Black Resin V5

General Purpose

SLA

Stiff & Strong

61 MPa

2,700 MPa

10 %

Select Printer Series and Resin Volume

| Bulk order quantity (L) | Discount % |

|---|---|

| 1 | 0% |

| 30 | 15% |

| 60 | 20% |

| 120 | 25% |

| 240 | 30% |

| 1,000 | 35% |

| 2,000 | 40% |

| 3,000 | 45% |

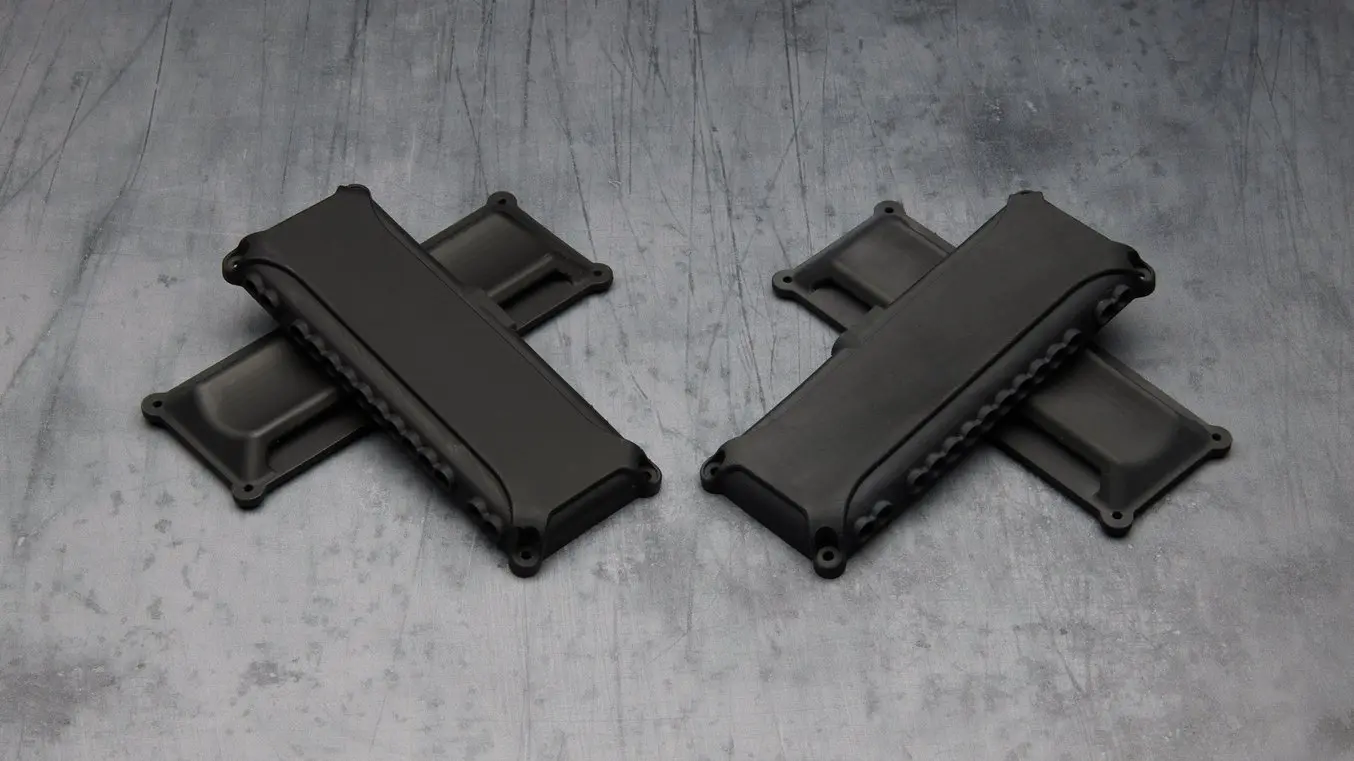

Create parts that are stiff and strong with a surface finish that rivals injection molding. Black Resin has a rich, matte shade that captures fine features accurately.

Black Resin V5 is a new material formulation that leverages the Form 4 Series to print three times faster than the previous version, while offering improved mechanical properties.

Black Resin V5 has been added to your cart.

Why Choose Black Resin?

Black Resin V5 is a versatile 3D printing resin formulated to leverage the new Form 4 ecosystem, offering an optimal balance of fast print speed, high accuracy, presentation-ready appearance, strong mechanical properties, and an easy, reliable workflow.

High Dimensional Accuracy

Achieve precise tolerances and fine features.

Superior Aesthetics

Rival the appearance of injection-molded parts with rich, matte color and crisp fine feature performance.

Versatile Mechanical Properties

Create parts with the optimal balance of strength, toughness, and stiffness for a wide range of applications.

Extremely Low-Odor Printing

Print with ultra-low volatile organic compounds (VOCs) for a pleasant and comfortable user experience.

Applications for Black Resin

Create dimensionally accurate parts that are stiff and strong with unmatched print reliability.

Consider Black Resin for:

What’s New With Black Resin V5?

Compared to Black Resin V4, Black Resin V5 is:

Mechanical Properties

Post-cured at room temperature for 5 minutes

Ultimate Tensile Strength

Tensile Modulus

Elongation at Break

Flexural Strength

Flexural Modulus

Notched Izod

Heat Deflection Temperature at 0.45 MPa

Post-cured at 60 °C for 15 minutes

Ultimate Tensile Strength

Tensile Modulus

Elongation at Break

Flexural Strength

Flexural Modulus

Notched Izod

Heat Deflection Temperature at 0.45 MPa

Post-Processing

Washing

The foundational step in any SLA post-processing workflow is to remove any excess resin on the surface of the parts through an alcohol or ether wash.

Curing

Post-curing for General Purpose Resins is optional. However, Formlabs recommends a short post-curing to reduce surface tack and improve mechanical properties.