SLS 3D Printing for Production

Bring production in-house and reduce cost per part with a proven, scalable, and accessible SLS ecosystem. Formlabs’ Fuse Series is the #1 SLS 3D printing platform that has helped thousands of customers bring new products to the market and achieve their lowest cost per part, ever. Contact our team for a detailed analysis of your part files to find out where you can reduce costs and improve your workflow.

Reduce Cost Per Part

New bulk powder pricing makes in-house production with the Fuse Series the most affordable production method possible.

Reduce Hands-On Labor

Leverage powerful post-processing solutions like Fuse Sift and Fuse Blast for a complete, end-to-end workflow. Reduce labor time and optimize your entire design-to-production process.

Accelerate Time to Market

With in-house SLS, there’s no waiting for a machine shop, or locking in tooling too early, only to change it and add weeks to your development schedule. Get parts in consumers’ hands now, risk-free, with in-house SLS production.

Optimize Part Design for Max Efficiency

Move past the limits of traditional machining or molding - SLS 3D printing creates opportunities for maximum efficiency in part design and assembly.

Provide a Better Customer Experience

Create an agile, responsive business model that can address customer demands and service requests quickly, without dependence on a third party supplier or partner.

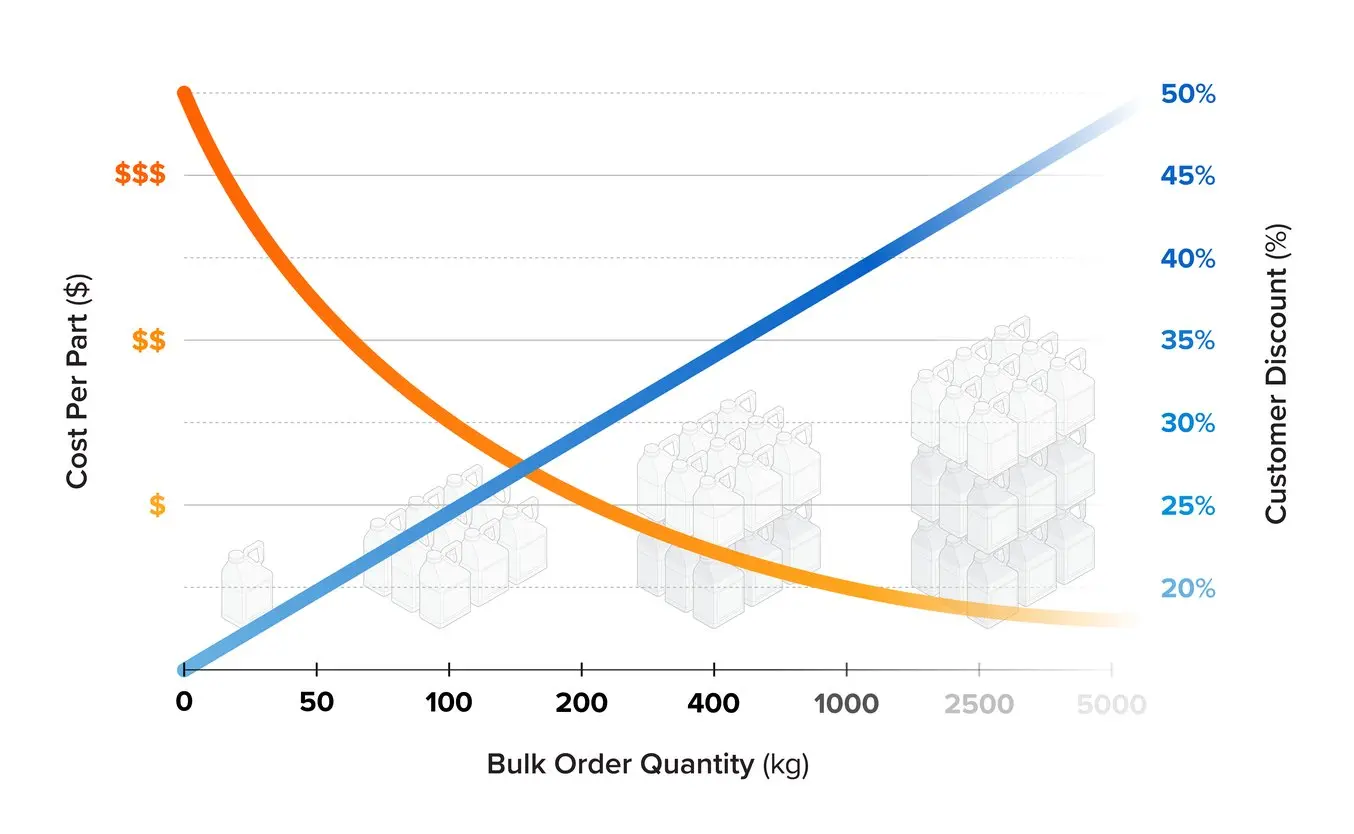

Bulk Powder Pricing for Your Lowest Cost Per Part

3D printing is now cost-effective even at higher volumes thanks to substantial volume discounts for our SLS Powders. Discounts start at 20% for customers purchasing 50 kg of powder in bulk and prices can reach as low as $45 per kilogram.

Explore End-Use Applications by Fuse Series Customers

Designer Eyewear

Comparing Options To Hit Targeted Cost Per Part

Part: Thermometer Enclosure

Production Target: 1000 parts per week

Injection Molding

Lead Time: 2 Weeks

Tooling Cost: $4,888

Material Cost Per Part: $0.59

Total Cost Per Part: $5.48

Outsourcing

Lead Time: 7 to 14 business days

Total Cost Per Part: $6.00 - $9.50

Fuse 1+ 30W

The #1 SLS 3D Printing Platform, Chosen by More Than Half the SLS Users in the World

Proven Reliability

Over 55% of SLS 3D printers sold worldwide are Formlabs Fuse Series — join a community of industrial customers leveraging scalable SLS to improve their production workflows.

Industry-Standard Materials

The Fuse Series combines revolutionary accessibility with familiar, industry-standard materials like nylon 12 & 11, TPU, and polypropylene.

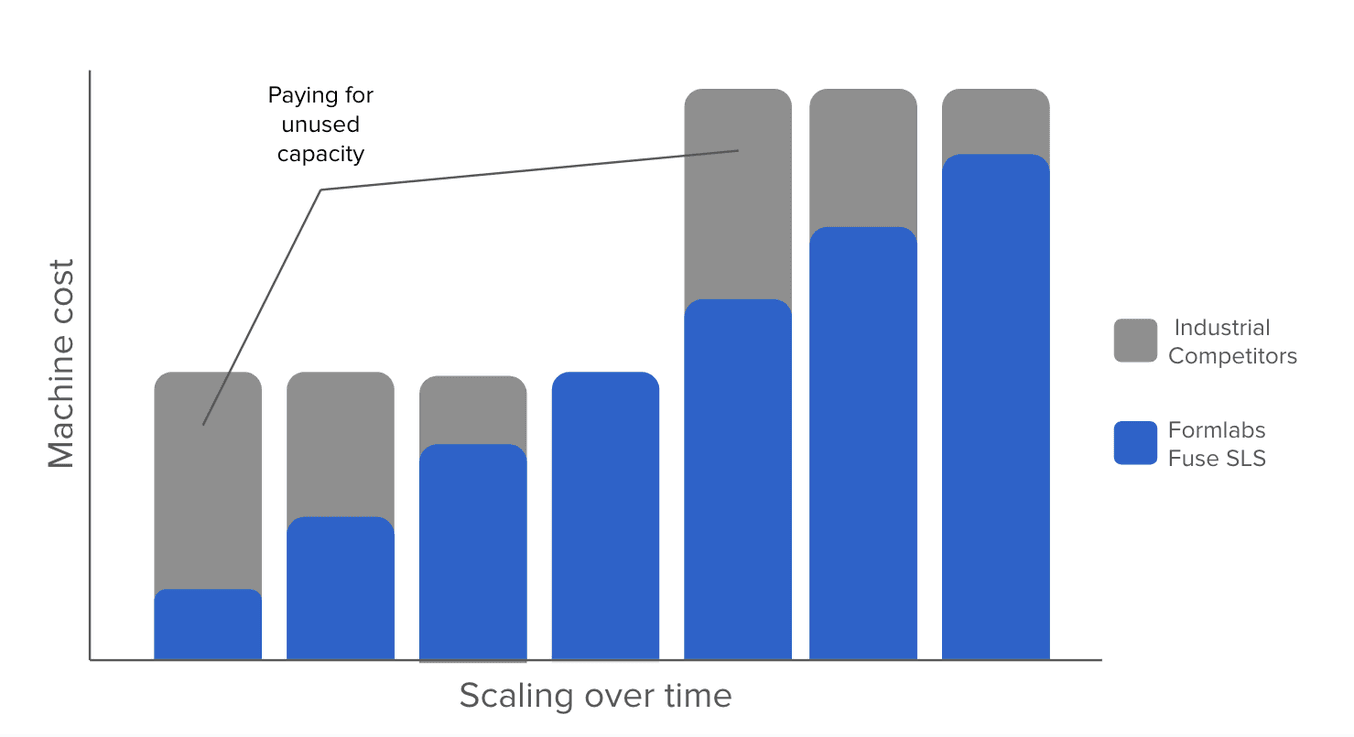

Scalable Capacity

Grow your fleet to meet demand and insulate your supply chain. Maintain continuous uptime and consistent production volumes.

Affordable Cost Per Part

New bulk powder pricing discounts make Fuse Series cost per part competitive with any additive technology.

Easily Start, Easily Scale, Easily Switch

Bring production in-house with a proven, scalable workflow. Grow your capacity as demand increases, without overspending upfront. With multiple machines, production never has to stop for maintenance or repairs, and you can pivot to new powders or products without disrupting the entire supply chain. The simplified, automated workflow is easy to learn, so oversight can be a shared responsibility, freeing up your technicians’ time for higher value tasks.

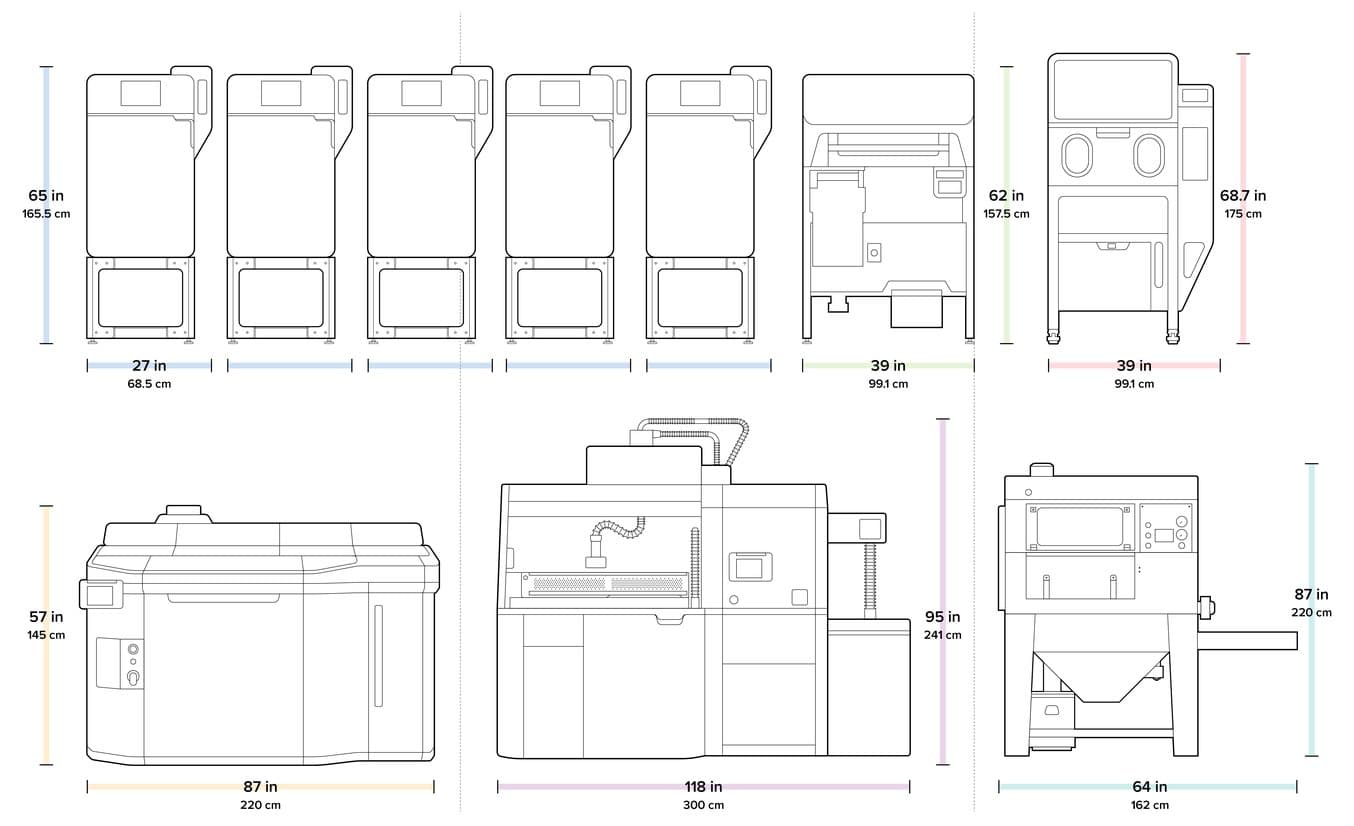

| Fuse 1+ 30W | Large Format MJF | |

| CapEx for the Initial Setup | $59,083 | $500,000+ |

| CapEx per Additional Printer | $29,000 | $350,000+ |

| Service Plan per Year | $4,500 per printer | $35,000+ |

| Power Requirements | Standard 120V (US) or 230V outlet | Dedicated 380-415V line |

| Dimensions (L x W x H) | 68 x 64 x 107 cm 27 x 25 x 42 in | 221 x 119 x 145 cm 87 x 47 x 57 in |

Curious to see how much you can save? Contact our team to run the numbers specifically for your parts and business.

A five printer Fuse 1+ 30W setup is the size of one large-format MJF setup.

Proven, Standardized Materials: Now Optimized for SLS

Formlabs is Open

Maximize your 3D printer’s potential with Formlabs Developer Platform. Unlock the possibility of printing with any 405 nm photopolymer resin or 1064 nm powder on Formlabs 3D printers, customize your print settings, or build software integrations.

Advanced Post-Processing

Fuse Blast Reduces Hands-On Labor By 80%

“Since getting the Blast, Autotiv has been able to take on more work due to the time savings the Blast provides, time savings are easily hours per day.”

Chris Haak, Operations Lead at Autotiv

Introducing Fuse Blast: Automated SLS Part Cleaning and Polishing

Guide to SLS Post-Processing Techniques: Media Blasting, Smoothing, Coating, Coloring, and More

Complete Guide to Cerakote: Ceramic Coating for SLA and SLS 3D Printed Parts

Resources

Outsourcing vs. In-House: When Does it Make Sense to Bring SLS 3D Printing In-House?

In-House Production, Simplified

Produce volumes of hundreds to thousands of parts each month with the most secure, agile manufacturing method available. End-use quality parts, with no expensive tooling or over-dependence on singular systems.

Bulk Powder Pricing for Your Lowest Cost Per Part

3D printing is now cost-effective even at higher volumes thanks to substantial volume discounts for our SLS Powders. For customers printing 1000+ kg of powder per year, discounts start at 30%, with lower prices possible after a verified cost per part analysis.