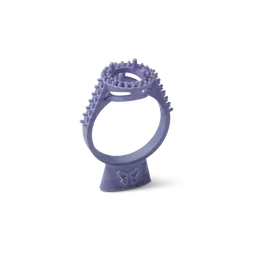

True Cast Resin

Casting

SLA

Patterns for Casting & Pressing

| Bulk order quantity (L) | Discount % |

|---|---|

| 1 | 0% |

| 30 | 15% |

| 60 | 20% |

| 120 | 25% |

| 240 | 30% |

| 1,000 | 35% |

| 2,000 | 40% |

| 3,000 | 45% |

True Cast Resin is a wax-filled material designed for precision casting of intricate jewelry to complex engineering components up to 5 mm thick. It delivers highly accurate parts with exceptional detail and smooth surfaces.

Engineered for reliability, quality, and versatility, True Cast Resin integrates easily into a wide range of burnout schedules. Low thermal expansion, minimal shrinkage, and 0.03% ash content ensure clean burnout and consistently excellent casting outcomes.

For fine wire filigree and lightweight jewelry, Castable Wax Resin is recommended to achieve optimal results. For large, demanding engineering parts, Clear Cast Resin is the recommended solution.

True Cast Resin has been added to your cart.

Why Choose True Cast Resin?

Castable Resin Formulated for Reliable, Precise Casting of Detailed Patterns

Designed for Consistent, High-Quality Casting

Crisp features, smooth surfaces, and superior accuracy enable highly detailed cast parts.

Reliable Printing and Forgiving Casting

Printed parts have low thermal expansion and maintain surface integrity with no wax migration or residue over time, allowing for a more forgiving casting experience.

Clean Burnout

With 0.03% ash content and low shrinkage, True Cast Resin delivers a clean burnout that integrates easily into existing investment casting workflows.

Versatile Casting Applications

Cast intricate jewelry patterns, heavy jewelry, and complex engineering components up to 5 mm thick.

Applications of True Cast Resin

True Cast Resin delivers precise, high-quality cast parts with crisp features, smooth surfaces, and clean burnout, making it ideal for a wide range of demanding casting applications.

Consider True Cast Resin for:

Post-Processing

Form Wash V2 Settings

5 min in IPA

Parts should be washed for 5 minutes in IPA or ethyl alcohol (concentration of 91% or higher). Immediately afterwards, dry the part thoroughly using compressed or forced air. Spray (or rinse) parts with fresh IPA or ethyl alcohol, then dry again using compressed or forced air.

Form Cure V2 Settings

3 min

Ambient

It is highly recommended to cure parts - this will significantly reduce any potential defects during casting. Cure for 10 minutes without heat in Form Cure or equivalent third-party curing machine. Cure for 3 minutes without heat in Form Cure V2.

For design guidelines and best practices, read our application guide.

Material Properties

True Cast Resin

Ash Content

Thermal Expansion

Detected Transition Metals (>10 ppm)

High Concentration Transition Metals (>50 ppm)

Compare Formlabs Castable Resins

Applications

Fine filigree

Lightweight jewelry

Dental

Compatibility

Form 2

Form 3/B/+

Form 3L/BL

Form 4/B

Form 4L/BL

Applications

Medium to heavy jewelry

Medallions

Figurines

Small engineering components up to 5 mm thick

Compatibility

Form 4/B

Applications

Demanding engineering applications over 3 mm thick

Compatibility

Form 2

Form 3/B/+

Form 3L/BL

Form 4/B

Form 4L/BL