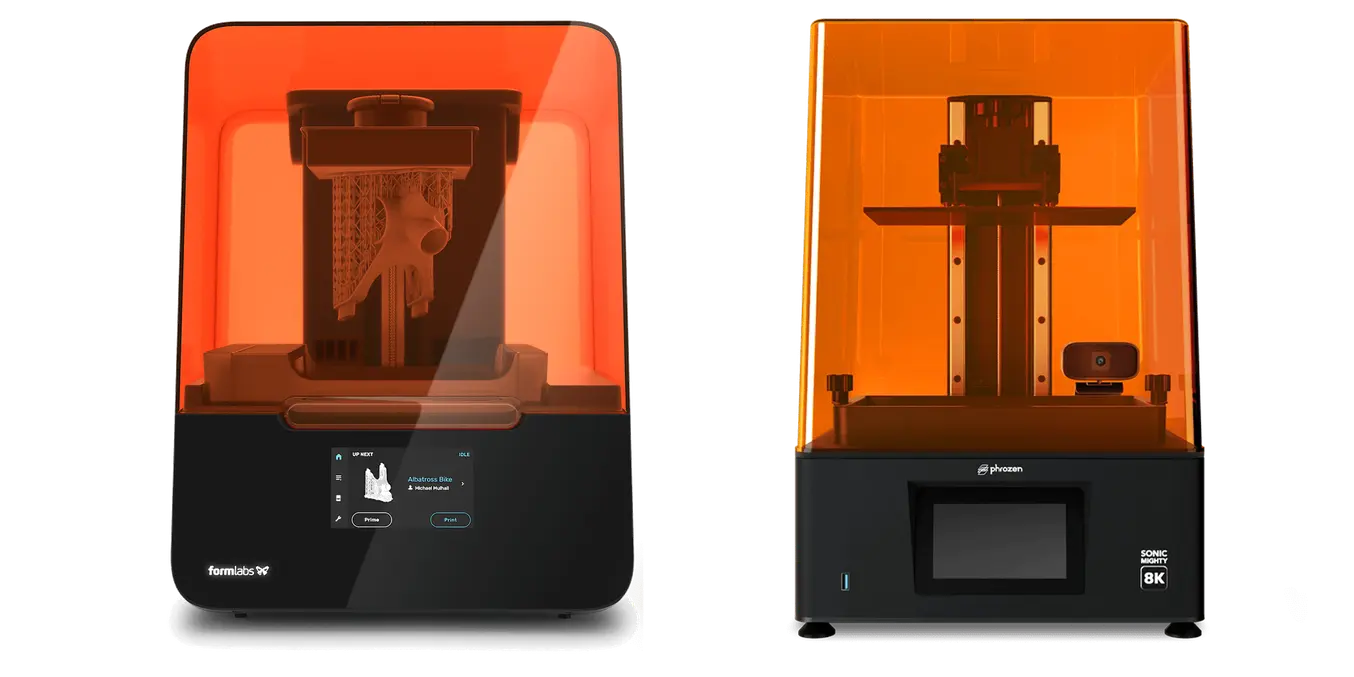

Formlabs Form 3+ vs. Phrozen Sonic Mini and Mighty Series

Looking for a resin 3D printer? Compare the Formlabs Form 3+ with the Phrozen Sonic Mini and Mighty Series side by side.

Formlabs Form 3+

Cost

Resin 3D printer for professionals

Form 3+ offers industry-leading technology and support so you can spend less time troubleshooting and more time printing. Go from design to finished part in fewer steps than ever with the streamlined, end-to-end ecosystem. Bring your parts to life with our extensive resins library, designed to deliver industrial- grade parts that are up to any challenge. Trusted by tens of thousands of professionals around the world.

BENEFITS

- High resolution and fine details

- Great accuracy and print quality

- Wide range of materials

- Reliable

- Easy to use

APPLICATIONS

- Rapid prototyping

- Functional prototyping

- Concept modeling

- Rapid tooling

- Manufacturing aids

- Short-run production

- Dental models and appliances

- Medical models and medical devices

- Jewelry prototyping and casting

- Models and props

Cost

Starting at $2,499

The $2,499 starting price includes all the essential tools required to start printing and acccess to the powerful software and online Dashboard. Complete package for $4,249 includes also custom-developed automated post-processing tools and a premier service plan for a turnkey solution.

Buy from Formlabs via sales or the online store, or purchase through one of our distribution partners.

Print Technology

Low-Force Stereolithography (LFS)™

LFS is the next phase in SLA 3D printing, that delivers incredible surface quality and print accuracy, meeting the demands on today’s market for scalable, reliable, industrial-quality 3D printing.

Build Volume

14.5 × 14.5 × 18.5 cm

5.7 × 5.7 × 7.3 in

Materials

30+ validated, functional resins for industrial-quality parts

A wide range of materials for prototyping and production from soft silicone-like to flexible, tough, durable, and rigid varieties. Polyurethanes for end-use parts, specialty materials for high-temperature applications and castable patterns. A comprehensive palette of resins for dental and medical applications is available on the Form 3B+, including 10+ materials for biocompatible parts.

All Formlabs materials come with optimized print settings to guarantee industry-leading print success and reliability.

Formlabs resins are designed with user safety and minimum odor in mind.

Software

Powerful, easy to use, free

Formlabs' free print preparation software, PreForm, automatically suggests optimal orientation, supports, and layout, with the ability to manually refine details as needed.

You can also use the online Dashboard to manage a fleet of printers, monitor prints, track materials and consumables, and work with your team.

Support

Professional support

All Formlabs hardware comes with one-year warranty and email support provided by a dedicated staff. Purchase a Pro Service Plan to extend your coverage further and get access to additional benefits like hot-swap replacements, dedicated phone support, training, and more, so you can stay focused on growing your business.

Features and Ease of Use

Automated resin dispensing

Automatically monitors the amount of resin in the tank and dispense resin as needed, without the need for user interaction.

Light-touch supports

Pre-tuned support settings with light touch supports are available for every material to facilitate support removal.

Automated post-processing tools

Automated washing and post-curing solutions designed for the Form 3 and validated for each material.

Resin mixing and heating system

Consistent printing and a wider variety of material options, including highly-filled materials.

Easy part removal with Build Platform 2

Remote printing

Reliability

94% print success rate

The Form 3+ delivers a print success rate of 94% out of the box, reported by customers across nearly one hundred million prints. This is achieved thanks to some key features of the Form 3+, such as Formlabs' patented Low Force Stereolithography (LFS) technology that minimizes peel forces during printing, built-in heaters that precisely heat the resin and print chamber, material and software validation, and more.

In case of failures, sensors detect common failure modes and alert the user in order to minimize wasted time and material.

Company

Market leaders

Formlabs brought SLA 3D printing to the desktop in 2011 and SLS printing to the benchtop in 2021, and has become the market leader in both technologies, selling more than 100,000 printers. The Form 3+ is a 3rd generation product, powered by a proven technology that has been used to print 100,000,000+ parts.

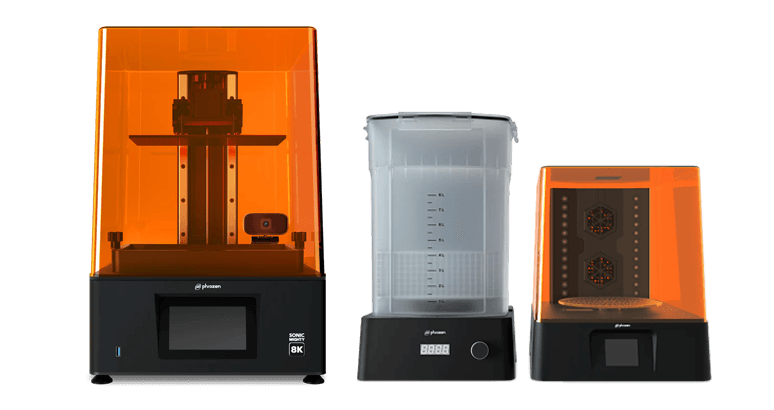

Phrozen Sonic Mini and Mighty Series

Cost

Resin 3D printer for hobbyists

Phrozen's Sonic Mini and Mighty Series offer a low-cost entry into the world of resin 3D printing. They're ideal for hobbyists, students, and anyone getting started with resin 3D printing, but they do require a great deal of tinkering and time invested to achieve successful prints. Material selection is limited, which curbs the range of potential applications.

BENEFITS

- Low entry price

- Quick prints

- High resolution and fine details

APPLICATIONS

- Hobby projects

- Models and props

- Concept modeling

- Jewelry prototyping and casting

Cost

Starting at $349 - $649*

Phrozen's Sonic Mini printers start at $349 while the Sonic Mighty Series start at $649. This doesn't include software, but Phrozen's Premium Slicer is available for $299. Manual washing and curing kit is also available for an additional $199. No option for professional service.

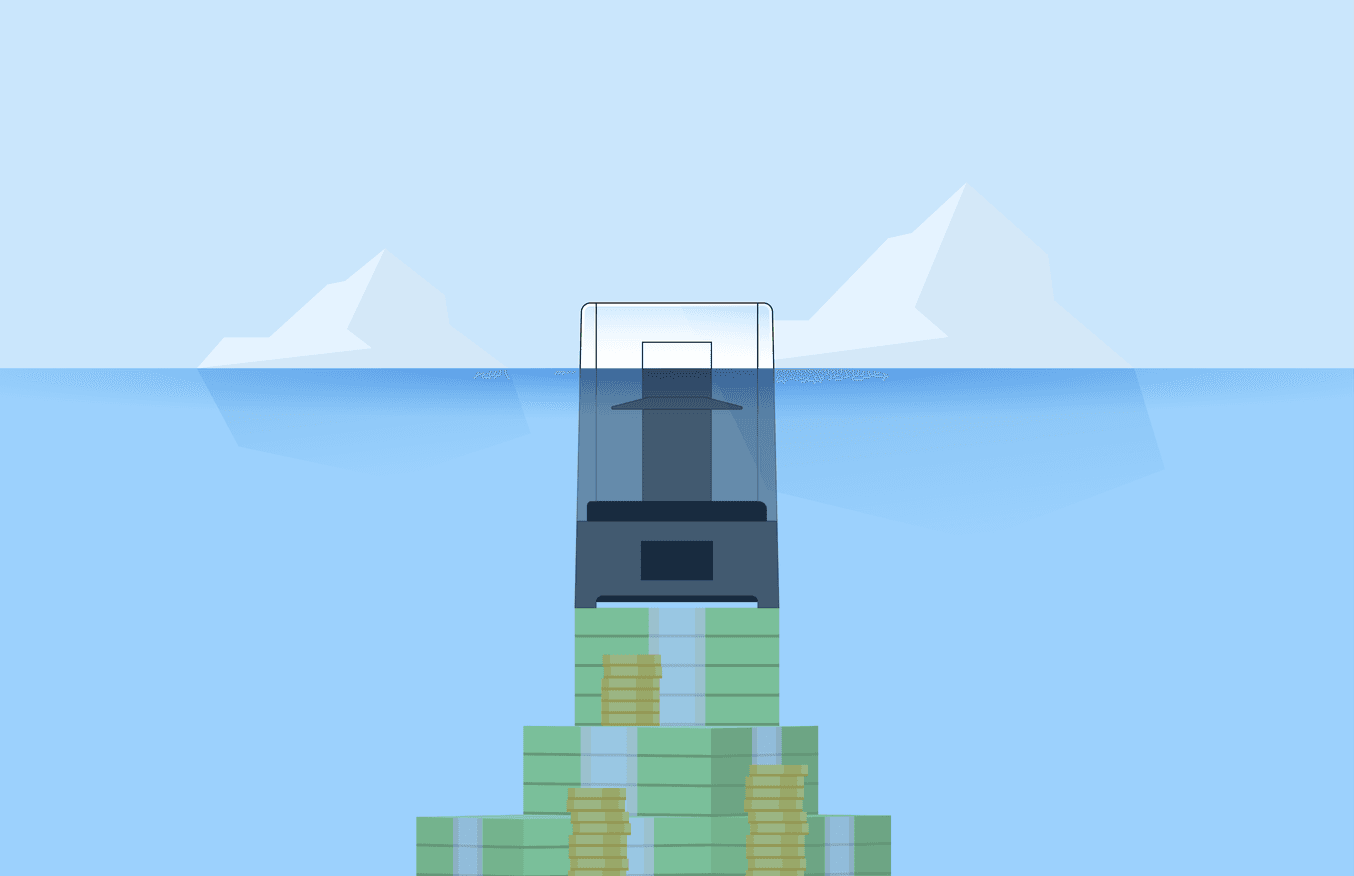

*Low-cost resin printing comes with hidden costs, mainly much higher labor costs due to the lower reliability and complex workflow. If you're planning to use 3D printing for your business, the Form 3+ will become more cost-effective than a low-cost resin printer in a few months of operation while delivering better part performance and fewer headaches.

Print Technology

Masked Stereolithography (mSLA)

mSLA uses an LED array as the light source and an LCD photomask to shape the layer image onto the bottom of the tank. The LCD screen in Phrozen Sonic Mini and Mighty Series printers is rated at 2,000 hours, which means that it requires frequent replacements.

Build Volume

13.4 x 7.5 x 13 cm

5.3 x 3.0 x 5.1 in

Phrozen Sonic Mighty 4K20 x 12.5 x 22 cm

7.8 x 4.9 x 8.7 in

Materials

10+ non-validated resins

Phrozen offers a more limited selection of materials, especially for professional applications. Functional resins have inferior mechanical, thermal, and creep performance, building parts that are often brittle, dimensionally inaccurate, not functional, or not fitting together.

Materials are not validated on the printer, which results in more failed prints and overall lower quality. The part may fail during use or simply not meet the specifications and needs to be reprinted or even outsourced.

Low-cost resins also have strong odors requiring ventilation and may contain more hazardous chemicals.

Software

Barebone, paid

Phrozen's Premium Slicer doesn't come included with the printer purchase, but costs an additional $299. It offers a more limited set of features and is only available for Windows.

There’s no logging system on the printers, no remote print monitoring, and no online dashboard to manage printers, print jobs, or materials.

Support

Minimal support

Phrozen hardware comes with 3-12 months of limited warranty and there is little or no support provided for customers other than self-service online. Knowledge base is limited and customers often need to rely on community forums to debug their printers.

Features and Ease of Use

Manual resin dispensing

Users have to monitor resin levels and fill the resin tank manually from a bottle.

Bulky supports

Supports with large tips and dense structures add time for sanding, reduce surface quality, and increase post-processing time.

Manual post-processing tools

Basic, more labor-intensive post-processing tools.

No resin mixing and heating system

Fewer material options, dimensional accuracy issues, and print failures.

Easy part removal with Build Platform 2

Remote printing

Reliability

60-70% print success rate

Low-cost resin printers typically have a 60-70% print success rate out of the box. This causes project delays from unexpected failure, resin waste from failed prints, extra labor costs from reprints, and worry from not knowing what will happen after pressing “print”. Tuning the printer can increase the print success rate but that requires time and experimentation.

There are no sensors to detect and prevent common failure modes. In case of failures, resin can cover and damage critical optical surfaces of the printer, and the printer requires a lenghty clean-up.

Software

Emerging company

Phrozen is an emerging company founded by 3D printing enthusiasts that develops resin 3D printers predominantly for hobbyist and personal use.

Do you have more questions about the differences between these solutions?

Request a Free Sample 3D Print

See and feel Formlabs quality firsthand. We’ll ship a free sample part printed on the Form 3+ to your office.

Uncovering the Hidden Costs of Low-Cost Resin 3D Printers

Compare costs and experience of low-cost resin printer and Formlabs Form 3+ SLA printer, revealing stark differences in hidden expenses.

24/7 Reliability, At Your Service

Form 3+ offers industry-leading technology and support so you can spend less time troubleshooting and more time printing.

The Parts You Want, Every Time

Best-in-class printer reliability and accuracy means your parts come out right the first time.

We Help You Succeed From The Start

Get up and running right away with personalized onboarding remotely or onsite.

Service With A Human Touch

Expert service, whenever you need it. When required, we come to you for implementation, training, optimization, and repairs.

Advanced Materials for Industrial-Quality Parts

Bring your parts to life with our ever-expanding materials library, designed to deliver industrial-grade parts that are up to any challenge.

30+ Materials, Ready To Be Put To The Test

Each resin in our ever-expanding library is optimized for standout mechanical properties like impact resistance, stiffness, flexibility, and more.

Formulated And Rigorously Tested In-House

All Formlabs materials come with optimized print settings to guarantee industry-leading print success and reliability.

Boundary-Breaking Photopolymers

Specialized materials offer UV stability, flame retardancy, ESD resistance, glass-filled rigidity, biocompatibility, and more.

An Easier, More Efficient Workflow

Go from design to finished part in fewer steps than ever with the streamlined, end-to-end Form 3+ ecosystem.

Hassle-Free Materials Management

Seamlessly switch between a wide range of materials in seconds with our spill-free, swappable cartridge system.

Intuitive Software

Prepare parts in PreForm with just a few clicks and manage printers, consumables, and teams through your online Dashboard.

Powerful Automation Tools

Minimize cost per part and unlock 24/7 production with the Formlabs Automation Ecosystem.

Pre-Production Validation

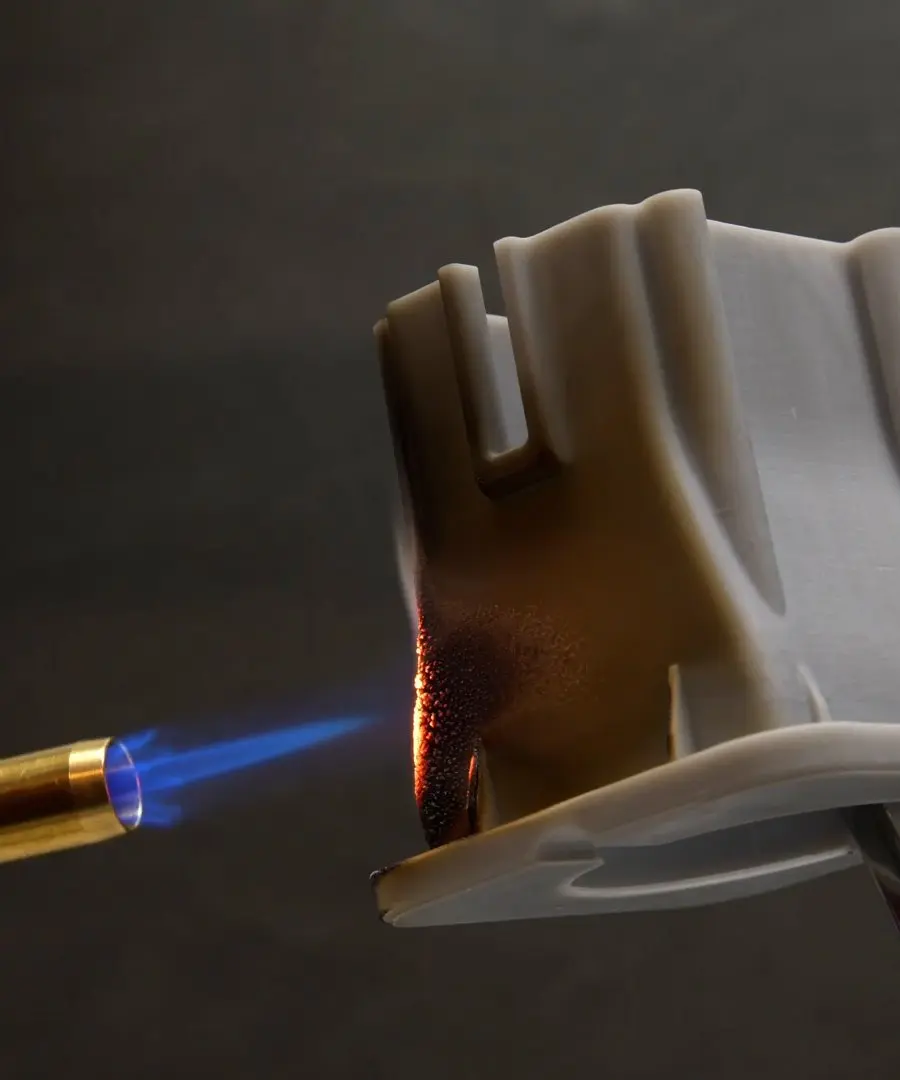

Tough 1500 ResinForge Motorsport reverse-engineered an underperforming part, 3D printed a new design, and tested it on a vehicle for five months before committing to tooling.

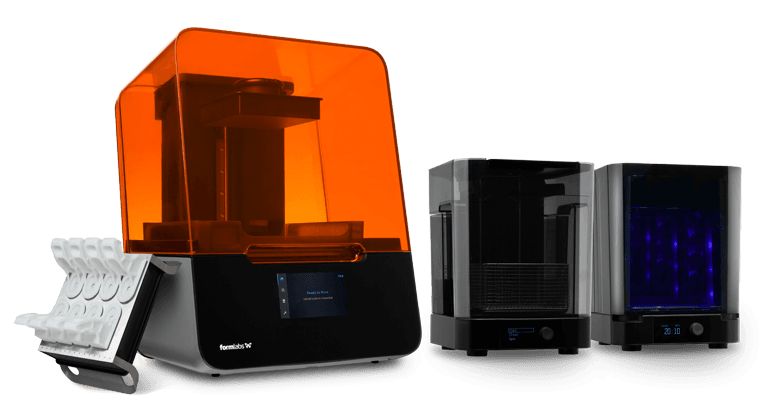

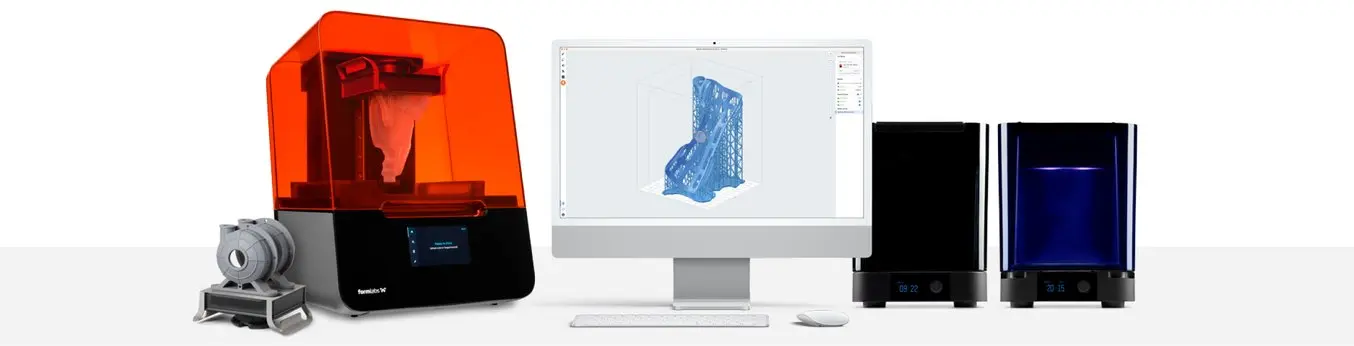

Form 3+ Ecosystem At A Glance

Get more done in a day with the Form 3 Series ecosystem, where every step was designed to save you time.

Materials

Print Preparation Software

3D Printer

Accessories

Post-Processing

Print Monitoring Software

Make Anything At Scale

With Formlabs Automation Ecosystem

Reach new levels of productivity with a fully-automated Form 3+ printer fleet you can operate from anywhere, at any time. Unlock 24/7 production with Formlabs Automation Ecosystem: Form Auto, Fleet Control, and the High Volume Resin System.

100,000,000 Parts Printed With Formlabs Technology