3D scanning has an important place at multiple stages of digital fabrication workflows. Engineers, product designers, researchers, dentists, and medical professionals use 3D scanners as a faster and more efficient way to start constructing digital models, whether by incorporating existing designs via reverse engineering, digitizing hand-sculpted clay designs, or referencing the exact shape of the human body.

After fabrication, 3D scanning can support quality control and help to verify the accuracy of a 3D printed part, or, after the part has been used, a scanner can reveal how it’s performed — a scan of a deformed part can show you where to reinforce the design in the next revision.

With such a wide range of product options from handheld 3D scanners to desktop 3D scanners, it can be difficult to choose the best 3D scanning system that’s right for your application and budget. In this guide, we explore the most important factors to consider when purchasing a 3D scanner and showcase some of the key applications that are empowered by combining 3D scanning and 3D printing.

Types of 3D Scanning Technologies

There are multiple scanning technologies currently on the market, all offering their own advantages and weaknesses, from handheld scanners to desktop 3D scanners. The best 3D scanning system for you will depend on your application and budget.

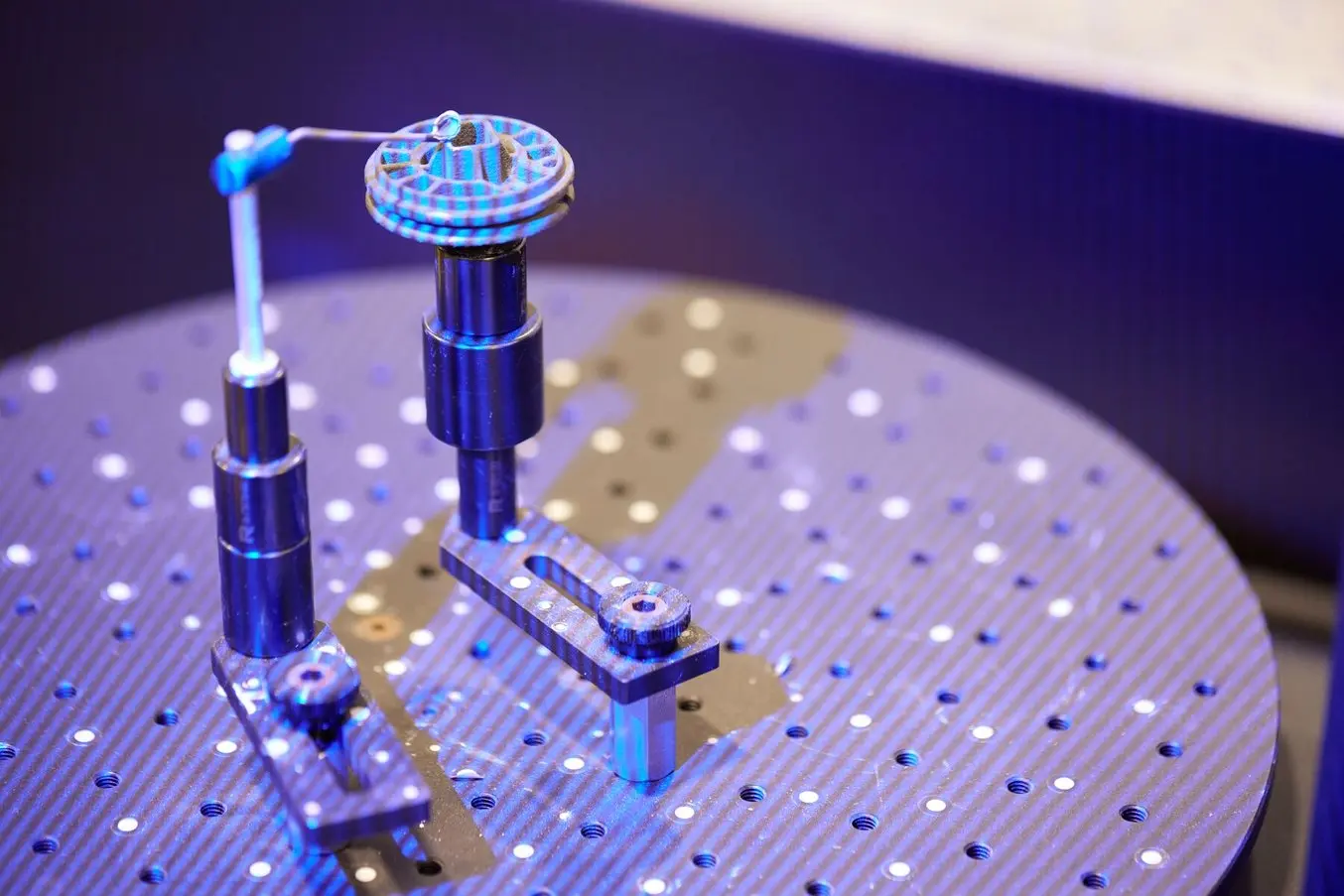

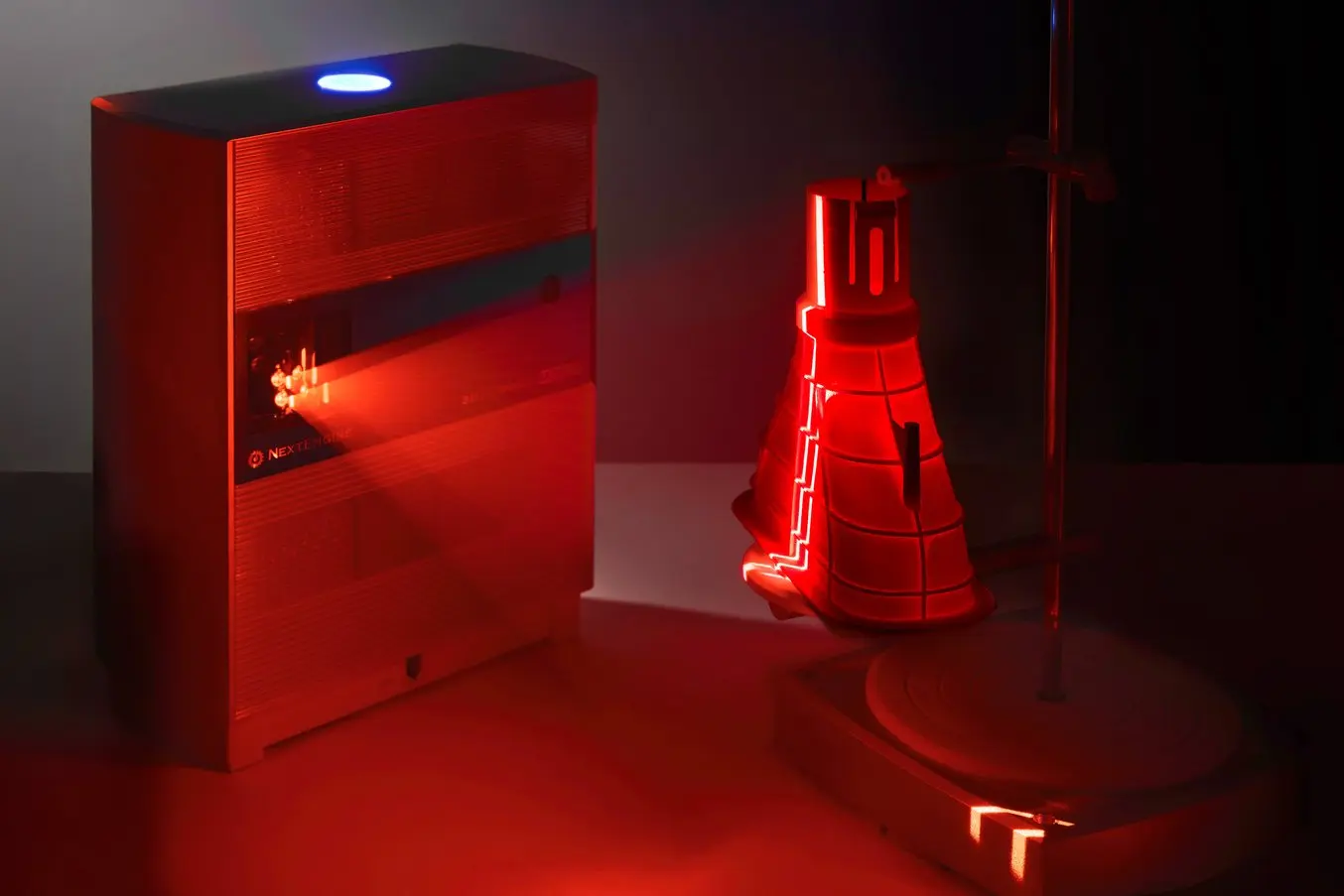

Laser triangulation uses light projected onto the object to take up to millions of measurements (dots) per second. The light reflected from the dots back into the scanner’s sensor to help it capture the geometry of the object. These types of scanners are often the most accurate, and are great for highly detailed parts that have opaque surfaces.

Laser triangulation scanners do have limitations. For example, this technology is not used in most portable scanners because the laser dots need to project from a stable source, and the source has to be kept a close distance from the scanned object. Laser triangulation scanners don’t always work on transparent or shiny surfaces either. Typically, they require reflective markers to be applied onto the object, which need to be removed after use and can be an obstacle depending on the object being scanned.

Finally, the laser dots can be harmful to human eyes, so it is important to use extra safety precautions when scanning body parts with a laser triangulation system, or to check with your scanner manufacturer to make sure the device is eye-safe.

Structured light scanners (also known as white light scanners or blue light scanners) generally use a projector with two cameras at angles on either side. A pattern of light is projected and laid over the component being scanned, the cameras capture the ways in which the object deforms the light pattern, and then multiple images are integrated into a single 3D snapshot.

Structured light scanners are available in both stationary and portable format the technology is the most commonly used process for handheld 3D scanners. Structured light scanners are far more common in medical applications, since it is safe to use on both humans and animals and excels when an object is not perfectly still. Traditional white light scanners have been slower to scan than laser triangulation scanners.

Structured light scanning is the most commonly used technology in handheld 3D scanners.

Depth-sensing cameras project a field of dots in infrared (IR) to sample a 3D scene. Depth-sensing cameras are simple to use and are the least expensive scanning option, but their accuracy and resolution are low, and fine details are sometimes lost. Large objects may be captured with depth-sensing cameras, but accuracy declines with increased distance from the subject and at steeper angles to the camera.

Photogrammetry means the act of deriving precise measurements from photographs. It involves taking a set of overlapping photos of an object, building, person, or environment, and converting them into a 3D model using a number of computer algorithms. This is the most commonly used method when creating a 3D scan with a smartphone, since modern phone cameras are capable of capturing and combining a large number of photos. Photogrammetry should be considered the least expensive and least accurate method for creating 3D prints, and is not suitable for serious business applications.

LiDAR (light detection and ranging) sensors can be found on some higher-end smartphones and tablets, such as the latest versions of the iPhone Pro and the iPad Pro. This has made the iPhone and iPad viable scanners for those with only occasional scanning needs, offering performance a step above devices that only have access to photogrammetry. Applications that generate 3D mesh files via your smartphone’s or tablet's camera should be seen as the floor for entry-level scanning; users should expect additional work in their CAD software to remove gaps in meshes and improve the 3D model for applications like sending it to a professional 3D printer. Smartphones use fewer light points when scanning objects, resulting in less detail than a true, stand-alone scanner. iPhones are good substitutes for scanners if you have significant CAD design ability or need to transfer basic models into a digital space.

How 3D Scanning Supports the Modern Product Development Process

Watch this webinar with Peel 3D to explore how to integrate 3D scanners into your 3D printing workflow to elevate your product development process.

How To Choose the Best 3D Scanner To Use With Your 3D Printer

3D Scanner Accuracy vs. Price

Scan accuracy varies considerably between scanner technologies, and higher accuracy generally comes at a higher cost. The required tolerances of your final part can be a helpful guide for determining your accuracy requirements for a 3D scanner.

| High Price, Highest Accuracy ($15,000 and more) | Higher Price and Accuracy ($10,000 and under) | More Affordable (under $2,000) | Low Price, Low Accuracy |

|---|---|---|---|

| Hexagon Atlascan Max Zeiss T-Scan Hawk 2 Shining 3D EinScan Libre Creaform HandyScan Silver Series | Shining 3D EinScan SP V2 Peel 3D Peel 3 Shining 3D EinScan HX2 | Revopoint Miraco Plus Revopoint MetroX Matter and Form Three Creality Raptor Pro | iPhone Pro & iPad Pro Revopoint Inspire Shining 3D Einstar Structure Sensor 3 |

Laser and structured light scanners are a good fit for professional applications and alongside high-resolution 3D printers. Low price scanners have an accuracy of up to 0.1 mm to 1 mm, while higher priced scanners have an accuracy up to 0.02 mm. Diferent scanners wil also have a different working distance, affecting how you can use them. Formlabs stereolithography (SLA) resin 3D printers (such as Form 4 Series 3D printers) produce parts at a similar accuracy of many desktop 3D scanners.

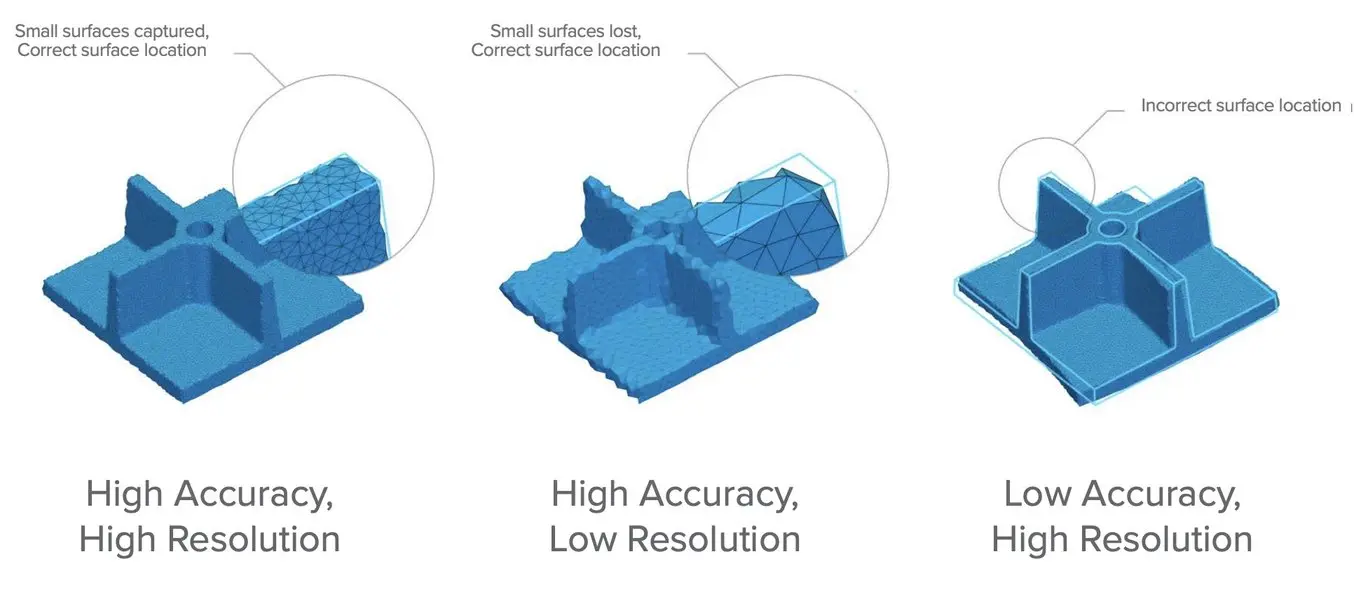

Besides the accuracy between measured points and their actual location, scanners also vary in terms of resolution, which is the distance between captured points at a given scan distance. This means that details on the scanned object that are smaller than the scanner’s resolution won’t be captured. For example, a highly accurate 3D scanner with a lower resolution might detect the general shape of jewelry on a statue, but not clearly show individual details on a ring or necklace. Depending on your project requirements, this may or may not be a dealbreaker.

An easy way to remember these metrics is: accuracy is the measurement error between the part and digital value. Resolution refers to the density of measurements.

Accuracy can mean slightly different things depending on the manufacturer and 3D scanning technology. For example, the accuracy of handheld scanners depends on the distance to the subject and the quality of scan reconstruction, while desktop scanners have consistent accuracy within the constrained scan volume. If you are considering buying a 3D scanner for precise measurement, make sure to compare like to like.

In general, structured light scanning provides the best resolution and accuracy when compared to laser scanning. For some artistic use-cases for 3D scanning you may need a lot of detail, while overall accuracy is less important especially if you don’t require your part to fit precisely with other parts in an assembly. In these cases, photogrammetry is an excellent low-cost option to explore.

Both depth-sensing cameras and photogrammetry are a good solution for scanning large objects in order to create 3D printed scale models and also offer enough accuracy for capturing the shape of the human body.

Several entry-level laser scanners are available using technology similar to higher-end systems. These scanners are a great way to start replicating small objects at 1:1 scale. As one would expect, the accuracy of entry-level laser 3D scanners is lower than a high-end scanner, but they can easily provide enough detail to replicate small decorative objects and figures where accuracy is not critical.

If you only have occasional 3D scanning needs, digitization services can scan your object, as well as perform CAD translation and accuracy inspection.

3D Scanner Volume and Coverage

The area that a 3D scanner can capture varies significantly between scanners. Find a scanner that fits your size and resolution requirements without too much overhead, as cost typically increases with scan volume.

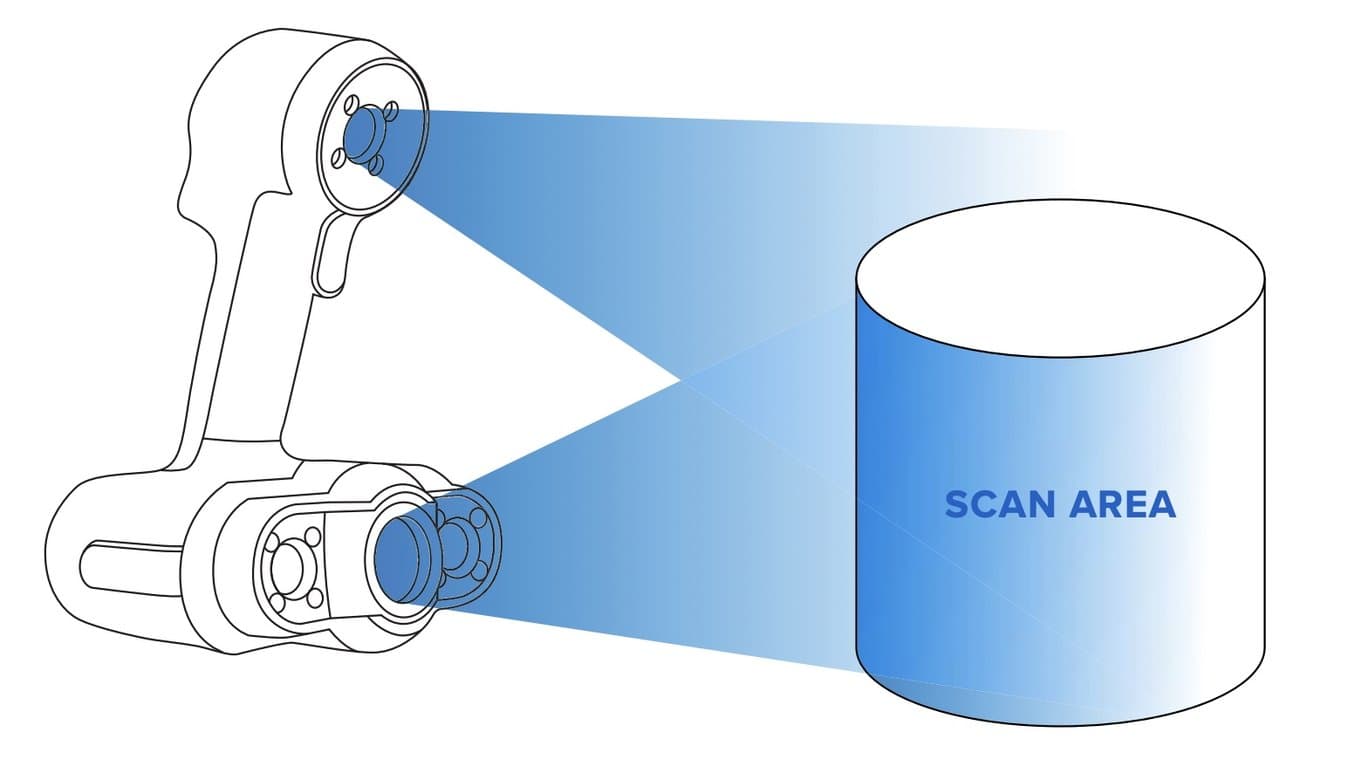

Handheld scanners can be manually moved around the object and have fewer size constraints than desktop models. Most inexpensive handheld scanners can capture objects from the size of a basketball to an entire room. High-end handheld scanners have an even wider range, and fill the niche for all objects that require precise measurements, but cannot fit in a desktop scanner. Handheld scanners are also able to capture objects nearly instantaneously, which makes them well-suited for taking human measurements (where the subject is not perfectly still) for ergonomics and medical applications.

If the area of the model can’t be seen by the scanner, it will cause a gap in the model. You can automatically repair small missing sections with most scan software programs to create a 3D printable model. However, repaired holes are rarely accurate to the original object. For parts that demand close to perfect accuracy, auto-repair of gaps or holes will not be sufficient. Read our MeshMixer tutorial for advanced tips to edit and repair 3D files for 3D printing.

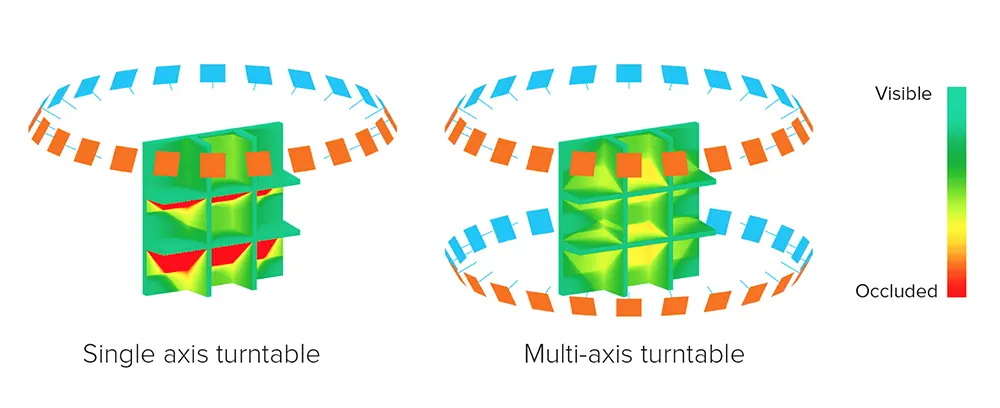

Many scanners use turntables to increase what the scanner can see. The sophistication of a scanner’s turntable affects how easily and completely the object is captured: some scanners have the ability to move the object around multiple axes, imaging the object from more angles. This feature is important when reverse engineering plastic parts with deep recesses and ribs, which are impossible to capture from a single angle.

Scanners may rotate the object to capture occluded areas. Red regions are occluded and will be missing in the scan. Areas with deep relief are difficult for a single axis turntable to fully capture due to occlusion.

Cost concerns are straightforward; how much you are willing to spend on a scanner will reflect your business’s budget and how often the scanner is going to be used. Higher cost scanners will be able to capture small objects and create highly-detailed meshes that don’t require significant touch-ups in CAD software. Handheld scanners are also often on the higher end of the price range, due to their portable nature. The low-cost scanning market offers a wide range of options, but you have to know what to look for.

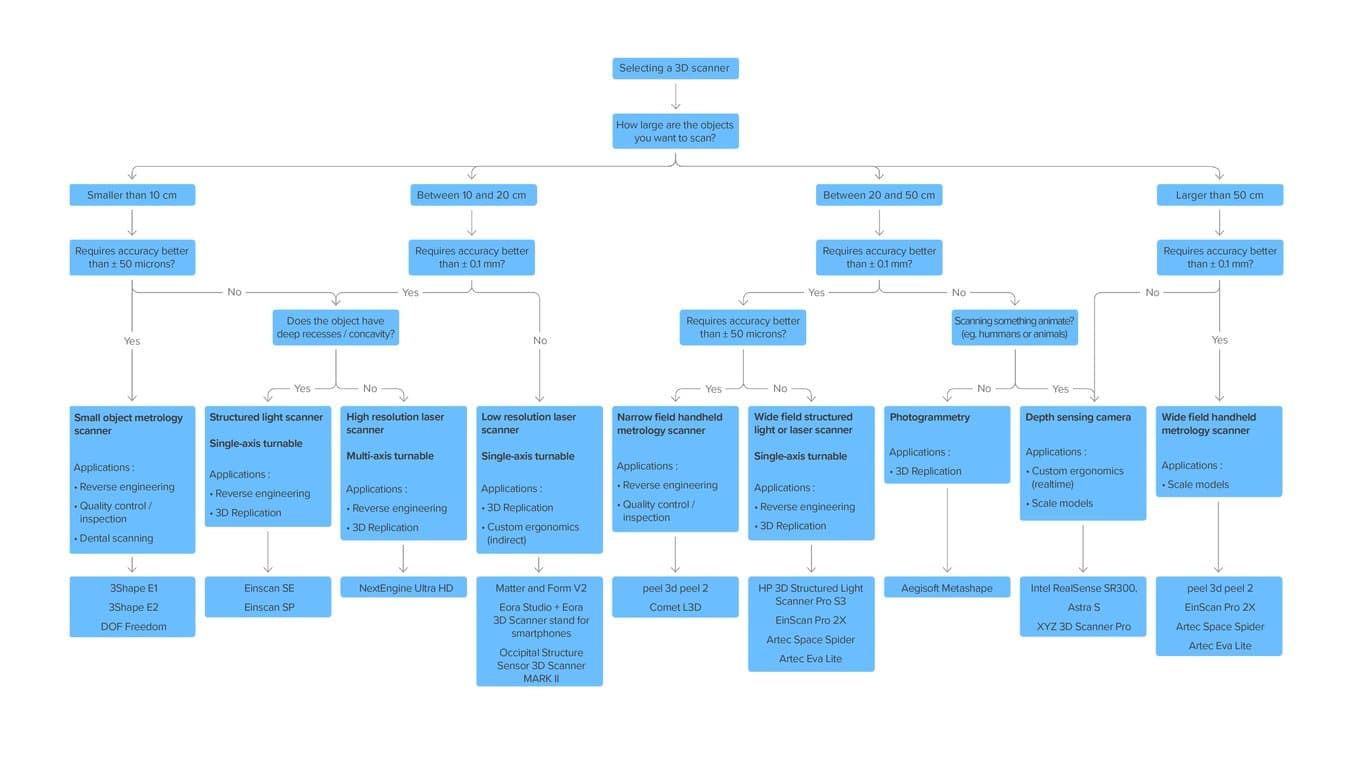

Flowchart: Choosing the Best 3D Scanner for Your Application

Use this flowchart to determine what scanner you need based on accuracy, scan volume, and budget.

Download the high-resolution version of this infographic here.

How Does 3D Scanning Complement 3D Printing?

A 3D scanner expands the capabilities of a 3D printer, allowing you to replicate the shape of almost any object. Together, the two technologies create a powerful, digital workflow that can simplify and sophisticate processes in a range of industries.

The output from a 3D scanner is a mesh of triangles representing the surface of an object at a real-world scale. In some cases, the scan can be used directly to replicate objects without any CAD work. A hybrid workflow can also be powerful, where solid CAD models are combined with scanned 3D models. For example, customized ergonomics capture a physical imprint of a part of the human body, and integrate them with a mechanical design.

A variety of powerful workflows are enabled by combining a 3D printer and a 3D scanner:

- Reverse engineering to create replacement parts, products with custom ergonomics, and more.

- Replication and restoration of parts, especially in art and jewelry.

- Dental and medical applications for the creation of patient-specific devices. Once a patient's anatomy has been scanned, a custom medical device, such as a prosthetic, can be 3D printed for the patient.

- Consumer audio for creating custom earphones.

- Metrology to validate and measure the accuracy of manufactured objects and provide a clear picture of how a material performs for demanding applications.

At Brose, an automative supplier, exisiting components are 3D scanned and altered before being manufactured via 3D printing.

Intraoral scanners are becoming the standard and replacing manual impressions in dental and orthodontic practices like Alvetro Orthodontics.

Orthopedic specialist medical providers like Kriwat GmbH use 3D scanning to capture foot impressions for producing custom insoles.

At Romans Ferrari, a pediatric rehabilitation center, 3D scanning and 3D printing are used to create custom compressive masks for treating facial burns.

3D Scan to 3D Print: Rapid Reverse Engineering for Machine Restoration, Assembly Jigs, and Aftermarket Products

Watch this webinar for a detailed look at how to start using 3D scanning to improve part design and production when paired with reverse engineering CAD and 3D printing.

Talk to Our Sales Team

Whether you need to prototype at speed, or are producing end-use parts, we’re here to help. The Formlabs Sales team is composed of dedicated specialists who know exactly how to support you and your company's needs.

Testing 3D Printing Accuracy: Metrology and High-Accuracy 3D Scanning

Applied metrology is the measurement of part dimensions, and is essential to all manufacturing processes, including 3D printing. One way Formlabs uses 3D scanning during product development is to measure and validate the accuracy of new SLA materials. 3D scanning is the most versatile metrology tool for 3D printed parts, which tend to have more complex surfaces than could be easily measured with a micrometre, or even a CMM (contact measuring machine).

Metrology-grade scanners and scan software allow you to measure accuracy by comparing the scan output to the source model. The models are aligned based on selected reference points and the software performs a deviation analysis, identifying areas where the printed surface differs from the source file.

Deviation analysis paints a statistical picture of part accuracy. However, accuracy is not always perfectly consistent across a 3D printed part. For instance, supported surfaces are less accurate than top surfaces, and post-curing shrinkage has a greater effect on a part across large spans.

Building a Digital Workflow With 3D Scanning and 3D Printing

3D scanners and 3D printers are essential parts of digital workflows across industries, empowering a variety of workflows in engineering, product design, and more.

Learn more about bringing your designs to life with 3D printing; explore stereolithography (SLA) and selective laser sintering (SLS) 3D printing technologies or request a free sample part to evaluate Formlabs materials for yourself.