Gillette Stays Ahead of the Competition by Using 3D Printing to Unlock Consumer Personalization

Barriers to entry have collapsed across every consumer product category forcing established brands to innovate constantly to stay ahead of new entrants. Major brands must introduce new products frequently and cultivate customer loyalty to avoid losing market share to a horde of niche competitors targeting segments of their audience with tailored products.

Brands can build loyalty by offering customers the opportunity to express themselves through their products. Successful digital experiences achieve this by combining a wide selection of pre-generated options with additional customization choices. Physical products, constrained by the rigidity of traditional manufacturing, haven’t caught up to their digital counterparts.

3D printing with Formlabs Factory Solutions breaks those constraints and allows brands to combine the best of the digital and physical worlds to forge deep personal connections with their customers.

Learn how Razor Maker™ uses 3D printing to produce unique products, and how Formlabs Factory Solutions can help you catalyze business transformation.

The world’s best brands are transforming their businesses with 3D printing. Want to do the same?

As part of its response to increasing pressure from direct-to-consumer shave brands, razor manufacturer Gillette turned to Formlabs Factory Solutions for help launching Razor Maker™ —a platform for designing and manufacturing mass customized and limited edition razor handles.

Using Formlabs 3D printers as its production engine, Razor Maker™ gives consumers the power to create and order customized 3D printed razor handles in a variety of designs and colors with the option to add custom text. It also allows Gillette to rapidly launch limited edition handles such as one commemorating the 50th anniversary of the Apollo moon landing.

“Our partnership with Formlabs, and the power of their 3D printers, enable consumers to have a say on how their razors should look. We are excited to work with our Boston neighbors to pilot this breakthrough concept of customization,” said Donato Diez, global brand manager for Gillette and Razor Maker™ co-founder

Watch the video to learn more about the story of Razor Maker™ powered by Gillette and Formlabs.

Guide to Mass Customization

This guide will provide manufacturers with insights into the different approaches to customization, how to choose the most applicable approach, and more.

Unlocking Design Freedom and the Power of Personalization

“Combining our best shaving technology with the power and flexibility of 3D printing opens up a whole new world of product design possibilities,” said Rob Johnson, design engineer and Razor Maker™ co-founder.

With 3D printing, complexity and variety are “free”; a 3D printer takes no more time, energy, or material to manufacture a complex shape than a simple one, and zero tooling means printing a variety of designs requires no extra production costs. 3D printed products are inherently lower risk because designs can be added, removed, or revised seamlessly with no incremental cost.

The design freedom unlocked by 3D printing allowed Razor Maker™ designers to draw inspiration from complex geometries found in nature, architecture, and technology.

Designers drew inspiration from geometries found in nature, architecture, and technology to create a wide variety of intricate shapes that would be difficult or impossible to realize through traditional manufacturing. Designers didn’t need to predict which razor handles would resonate the most with their customers because they were confident that 3D printing would help them adapt quickly to customer preferences and buying patterns.

“It allows us to think about form in a way that was never possible before,” said Rory McGarry, industrial design lead at Razor Maker™. “In a traditional sense, we could only do one or two razor designs a year, whereas now we can have an idea, create it in 3D, print it, look at it, adjust it, and say that’s it.”

With 3D printing, Razor Maker™ designers are able to quickly test ideas, moving seamlessly from concept to 3D model to physical product within days.

Ultimately, the absence of design constraints fuels the ability to offer consumers freedom of choice. In a market saturated by mass-produced goods, the goal of Razor Maker™ is to offer consumers the chance to make razors that are completely their own.

“We know consumers today are looking for brands that innovate in ways that let them express themselves – and that’s exactly what this pilot is all about,” said Evan Smith, global product manager for Razor Maker™.

A Workflow for Custom Manufacturing

Pursuing such a high level of customization for Razor Maker™ required the team to completely rethink their approach to manufacturing.

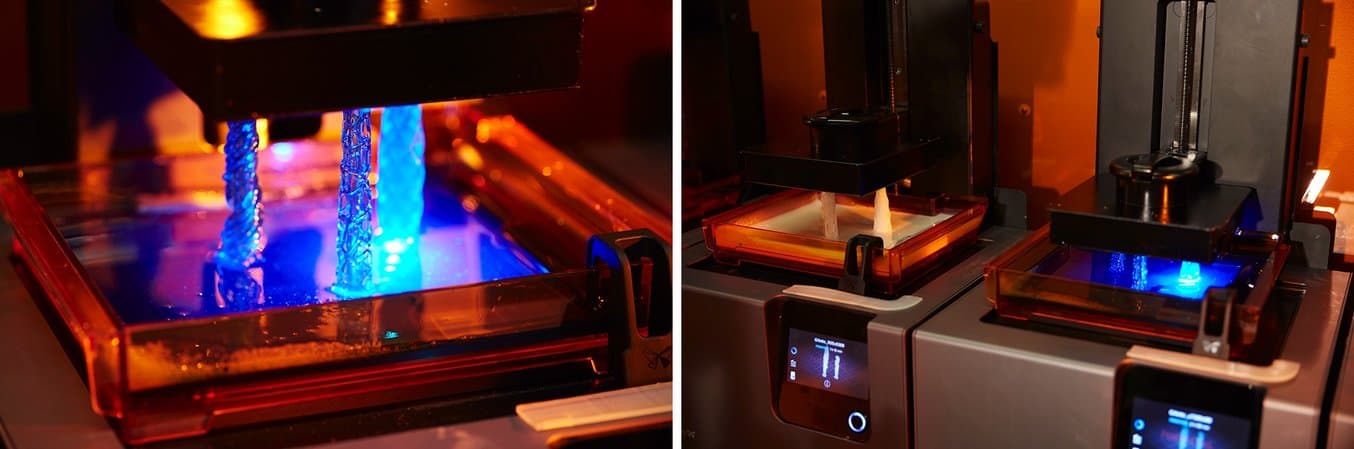

The initial steps in the process are completely digital: a consumer customizes a unique handle through the Razor Maker™ website and the resulting design is converted into a 3D file. Multiple design files are then sent to a 3D printer to be simultaneously printed in a single batch. Each handle is then washed, post-cured, coated, and assembled before being shipped directly to a consumer’s door.

Each Razor Maker handle is printed at Gillette’s Boston headquarters using Formlabs stereolithography (SLA) 3D printers.

Previously, Gillette had only applied 3D printing for prototyping, but advancements in materials and hardware have made the technology a viable option to produce end-use parts.

Ease of customization is an inherent advantage of 3D printing. The technology removes the need for tooling, requiring no up-front investment in molds and eliminating the costs of producing a variety of complex designs. Plus, scaling custom manufacturing can be as easy as adding more printers.

“The Razor Maker™ concept allows us to create a new design, print and test it, and then the next day that design becomes a new handle available on the website,” Johnson said. “That was never possible before.”

Gillette continues to explore new avenues of customization within the Razor Maker concept. In the fall of 2019, Gillette offered three special edition razors printed on the Formlabs industrial 3D printers. This type of small batch production just isn’t feasible under traditional manufacturing methods. 3D printing allows the team to come up with new ideas, such as a razor to celebrate the moon landing, and bring a product to market in a much shorter timeframe than ever before.

How to Unlock Low Volume Production and Custom Manufacturing with 3D Printed End-Use Parts

Watch this webinar to learn how to achieve custom manufacturing and low volume production of end-use parts quickly and cost-effectively with 3D printing.

Rethinking Production and Business Models

New technology alone isn’t enough to transform manufacturing. Companies like Gillette are leveraging 3D printing to explore new business models that change the way they work across the entire product lifecycle, from design through production.

Through Razor Maker™, Gillette is able to offer thousands of consumers the power to design a handle unique to their lifestyle and preferences.

“For Gillette, piloting Razor Maker™ represents a crucial step in our customization journey where new technology and new business models must come together in order to deliver products that are as unique as our consumers,” Diez said.

Interested in creating and launching mass-customized or limited edition products with 3D printing?