailed thermoforming molds capable of producing dozens to hundreds of parts under demanding molding conditions.

Thermoforming Tools

Form 4

High Performance SLA 3D Printer

The Form 4 produces molds with high-quality surface finish and fine features, ensuring that the thermoformed parts come out true to design with minimal post processing.

Use the Form 4 at various points of the product development process for a faster ROI. From 3D printing prototype parts to producing molds for short run production of those same parts, the Formlabs ecosystem is easy to integrate into any product development process.

Additional Thermoforming Resources

Check out some additional resources to help you get started using Formlabs 3D printers to fabricate low-volume thermoforming molds.

Get Started 3D Printing Thermoforming Molds

Contact a Formlabs Solution Specialist to get started 3D printing thermoforming molds for low-volume production today.