Fast, Clean SLA Post-Processing

From print to final part in as little as 11 minutes*

2 hours

or less

5-10

minutes

1-15

minutes

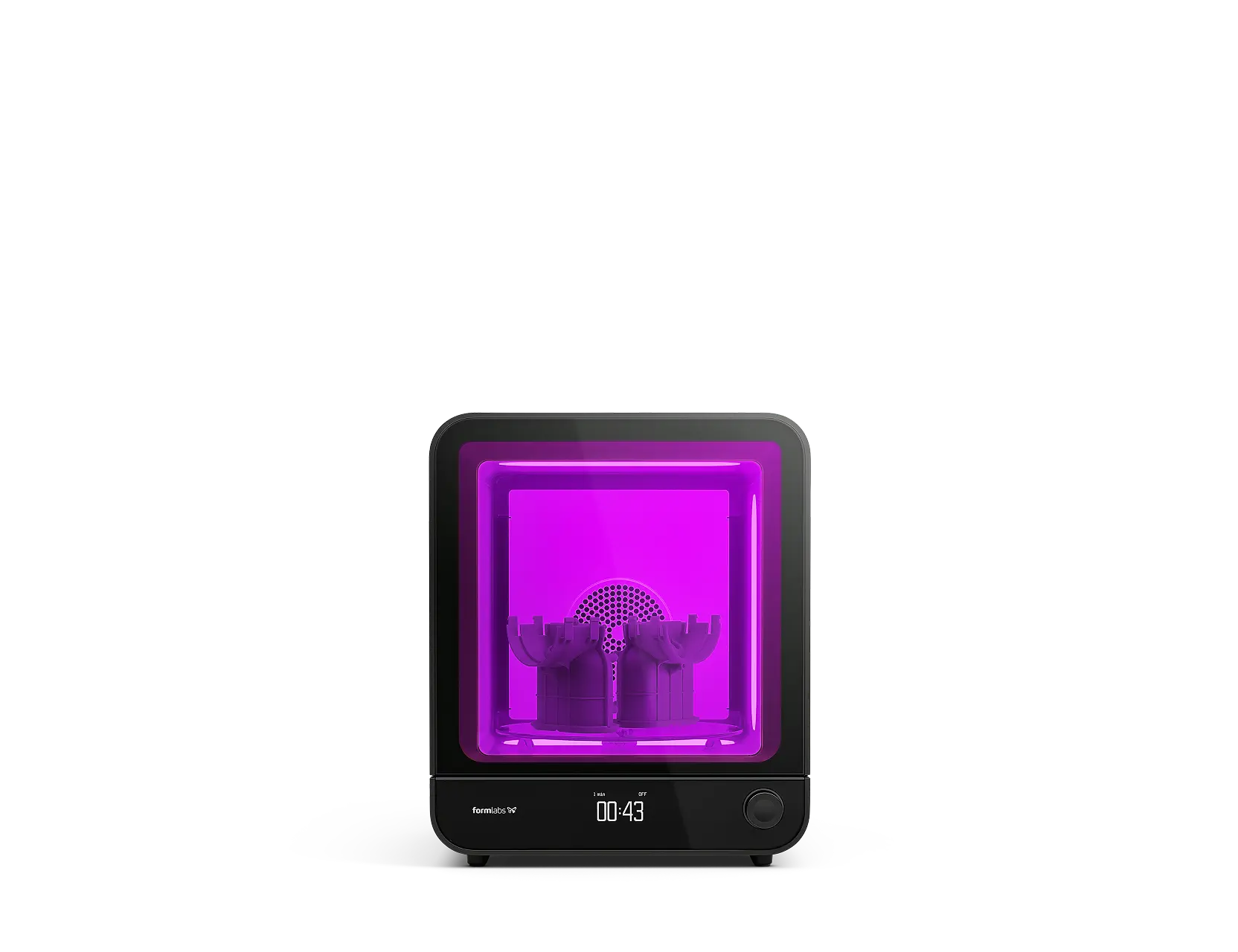

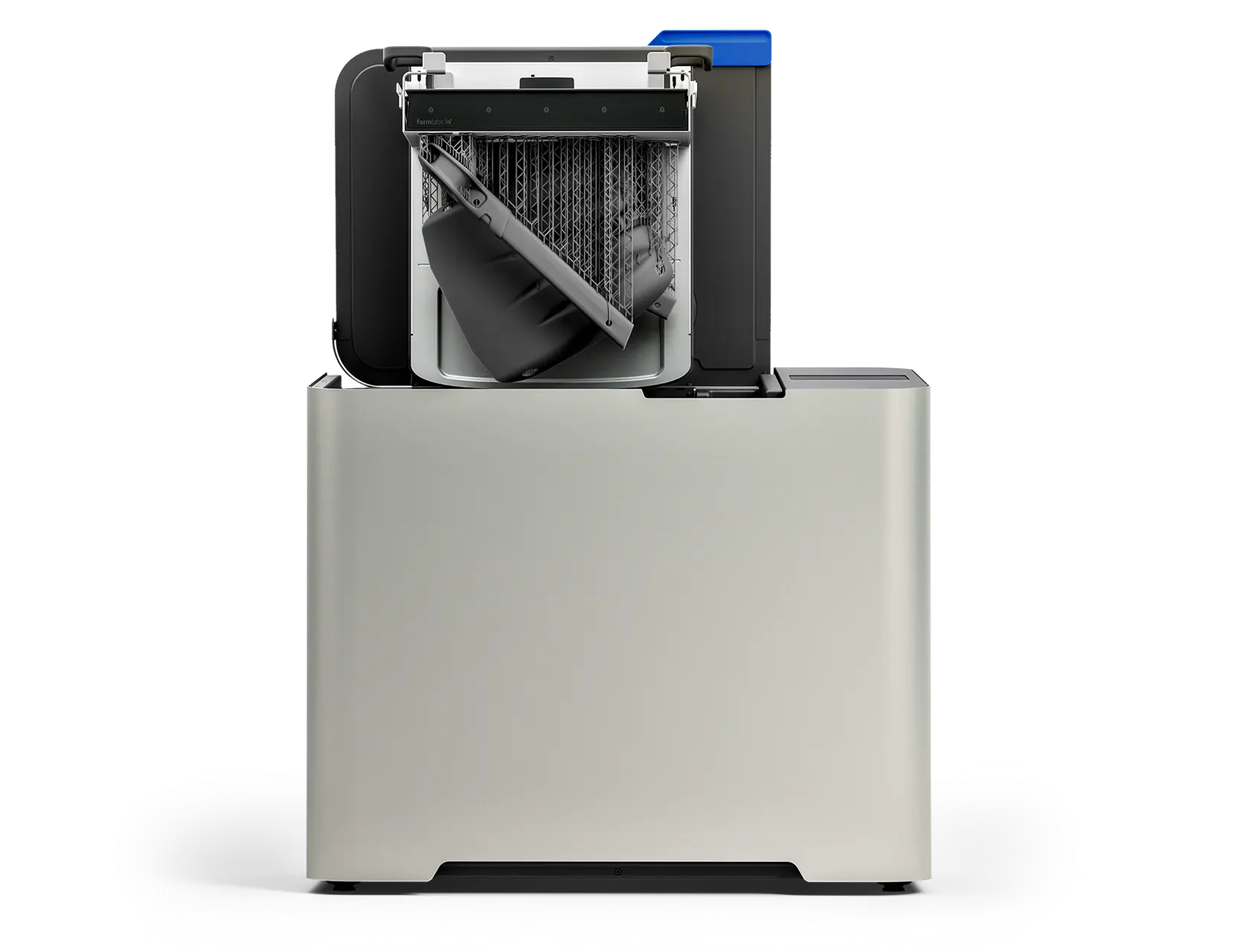

Effortless, Mess-Free Cleaning for Perfect Parts

Washing

How the Wash Works

Form Wash and Form Wash L provide thorough cleaning with powerful agitation to ensure residual resin is completely removed. After the preset wash cycle, the parts are automatically lifted from the bath to air dry.

Washing

Powerful Agitation

Let Form Wash auto-clean your parts faster with powerful agitation to clear every nook and cranny.

Washing

Adaptable to Build Platforms

Seamlessly switch between build platforms with adjustable platform mounts, configurable at various heights and widths.

Washing

Flexible Solvent Volume

Tailor the solvent volume to the size and quantity of your parts. Use lower solvent quantities for smaller parts and builds to increase resource efficiency.

Washing

Compatible With Variety of Solvents

Our recommendation is to use IPA for the best cleaning experience. Alternative solvents such as TPM and Formlabs Resin Washing Solution are also compatible with Form Wash.

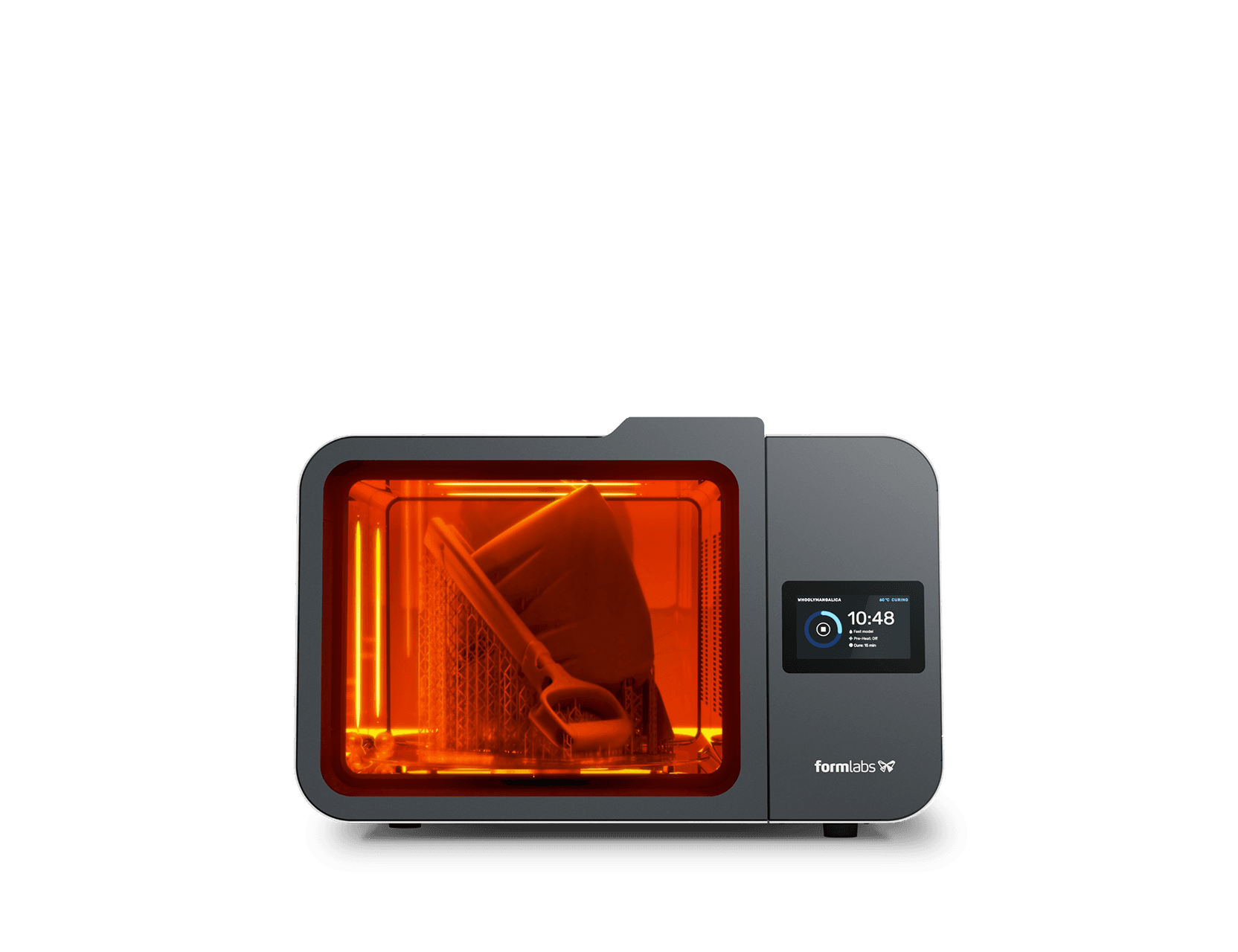

Optimal Material Properties in Record Time

Curing

How the Cure Works

Form Cure and Form Cure L use powerful LEDs, convective heating, and validated presets to achieve optimal mechanical properties with speed and precision.

Curing

Why Post-Curing Matters

Post-curing improves your part on a molecular level. 405 nm light initiates a reaction that cross-links the individual polymers, creating an interconnected, isotropic, and 100% dense final part.

-Higher strength and stiffness

-Higher surface hardness

-Higher toughness

-Higher temperature resistance

-Better creep resistance

Curing

Blazing Fast Curing, Nearly Instant Heat Up

Post-cure general purpose resins in just 60 seconds or engineering resins in less than 15 minutes, with just 60 seconds required to heat to 60 °C.

Curing

Consistent, Validated Results

48 LED array and convective heating system ensure uniform light and heat exposure, delivering 14.5 mW/cm² irradiance and a maximum temperature of 100 °C.

Curing

Post-Cure Full-Size Form 4 and Form 4L Prints

Designed to fit any part on the Form 4 or Form 4L, with a 235 mm turntable for Form Cure and a 395 mm turntable for Form Cure L.

Curing

Easier than Ever

Pre-programmed cure cycles, an easily cleaned glass turntable, and side-hinged door to allow easy access within a compact footprint.

Outstanding Finish and Performance

Smooth Surfaces With Crisp Details

- Unparalleled surface finish

- No visible layer lines

- Accurate details down to 50 µm

Superior Mechanical Properties

- Thermoset plastics that never melt

- Strong and stiff engineering materials

- Soft elastomers with good tear strength

100% Dense and Isotropic

- Equal strength in all directions

- Fully dense parts

- Watertight and airtight

Set It and Forget It

To Unlock Peak Performance

Choose your Ecosystem

For Form 4 and Form 4L

Form 4 Package

Form 4L Package

* Based on a five minute wash, five minute dry, and one minute cure for General Purpose resins