TPU 90A Powder is relied upon by Formlabs customers for diverse applications: from cushioning parts used by train manufacturers to grippers for robotics applications and more. The Fuse Series has made it possible to fabricate high-quality, long-lasting elastomeric parts with geometric freedom and without multi-step tooling processes.

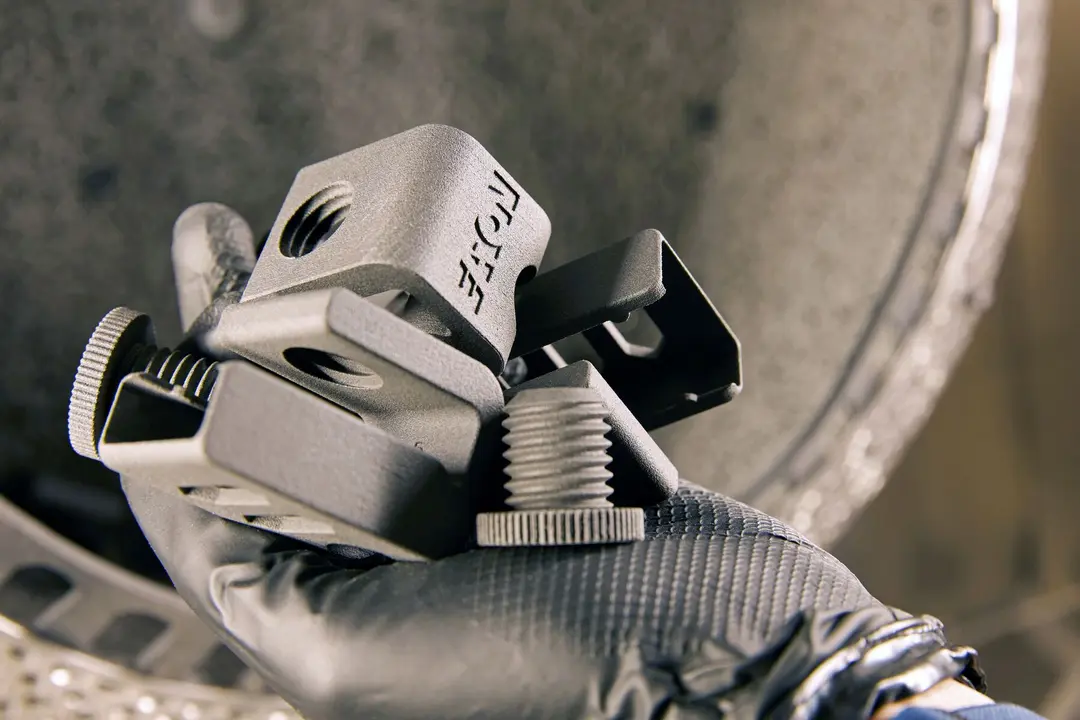

Now, Formlabs’ Print Settings Editor (PSE) is expanding the possibilities of SLS 3D printed TPU. Using Print Settings Editor in PreForm, you can modify the hardness of TPU 90A Powder to experiment with softer, more compliant parts. Without changing materials or any extra cleaning or maintenance, you can now leverage PSE to innovate with your designs and get closer to your preferred elastomeric end-use material.

Formlabs has tested different combinations of settings to create variable durometer TPU parts, and our findings are included below. However, Print Settings Editor is part of our efforts to encourage developers and innovators to try new things, and it may take some testing and tweaking on your own to achieve a part with the right durometer and surface finish for your application.

Using Print Settings Editor for Variable Durometer TPU

In order to unlock new print possibilities with variable durometer SLS TPU powder, there are two main settings to understand.

-

Fill Laser Power: PSE can control the laser’s power. Lower-powered lasers do not sinter the TPU particles together as densely, resulting in a softer part. However, if the Fill Laser Power is set too low, the part may not sinter at all, and features will not resolve.

-

Fill Hatch Spacing: PSE can control the spacing of the laser’s scanning process. A wider spacing of the laser’s scan undersinters the material, resulting in a softer part. If the Fill Hatch Spacing is too wide, it can result in visible defects on the surface and some delamination of certain positive features.

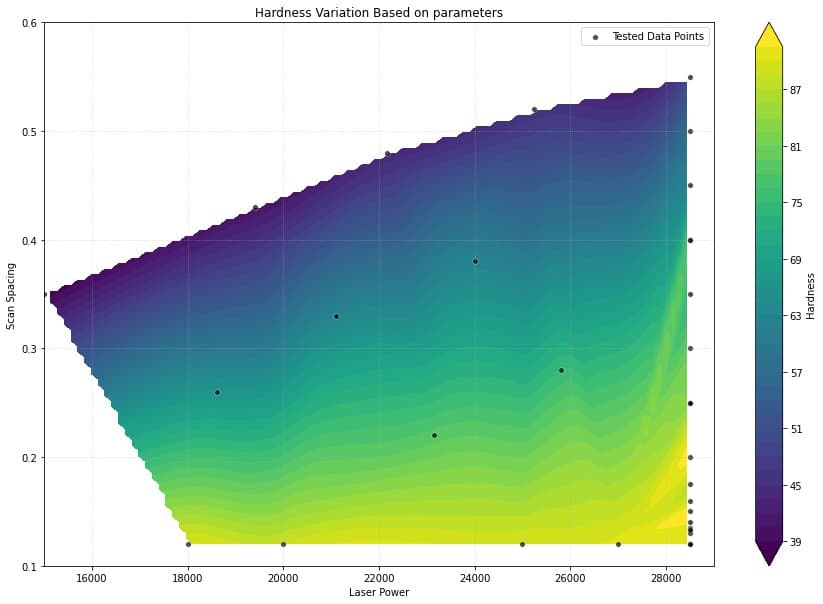

To achieve a softer durometer TPU, you can alter either Fill Laser Power, Fill Hatch Spacing, or both. The following results can be achieved through a combination of changes to these two settings.

As the graph shows, a shore hardness of 38A was achieved during testing. In general, changing Fill Hatch Spacing has a much larger effect on the hardness of the part, while Fill Laser Power amplifies the effect. For example, to sinter a part with a hardness of 60A, a good starting point would be a Fill Hatch Spacing of 0.35 mm and a Fill Laser Powder of 21,000 mW.

At the extremes of very low Fill Laser Power or wide Fill Hatch Spacing, there may be visible surface effects. Certain features may not resolve, and there may be a ‘fuzzy’ or ‘crumbly’ surface texture. Changing the thickness of a part can help mitigate the effect of changing a setting on the feature resolution; thick parts typically resolve better, even with wider Fill Hatch Spacing settings. Formlabs does not recommend printing thin parts with greater than 0.45 mm spacing.

Further instructions for using PSE to customize your powder’s shore hardness can be found in our PSE usage guide.

Testing and analysis on variable durometer settings using PSE were performed on the Fuse 1+ 30W printer, and though PSE is available for the Fuse 1 as well, the results may not match exactly those detailed above.

Effect of Settings Changes on Mechanical Properties

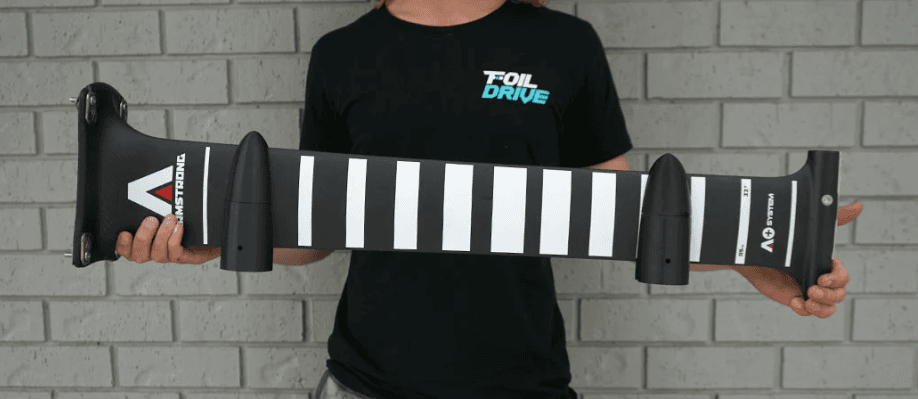

Variable durometer TPU can be helpful when prototyping cushioning components.

TPU 90A Powder already has a skin-safe certification, so softer durometers can be ideal for customizing gear.

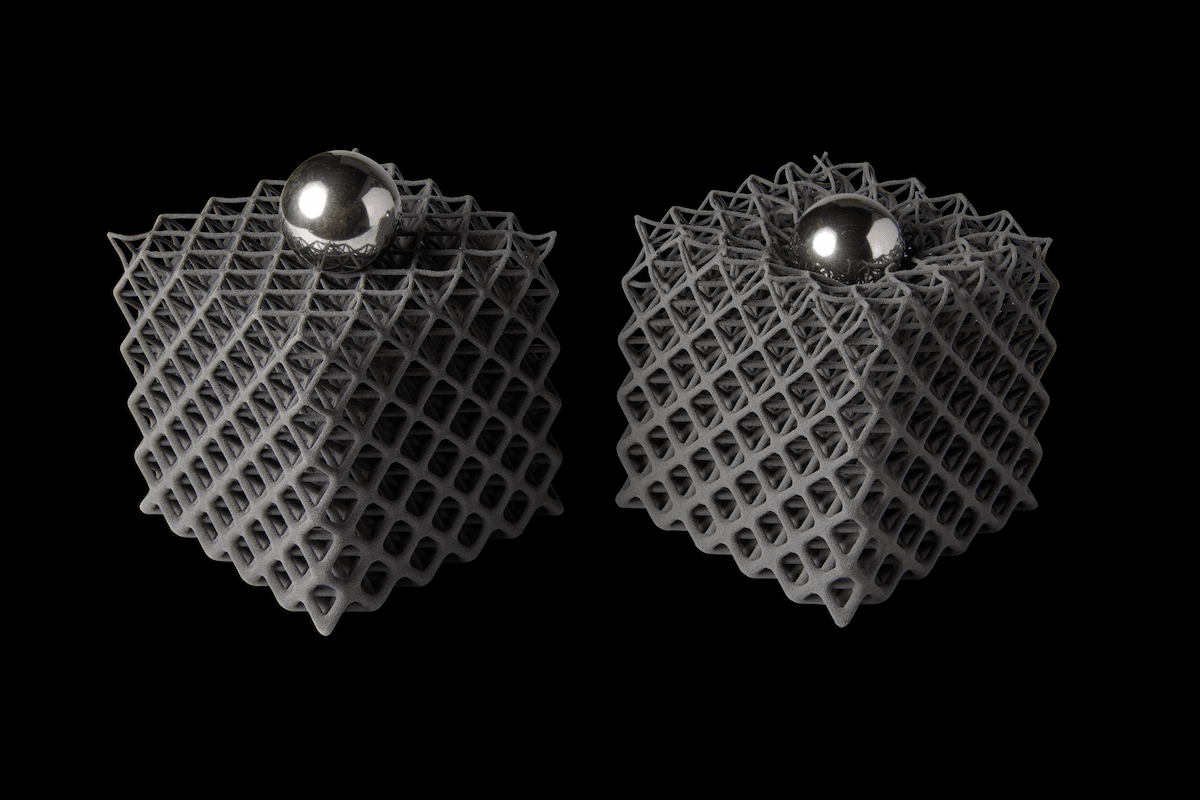

As parts become softer, their bulk density decreases — the part becomes more foam-like at a microscopic level. This impacts mechanical properties as well as watertightness. If you are planning on using the part in an application that requires a certain amount of mechanical resistance or wear, make sure to test the part fully.

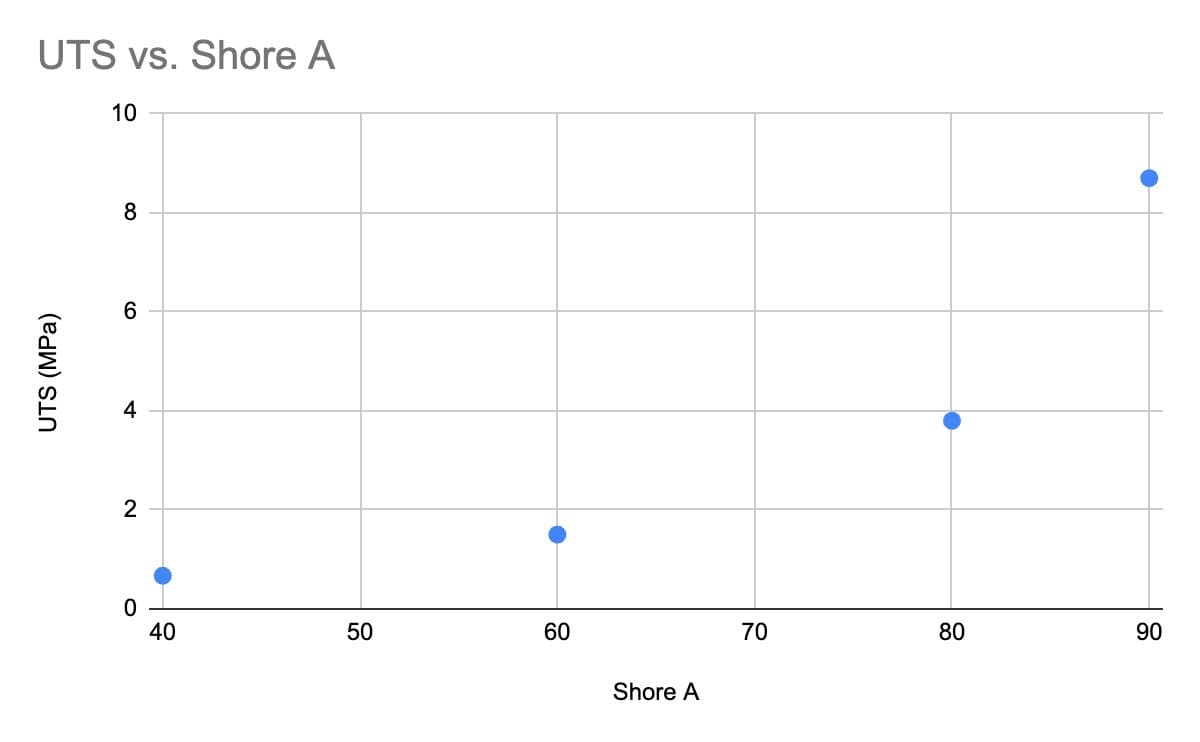

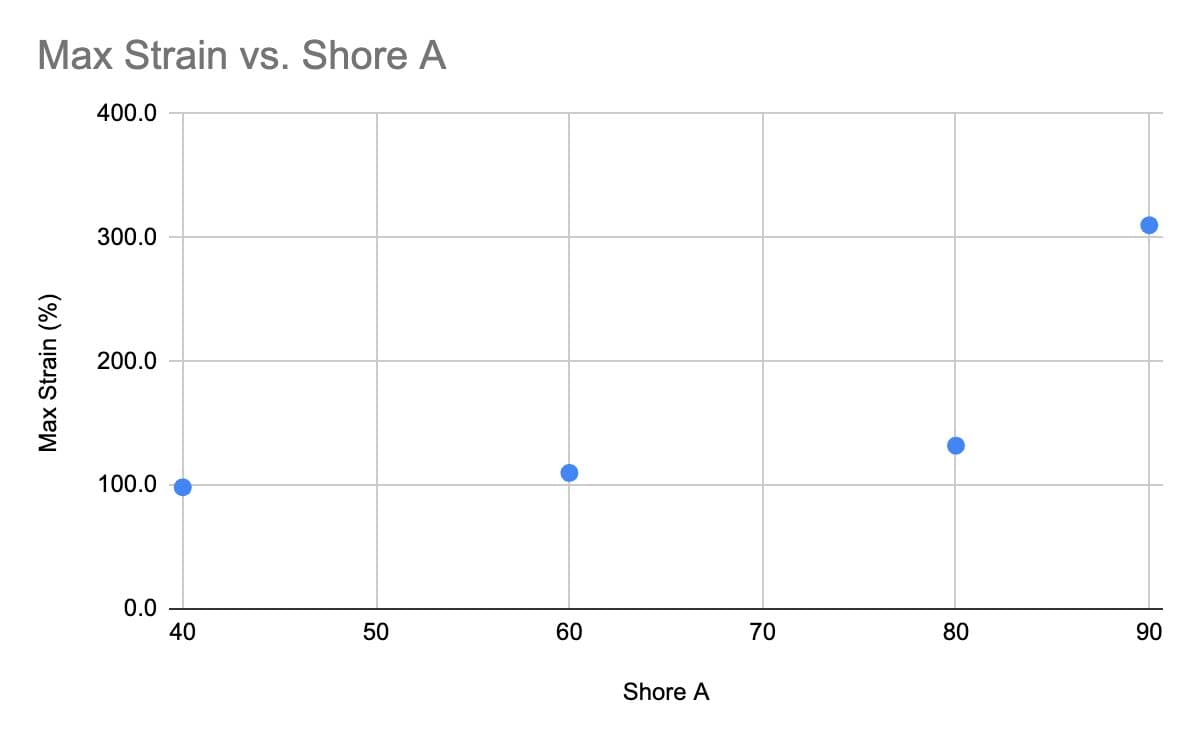

Elongation at break (EAB), ultimate tensile strength (UTS), and stiffness are particularly affected by changing Fill Laser Power and Fill Hatch Spacing.

On long strips like the tensile bars in this image, changing material properties are particularly evident. Rearmost bar (40A), middle bar (60A), and front bar (80A) all exhibit different levels of stiffness.

To quantify this effect more precisely, see the graphs below. Reducing the hardness from 90A to 80A also reduces the UTS and maximum strain of the parts by over 50%. This makes it more likely for parts to tear during depowdering, damaging fine features.

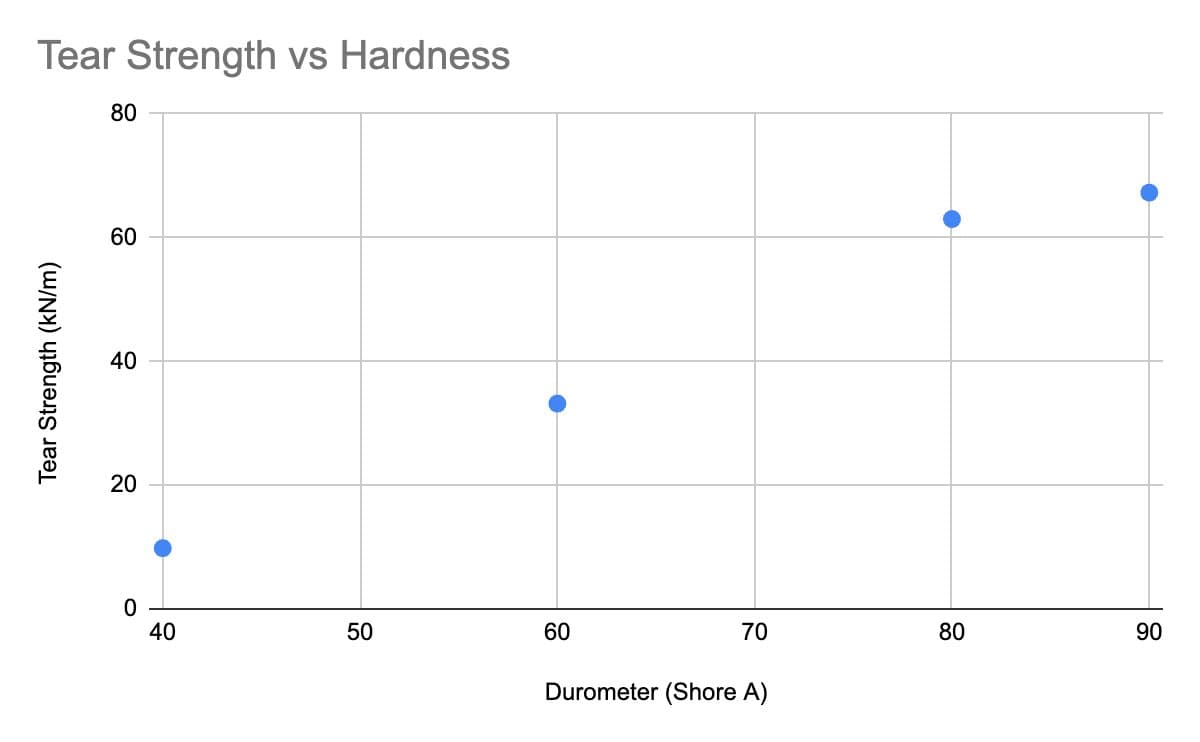

Reducing the hardness from 90A to 80A also has a significant effect on the tear strength of the parts, with the higher hardnesses coming in at closer to the nominal tear strength of 66 kN/m and the lower hardness parts rapidly decreasing in strength.

Variable Durometer TPU Powder Enables New Applications

Variable durometer TPU can be used to design gaskets and vibration-dampening parts that fit your unique assembly and application.

For consumer product testing, softer elastomeric materials like a TPU powder with a durometer of 60A can help get your design team closer to the final injection molded product.

TPU 90A Powder has enabled leading footwear designers, sports equipment manufacturers, and aerospace manufacturers, among others, to prototype a wider range of materials more accurately and earlier in their design process. Now, with variable Shore hardness possible — without changing your printer or adding extra cleaning or maintenance — entirely new material properties are possible. With the right testing protocol for your own unique settings, it’s possible to achieve softer, more elastic parts with a good surface finish.

To learn more about TPU 90A Powder, or request an SLS 3D printed TPU sample of a different durometer, contact our team. To learn more about PSE, visit our support page.

Raw Testing Data

The table below lists raw data from Formlabs testing on the effect of Fill Laser Power and Fill Hatch Spacing on Shore hardness. Reference this data when developing your own print settings.

| Fill Laser Power | Fill Hatch Spacing | Hardness |

|---|---|---|

| 15000 | 0.35 | 37.7 |

| 18000 | 0.12 | 90.1 |

| 18625 | 0.26 | 66.3 |

| 19400 | 0.43 | 40.4 |

| 20000 | 0.12 | 88.5 |

| 21100 | 0.33 | 62.7 |

| 22160 | 0.48 | 43.6 |

| 23150 | 0.22 | 78.6 |

| 24000 | 0.38 | 62.3 |

| 25000 | 0.12 | 89.8 |

| 25250 | 0.52 | 45.3 |

| 25800 | 0.28 | 74.9 |

| 27000 | 0.12 | 90.6 |

| 28500 | 0.12 | 89.8 |

| 28500 | 0.12 | 91.4 |

| 28500 | 0.13 | 90.7 |

| 28500 | 0.1325 | 89.5 |