Castable Wax Resin

Casting

SLA

Fine Details

Select Printer Series and Resin Volume

| Bulk order quantity (L) | Discount % |

|---|---|

| 1 | 0% |

| 30 | 15% |

| 60 | 20% |

| 120 | 25% |

| 240 | 30% |

| 1,000 | 35% |

| 2,000 | 40% |

| 3,000 | 45% |

For dental: Castable Wax Resin produces highly accurate patterns for casting and pressing dental prosthetics. Tested at length by dental technicians, 3D printed patterns for copings, substructures, full contour crowns, and removable partial denture frameworks are made easy with Castable Wax Resin. Read our Application Guide to learn the complete workflow and best practices for making 3D printed patterns for casting and pressing on your Formlabs 3D printer.

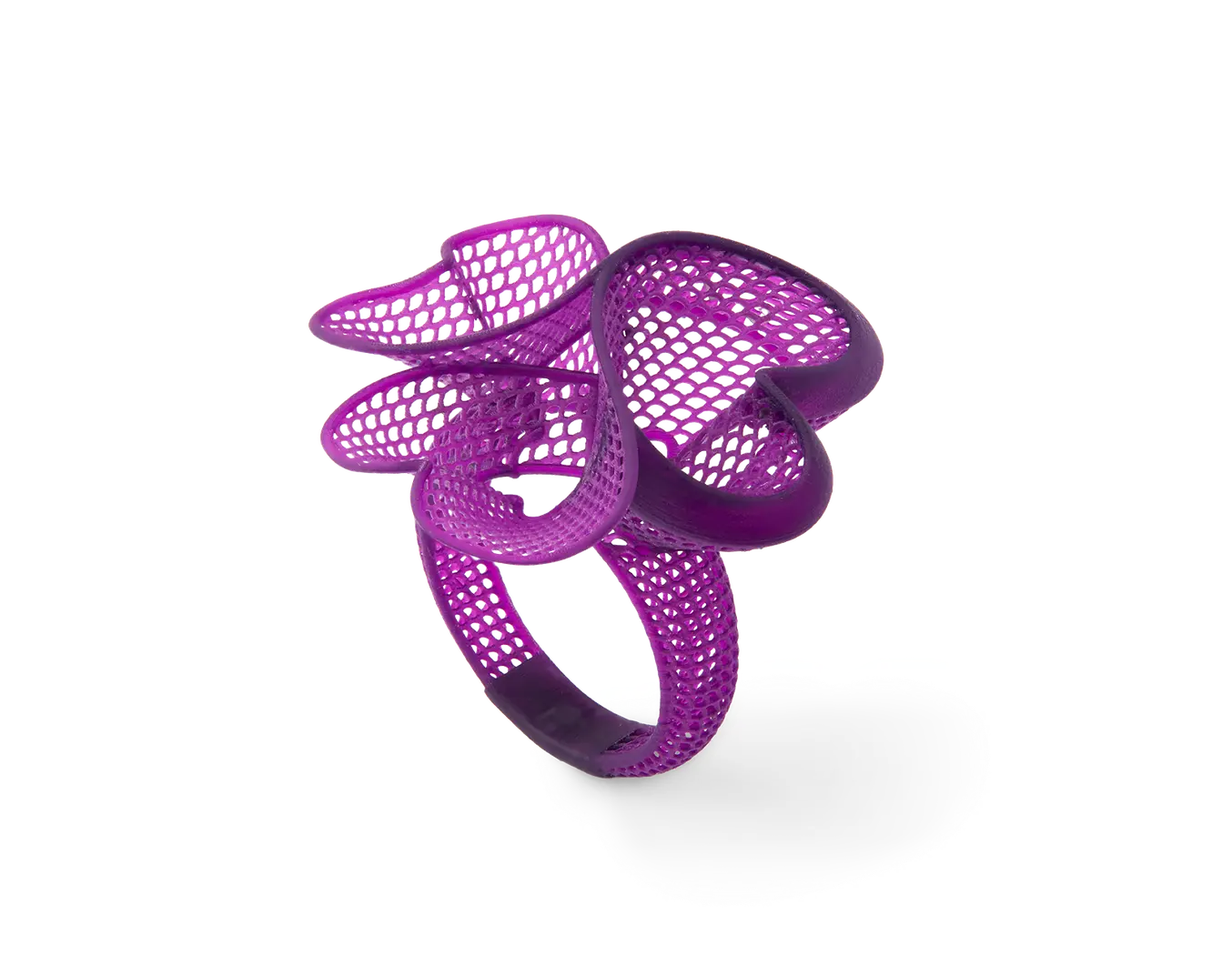

For jewelry: Castable Wax Resin offers high strength and stiffness, making it capable of printing ultrafine structures. The high green strength ensures excellent shape retention for thin patterns such as wire filigree. For heavier jewelry, we recommend using Castable Wax 40 Resin.

Castable Wax Resin has been added to your cart.

Why Choose Castable Wax Resin?

With high strength and stiffness, Castable Wax Resin makes it possible to print ultrafine and thin structures.

Clean, Reliable Casting

Contains 20% wax with zero ash content and clean burnout.

Faster and Simpler Workflow

Printed parts are strong enough to handle with no post-cure required, meaning they are ready to use right away.

Smooth, Refined Surfaces

Easily remove light-touch support tips that don’t leave dimples in your parts.

High Green Strength

Ensure shape retention for thin patterns such as wire filigree.

Applications

Castable Wax Resin is ideal for lightweight, intricate jewelry or for prototypes and production. For Dental, this material is ideal for crowns, bridges, removable partial denture frameworks, and patterns for casting and pressing.

Consider Castable Wax Resin for:

Material Properties*

Castable Wax Resin does not require post-curing. Allow parts to fully dry before casting.*

Castable Wax Resin

Ultimate Tensile Strength

Tensile Modulus

Elongation

Temp @ 5% Mass Loss

Ash Content (TGA)

* Material properties may vary based on part geometry, print orientation, print settings, and temperature.

** Data was optained from green parts, printed using Form 2, Castable 50 μm Fine Detail settings and washed without post-cure.

Post-Processing

Form Wash Settings

5 min in IPA

Wash Castable parts for the shortest time necessary to remove liquid resin. Ensure that all solvent has evaporated or been removed from the parts before curing and casting.

Form Cure Settings

N/A min

N/A °C

Castable Wax Resin does not require post-curing. Allow parts to fully dry before casting. While post-curing Castable Wax parts should not affect castability, post-curing may shrink parts slightly (by less than 1%), which can cause distortion.

Compare Formlabs Castable Resins

Applications

Fine filigree

Lightweight jewelry

Dental

Compatibility

Form 2

Form 3/B/+

Form 3L/BL

Form 4/B

Form 4L/BL

Applications

Medium to heavy jewelry

Medallions

Figurines

Small engineering components up to 5 mm thick

Compatibility

Form 4/B

Applications

Medium to heavy jewelry

Small engineering components

Compatibility

Form 2

Form 3/B/+