Pre-operative planning is crucial to delivering successful surgery, thereby delivering optimum patient outcomes. The arrival of 3D printed anatomical models has revolutionized how surgeons obtain the critical insights that are needed before performing complex surgical procedures, leading to better outcomes for patients. With the help of Formlabs and Axial 3D, Mr. Alistair Irwin was able to successfully remove a tumor from a young patient.

For over five years, Irwin has been a Consultant Orthopaedic Surgeon, practicing at the Royal Victoria Infirmary in Newcastle Upon Tyne, one of just four specialist spinal sarcoma centres in England. Irwin undertakes all aspects of adult spinal surgery including minimally invasive techniques, with a specialist interest in spinal tumors, including spinal sarcomas shown in the case below.

How the Team Assesses Tumors

The team at Newcastle completes approximately 10 spinal sarcomas resections per year. In what is a one in a million case, a young girl from Newcastle UK was faced with an extremely rare and aggressive form of cancer that was growing quickly from the thoracic spine and chest wall into the anterior thoracic cavity and mediastinum. After biopsy this was diagnosed as a Mesenchymal Chondrosarcoma, a cartilage producing tumor that was rapidly destroying local structures and causing damage. If left alone, it could cause catastrophic harm—compressing vital structures (such as major veins, arteries and even the structure of the heart), or start to compress the spinal cord and cause damage to the nerves and motor functions.

Spinal sarcomas are rare and require a highly specialized team including specialist oncologists, radiologists, pathologists and surgeons to care for them. In this particular case the site, size and complexity of the tumour required a surgical team comprising plastic, paediatric, cardiothoracic, paediatric cardiac and spinal surgeons. Because of its complexity, planning and visualization of the anatomical sites involved was crucial.

This particular type of tumor is usually only treatable with radical surgery. However, because of the young age of the patient and aggressive nature of the tumor, a trial of adjuvant chemotherapy was started under the care of the paediatric oncologist. Unfortunately, the tumor continued to grow.

This left two options for the team. Either declare the tumor inoperable because of its size and tricky location (sitting behind the heart, close to the lungs, bronchial tree, the aorta and the major Azygos vein in relation to the spine), or attempt to resect the tumor.

This type of tumor must be removed in one procedure, as they are likely to grow back if they are removed in pieces. So, the only safe way to remove the tumor was in one single resection with a safe margin of healthy tissue surrounding it to ensure the entire tumor was successfully removed.

The biggest difficulty for the team at this point was knowing exactly which structures were involved. Even with detailed MRI and CT imaging as well as transesophageal echo it was impossible for the team to ascertain whether the tumor was invading the heart or the atrium, or the involvement of the aorta and Azygos vein.

To better assess the anatomy, one of the cardiothoracic surgeons had put a camera inside the patient’s chest to get a better look. However, due to the size of the tumor he was unable to get an accurate view of the anatomy and structures such as the heart or aorta. Attempting to resect the tumor without a complete understanding of it and the surrounding anatomy was far too great a risk.

Why the Surgical Team Turned to 3D Printing

The Problem 3D Printing Solved

The surgical team, the patient, and her family all understood that this was a major operation that carried high risks, with a ~50% chance of causing significant neurological injuries and paralysis and a ~50% chance of the patient not making it because of major intraoperative complications. If the team were to go ahead with the procedure, they needed to get a complete picture of the anatomy with the tumor in-situ.

3D modeling software was unable to give the team the level of confidence and detail they needed, and the team was still unable to understand how the resection could take place. This is where Axial3D and Formlabs came in.

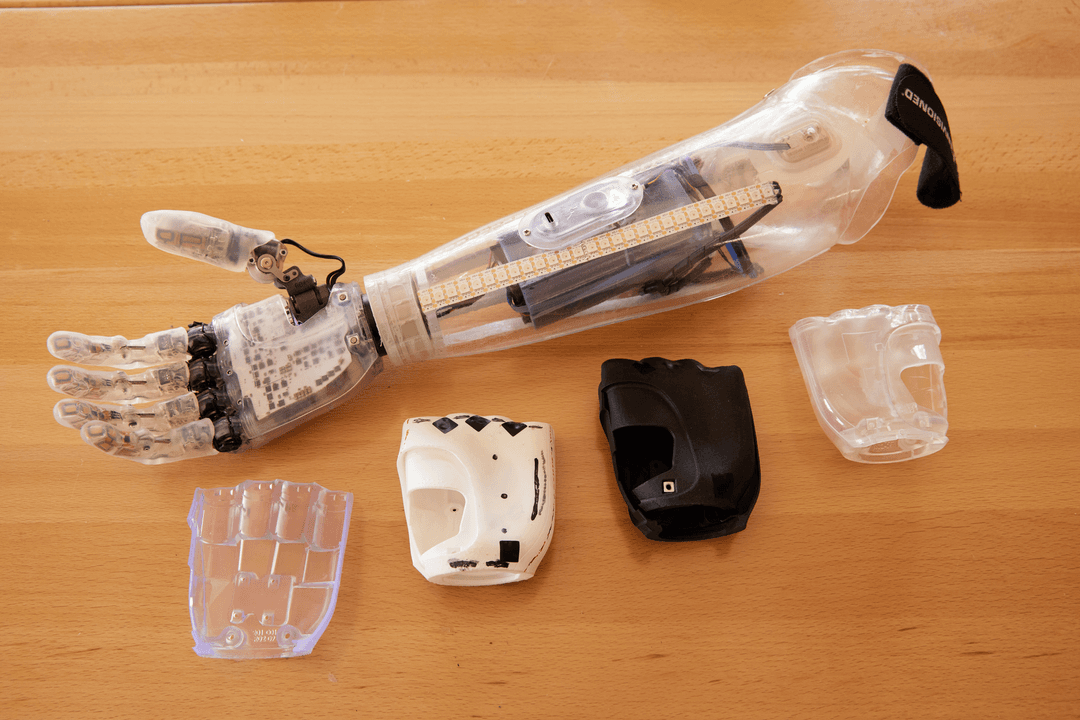

The team produced a physical 3D printed model to augment the 2D scans and improve planning with enhanced insights into the patient’s anatomy. Crucially, planning with the 3D model enabled the surgeons to remove structures such as the heart and the aorta to get a much better understanding of the area behind them, which was proving impossible on the scans.

Surgeons are used to looking at scans and then building the 3D image in their mind. In this case, the surgeons used the 3D model to guide their decision making—consequently the accuracy of the 3D model was incredibly important. Axial3D’s expert machine learning algorithms and robust validations alongside Formlabs’ detailed 3D printers ensure that the surgeon consistently gets a micro-millimeter perfect replica, based on the patient’s scans.

Given the sheer scale of the tumor and the affected surrounding tissues that needed to be visualized in one 3D print, Axial3D utilized Formlabs’ new Form 3BL 3D printer. Over five times the size of a standard desktop printer, the printer’s capacity enabled the team to print the entire torso and surrounding anatomy of the patient to give the clinical team an exact and comprehensive representation of the young patient's anatomy.

Why Large-Format Printing Matters

Want to learn more about the Form 3L and Form 3BL ecosystem, and how they compare to other methods of creating large prints?

In this free report, we look at how in-house large-format 3D printing with the Form 3L stacks up against other methods of production, chiefly outsourcing and using FDM printers.

Taking the Guesswork Out of Pre-operative Planning

Being able to rely on Axial3D and Formlabs for these details and accurate models gave the surgical team a much clearer picture of the anatomy and enabled them to eliminate the guesswork well ahead of the resection.

The model became a critical tool in helping the team understand and plan exactly which ribs were intersecting with the tumor and how closely the team needed to make cuts on the ribs or the spine. Being able to practice on the model beforehand gave the team a great level of insightful detail on patient anatomy, and the confidence to carry out the procedure.

The Value of a Physical Model

“Of course, you still have an idea of what you're trying to achieve and where your margins need to be without a 3D model, but having the model in front of you provides you with a lot more confidence. We can certainly say that it reduces planning time and makes for more accurate planning,” Irwin said.

“It's easy to use, efficient, and quick. The models Axial3D produces are very good, accurate and easy to use. The service is fairly seamless and efficient compared to other types of new where it can be an onerous, complicated, lengthy process. The model produced in this case was very intuitive, very interactive and seamless which meant we could get things turned around quickly. I've been very impressed with how Axial3D can rapidly turn around complex requests,” Irwin said.

The outcomes for the patient have been incredibly positive. While she had to spend a few weeks in hospital after the procedure, she was able to walk out with no signs of weakness or paralysis. Her blood loss during the operation was at normal levels.

The greatest outcome of the model was the accurate tumor resection (confirmed by a pathology sample). After clear margins were determined and the young girl’s vitals were stable, she was able to return home with her family. With the help of the 3D printed model, she was discharged from the cancer ward with the comfort that the team had been able to resect the entirety of the tumor.