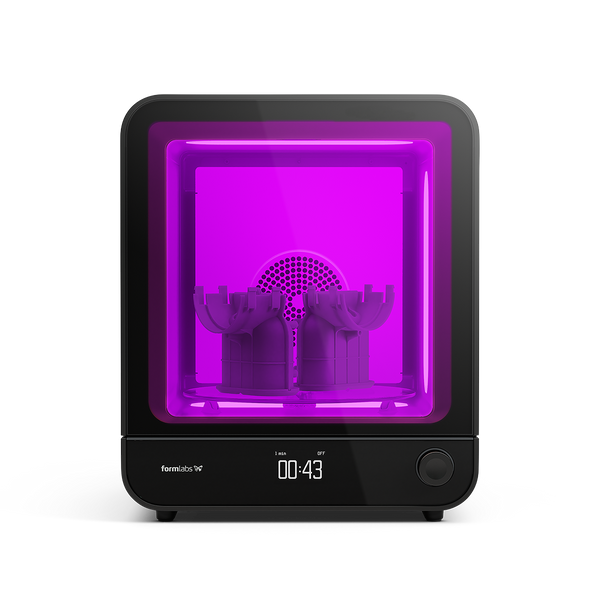

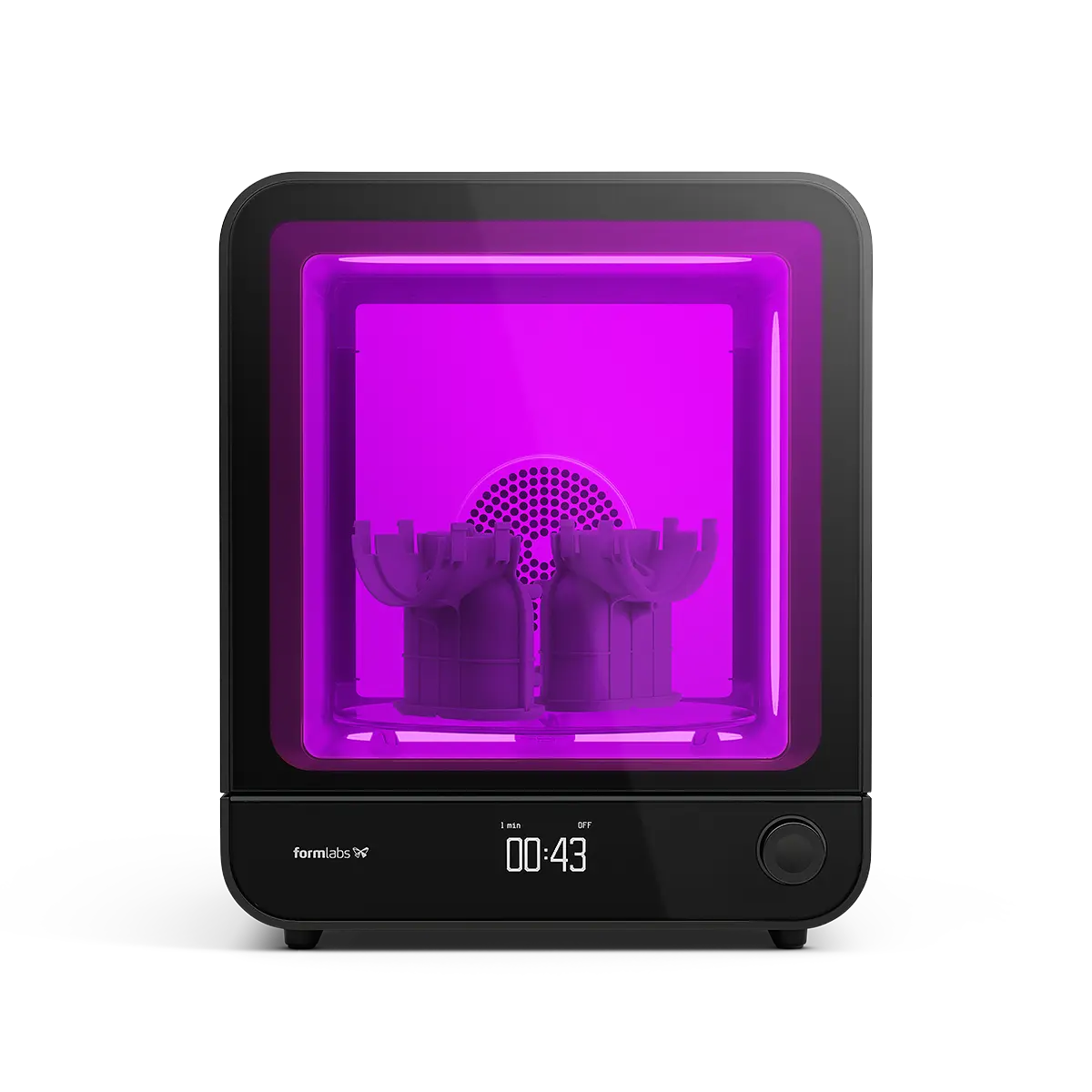

Form Cure V2 120V

FH-CU-120V-02

Estimated delivery: Feb 25 - Mar 2Form Cure V2 precisely combines heat and 405 nm light to deliver tough, strong prints with unprecedented speed and consistency. Now you can post-cure Form 4/B prints in as little as 60 seconds, with 4x more UV power, 5x faster heat-up times, and a 1.3x larger chamber. To begin curing, just select a validated preset for Formlabs 45+ materials. Advanced users can customize time and temperature to fit their specific needs.

Post-curing completes the chemical reaction started during printing, enhancing final part strength, toughness, heat resistance, and creep resistance while creating a harder, less tacky surface.

For biocompatible materials, post-curing is necessary to achieve the safety standards determined by regulatory agencies.

- Form Cure V2 120V

Cure Most Parts in 60 Seconds

Rapid UV curing and instant heat up for consistent, validated results and effortless post-curing of large Form 4 prints.

Blazing Fast Curing, Nearly Instant Heat Up Time

Post-cure general purpose resins in just 60 seconds or cure engineering resins in less than 15 minutes with just 60 seconds required to heat to 60 °C (230 V version).

Consistent, Validated Results

48 LED array and convective heating system ensure uniform UV and heat exposure, delivering 14.5 mW/cm² irradiance and a maximum temperature of 100 °C.

Post-Cure Large Form 4 Prints

Designed to fit any part on the Form 4, enabling curing of parts up to 200 x 125 x 245 mm on a 235 mm turntable.

Easier than Ever

Sleek new design with pre-programmed cure cycles, an easily cleaned glass turntable, and side-hinged door to allow easy access within a compact footprint.

Blazing Fast Curing

Form Cure V2 is engineered to deliver rapid, consistent, and high-quality post-curing results.

Near instant heat-up:

60 °C

80 °C

Fast curing:

General Purpose Resins

Engineering & Biocompatible Resins

Precise and Consistent Results

Reach temperatures up to:

Fit Large Form 4 Parts

Form 4 Workflow in Minutes

Form Cure is a part of a 3D printing ecosystem that’s easy to learn and use and requires little intervention or maintenance. Watch the video to learn the basics of how to use Form 4, from the software and materials to printing and post-processing.

Tech Specs

| Form Cure V2 | Form Cure V1 | Form Cure L V2 | Form Cure L V1 | |

|---|---|---|---|---|

| Printer Compatibility | Form 4, Form 4B, Form 3/+, Form 3B/+, Form 2 | Form 3/+, Form 3B/+, Form 2 | Form 4L, Form 4BL, Form 4, Form 4B, Form 3/B/+, Form 2 | Form 4L, Form 4BL, Form 3L, Form 3BL, Form 4, Form 4B, Form 3/+, Form 3B/+, Form 2 |

| Dimensions | 33.7 × 40.4 × 37.2 cm 13.3 × 14.0 × 15.9 in | 26.2 x 26.2 x 34.0 cm 10.3 x 10.3 x 13.4 in Height when open: 64 cm (25.2 in) | 507 × 543 × 545 mm 20.0 × 21.4 × 21.5 in | 69.0 x 54.0 x 44.5 cm 27.2 x 21.3 x 17.5 in |

| Weight | 12.1 kg 26.7 lb | 5.6 kg 12.4 lb | 40.0 kg 88.2 lb | 24 kg 53 lb |

| Turntable Diameter | 23.5 cm 9.25 in | 19.3 cm 7.6 in | 404 mm 15.9 in | 39.5 cm 15.6 in |

| Maximum Part Height | 24.5 cm 9.64 in | 18.5 cm 7.28 in | 365 mm 14.4 in | 32 cm 12.6 in |

| Maximum Cure Chamber Temperature | 100 °C 212 °F | 80 °C 176 °F | 100 °C 212 °F | 80 °C 176 °F |

| Light Source | 48 multi-directional LEDs | 13 multi-directional LEDs | 96 multi-directional LEDs | 45 multi-directional LEDs |

| LED Power | 150 W | 39 W | 350 W | 70 W |

| LED Radiant | 50 W | 9.1 W | 120 W | 36 W |

| LED Wavelength | 405 nm | 405 nm | 405 nm | 375 nm, 405 nm |

| Power Requirements | Input (NA) 100 - 120 V VAC, 50-60 Hz, 15 A Input (EU) 220 - 240 V VAC, 50-60 Hz, 8 A | 90–240 V 6.0 A 50/60 Hz 144 W | Input (NA): 100 – 125 VAC, 50–60Hz, 15 A Input (EU): 220 – 240 VAC, 50–60Hz, 8 A | Input (NA) 100 - 120 V VAC, 50-60 Hz, 15 A Input (EU) 220 - 240 V VAC, 50-60 Hz, 8 A |