Form X is a line of products to get innovative manufacturing processes into the hands of experts that want to use powerful manufacturing technologies with the help of 3D printing.

Form X products are not as “plug and play” as some of our other products, but they push the boundaries of what’s possible with 3D printing.

Pushing the Boundaries of Materials and Manufacturing

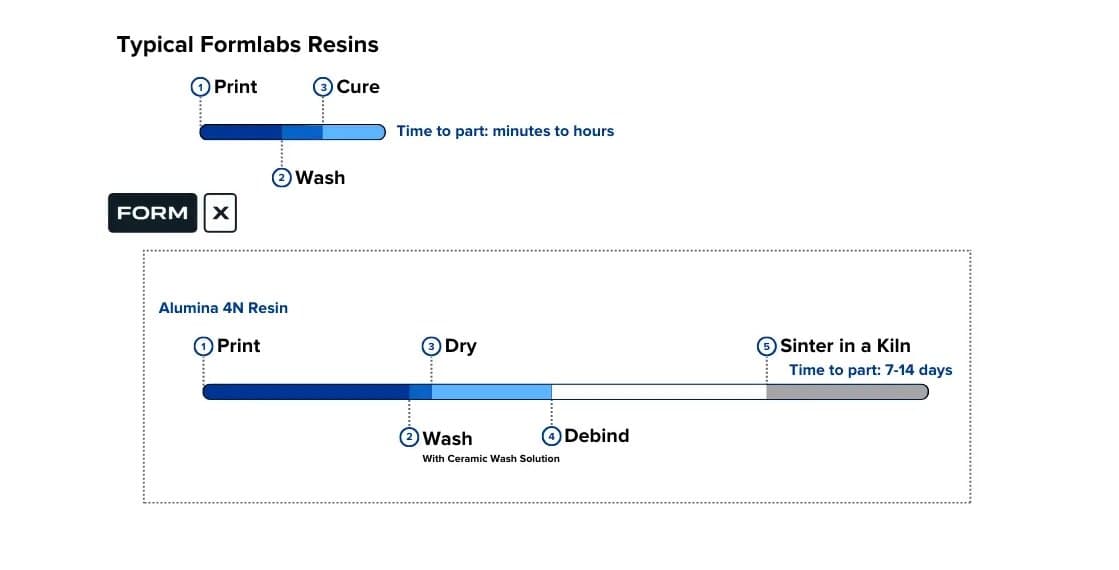

Materials within the Form X family feature novel chemistries and multi-step workflows to transcend the existing limitations of 3D printing materials to create final parts in extremely robust polymers — or even sintered technical ceramics.

Form X materials are not as "plug and play" as some of our other products and require equipment not provided by Formlabs. These products are intended for experts and are not suitable for users that either do not have experience or are not willing to invest significant time and effort learning the material workflow.

Unparalleled Properties

Mechanical performance suited for demanding applications.

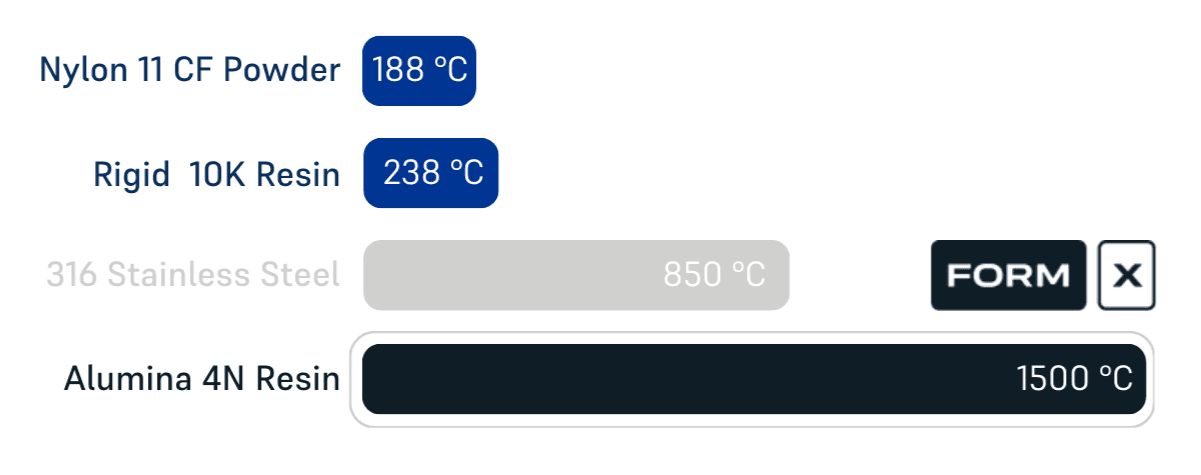

Maximum Temperature

Learn More About Form X Material Workflows

Ceramic Workflow

Alumina 4N Resin, like other ceramics, shrinks when fired. The material also requires a special wash solution provided by Formlabs and the dried green parts a 4.5-day burnout and 2-day sintering cycle in an oven that is capable of at least 1500 °C.