Printing an Entire Spine in 90 Minutes: Anatomical Models at St. Louis Children’s Hospital With Form 4BL

3D printing at point-of-care can involve quick turnaround of large parts and 3D printers need to keep up. At St. Louis Children’s Hospital in Missouri, USA, Brian Albers, 3D Printing Engineer, 3D prints anatomical models and surgical guides, using Formlabs printers for orthopedic and cranial maxillofacial cases, including for pre-bending titanium plates.

Due to the unpredictability of clinical demands, Albers says, “We have to make sure we have a good process so we know that we can respond to every case that comes our way.” Clinical demands include rush jobs, large anatomical models, and highly detailed parts with fine features, some of which need to be sterilizable for use in the operating room.

“We lean very heavily on the Formlabs printers. It's great on the cost savings side of it, but it's also a quick and efficient process. We're manufacturing anatomic models very quickly with very little hands-on cleaning. Just this last month we've nearly doubled the most models we've produced in a month since the lab's inception.”

Brian Albers, 3D Printing Engineer, St. Louis Children’s Hospital

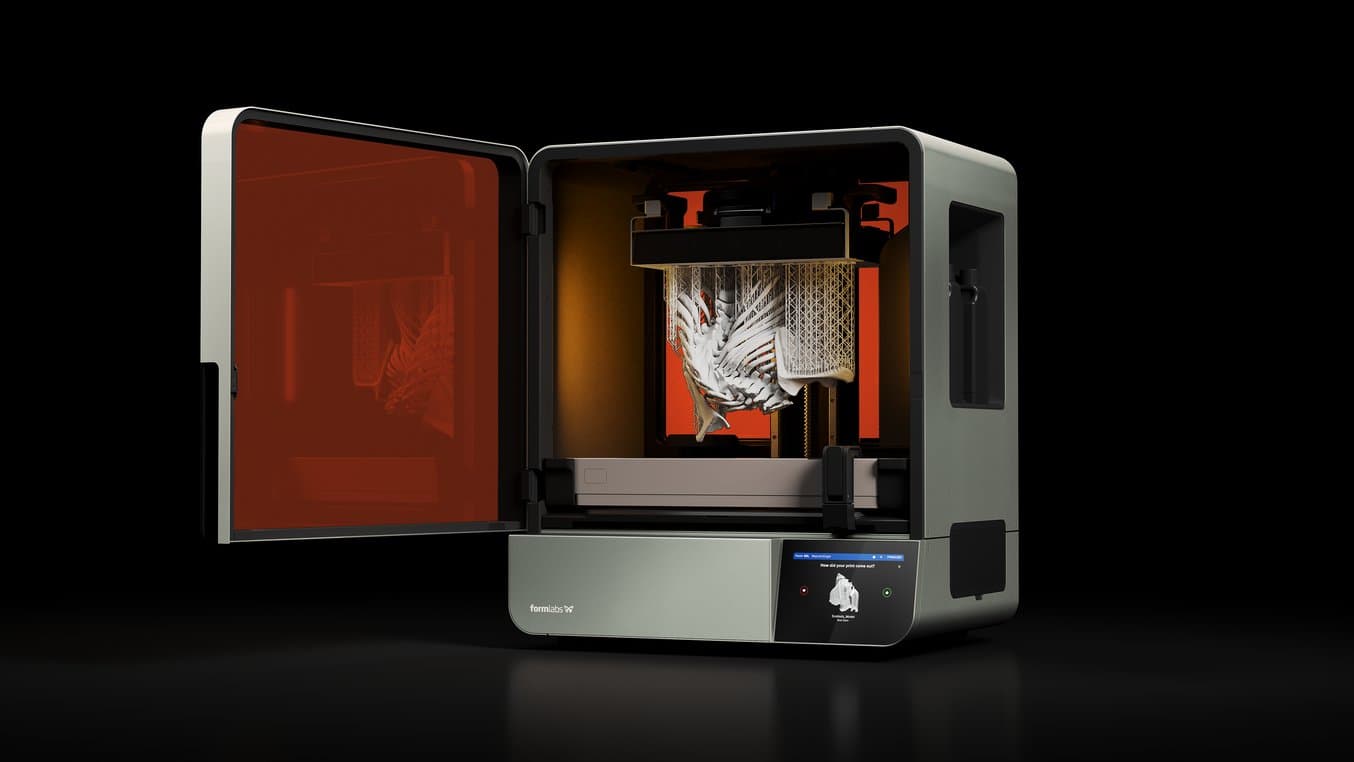

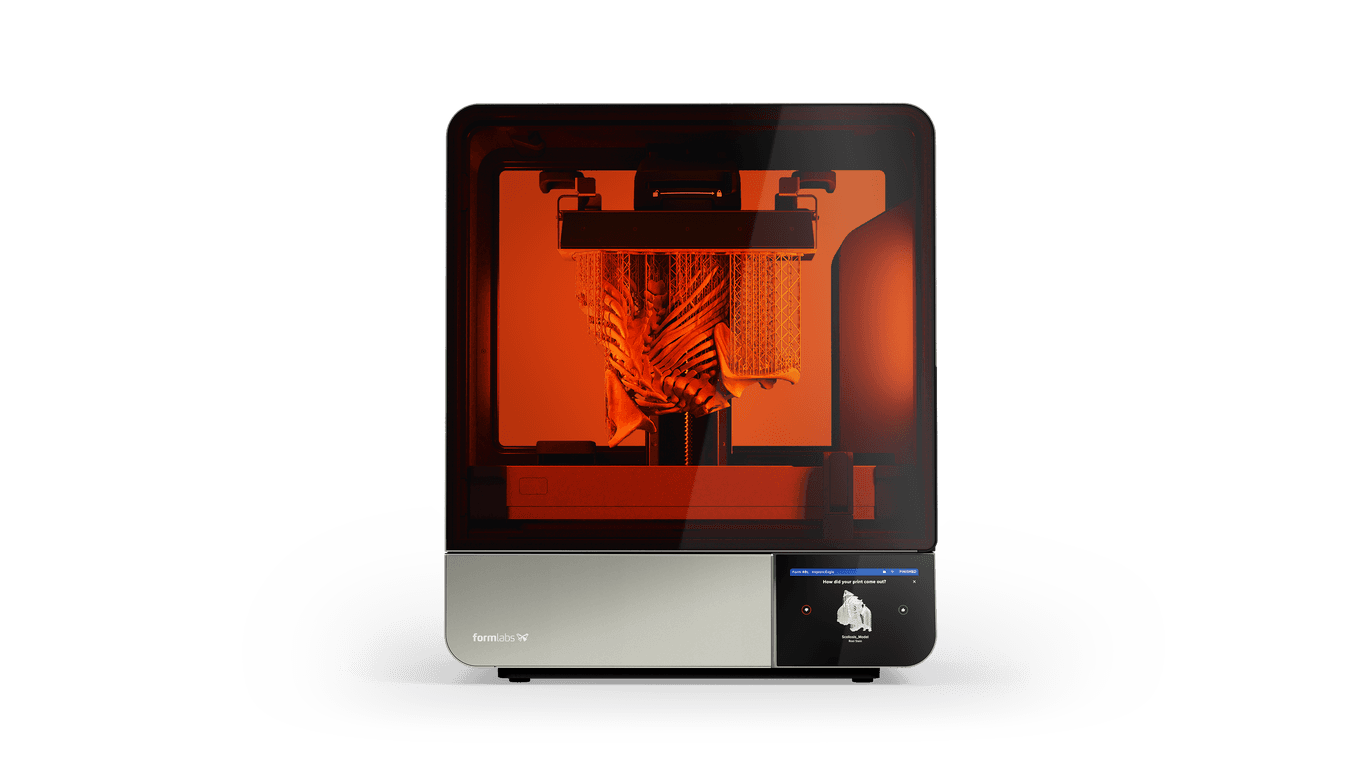

Albers prints with a Form 3L stereolithography (SLA) 3D printer, Form 3BL for biocompatible printing, three Form 3Bs, one Form Auto, and a Fuse 1 selective laser sintering (SLS) 3D printer. But with the added speed and volume of Form 4BL, he’s been able to meet last-minute requests and save more time than ever before.

Talk to Our Medical Sales Team

Whether you need to make patient-matched surgical tools or are prototyping for a cardiac medical device, we’re here to help. Formlabs Medical team are dedicated specialists who know exactly how to support you and your company's needs.

Tackling Large, Last-Minute Cases With Form 4BL

"I'm blown away by how fast the Form 4BL prints. We've been able to tackle cases we otherwise wouldn't have had time to print, and it's done so with incredible reliability. When I rendered a print and saw the estimated time was just an hour and 26 minutes, I honestly thought it was a glitch. I didn’t believe it until we printed it."

Brian Albers, 3D Printing Engineer, St. Louis Children’s Hospital

The speed of Form 4BL has made it possible for Albers to respond to urgent, last-minute cases.

Generally, orders for anatomical models have a two-week turnaround time, building in time for radiologists to review and sign off on scans, plus some time to reprint if necessary. But within a week of receiving Form 4BL, Albers had an urgent, rushed case come in two days before a procedure — for a print that would normally take 20 hours.

"With our other 3D printing technologies, producing an anatomical model of a spine would take 20 hours, making it impossible to complete in time for procedure planning. Using Fast Model Resin on Form 4BL, we printed it in just an hour and a half and delivered it the same day. Without that speed, we wouldn’t have been able to respond to the case in time."

Brian Albers, 3D Printing Engineer, St. Louis Children’s Hospital

Additional rush cases have come in since, including an unplanned surgical intervention on a spine. With a holiday weekend coming, the model was needed the next day. Due to size, some adult spines even need to be printed in three or more pieces on multiple printers to cut down on print time. The size of Form 4BL and the speed of printing Fast Model Resin enabled Albers to print the spine in one print batch in just two parts and in under two hours, for delivery the next day.

Product Demo: Form 4L and Form 4BL

See how Form 4L and Form 4BL can enable new levels of productivity and innovation through its unmatched speed, accuracy, and reliability.

Strong Parts With Fine Details

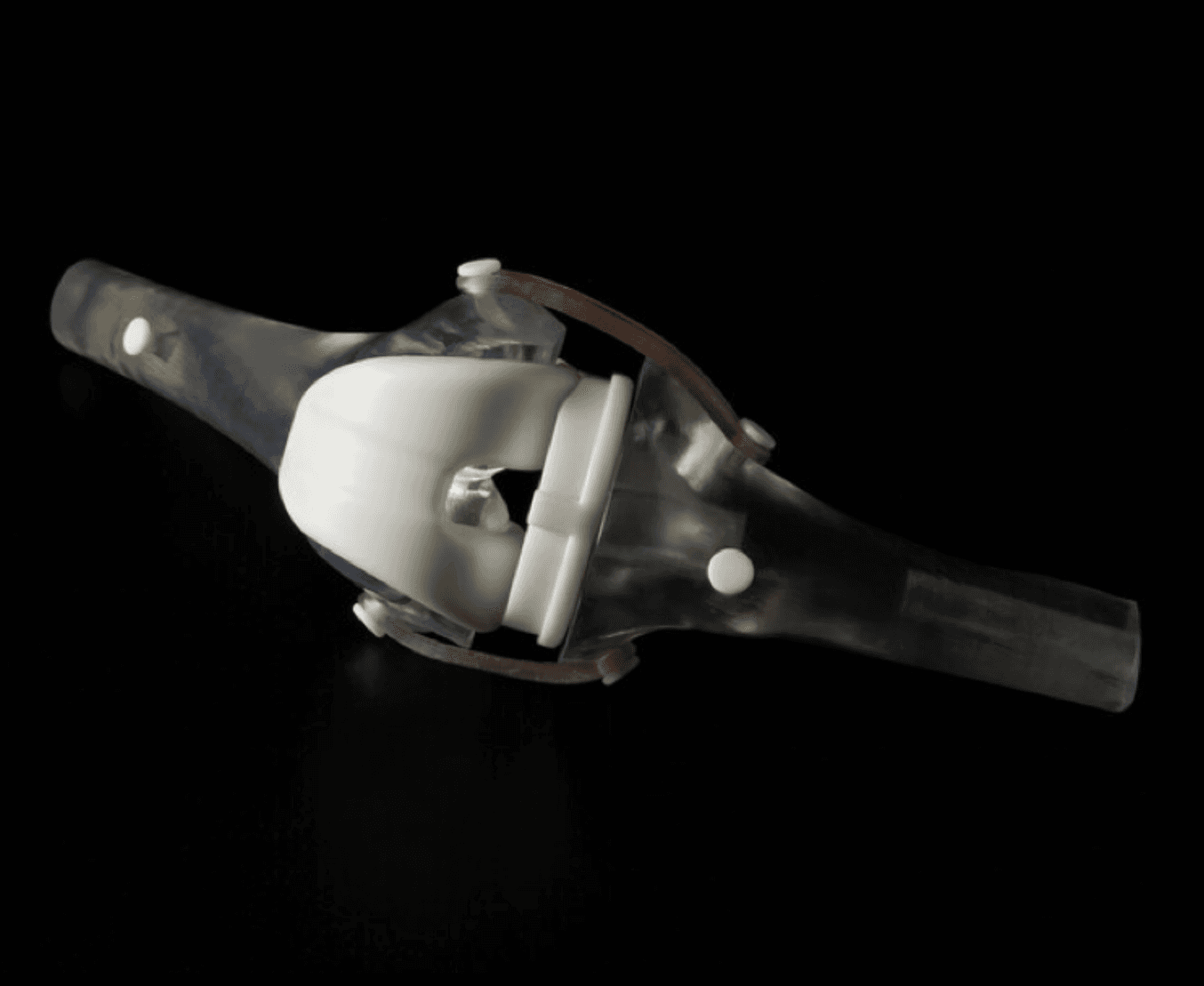

DIEP flaps for mastectomies involving fat grafting also require quick responses as case timelines often move. These models map out the abdomen, specifically the blood vessels supplying the subcutaneous fat in the area, so that the surgeon can map out where they are going to pull the fat for a breast reconstruction. Having a blood vessel in the fat being removed increases the odds of success.

These models have very tiny features in them. Albers says, “Form 4BL handled the small details, the very small fine parts on these DIEP flaps, just as well as it handled the big parts. Really there's been no other way to print than Formlabs SLA. The PolyJet is very expensive but very fragile when trying to clean supports off.”

BioMed Clear Resin can be used for biocompatible applications and is sterilizable, enabling models printed with the resin to be brought into the operating room for reference during surgery. For situations where models are used prior to surgery, Rigid 4000 Resin and Fast Model Resin can be used. Fast Model Resin, as Formlabs’ fastest-printing resin, is specifically useful in rush cases.

Surface finish on these models is important, especially for those that are going to be sterilized, as sharp features have the potential to break gloves. Form 4BL delivers smooth finishes and light-touch supports for easy removal and less time spent finishing. Additionally, PreForm’s settings enable Albers to customize his support settings and save these custom settings so they’re easier to apply to future models.

BioMed Resin Swatches

Each BioMed Resin swatch features embossed and debossed designs, 0.5-2.0 mm cutout thicknesses, as well as regulatory information unique to that resin.

Fast, Cost-Efficient Delivery of Large Parts

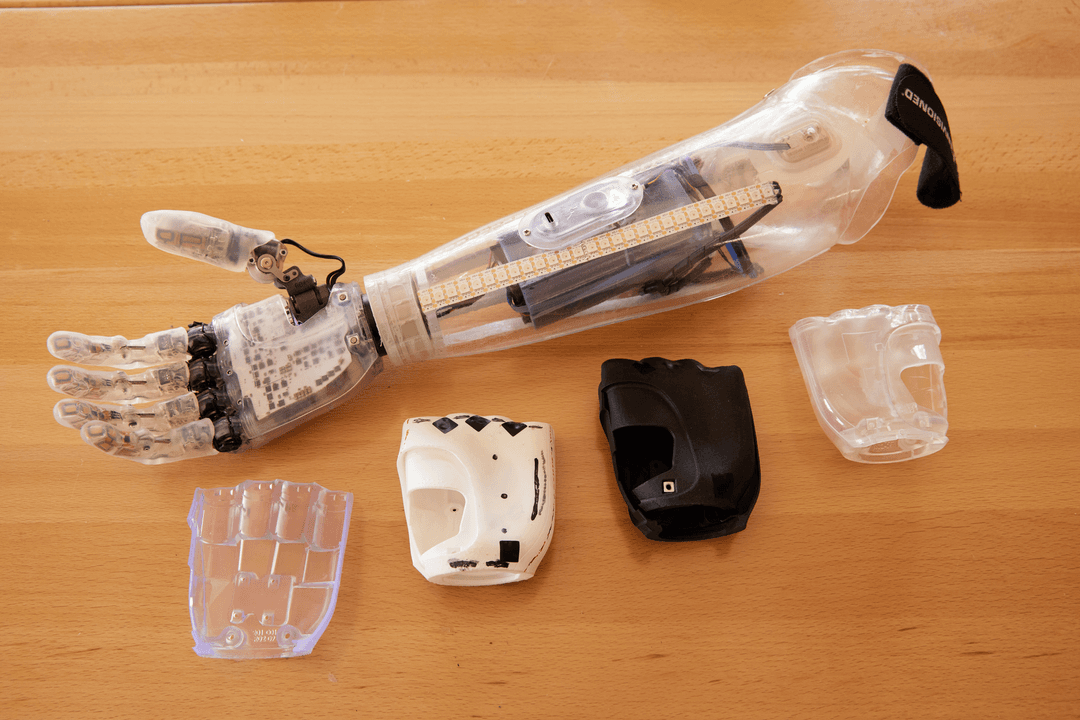

Albers uses Form 4BL to print large anatomical models, like this spine. He has found that it’s less expensive to produce parts on Form 4BL than on competing printers.

Large anatomical models like hips and adult spines have to be printed in multiple parts on Formlabs desktop 3D printers. Albers has been using Form Auto so that he could have a queue of multiple parts run over an evening to assemble in the morning. But with the combined volume and speed of Form 4BL, he can fit both hips or all the parts of a spine in one build, for fewer print batches in less time, often eliminating the need to print overnight.

In addition to reducing the turnaround time for large parts, Albers has found that parts printed on Form 4BL are less expensive to produce than on competing printers.

“The spines for instance, we did them on the PolyJet and it was about $1600 in resin. To do it on the Formlabs, we got it down to about $80 in material per spine.”

Brian Albers, 3D Printing Engineer, St. Louis Children’s Hospital

This is a cost-savings of 20x in materials alone, for cost-effective and efficient production of large parts.

Creating Bone Simulation Models for Cutting and Drilling

3D printed bone-simulation models are revolutionizing medical training, surgical planning, research, and medical device development. This application guide walks through the bone-simulation material options for stereolithography (SLA) 3D printing and the entire in-house manufacturing process for bone-like anatomical models intended for cutting and drilling.

Large-Format Printing at Point-of-Care

"We’ve pushed Form 4BL to its limits, and it hasn’t failed a single print. Its reliability under pressure has been outstanding."

Brian Albers, 3D Printing Engineer, St. Louis Children’s Hospital

The large build volume and blazing speed of Form 4BL enables Albers to not only print large, rush jobs, but multiple smaller models. With Form 4BL, Albers can see the potential to batch parts so he can print exclusively during the day, with no need to queue up prints to run overnight.

Buy Form 4BL now or watch our webinar learn more it. To see how Form 4BL can help you reach your business goals, contact sales.