Clear Cast Resin

Engineering, Casting

SLA

Fine Details

Select Printer Series and Resin Volume

| Bulk order quantity (L) | Discount % |

|---|---|

| 1 | 0% |

| 30 | 15% |

| 60 | 20% |

| 120 | 25% |

| 240 | 30% |

| 1,000 | 35% |

| 2,000 | 40% |

| 3,000 | 45% |

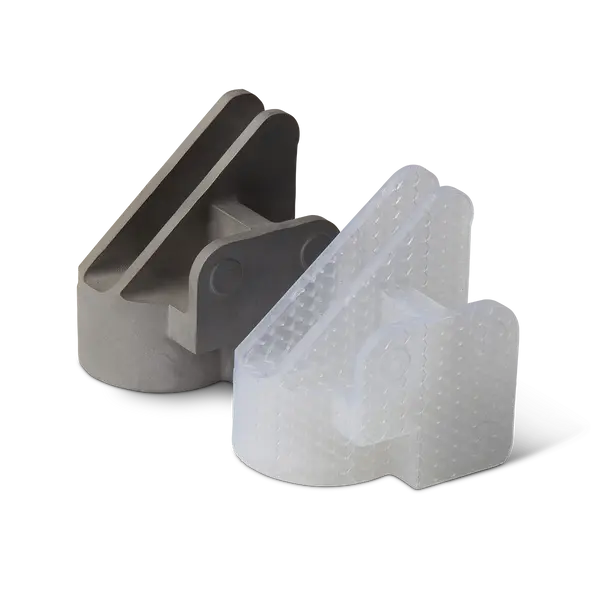

Clear Cast Resin is a resin designed for investment casting, to directly print patterns that can be invested and cast. It has an extremely low thermal expansion, low ash, and no trace heavy metals.

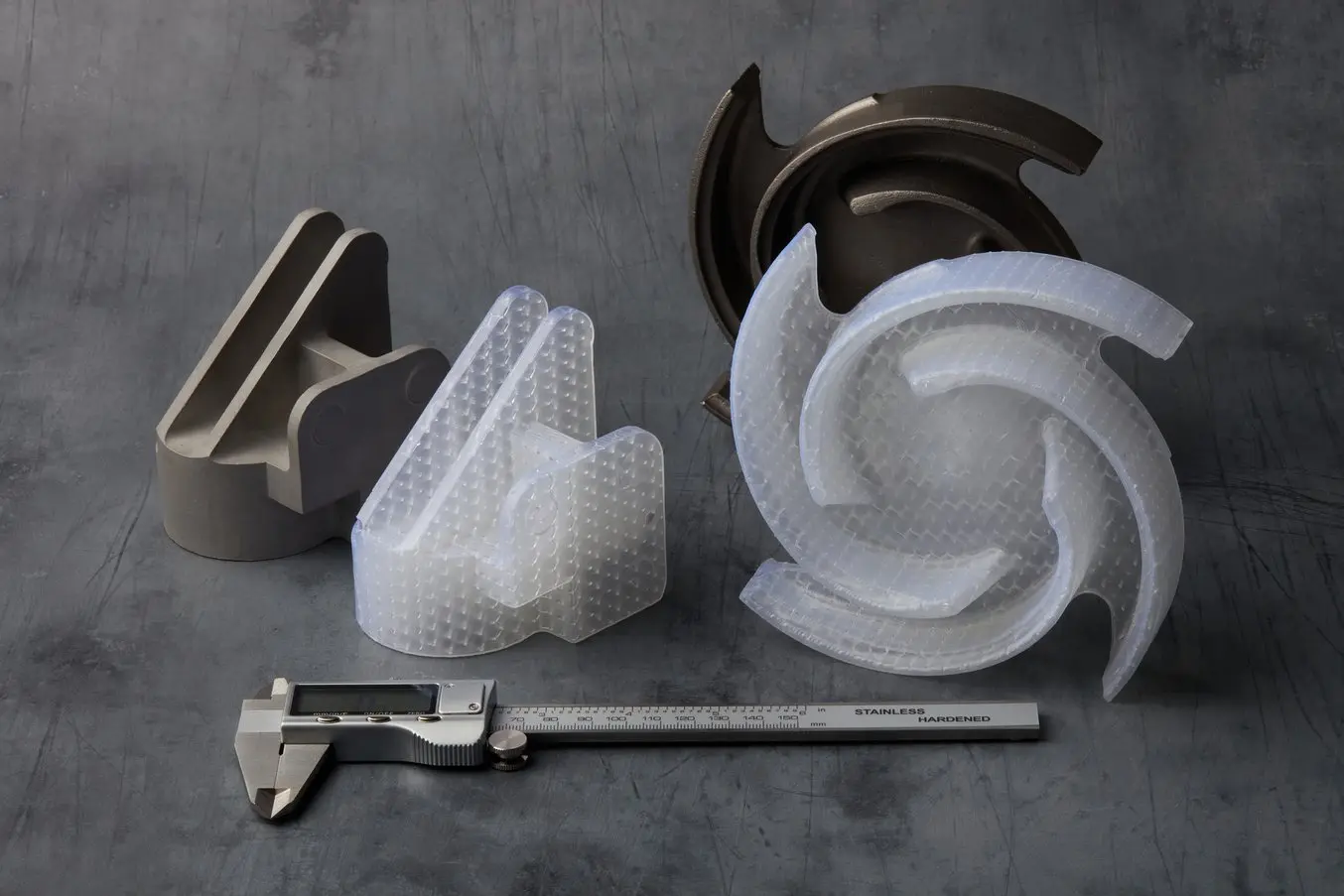

Clear Cast Resin, paired with a latticing software, is recommended for use with larger parts, excelling at producing geometries thicker than 3 mm.

Clear Cast Resin has been added to your cart.

Why Choose Clear Cast Resin?

Clear Cast Resin is an accessible solution for directly printing casting patterns in house.

Accessible pattern production in-house

Clear Cast Resin on Formlabs SLA printers enables direct production of casting patterns in-house which reduces costs, decreases turnaround times, and improves flexibility in iterating and production.

Low Thermal Expansion

Best in class thermal expansion for reliable casting shells with minimal cracking.

Clean Burnout

Clear Cast Resin achieves a clean burnout with low ash and no trace metals, leaving nothing to contaminate the final cast part. Clear Cast Resin is fully antimony free.

Accurate and Versatile

Create accurate patterns within 0.25 mm of the design. Compatible with any metal or shelling system, allowing foundries to cast new designs in record time.

Workflow for 3D Printing Investment Casting Patterns

3D printed patterns can be used to directly replace the molded wax patterns typically used for investment casting allowing for complex geometries, and faster iterations without dedicated tooling. The process for creating a 3D printed pattern is typically:

- Shell, lattice, and add drain holes to the part with a tool like Materialise Magics or Formware

- Orient, support, and slice the pattern in PreForm

- Print the pattern

- Wash, post-cure, and remove supports

- Plug any drain holes with wax or cure a small amount of Clear Cast Resin over the hole

- Attach the pattern to a casting tree and proceed with the rest of the casting process

Mechanical and Burnout Properties

Tech Specs

Ultimate Tensile Strength

Tensile Modulus

Flexural Modulus

Thermal Expansion, -30-140°C

Ash Content

Antimony

Detected Transition Metals (>10 ppm)

High Concentration Transition Metals (>50 ppm)

Post-Processing

Washing

The foundational step in any SLA post-processing workflow is to remove any excess resin on the surface of the parts through an alcohol or ether wash.

Curing

Post-curing Engineering and Specialty Resins is essential for parts to achieve their full strength and functionality. This step completes the chemical reaction initiated during printing, transforming the part from its green state into a fully finished component.

Compare Formlabs Castable Resins

Applications

Fine filigree

Lightweight jewelry

Dental

Compatibility

Form 2

Form 3/B/+

Form 3L/BL

Form 4/B

Form 4L/BL

Applications

Medium to heavy jewelry

Medallions

Figurines

Small engineering components up to 5 mm thick

Compatibility

Form 4/B

Applications

Demanding engineering applications over 3 mm thick

Compatibility

Form 2

Form 3/B/+

Form 3L/BL

Form 4/B

Form 4L/BL