Tackle any problem with our industry-leading materials, or use Open Material Mode.

Form4L

Solve big problems with big parts

Large prints in under 6 hours

Parts that always fit

Industry-leading materials and Open Material Mode

Large format 3D printing you can depend on

Anyone can learn in 15 minutes

Form4L

Solve big problems with large-scale parts.

Or print multiple parts in one job, so you can accelerate product development or keep production running.Speed at scale. Large prints in under 6 hours.

- 4h54minForm 4L

14h24minLeading FDM62h32minBenchmark FDM21h57minForm 3L

14h24minLeading FDM62h32minBenchmark FDM21h57minForm 3LLacrosse Head

- 2h37minForm 4L

0minLeading FDM - part doesn't fit42h3minBenchmark FDM21h6minForm 3L

0minLeading FDM - part doesn't fit42h3minBenchmark FDM21h6minForm 3LRadio Flyer Seat Prototype

- 4h12minForm 4L

12h48minLeading FDM86h49minBenchmark FDM22h52minForm 3L

12h48minLeading FDM86h49minBenchmark FDM22h52minForm 3LSpaceCraft Display Holders

- 5h50minForm 4L

10h38minLeading FDM68h34minBenchmark FDM17h17minForm 3L

10h38minLeading FDM68h34minBenchmark FDM17h17minForm 3LGolf Training Club Assembly

- 4h58minForm 4L

12h43minLeading FDM76h48minBenchmark FDM18h47minForm 3L

12h43minLeading FDM76h48minBenchmark FDM18h47minForm 3LRadioFlyer Scooter Cover

Stunning parts that always fit.

Sharpest Details

Highly collimated light and 46 µm pixel size with pre-tuned anti-aliasing for sub-pixel resolution.

Smoothest Surfaces

Lower peel forces, Light Touch Supports, and 46 µm pixel size with pre-tuned anti-aliasing.

Most Accurate Assemblies

±0.15% XY dimensional tolerances so assemblies always fit.

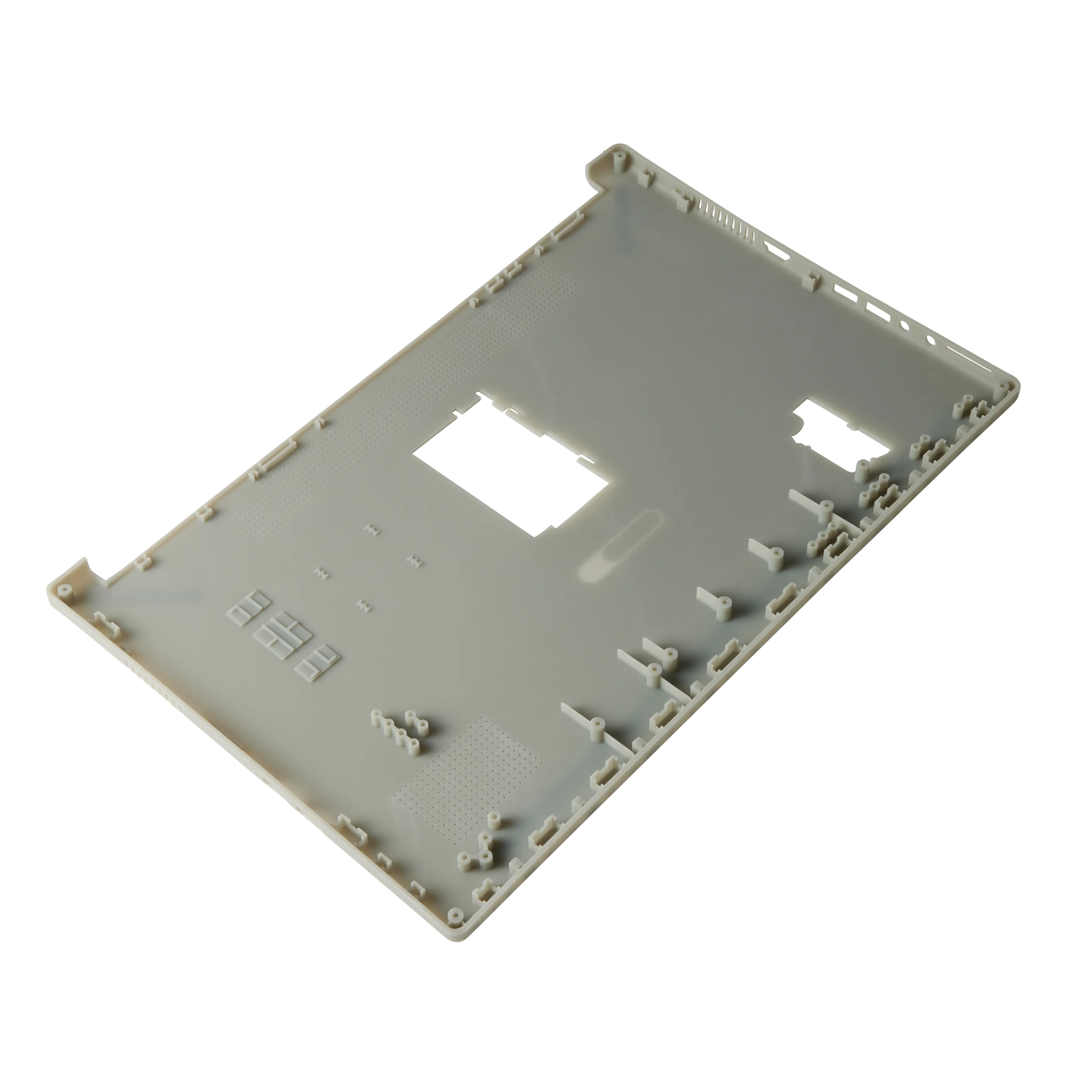

LAPTOP BOTTOM CHASSIS

LAPTOP BOTTOM CHASSISSharpest Details

Highly collimated light and 46 µm pixel size with pre-tuned anti-aliasing for sub-pixel resolution.

Smoothest Surfaces

Lower peel forces, Light Touch Supports, and 46 µm pixel size with pre-tuned anti-aliasing.

Most Accurate Assemblies

±0.15% XY dimensional tolerances so assemblies always fit.

Laptop ChassisConsumer Electronics UNILEVER SOAP BOTTLE BLOW MOLD

UNILEVER SOAP BOTTLE BLOW MOLDSharpest Details

Highly collimated light and 46 µm pixel size with pre-tuned anti-aliasing for sub-pixel resolution.

Smoothest Surfaces

Lower peel forces, Light Touch Supports, and 46 µm pixel size with pre-tuned anti-aliasing.

Most Accurate Assemblies

±0.15% XY dimensional tolerances so assemblies always fit.

Bottle MoldManufacturing STEERING WHEEL ERGONOMIC MODEL

STEERING WHEEL ERGONOMIC MODELSharpest Details

Highly collimated light and 46 µm pixel size with pre-tuned anti-aliasing for sub-pixel resolution.

Smoothest Surfaces

Lower peel forces, Light Touch Supports, and 46 µm pixel size with pre-tuned anti-aliasing.

Most Accurate Assemblies

±0.15% XY dimensional tolerances so assemblies always fit.

Steering WheelAutomotive OUTSOLE COMPRESSION MOLD

OUTSOLE COMPRESSION MOLDSharpest Details

Highly collimated light and 46 µm pixel size with pre-tuned anti-aliasing for sub-pixel resolution.

Smoothest Surfaces

Lower peel forces, Light Touch Supports, and 46 µm pixel size with pre-tuned anti-aliasing.

Most Accurate Assemblies

±0.15% XY dimensional tolerances so assemblies always fit.

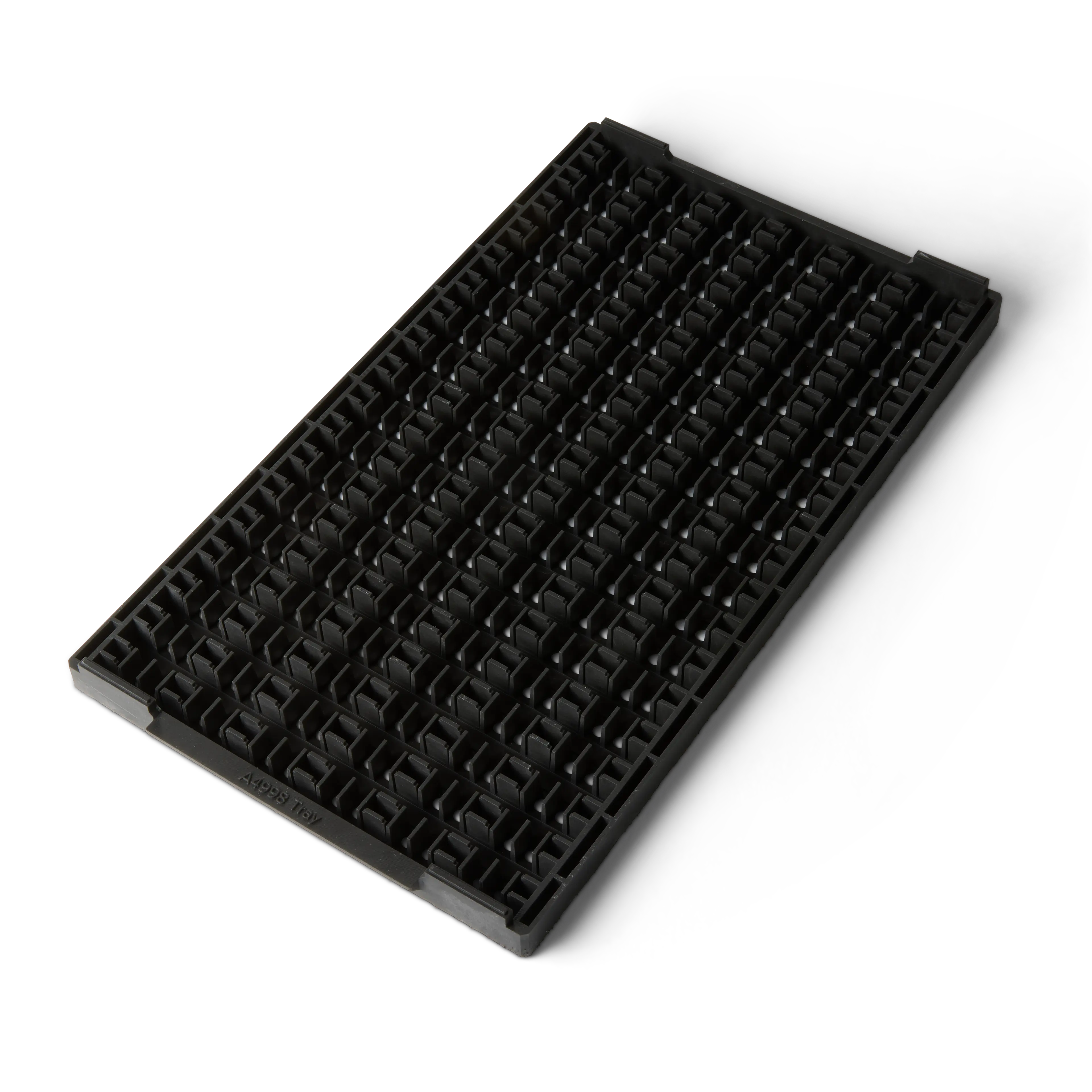

Outsole MoldManufacturing ESD-SAFE PCB TRAY

ESD-SAFE PCB TRAYSharpest Details

Highly collimated light and 46 µm pixel size with pre-tuned anti-aliasing for sub-pixel resolution.

Smoothest Surfaces

Lower peel forces, Light Touch Supports, and 46 µm pixel size with pre-tuned anti-aliasing.

Most Accurate Assemblies

±0.15% XY dimensional tolerances so assemblies always fit.

PCB TrayManufacturing IMPELLER CASTING PATTERN

IMPELLER CASTING PATTERNSharpest Details

Highly collimated light and 46 µm pixel size with pre-tuned anti-aliasing for sub-pixel resolution.

Smoothest Surfaces

Lower peel forces, Light Touch Supports, and 46 µm pixel size with pre-tuned anti-aliasing.

Most Accurate Assemblies

±0.15% XY dimensional tolerances so assemblies always fit.

ImpellerInvestment Casting

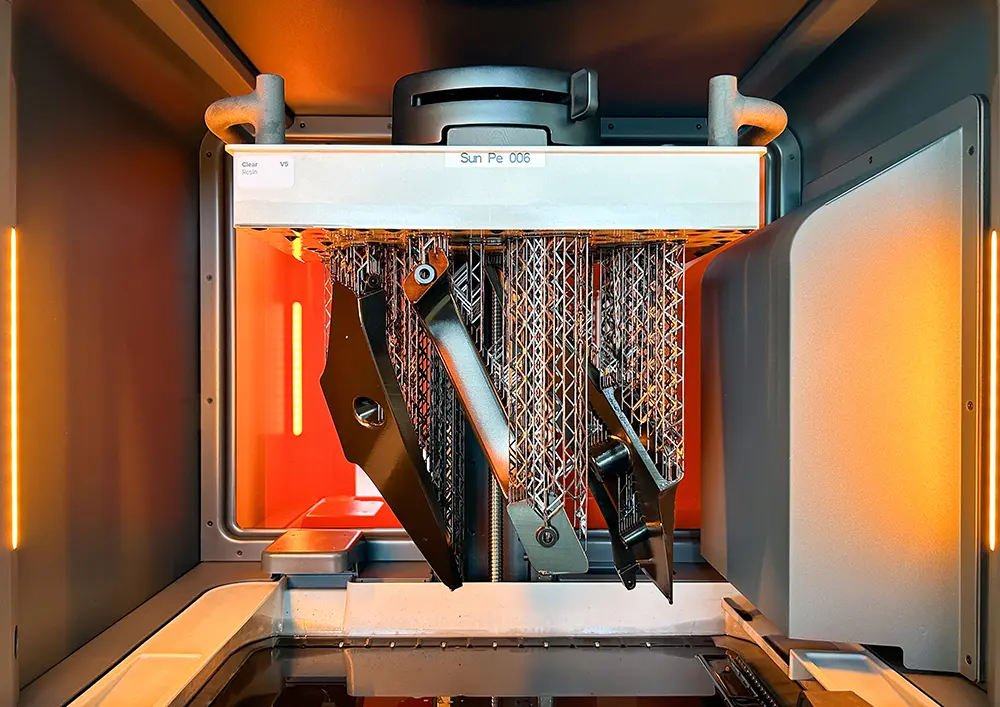

Unmatched reliability. Large format 3D printing you can depend on.

Formlabs optimization engineers put hundreds of printed parts to the test to ensure each material performs to the most reliable standards, right out of the box.

Unmatched reliability. Large format 3D printing you can depend on.

Formlabs optimization engineers put hundreds of printed parts to the test to ensure each material performs to the most reliable standards, right out of the box.

Learn to print in four simple steps:

So intuitive that anyone can learn to print in 15 minutes.

- 1

Import your model and prepare your print.

- Smart auto-orientation

- Advanced support generation

- Live printability checks

- 2

Load a material and click print.

- Validated print settings

- No-hassle cartridge and tanks

- Automatic resin dispensing

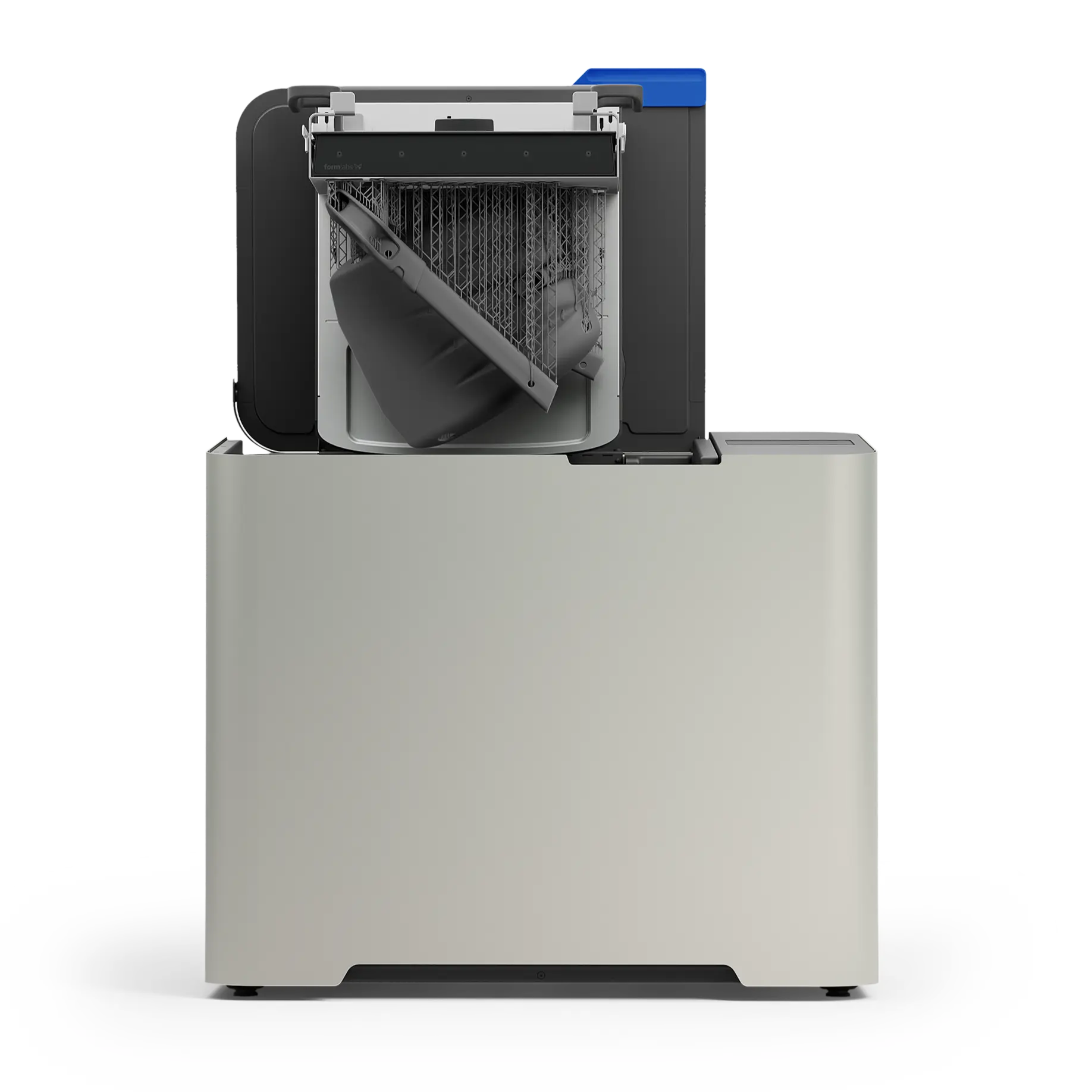

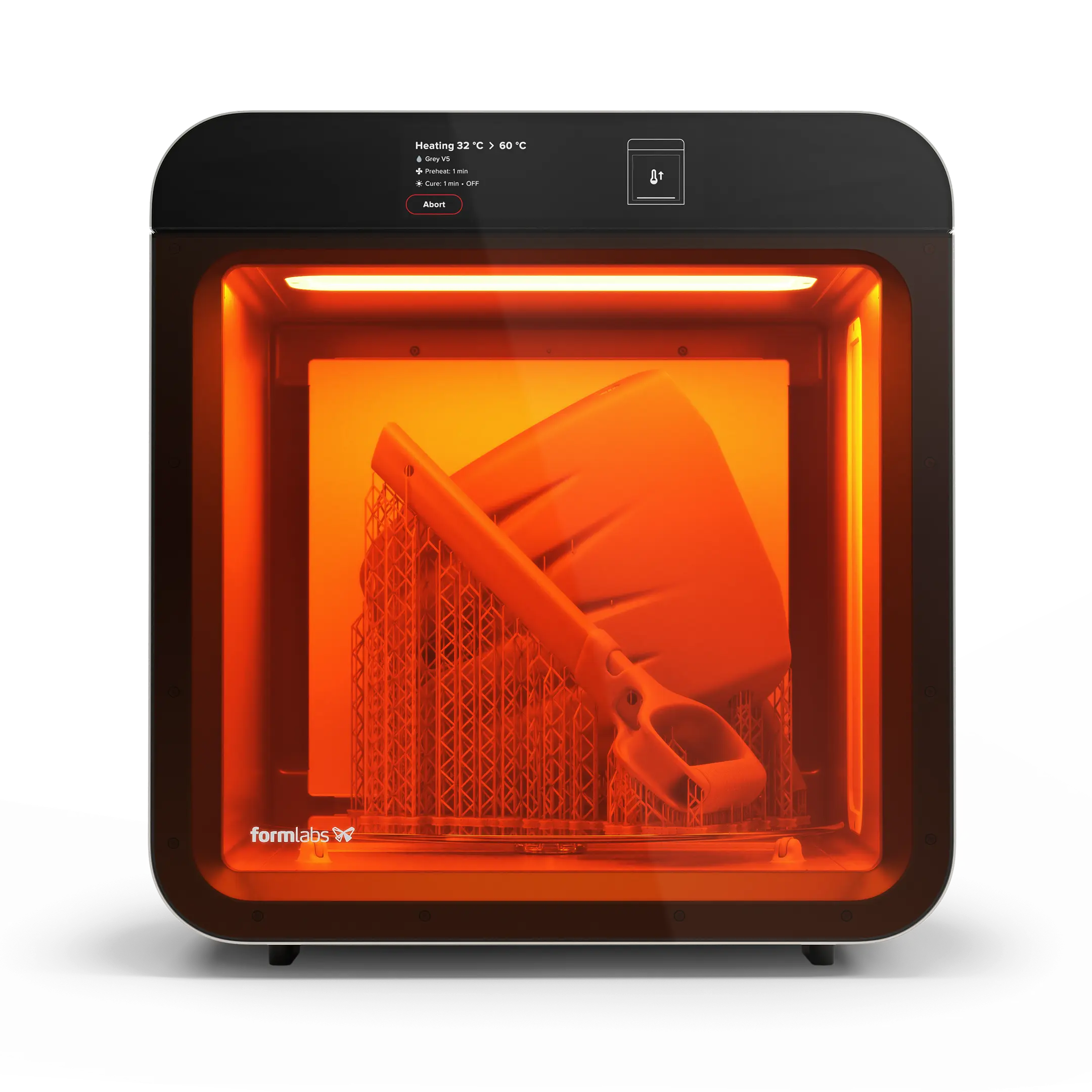

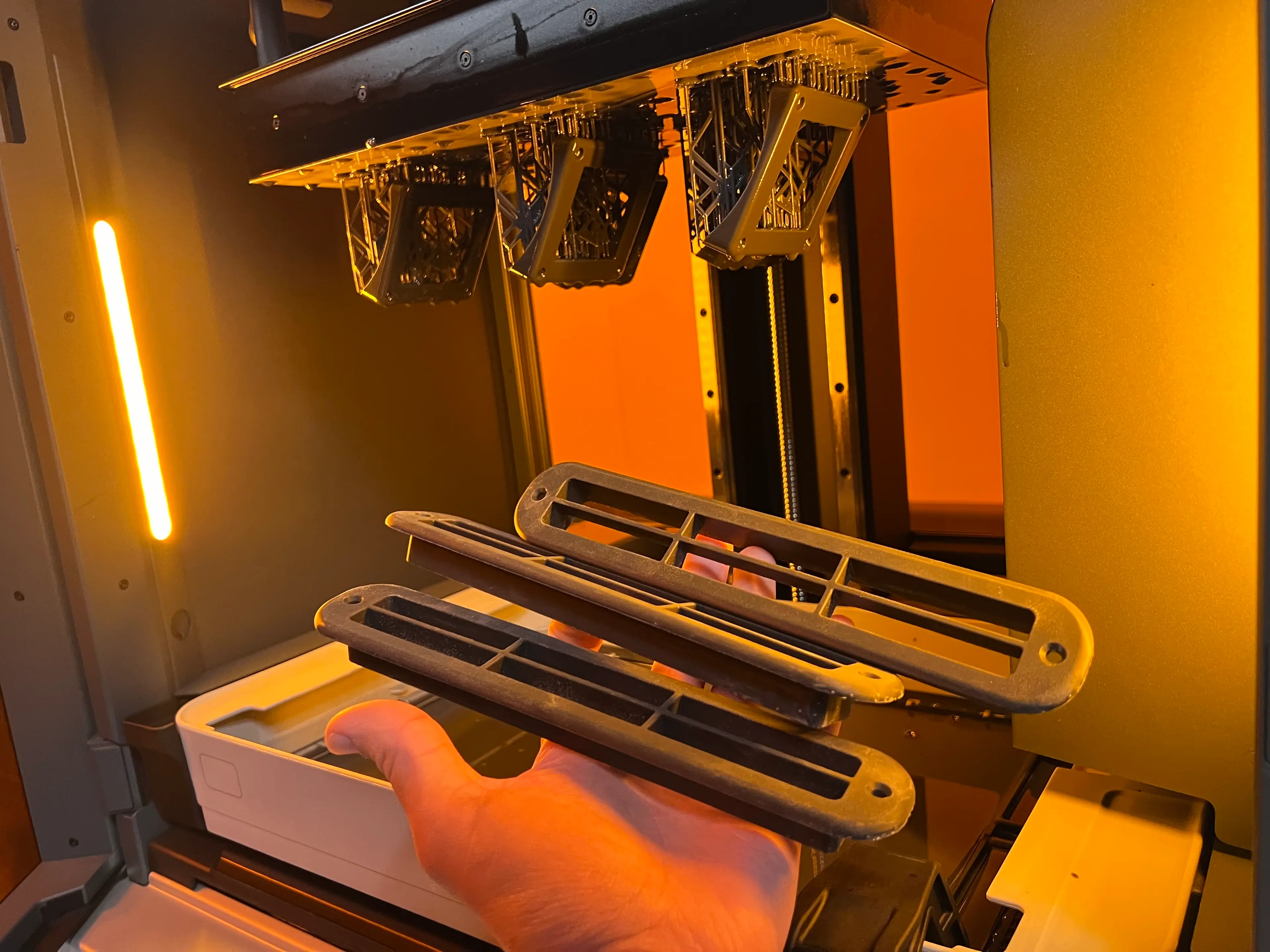

- 3

Remove, wash, cure.

- Quick release part removal

- Automatic part cleaning

- Precision post-curing for peak material properties

- 4

Finish your part.

- Light touch supports for quick, clean support removal

- Optional sanding, coating, or painting

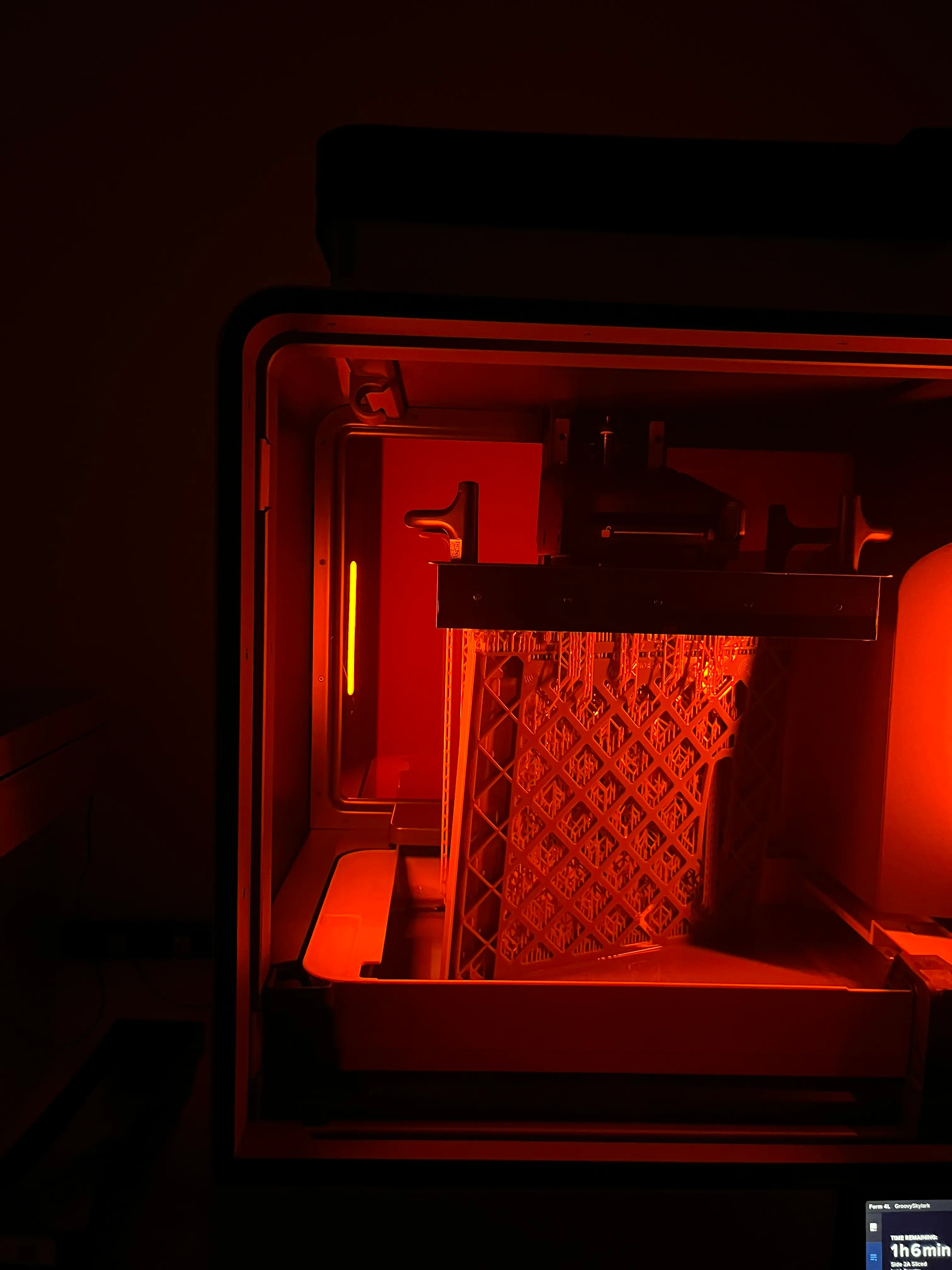

Low Force Display™ (LFD)

The Power Behind Form 4LLow Force Display™ (LFD)

The Power Behind Form 4LA wide range of applications to help you excel in your work.

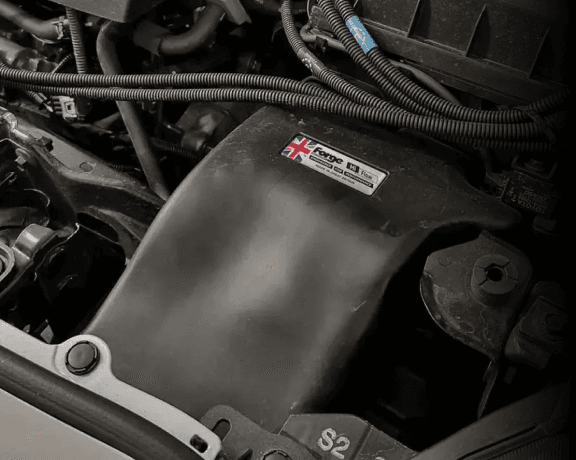

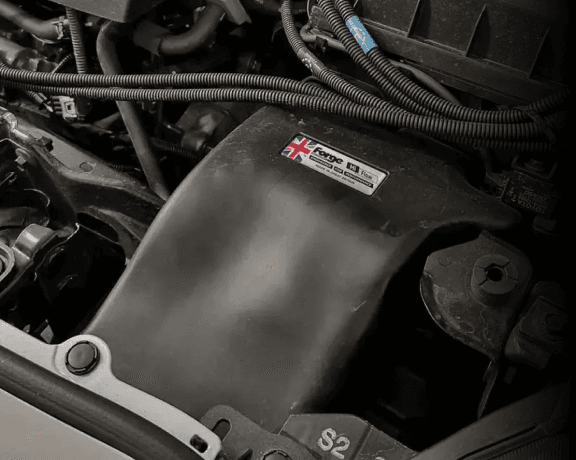

Forge Motorsport reverse-engineered an underperforming part, 3D printed a new design, and tested it on a vehicle for five months before committing to tooling.

Forge Motorsport reverse-engineered an underperforming part, 3D printed a new design, and tested it on a vehicle for five months before committing to tooling.

Rapid Prototyping

Brose

“The new Formlabs 4L allows us to print large parts fast. For example, we use Form 4L to print setup parts for our weld cell in just hours instead of overnight. This allows the Brose welding experts to program the robot prior to the metal stamping components arriving. With the new Fast Model Resin, we receive the detail required and the rigidity needed in a faster time than ever before.”

Matthias Schulz,

Manager, Seat Prototyping, Brose North America

Manufacturing Aids

Eaton

“When we upgraded to Form 4, it truly was like a step change in the technology. All of a sudden, this process that was really intriguing from a quality standpoint and a dimensional accuracy standpoint is now lightning fast. So now we’re combining ease of use with efficiency and accuracy and reliability.”

Cameron Peahl,

Global Industry 4.0 Additive Manufacturing Strategy Manager

Rapid Prototyping

Radio Flyer

“Having the ability to prototype our ideas quickly because we can generate more versions and test those ideas quickly with Form 4L has allowed us to bring concepts further, faster. We can integrate new features into products that would have been difficult to before.”

Agostino LoBello,

Product Design Engineer, Radio Flyer

Rapid Prototyping

Archer

“Form 4L allows us to print big parts of super high-quality, barely any hand finishing on them, and readily usable. The machine has been flawless for the entire time we have had it.”

Julien Thiebaud,

Design Manager, Advanced Technologies, Archer

Rapid Prototyping

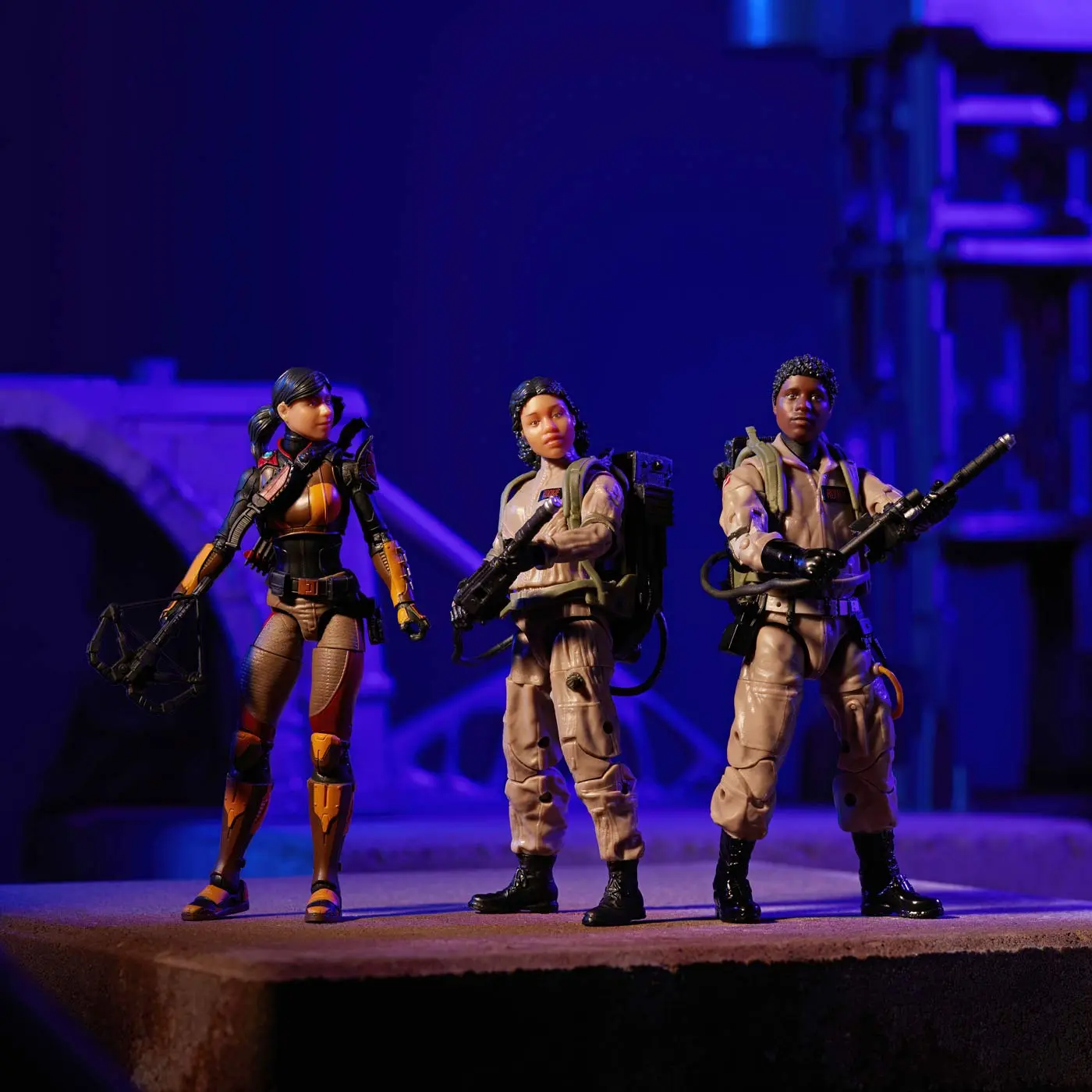

Hasbro

"I really appreciate the reliability paired with the speed. It's not one or the other, like many other tools. Now I can commit to internal deadlines and feel confident that I can deliver every time."

Robert Mackowiak,

Rapid Prototyping Engineer

Manufacturing Aids & End-Use Parts

Viking Yachts

“The Form 4L benefits boat manufacturers of every size. I’m making one-off custom parts that look like they were injection molded — that’s the extra Viking touch, something you can take pride in. 3D printing has game-changing potential for the industry.”

Winston Zeberlein,

Advanced Manufacturing Engineer, Viking Yachts

Manufacturing Aids & Rapid Prototyping

UbeCube

“Before we got the Form 4L, we had to prototype larger items and we needed to get those relatively quickly. Sometimes those part batches shipped to the US in a month and would be $3,000-4,000. To get those same parts manufactured at a USA printing company is even more expensive, five to six thousand. At that point, Form 4L wasn't even a long-term payout — it paid for itself in two runs of parts.”

Isaiah Tarwater,

Industrial Designer, UbeCube

End-Use Parts

Sirris

“With the Form 4L, we’re just scratching the surface of what’s possible. The ability to customize and iterate quickly gives us a significant edge in the market.”

Jon Howard,

Co-Founder and Operations, Sirris

End-Use Parts

Steam Factory

“The printed parts cost 25% less to print on Form 4L than when we were printing on the Form 3Ls. That's a combination of lower material cost and higher speeds.”

Rick Beddoe,

Principal Engineer/CEO, Steam Factory Design and Development

Rapid Prototyping

Microsoft

“We were able to do three full builds in three days instead of a week and a half. So Form 4L already paid for itself in that build alone.”

Mark Honschke,

Additive Prototyping Lead at Microsoft’s Advanced Prototyping Center

End-Use Parts

Ali Sayed

“Every interaction you have with these printers is so easy and refined. When your tools are this nice to use, it not only removes the friction of making stuff but makes it thoroughly enjoyable every time you fire them up.”

Ali Sayed

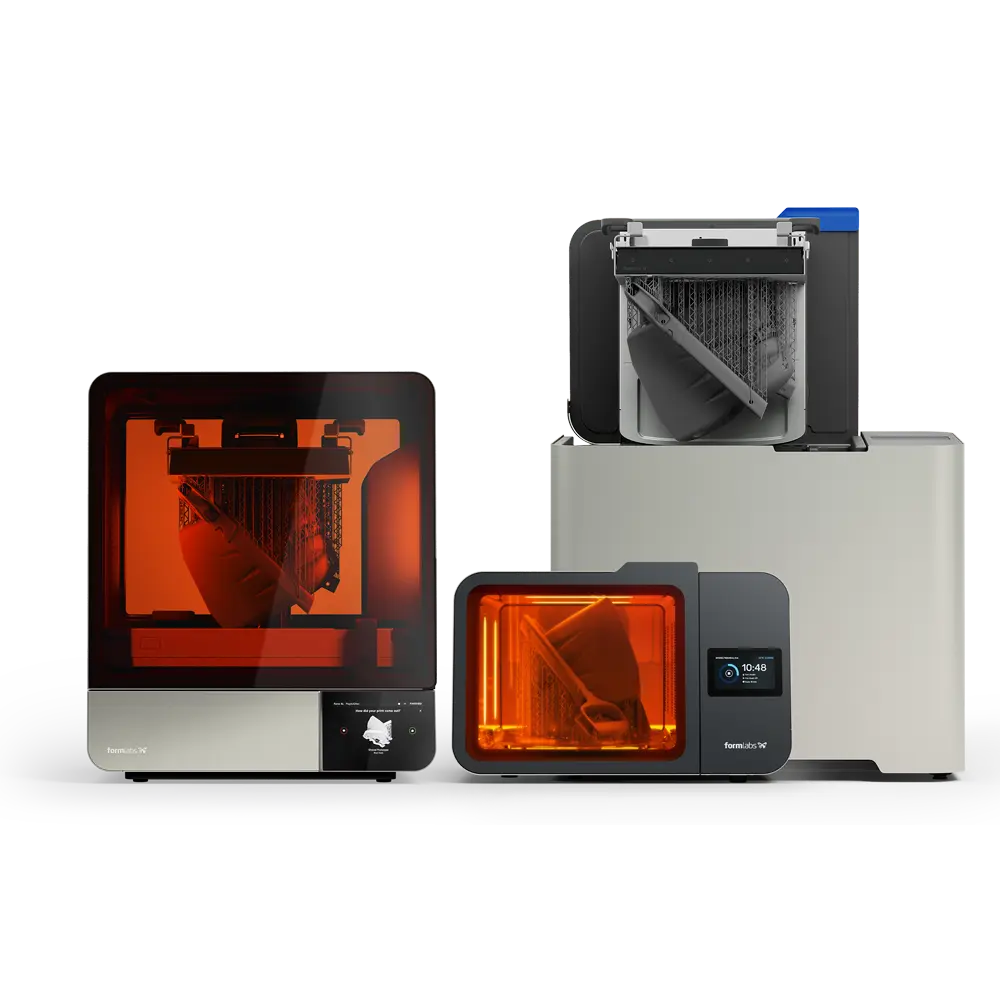

The Form 4L Ecosystem

Complete Your 3D Printing Experience

Form 4L