Eyewear, from reading glasses, to safety goggles, to celebrity-endorsed sunglasses, are the rare example of a product that can be endlessly personalized in terms of both style and functionality. Eyewear manufacturers make adjustments on things as big as material choice or as small as micron-level differences in lens thickness.

As resolution, accuracy, material versatility, and finishing processes for 3D printing become more advanced, the technology presents a cost-effective method of designing and manufacturing eyewear.

In this guide, we’ll walk through design and material considerations for 3D printed glasses, case studies of current manufacturers leveraging the power of 3D printing in the eyewear industry, and ROI calculations to help you build a business case. For our full in-depth report, download on white paper 3D printed eyewear.

Production of 3D Printed Eyewear on the Formlabs Fuse Series SLS Ecosystem

In this white paper, we’ll walk through design and material considerations of current manufacturers leveraging the power of 3D printing in the eyewear industry.

Introduction: Advent of 3D Printed Glasses

The adoption of end-use 3D printed eyewear has increased significantly over the past five years, with small companies and larger brands alike taking advantage of the design freedom, small batch production capacity, and sustainability benefits that 3D printing provides.

Whether for workplace protection, functional performance, or fashion, 3D printing has seeped into the eyewear industry and changed the way designers and manufacturers think about production.

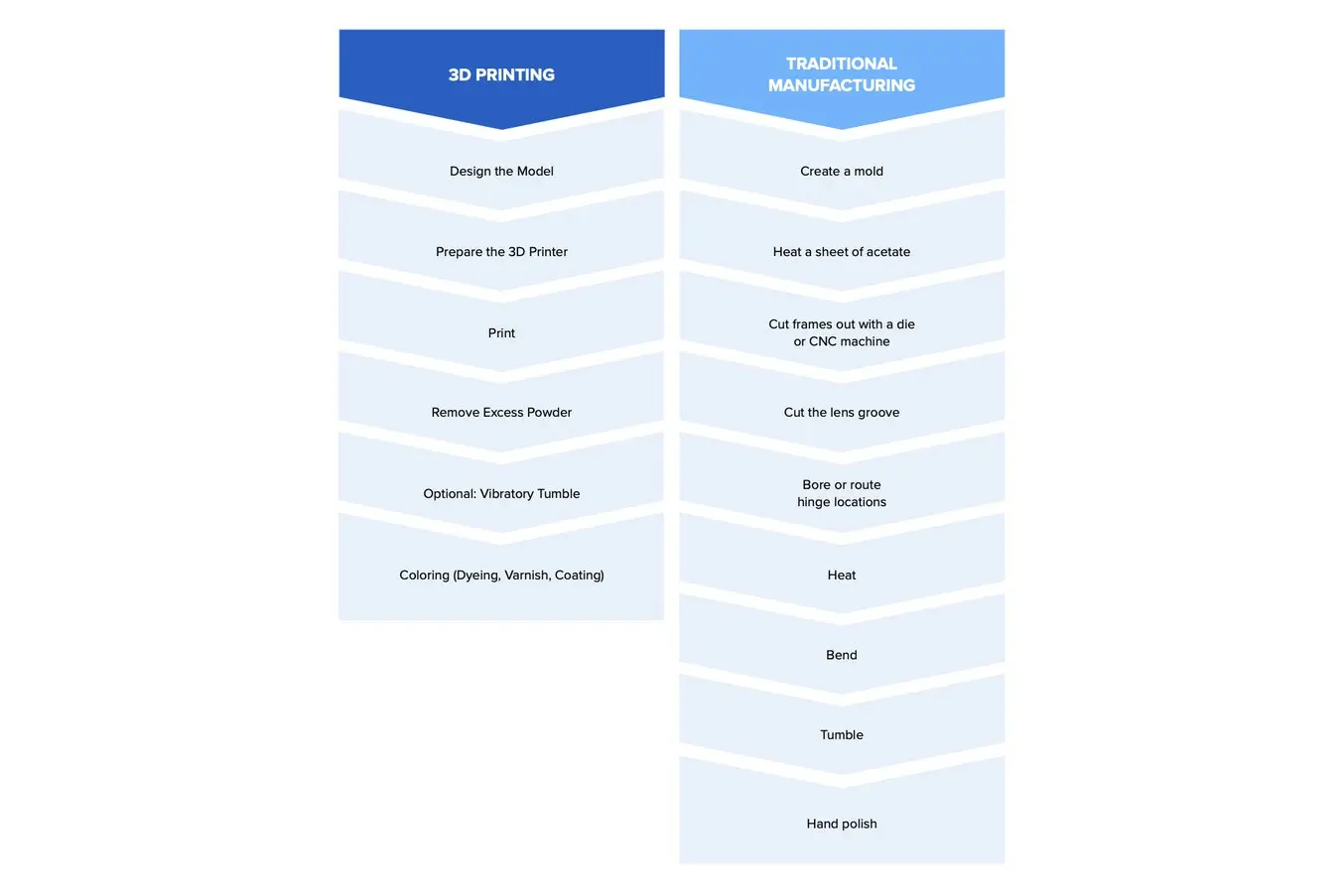

A major benefit of 3D printing can be found in the reduction of assembly steps during manufacturing, while maintaining a high level of product consistency and quality. Some eyewear manufacturers quote the production of acetate frames as taking as many as sixty individual steps.

3D printing offers a significant reduction in assembly complexity and associated labor, with the following basic process:

Selective laser sintering (SLS) 3D printing is the most common additive manufacturing technology for industrial applications, trusted by engineers and manufacturers across different industries for its ability to produce strong, functional parts.

SLS 3D printers use a high-powered laser to fuse small particles of polymer powder. The unfused powder supports the part during printing and eliminates the need for dedicated support structures. This makes SLS ideal for complex geometries, including interior features, undercuts, thin walls, and negative features. Parts produced with SLS printing have excellent mechanical characteristics, with strength resembling that of injection-molded parts, which makes the process ideal for producing 3D printed eyewear.

Continue reading to learn how 3D printing can increase speed to market, reduce labor, and eliminate the need for minimum order quantities (MOQs) for eyewear frames and temples.

Swiss eyewear manufacturer Marcus Marienfeld utilizes the Fuse 1+ 30W SLS 3D printer to produce end-use 3D printed eyewear, as seen above.

Why 3D Print Glasses?

1. Manufacturing Sustainability

Current eyewear frame production is primarily accomplished through injection molding, die cutting, or precision CNC milling, forcing manufacturers to invest in significant mold and equipment costs. Outsourcing production of molds or machined parts can take weeks and cost thousands of dollars. To justify the expense, the manufacturer has to commit to extremely high quantities of the product which can result in lower profits and high volumes of unsellable stock.

This system is unsustainable both financially and environmentally. 3D printing allows companies to own their manufacturing with no mold investment, lowering the risk of starting a new product line substantially. In-house 3D printing frees manufacturers from high MOQ requirements and commitments to unpopular product designs by enabling the production of small, on-demand batches with no upfront molding costs.

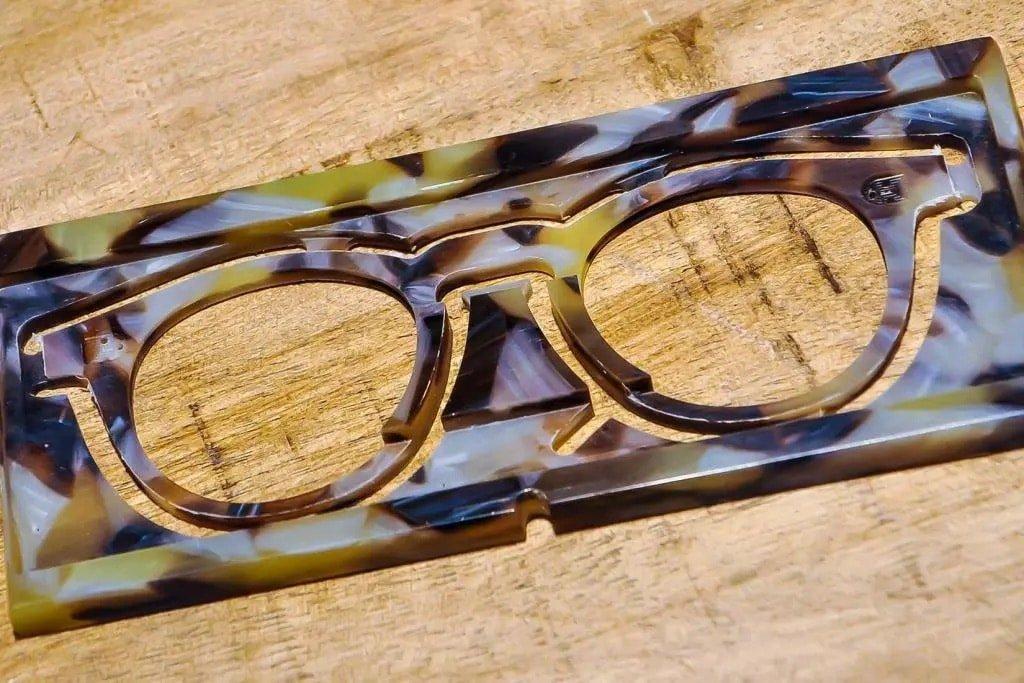

Most pieces of eyewear today are created through injection molding or a subtractive process where acetate is cut into the designated shape. The cutting process takes large sheets of acetate and cuts away the frame shape, leaving all resulting material as waste.

A traditional acetate frame created by a cutting process. Source: Visio Optical

Comparatively, 3D printing is an additive process, meaning that parts are created layer by layer from a base supply of material. With the Formlabs SLS ecosystem, unused powder material can be recycled to be reused in the next print, resulting in little to no wasted material.

Nylon 11 Powder 3D printed frames being removed from the Fuse 1+ 30W build chamber.

The small footprint and affordable price point of the Fuse SLS ecosystem allows manufacturers to purchase multiple machines for multiple locations, thus distributing production capacity to regions that are physically close to consumers, and reducing the reliance on overseas production that can be slowed by global supply chain complications. Having distributed production also reduces the negative environmental impact associated with overproduction and shipping.

2. Design Freedom

Unlike other polymer 3D printing technologies, parts produced through SLS 3D printing do not require support structures, as they are supported by the surrounding powder bed. With no support structures, sprues, or restrictions on draft angles and undercuts common in traditional molding or cutting processes, SLS 3D printing offers almost unlimited design freedom, enabling advanced designs that were previously too costly or even impossible to produce.

Manufacturing restrictions no longer prevent product designers from creating the most functional, best fitting, and most fashionable designs. 3D printed eyewear enables responsiveness to consumer trends faster than ever before, allowing brands to capture new and emerging market segments.

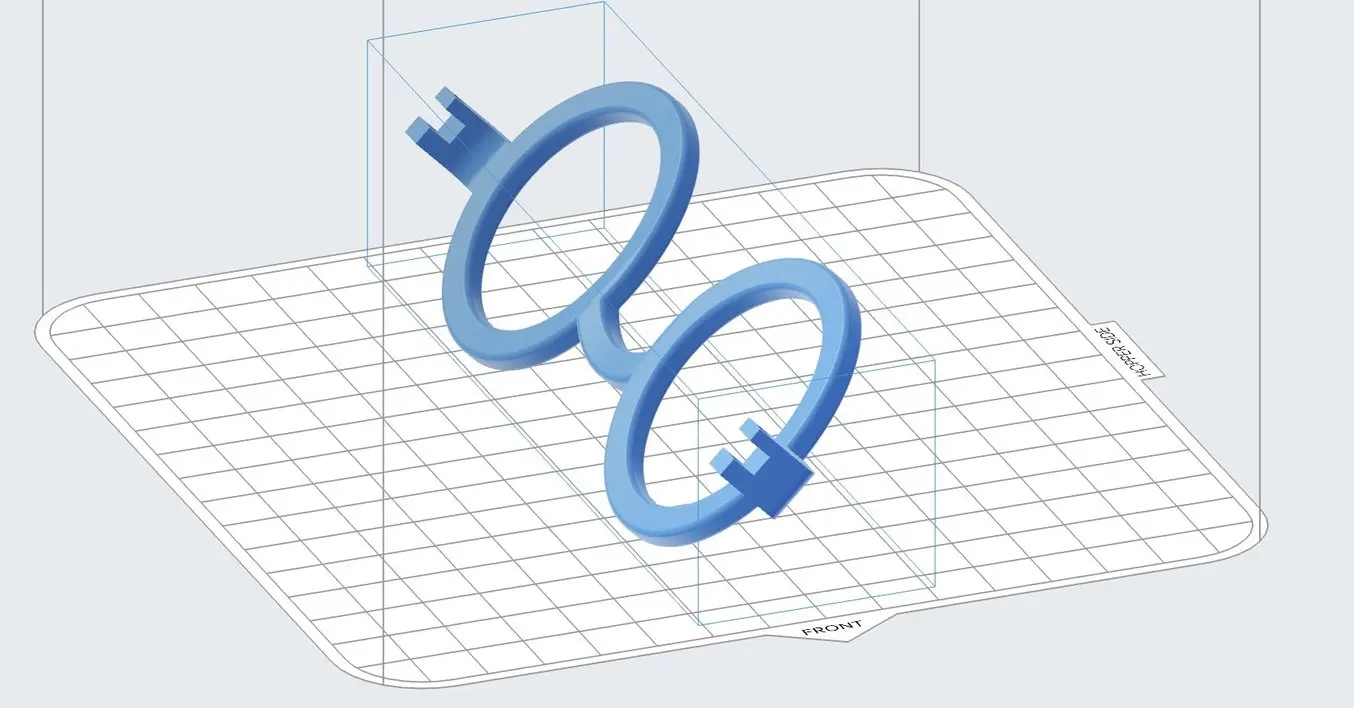

A complex 3D printed temple design that would be hard or impossible to produce efficiently with traditional tools.

3. Customization and Personalization

Similarly, with no tooling requirements or minimum order quantities, product personalization is finally within reach, enabling custom sizing and design choices to provide customers with a completely unique or better-fitting product.

3D printing is already being used to enable product customization in fields from orthotics, to action figures, to audiology, typically finding the most success when consumers feel the product is truly elevated to be more functional or more personally appealing. With the wide variety of ages, ethnicities, and facial features in the world today, product designers are being forced away from a “one size fits all” mentality, and further into a world of personalization.

“With 3D printing, I can do it immediately. If you are familiar with CAD design, you can easily make adjustments to the 3D model, upload it to the software, and print it directly. When it comes to milling, on the other hand, I would always need an individual and expensive tool development to hold the elements in the machine.”

Marcus Marienfeld, eyewear designer and manufacturer

How to Manufacture 3D Printed Glasses

1. Design

Creating end-use eyewear with 3D printing offers unique benefits and challenges. In this section, we will cover part texture, hinge options, designing unmoldable geometries, and customization.

Texture

Additively manufactured parts are formed layer by layer, meaning that some surfaces may have visible layer lines. Layer lines can be mitigated through part orientation optimization, part design, and additional post-processing to smoothen the surface.

Adding embossed or debossed texture to the surface of frames and temples is a well-known strategy to mask layer lines on end-use 3D printed goods. Formlabs recommends a minimum 0.35 mm high emboss and 0.15 mm deep deboss to ensure sufficient masking of any layer lines.

Finally, part layer lines can be used as a tool to increase grip and friction, preventing slippage on the face.

Hinge Options

3D printed eyewear hinges can be achieved in four main ways:

-

Traditional screws

-

Heat set inserts

-

Snap-fit

-

Print-in-place hinges

Hinge threads can be added to the design of 3D printed parts, but traditional eyewear screw threads are typically too small to resolve consistently. Stick to thread sizes of at least ¼”–20 (imperial) or M6 (metric) or larger.

3D printed eyewear assembled with a printed thread and metal screw.

Both Nylon 11 Powder and Nylon 12 Powder allow for the use of heat-set inserts and tapped threads, which can be longer lasting and more durable than other options. Read the step-by-step guide here.

Lastly, due to the lack of support structures, SLS 3D printing enables the use of print-in-place geometries. Frames can be designed and printed with temples already attached, with no further assembly required. Formlabs recommends 0.3 mm of clearance on features less than 20 mm2, and 0.6 mm of clearance on features greater than 20 mm2. Read the entire SLS design guide here.

Unmoldable Geometries

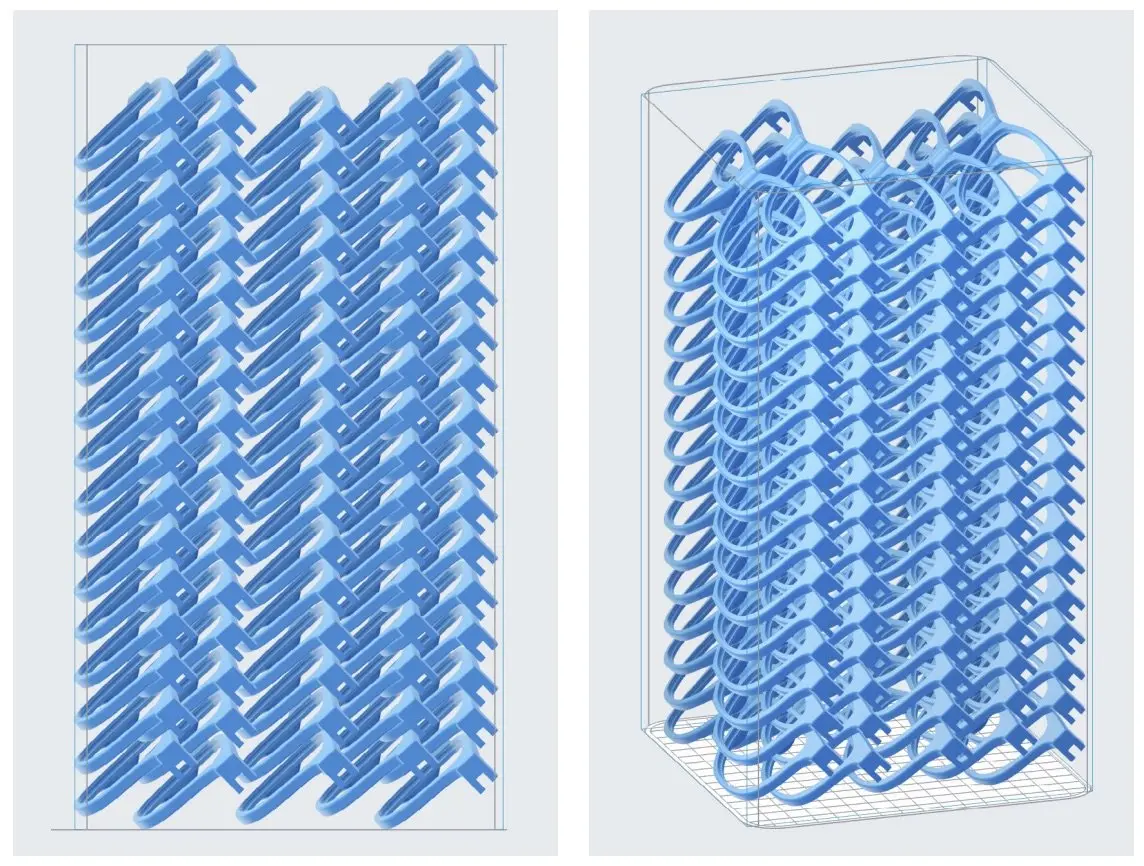

Nylon 11 Powder temples designed with latticing options in nTopology software.

Seen mainly in more fashion-forward applications, 3D printing has allowed designers to create unmoldable and uncuttable eyewear designs. Unmoldable geometries, such as the temples in the image above, can tap into new realms of user expression, or alternatively, can allow for the extreme lightweighting of components to improve user comfort.

Eyewear frames and temples 3D printed on the Fuse 1+ 30W printer, designed and manufactured by Alvaro Planchart.

2. 3D Printing

3D Printer for Eyewear

The Fuse Series SLS ecosystem offers an accessible and scalable production solution for eyewear, due to its reliable hardware, industrial grade materials, and intuitive user interface. The sections below will cover tips and tricks specific to producing eyewear with SLS 3D printing.

The Fuse 1+ 30W SLS 3D Printer (left) and Fuse Sift post-processing unit (right)

Request a Free SLS Sample Part

See and feel Formlabs quality firsthand. We’ll ship a free SLS sample part printed on the Fuse 1+ 30W to your office.

Materials for 3D Printing Glasses Frames

The Fuse 1+ 30W system offers two material candidates sufficient for eyewear production: Nylon 11 Powder and Nylon 12 Powder. Both materials are thermoplastics, just like acetate, meaning that opticians can heat the frames and temples to better fit the face after printing.

When comparing functional performance against acetate, TR90, and polycarbonate, both SLS materials are extremely comparable, with Nylon 11 Powder being preferred by some customers due to its superior elongation at break and sustainability benefits.

| Cellulose Acetate* | Grilamid TR90** | Nylon 11 Powder | Nylon 12 Powder | |

|---|---|---|---|---|

| Ultimate Tensile Strength | 30 MPa | 60 MPa | 49 MPa | 50 MPa |

| Tensile Modulus | 1700 MPa | 1500 MPa | 1600 MPa | 1850 MPa |

| Elongation at Break | 30% | 50% | 40% | 11% |

| Flexural Strength | 40 MPa | N/A | 55 MPa | 66 MPa |

In real-world functional testing, Nylon 11 Powder has demonstrated impressive ductility and impact strength:

Additional environmental and material properties should be considered when creating a long-lasting, sustainable product that will be exposed to the elements.

Due to their lower densities, low water absorption, and high heat and flammability resistance, Nylon 11 Powder and Nylon 12 Powder can be considered for more functional applications, such as protective eyewear on the factory floor or for in-field use, enabling the creation of lightweight frames that can withstand intense environmental conditions.

Lastly, the Formlabs Nylon 11 Powder is a 100% bio-based renewable material, as it is sourced from sustainable castor beans, offering a more eco-friendly option than some petroleum-derived plastics. Compared to Nylon 12 Powder, Nylon 11 Powder offers a 60% reduction in carbon impact.

Surface Finish

Surface finish of 3D printed glasses frames is highly dependent on model design, and different orientations will yield varying surface finishes. Formlabs has conducted extensive part orientation testing, finding that a 45-degree frame print orientation in Nylon 11 Powder and Nylon 12 Powder results in the most optimal aesthetic surface finish on an example round frame design. Whichever side of the part is facing towards the bottom of the build chamber will have a slightly smoother surface finish.

Front of a frame oriented at a 45-degree angle in PreForm for the most optimal aesthetic surface finish

Build Capacity

When oriented at a 45-degree angle, 82 example frames can fit in the Fuse 1+ 30W build chamber. This scenario offers a 10% pack density and a build time of 21 hours when using Nylon 12 Powder as of March 2023.

Formlabs is continually improving print settings. Contact Formlabs for the most up to date print time and cost analysis, or to receive an analysis for your own part design.

| Nylon 12 | Nylon 11 | |||

|---|---|---|---|---|

| Number of Parts Per Build | 82 | 60* | ||

| Pack Density** | 10% | 10% | ||

| Print Time | 21 hours | 22.5 hours | ||

| Maximum Yearly Production Per Machine | 19,680*** | 14,400*** |

* Throughput is calculated based on a Formlabs standard frame design. The number of parts was reduced to achieve a print time of sub-24 hours, resulting in a higher production throughput. Nylon 11 is also capable of printing 82 frames at one time, but with a >24 hour print time.

** Read more about pack density and refresh rate here.

*** Assuming one print per day, five days per week, for 48 weeks a year. A second build chamber is required to quickly change over and start new prints.

82 frame models packed in PreForm, Formlabs’ free print preparation software.

3. Finishing Options

The natural aesthetic finish of both Nylon Powders is an opaque gray color with a surface finish rougher than that of polished acetate. To achieve a finish more similar to that of traditional acetate or TR90 eyewear, a variety of finishing options should be considered.

Frames printed in Nylon 11 Powder, from left to right: raw off the printer; vibratory tumbled; vapor smoothed; dyed black; dyed blue; white Cerakote.

Preparing the Part Surface

Just as traditional acetate frames are often tumbled in a wood media, 3D printed frames benefit greatly from a few hours in a vibratory tumbler. When using ceramic media with a lubricant, Formlabs has seen an 80% reduction in surface roughness, resulting in a smooth-to-the-touch feel. Formlabs uses the Mr. Deburr 300DB vibratory tumbler, a low-cost and easy-to-use option.

Frames printed in PA11; (Bottom) Vibratory tumbled; (Left Center): Cerakote; (Right Center) Vapor Smoothed; (Top) Cerakote.

Coloring Options

A simple and cost-effective option for part coloring is to utilize a water bath dye system. Parts are submerged in a heated water bath with a color dye that penetrates all surfaces of the part, permanently altering the color of the part. Due to the gray powder color, it is impossible to achieve very light color options, such as white or bright yellow through a dyeing process.

However, colors such as black, red, green, purple, and blue are achievable even with a basic dyeing set up with a hot plate, a pot, and RIT nylon dye. Alternatively, industrial solutions are available from companies such as Dyemansion that offer increased color consistency and exact color matching.

Frames printed in Nylon 11 Powder and dyed in a water bath.

Formlabs also utilizes Cerakote coating to both improve the mechanical properties of the part and enable a wide variety of colorways. Cerakote is a thin-film ceramic coating that ranges in thickness from 0.00635 mm to 0.0254 mm and does not require a primer.

Once applied, SLS 3D printed parts can expect an improvement in chemical and scratch resistance. Cerakote can also be used to achieve a glossy surface finish, with colors ranging from pastels to metallics and everything in between. Additionally, once coated, parts can be laser-imaged to achieve interesting patterns or to carry information, such as logos or serialization.

Cerakote can also be used to achieve a glossy finish, through their customizable gloss curing schedules.

Frames printed in Nylon 11 Powder and coated with Cerakote H-Series.

Hydro dipping is also achievable with SLS 3D printed parts; read this blog post to learn more. Similarly, varnishing and pad printing processes are compatible with SLS technology.

Lastly, vapor smoothing is a process to chemically seal and smooth the surface of SLS 3D prints. Vapor smoothing offers an injection molded-like surface with greatly improved surface roughness, as well as resistance to moisture and bacteria growth, while enabling glossy surface finishes.

Formlabs utilizes Additive Manufacturing Technologies (AMT) to vapor smooth eyewear components. Additionally, parts can be dyed in a water bath before or after vapor smoothing, thus sealing in the new part color with additional glossiness.

Nylon 11 Powder frames after vapor smoothing.

Try it Yourself

While Formlabs has explored and developed many finishing options to improve the surface finish of SLS 3D printed parts, there are still many more avenues not yet explored. Many customers have had success with ordering a free custom sample part of their eyewear and then applying their own proprietary finishing techniques (different tumbling media, varnishing, coatings, etc) to achieve unique aesthetics.

Contact our Sales Team to order a free sample of your own design, or order a standard Nylon 11 Powder or Nylon 12 Powder sample part on which to try confidential or proprietary finishing techniques.

Additional Uses for 3D Printing in the Eyewear Industry

Prototyping

Both the Fuse 1+ 30W SLS system and the Form 3+ SLA system can be used to prototype eyewear to test for dimensionality, fit, and overall design.

Choose nylon materials on the Fuse 1+ 30W system to create functional prototypes that can be worn and tested for long periods of time. Choose the Form 3+ system to create aesthetic prototypes that demonstrate looks-like designs with translucency similar to acetate and polycarbonate. SLA printed prototypes can be worn for weeks at a time, but are not suitable for long-term wear unless applied with a UV-blocking coating.

Plastinax uses the Form 3+ SLA printer to produce looks-like prototypes for semi-translucent materials.

User Testing

Utilize the Fuse 1+ 30W to create eyewear that can be tested and evaluated during lifetime and user testing to quickly gain feedback and iterate on dimensions and design.

Nylon 12 frames printed and finished by Plastinax.

Smart Eyewear

With 3D printing, design complexity comes for free. Adding housings for electronics or the intricate assemblies needed for wearables adds no strain onto the 3D printer. Consider SLS 3D printing when creating complicated enclosures for smart eyewear that would otherwise be difficult to manufacture with costly, multi-part injection molds.

Jigs and Fixtures

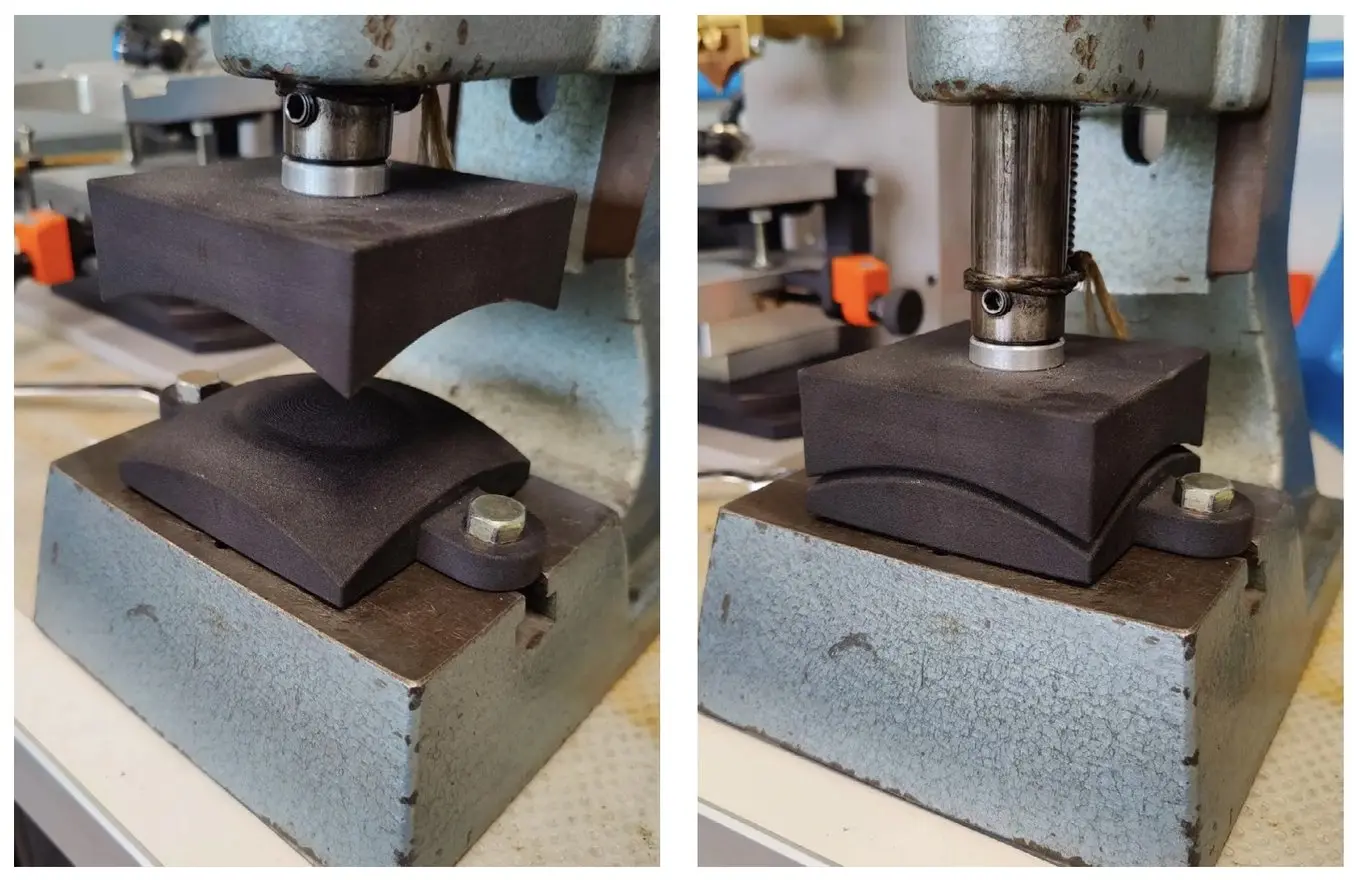

Due to their high impact resistance, Nylon 12 Powder and Nylon 11 Powder are well-suited for custom jigs and fixtures. Formlabs Nylon materials are strong enough to bend some metals used in traditional frames and temples, such as titanium, with pressures of more than 90 kg.

Marcus Marienfeld uses the Fuse 1+ 30W and Nylon 11 Powder material to bend frames and temples.

Short Run Injection Molding and Vacuum Forming

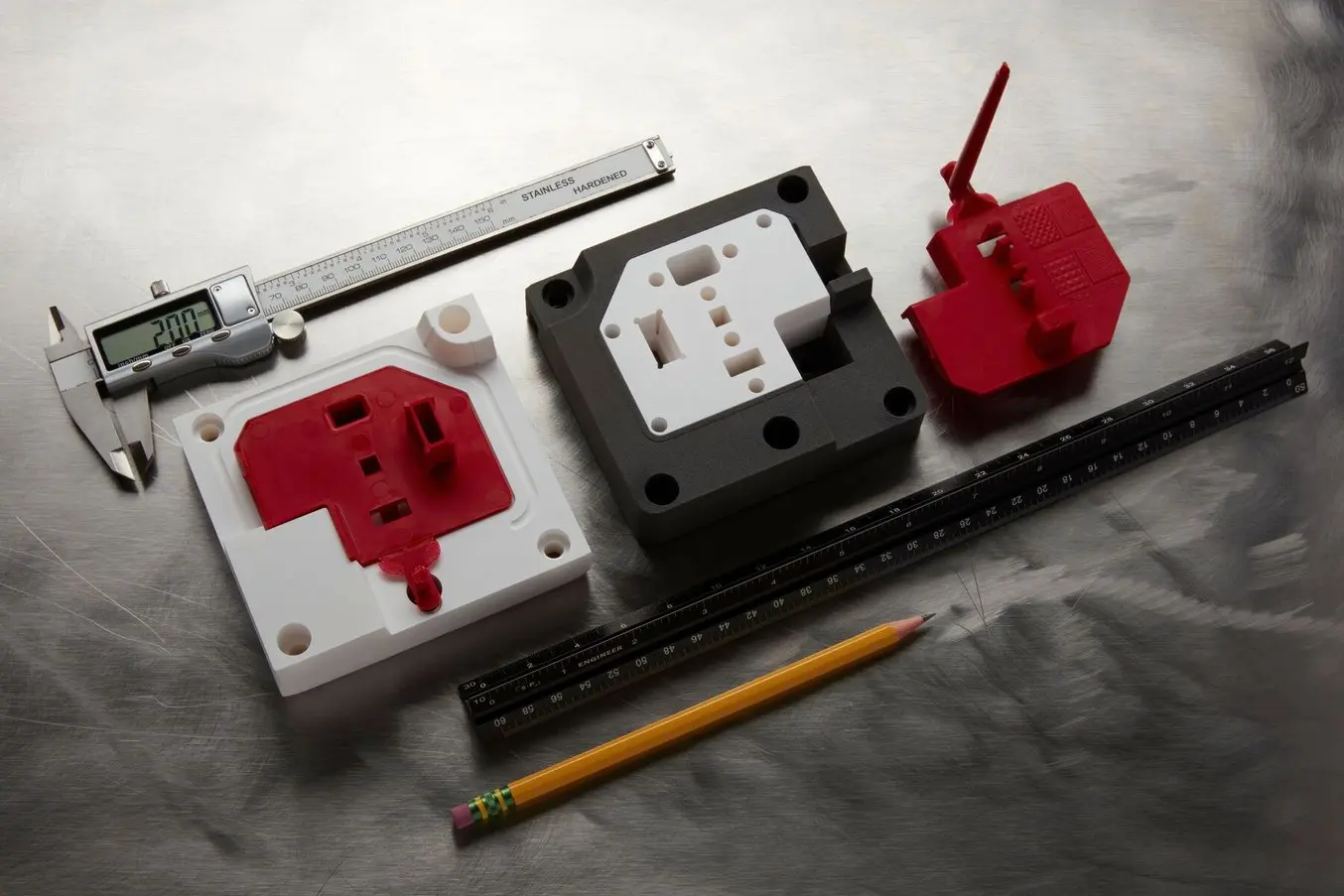

Use the Form 3+ or the Form 3L SLA 3D printers and Rigid 10K Resin to produce injection molds is common across many industries. Due to its high heat resistance and fine surface finish, Rigid 10K Resin can be used for low-volume injection molding of frames and temples, as well as mold making to produce vacuum-formed packaging.

3D printed injection molds made with Rigid 10K Resin.

3D printed molds for thermoforming packaging made with Rigid 10K Resin.

Building A Business Case

Owning a business or creating a new product line enabled by 3D printing is becoming more obtainable and cost-effective by the day. A single Fuse 1+ 30W 3D printer can enable a production run of 19,000+ frames per year or 50,000+ temples per year on an unoptimized five-day production schedule.

| Nylon 12 Powder Frames Yearly Capacity* | Cost Per Part of Sintered Powder | Adjusted Cost Per Part** | ||

|---|---|---|---|---|

| 1 Fuse 1+ | 19,680 | $0.66 | $1.92 | |

| 5 Fuse 1+ | 98,400 | Contact Formlabs | Contact Formlabs | |

| 10 Fuse 1+ | 196,800 | Contact Formlabs | Contact Formlabs | |

* Assuming a five day workweek with five prints per week, for 48 weeks a year.

** Cost per part adjusted for the material loss due to lower packing density. Learn more about refresh rate.

Option 1: Own Your Own Production

The most efficient and cost-effective way to produce 3D printed eyewear is to own the production equipment. This entails purchasing a Fuse 1+ 30W ecosystem.

The benefits of vertically integrated 3D printing production include achieving faster ROI, tighter control over quality, agility to alter design and move from prototyping to production on the same machine, and the ability to utilize the ecosystem for other purposes, such as creating jigs and fixtures.

Designed to be as accessible as possible, the Fuse 1+ 30W ecosystem is extremely plug-and-play, with most users learning how to operate the equipment in a matter of hours. Similarly, the ecosystem has minimal facility requirements, allowing for quick installation and easy scalability as demand grows.

With the Fuse Series, it’s easy to scale up as the demand grows.

It’s also important to note that a new Fuse Sift is not required with every additional Fuse 1+ 30W printer. Most customers keep a ratio of 4:1, printers to post-processing stations.

The cost to incorporate a full Formlabs SLS printing ecosystem, including a Fuse 1+ 30W, a Fuse Sift post-processing unit, two build chambers, two cartridges, 24 kg of Nylon 12 Material, and two years of expert customer support is $53,350.

Option 2: Outsource to a Service Bureau

There are many service bureaus globally with varying levels of turnkey capabilities, ranging from those that only handle the 3D printing component, to service bureaus that offer design, printing, post-processing, and packaging services.

Expect to pay more per part when working with a service bureau. However, service bureaus can be a good option for those without the space or capital to invest in production equipment, or those looking to run a low-volume experiment.

Contact Formlabs for a list of approved service bureau partners.

Get Started With 3D Printed Glasses

Interested in receiving one of our standard eyewear sample parts, or getting your own design printed? Contact the Formlabs Eyewear Team.