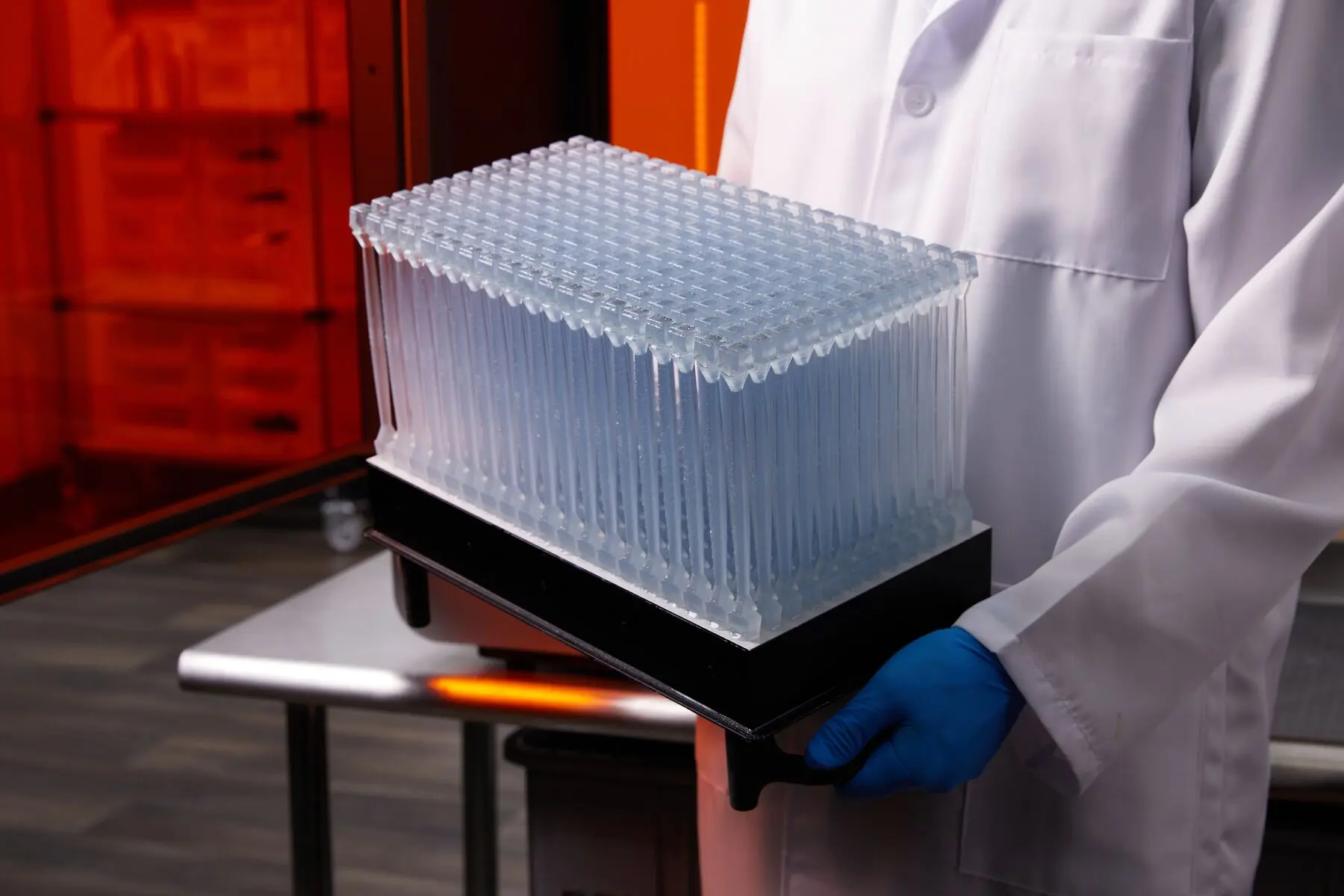

Tackle any problem with our industry-leading materials, including biocompatible options, or Open Material Mode.

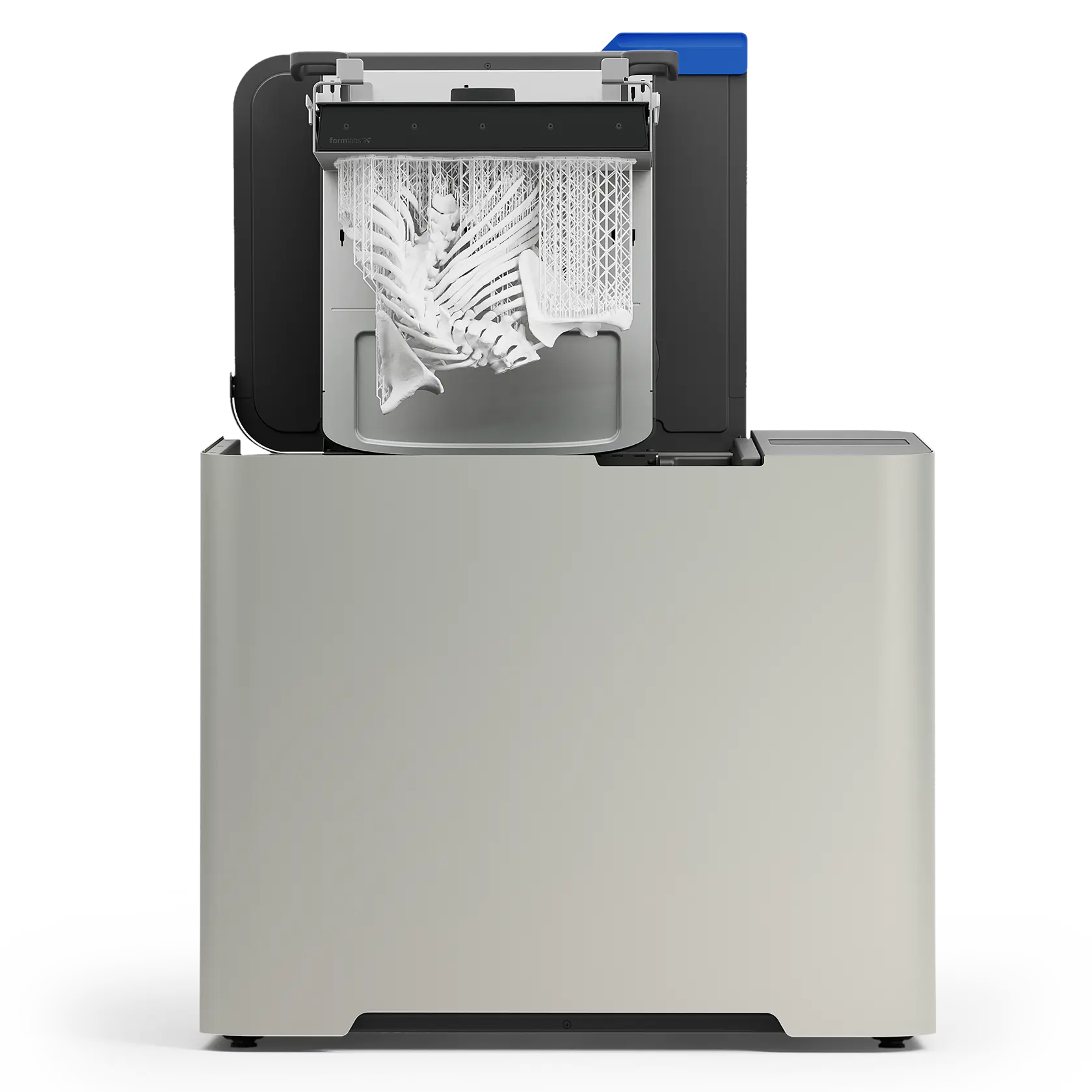

Form4BL

Innovate at scale without limitations

Same-day turnaround for large or high-volume parts

Parts that always fit

High-performance biocompatible materials and Open Material Mode

Dependable production with stunningly accurate results

Anyone can learn in 15 minutes

Form4BL

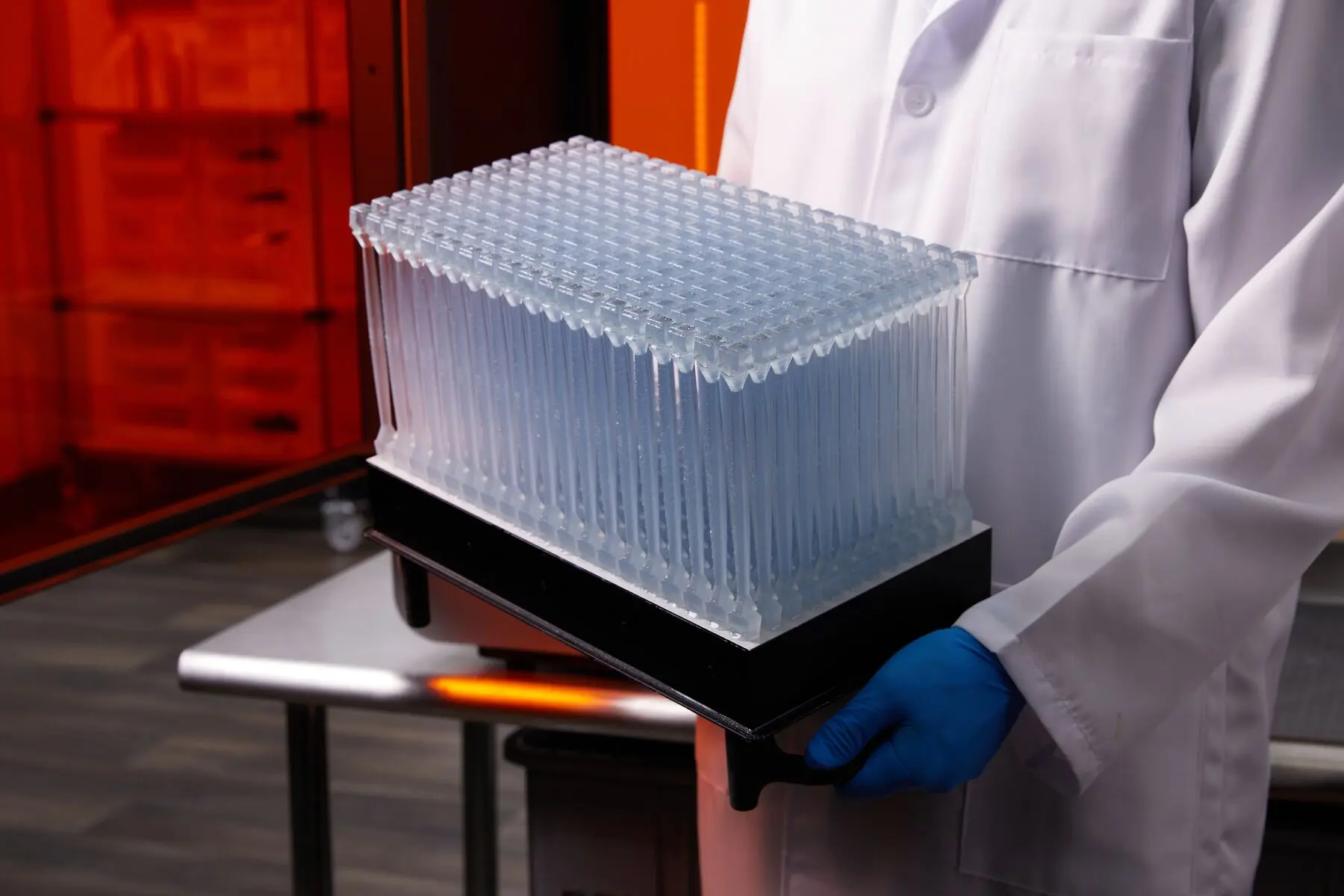

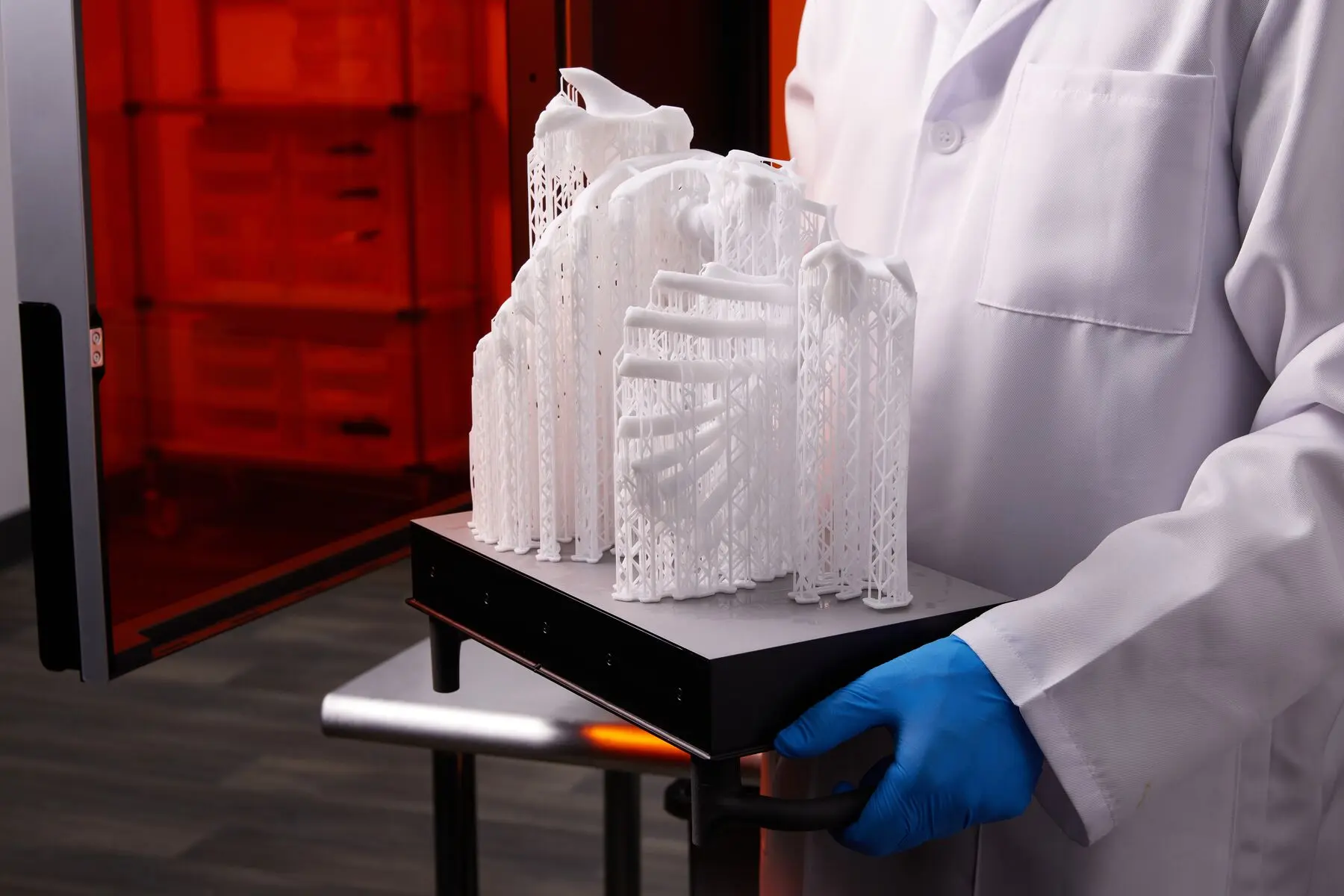

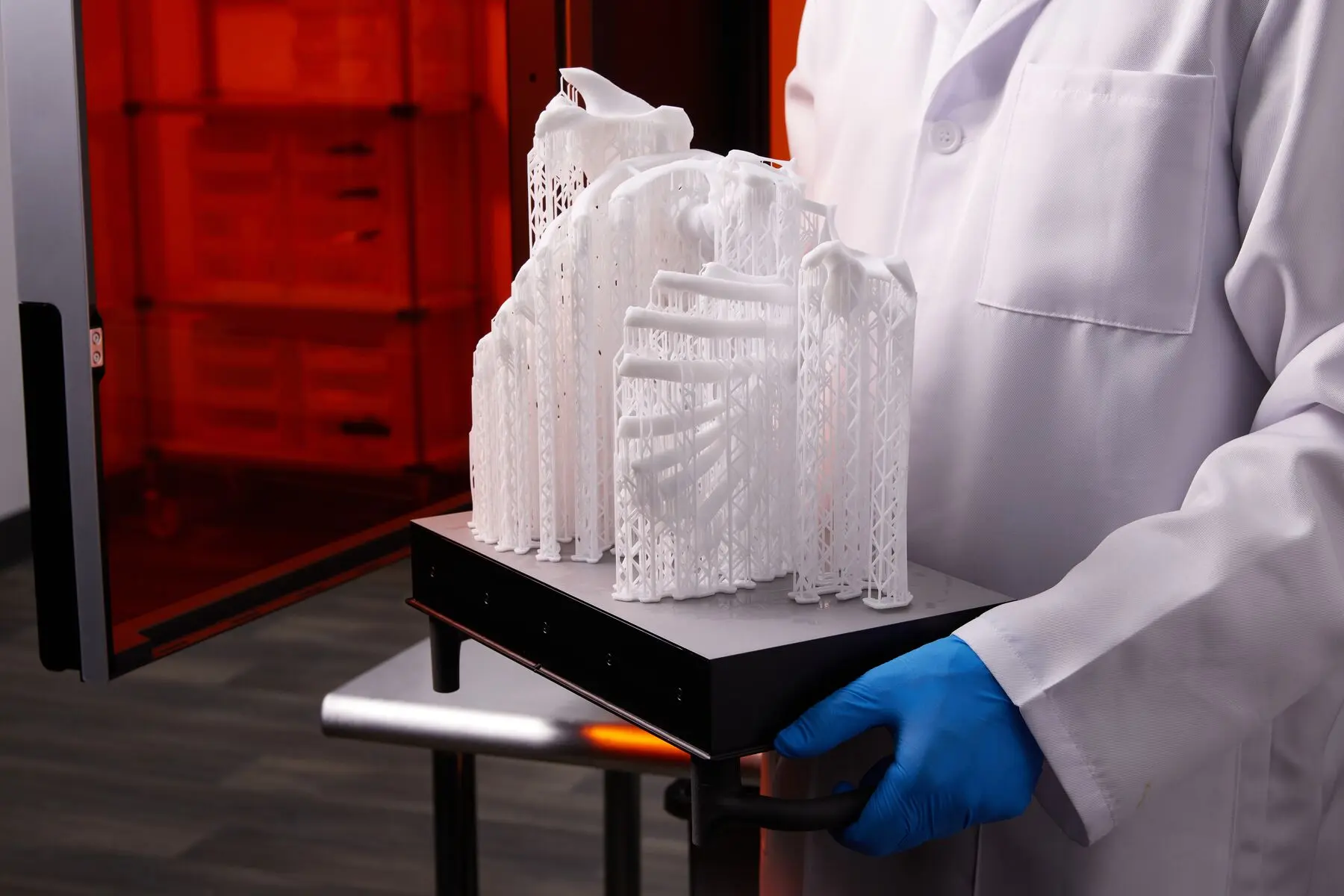

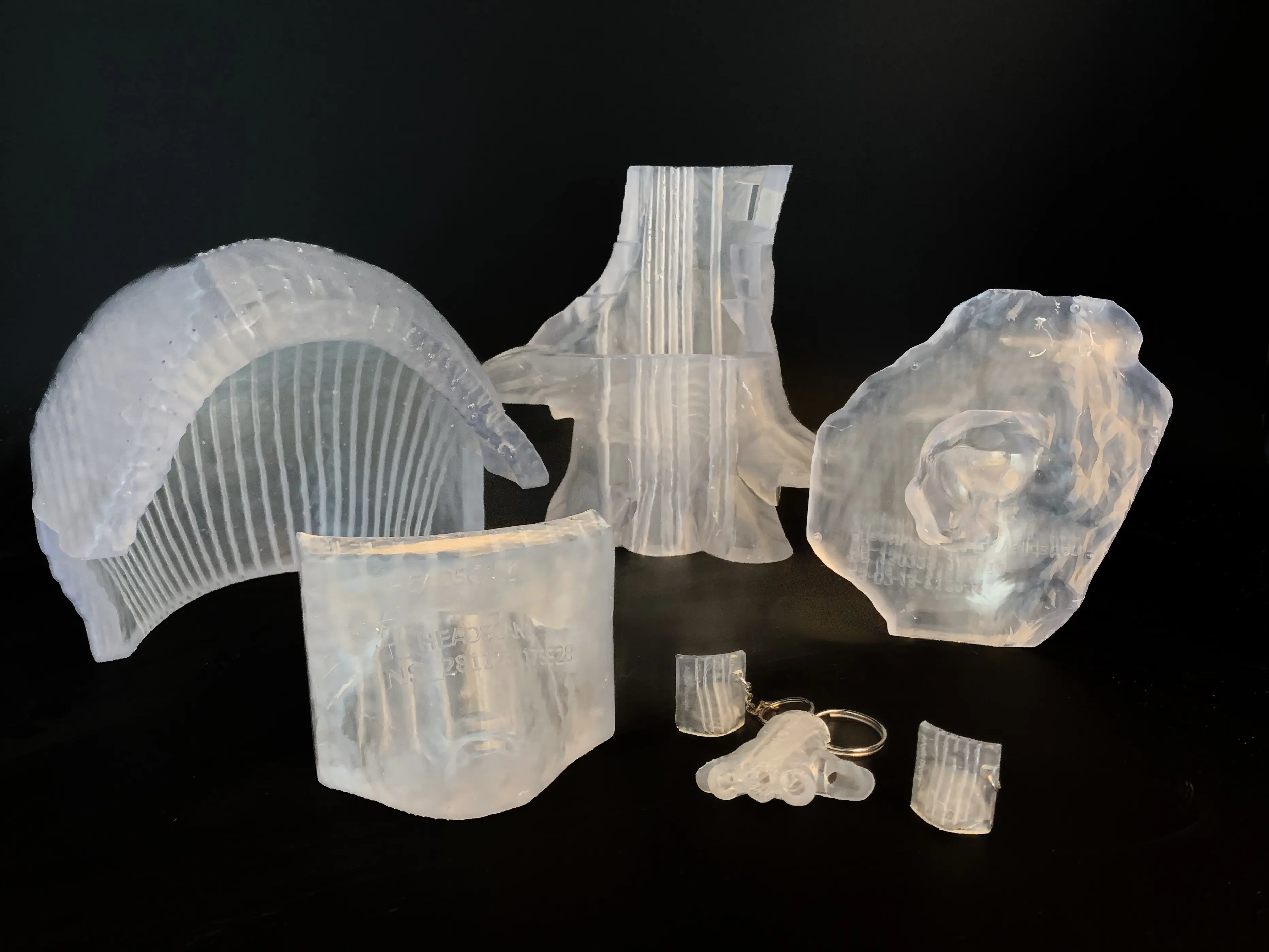

Solve big problems with large-scale medical parts

or produce many parts in one print job, so you can accelerate product development or keep production running.Speed that scales. Same-day turnaround for large prints.

- 9h56minForm 4BL

27h6minLeading FDM16h4minBenchmark SLA50h18minForm 3BL

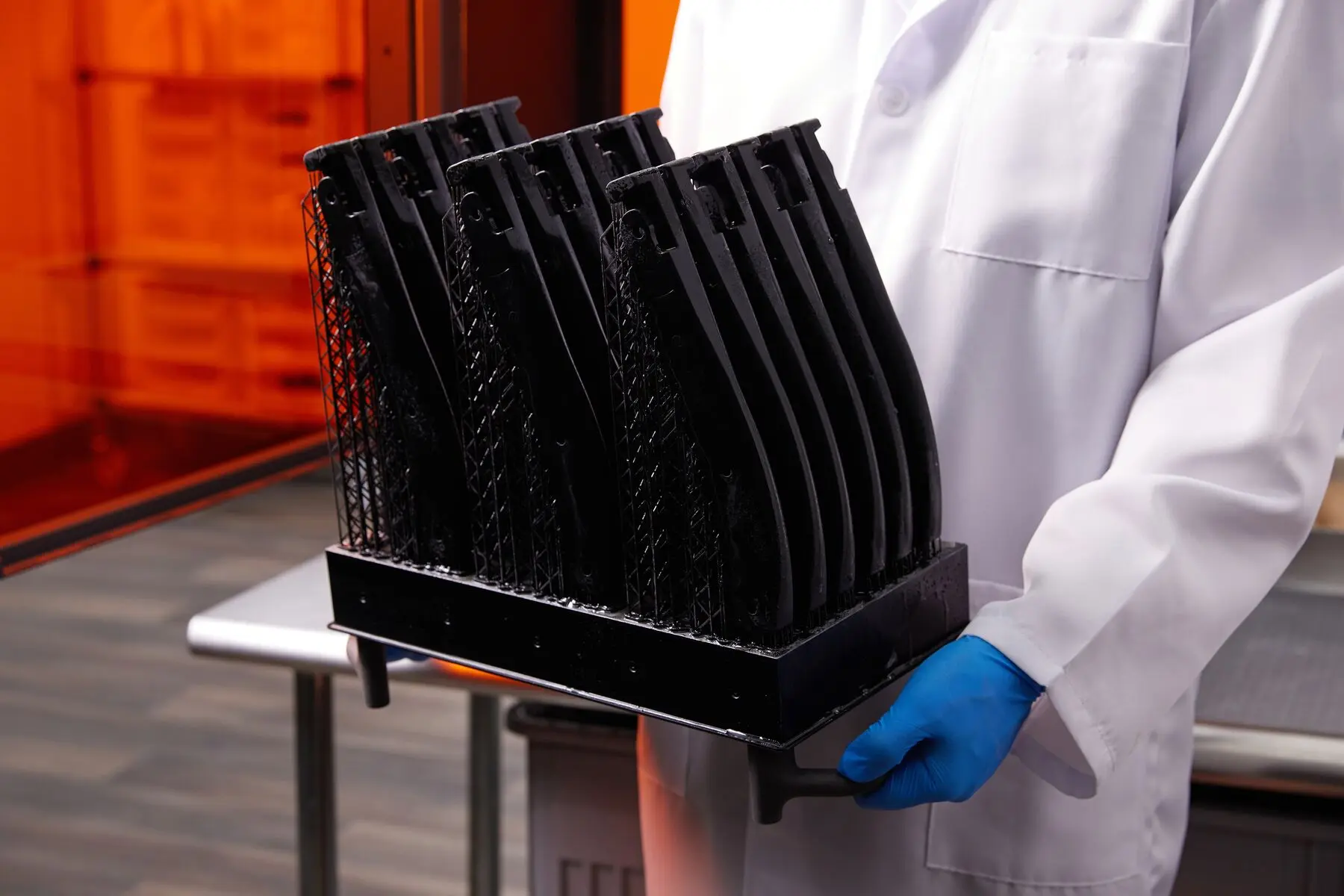

27h6minLeading FDM16h4minBenchmark SLA50h18minForm 3BLArbutus Medical QuikBow Arms

- 7h46minForm 4BL

43h20minLeading FDM10h35minBenchmark SLA68h15minForm 3BL

43h20minLeading FDM10h35minBenchmark SLA68h15minForm 3BLrestor3d Spinal Sizing Trials

- 11h57minForm 4BL

27h25minLeading FDM*13h5minBenchmark SLA*92h17minForm 3BL

27h25minLeading FDM*13h5minBenchmark SLA*92h17minForm 3BLAxial3D Scoliotic Thorax

- 8h18minForm 4BL

17h28minLeading FDM**11h8minBenchmark SLA**47h16minForm 3BL

17h28minLeading FDM**11h8minBenchmark SLA**47h16minForm 3BLSkull

- 2h39minForm 4BL

13h10minLeading FDM18h6minBenchmark SLA21h36minForm 3BL

13h10minLeading FDM18h6minBenchmark SLA21h36minForm 3BLVentilator

* Scaled to 80% to fit

** Reduced number of parts per build

Produce stunning parts that always fit, rivaling injection molding.

Smoothest Surfaces

Lower peel forces, Light Touch Supports, and 46 µm pixel size with pre-tuned anti-aliasing.

Sharpest Details

Highly collimated light and 46 µm pixel size with pre-tuned anti-aliasing for subpixel resolution.

Most Accurate Assemblies

±0.15% XY dimensional tolerances so assemblies always fit.

QUIKBOW® IS A STERILE-READY, SINGLE-USE TENSION BOW FOR SKELETAL TRACTION IN THE OPERATING ROOM. IT ALLOWS TRAUMA CENTERS TO USE A SMALLER WIRE WITHOUT A KIRSCHNER BOW (K-BOW).

QUIKBOW® IS A STERILE-READY, SINGLE-USE TENSION BOW FOR SKELETAL TRACTION IN THE OPERATING ROOM. IT ALLOWS TRAUMA CENTERS TO USE A SMALLER WIRE WITHOUT A KIRSCHNER BOW (K-BOW).Smoothest Surfaces

Lower peel forces, Light Touch Supports, and 46 µm pixel size with pre-tuned anti-aliasing.

Sharpest Details

Highly collimated light and 46 µm pixel size with pre-tuned anti-aliasing for subpixel resolution.

Most Accurate Assemblies

±0.15% XY dimensional tolerances so assemblies always fit.

QuikBow®Arbutus Medical

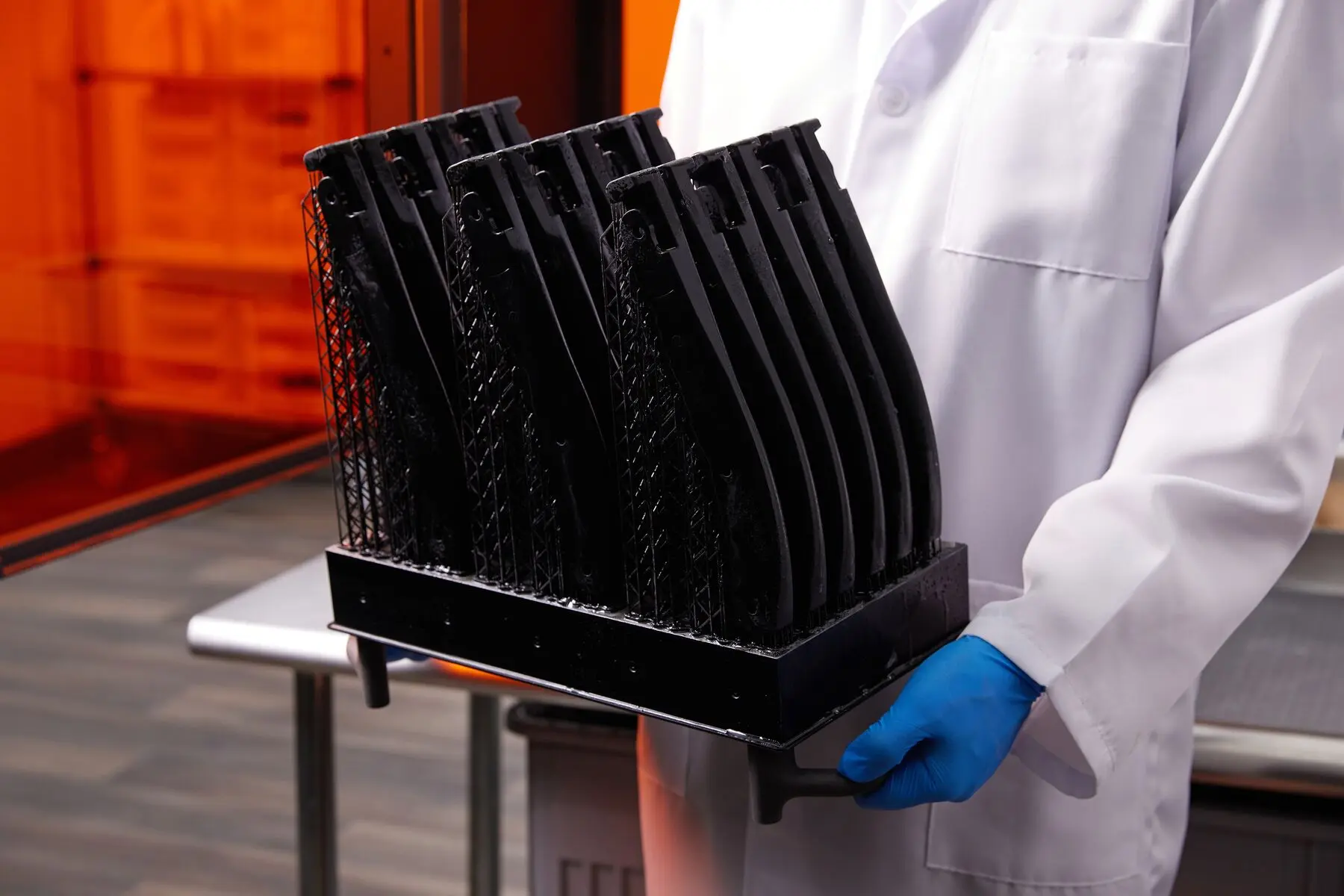

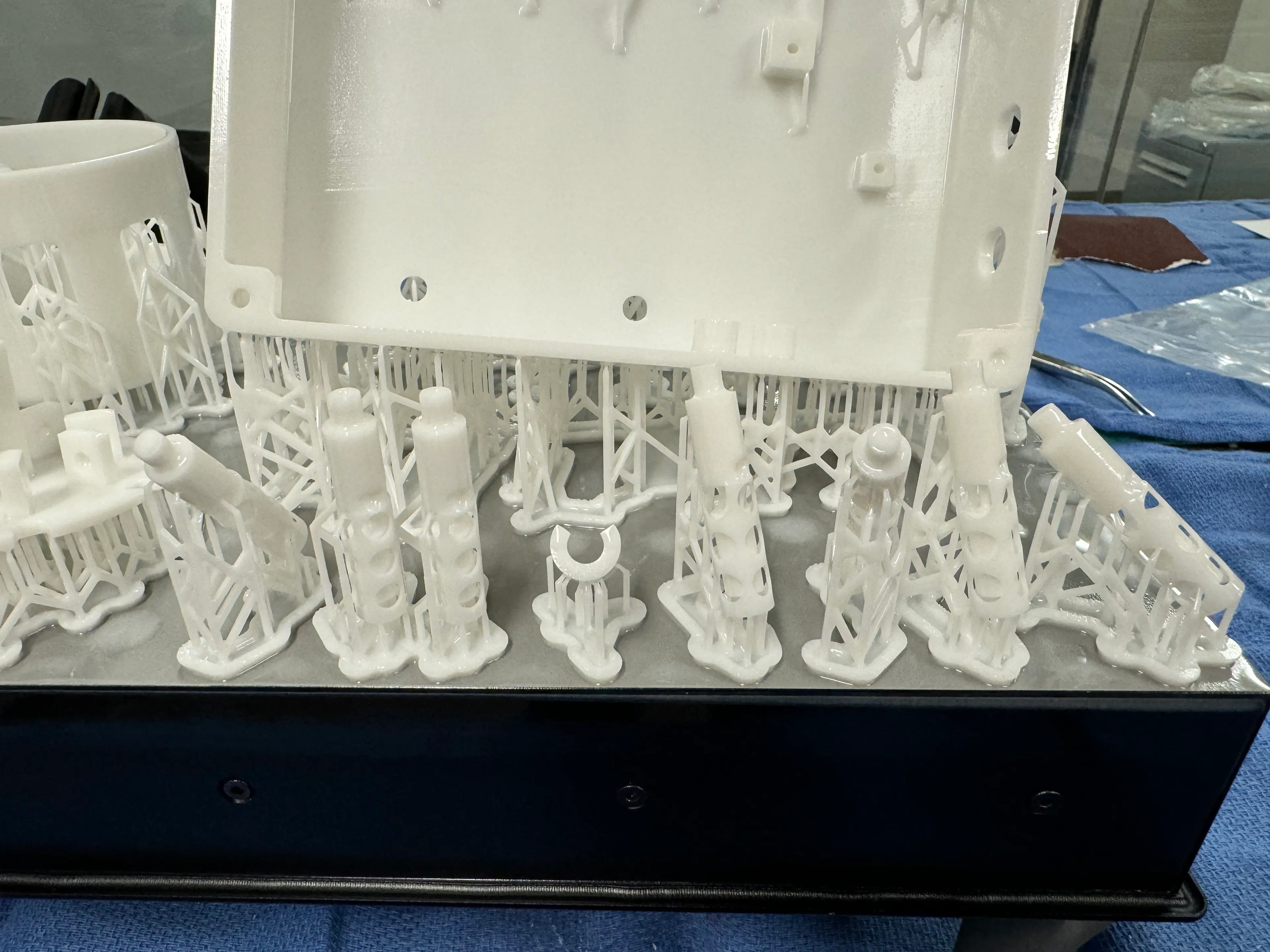

Reliability at scale. Large format 3D printing you can depend on.

Formlabs optimization engineers put hundreds of printed parts to the test to ensure each material performs to the most reliable standards, right out of the box.

Reliability at scale. Large format 3D printing you can depend on.

Formlabs optimization engineers put hundreds of printed parts to the test to ensure each material performs to the most reliable standards, right out of the box.

Learn to print in four simple steps:

So intuitive that anyone can learn to print in 15 minutes.

- 1

Import your model and prepare your print.

- Smart auto-orientation

- Advanced support generation

- Live printability checks

- 2

Load a material and click print.

- Validated print settings

- No-hassle cartridge and tanks

- Automatic resin dispensing

- 3

Remove, wash, cure.

- Quick release part removal*

- Automatic part cleaning

- Precision post-curing for peak material properties

- *Build Platform Flex L is not yet available. Coming soon.

- 4

Finish your part.

- Light touch supports for quick, clean support removal

- Optional sanding, coating, or painting

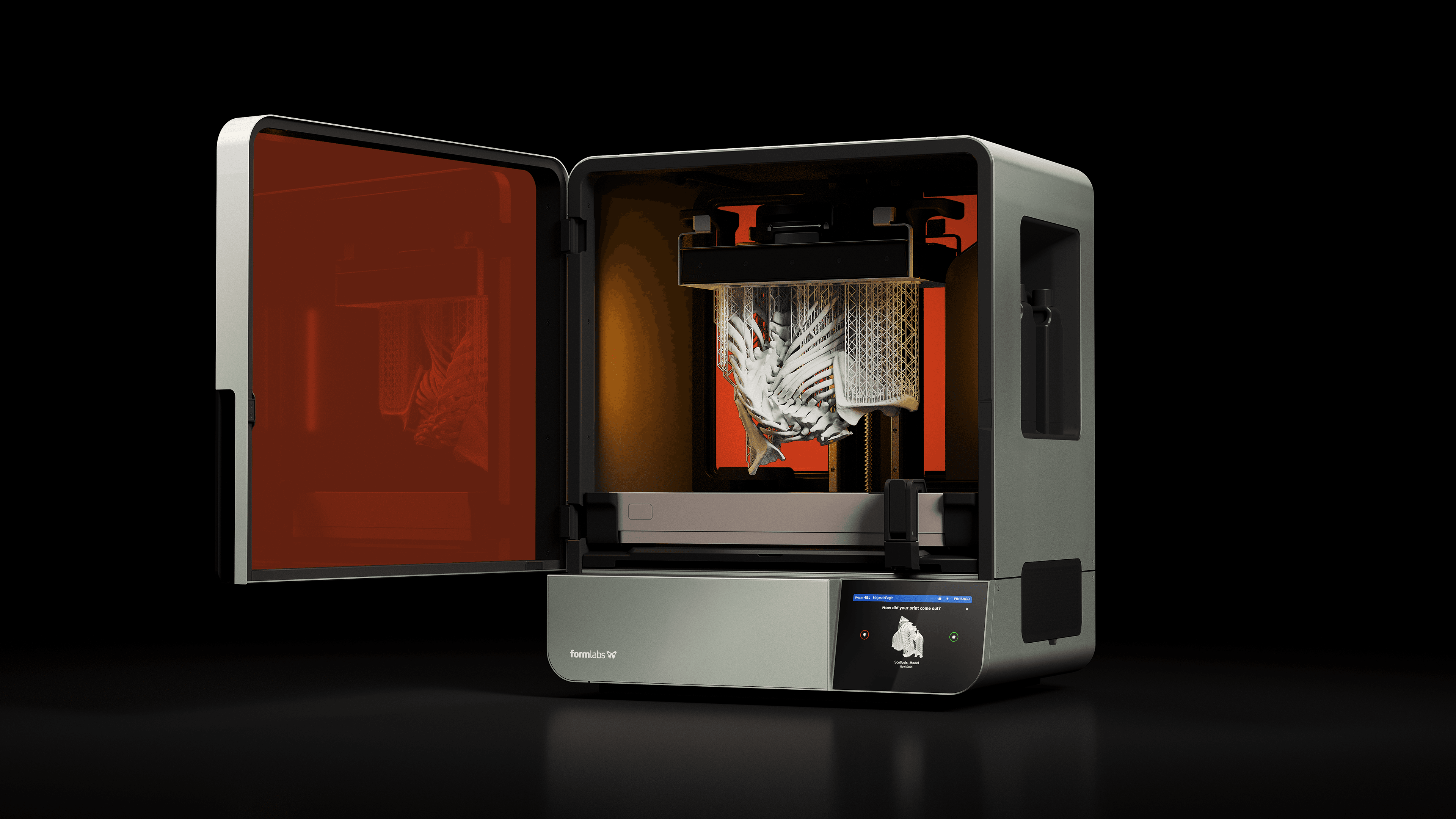

Low Force Display™ (LFD)

The Power Behind Form 4BLLow Force Display™ (LFD)

The Power Behind Form 4BLSolutions for every stage of the process, from prototyping to commercial product.

Formlabs 3D printers helped PSYONIC create the Ability Hand, an FDA-registered, Medicare-covered, industry-defining upper-limb prosthesis from scratch. In-house printing enables rapid iteration and versatile testing with specialized resins, eliminating the need for costly outsourcing. This accelerates medical device development, saving time and resources while bringing products to market faster and at lower costs.

Formlabs 3D printers helped PSYONIC create the Ability Hand, an FDA-registered, Medicare-covered, industry-defining upper-limb prosthesis from scratch. In-house printing enables rapid iteration and versatile testing with specialized resins, eliminating the need for costly outsourcing. This accelerates medical device development, saving time and resources while bringing products to market faster and at lower costs.

"With our other 3D printing technologies, producing an anatomical model of a spine would take 20 hours, making it impossible to complete in time for procedure planning. Using Fast Model Resin on Form 4BL, we printed it in just an hour and a half and delivered it the same day. Without that speed, we wouldn’t have been able to respond to the case in time."

Brian Albers,

3D Printing Engineer, St. Louis Children’s Hospital

“Form 4BL is great. We’ve pushed it to its limits and not had any failed prints.”

Allison Sibley,

Product Specialist, Adaptiiv

"Since we're producing surgical-grade equipment, the biocompatibility of the resins is crucial. The ability for prints to start and finish correctly, along with the duration of the prints, can impact patient care if we’re working against a deadline. With Form 4BL, we’ve achieved a 100% success rate on our parts."

Todd Goldstein,

Northwell Health

The Form 4BL Ecosystem

Complete Your 3D Printing Experience

Form 4BL