Form 4 unlocks the ability to print new resins, including the new Fast Model Resin, Formlabs’ fastest resin. With print speeds of up to 100 mm per hour at a 200 μm layer height, Fast Model Resin can accelerate the iterative speed of a design team or increase the volume of production, for the printing of large prototypes in less than two hours.

With improved strength, stiffness, and impact strength, Fast Model Resin improves efficiency in multiple applications, such as functional prototyping or medium-duty jigs and fixtures. With new, reduced resin pricing, these applications make even more sense for the bottom line; affordable material and blazing speeds makes cost per part lower than ever.

Formlabs formulates materials in tandem with software and hardware, leveraging our in-house materials expertise to develop industry-leading materials optimized for printing on our ecosystems. Fast Model Resin joins our library of over 45+ high performance materials that make it possible for anyone to bring their ideas to life.

Fast Model Resin

Fast Model Resin is Formlabs’ fastest 3D printing resin, capable of printing at speeds up to 100 mm per hour. Print dental models in minutes or large prototypes in less than two hours.

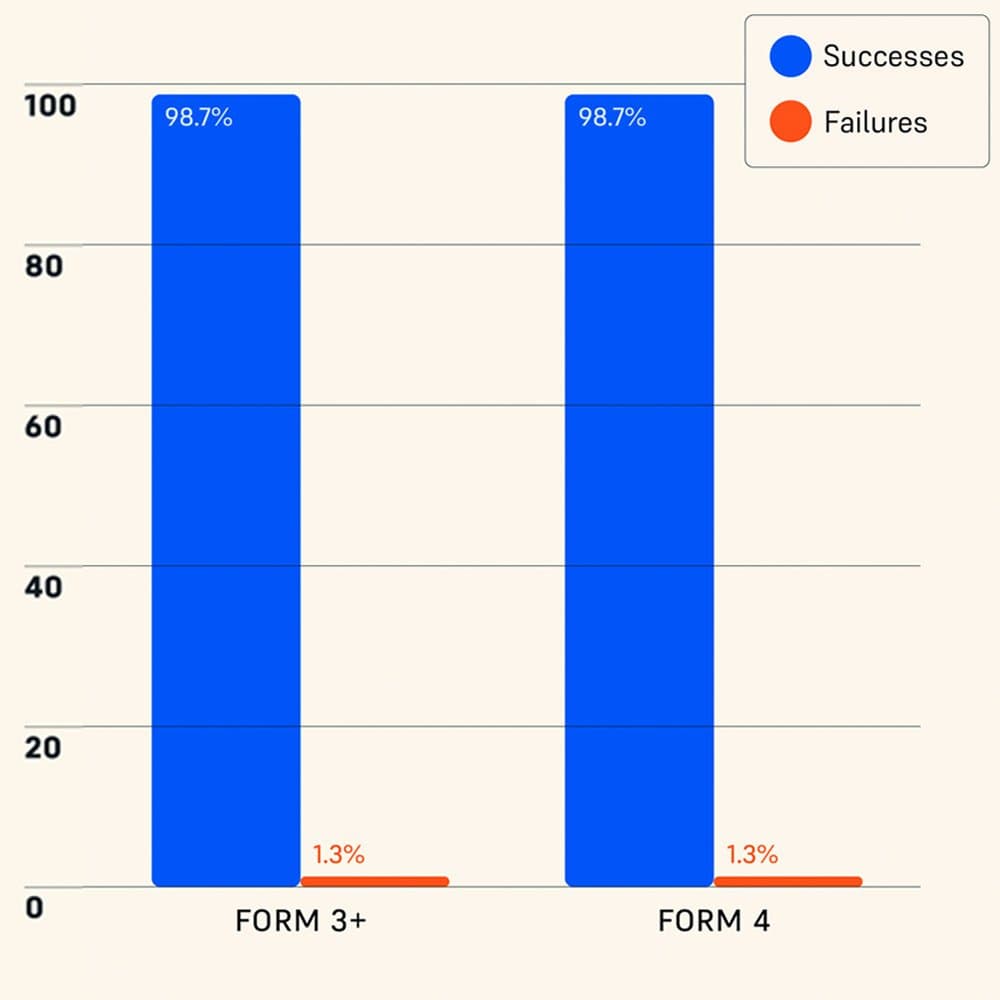

Independently Tested Reliability of Form 4 and Other Resin 3D Printers

Formlabs Form 4 was measured to have a 98.7% print success rate by an independent global leader in product testing. Read a complete description of the test methodology and see the results in our white paper.

Fast Model Resin vs. Draft Resin

Fast Model Resin (on the left) compared to Draft Resin V2 (on the right). Fast Model Resin is more opaque and matte for a consistent color and surface.

Fast Model Resin is the next generation of Draft Resin, formulated to leverage the advancements of the Form 4 ecosystem. Form 4's Low Force DisplayTM (LFD) Print Engine makes it possible to print most resins faster. By formulating Fast Model Resin specifically around the new LFD Print Engine and hardware, the materials development team was able to extract even more performance in terms of speed, mechanical properties, and aesthetics. By creating resins specifically for the Formlabs ecosystem, we’re able to optimize the performance of the material from the start, rather than trying the imperfect art of tuning printer settings for a material.

Fast Model Resin has better accuracy and part quality, increased toughness, and better aesthetics as it is more opaque and matte than Draft Resin. Additionally, it offers a more pleasant and comfortable user experience with ultra-low volatile organic compounds (VOCs).

Formlabs’ Fastest-Printing Resin

Fast Model Resin prints three times faster on Form 4 than Draft Resin on Form 3, with speeds of over 100 mm/h at the 200 μm layer height setting. This enables the printing of large prototypes in less than two hours, and dental models in minutes.

Additional speed advantages come in post-processing, with a five minute wash and five minute room temperature post-cure, for time savings in the overall workflow.

Print Speeds for the Formlabs Form 4 Tower Cap

| Time to Print | |

|---|---|

| Form 4 in Fast Model Resin | 1 h 37 min |

| Benchmark FDM | 5 h 32 min |

| Benchmark SLA | 4 h 38 min |

| Form 3+ | 4 h 29 min |

Form 4 Materials Guide

Learn more about all the high performance materials available on Form 4 and how to leverage the right material for your application.

Enhanced Mechanical Properties

Fast Model Resin is stronger and stiffer than Draft Resin, for supporting higher loads with less bending and deflection. Higher impact strength and elongation at break make it more resistant to fracture, meaning you can print functional parts at blazing fast speeds.

Parts can be used after post-curing at room temperature for five minutes, or post-cured in Form Cure for 15 minutes at 60 °C for improved strength, stiffness, and heat deflection temperature.

| Fast Model Resin | Fast Model Resin | Draft Resin | |

|---|---|---|---|

| Post cured | At room temperature for 5 min | At 60 °C for 15 min | At 60 °C for 5 min |

| Ultimate Tensile Strength | 55 MPa | 62 MPa | 52 MPa |

| Tensile Modulus | 2.5 GPa | 2.67 GPa | 2.3 GPa |

| Elongation at Break | 15% | 11% | 4% |

| Flexural Modulus | 2.60 GPa | 2.74 GPa | 2.3 GPa |

| Notched Izod | 30 J/m | 37 J/m | 26 J/m |

| Heat Deflection Temp. at 1.8 MPa | 49 °C | 61 ℃ | 57 ℃ |

| Heat Deflection Temp. at 0.45 MPa | 58 ℃ | 76 ℃ | 74 ℃ |

| Flexural Strength | 98 MPa | 106 MPa | N/A |

Product Demo: Form 4

See how Form 4 can enable new levels of productivity and innovation through its unmatched speed, accuracy, and reliability.

Prototype and Produce

Speeds of up to 100 mm per hour unlock faster prototyping for more iterations per day, or quick turnaround for functional applications like on-demand jigs and fixtures.

The introduction of 3D printing significantly cut down on prototyping times, enabling overnight turnaround times. Now, with Fast Model Resin on Form 4, it’s possible to print large prototypes in less than two hours, unlocking the ability to print multiple full-build volume prototypes in a day.

"Really impressed with the 100 μm layer print. I would run this material all day long."

Scott Tuominen, Senior Principal Design Technician, Medtronic

Unlike Draft Resin, which was intended for prototyping, the improved material properties of Fast Model Resin also enable the printing of end-use manufacturing aids, such as medium-duty jigs and fixtures. Whether a jig is a specific one-off, or sees regular use on a production line, it needs to be made quickly to ensure efficient production, but also have the robustness to survive repetitive use. The toughness, strength, and print speeds of Fast Model Resin make it an optimal resin for these applications.

Fast Model Resin can be used for some rapid tooling applications, for example, to quickly and easily 3D print thermoforming molds. These thermoforming molds can be used with both benchtop and industrial machines to efficiently and affordably produce dozens of functional prototypes, parts for pilot production, or custom and low volumes of end-use parts.

Low-Volume Rapid Thermoforming With 3D Printed Molds

This white paper provides methods and guidelines for using 3D printed thermoforming molds.

Start Printing at Blazing Speeds

At release, Fast Model Resin on Form 4 is Formlabs’ fastest printing resin, made possible by in-house materials development specifically for our best-in-class hardware. As a vertically integrated company, we can tune every aspect of development, production, and printing to achieve industry-leading performance, which wouldn’t be possible by simply making adjustments only to the resin or hardware.

The blazing fast print speeds and enhanced mechanical properties of Fast Model Resin expand what it’s possible to print, opening up opportunities for 3D printing jigs and fixtures, large functional prototypes, molds for thermoforming, and more — all at lower costs per liter of resin. Additional discounts are available for resin purchases over 30 L. Contact a sales representative to learn more.

In the time that it took you to read this, Form 4 could print over 6 mm in Fast Model Resin. Purchase Fast Model Resin for Form 4 to start printing now, or request a free sample part to evaluate the quality and aesthetics for yourself.