Tackle any problem with our industry-leading materials, or use Open Material Mode.

Get more done with most prints in under 2 hours.1

- 1h38minForm 4

3h37minBenchmark FDM4h11minBenchmark SLA10h47minForm 3+

3h37minBenchmark FDM4h11minBenchmark SLA10h47minForm 3+Battle Beaver Customs, Game Controller

- 2h49minForm 4

4h28minBenchmark FDM6h52minBenchmark SLA10h35minForm 3+

4h28minBenchmark FDM6h52minBenchmark SLA10h35minForm 3+Holley, LED Light Bar and Mount

- 2h1minForm 4

3h54minBenchmark FDM3h37minBenchmark SLA8h31minForm 3+

3h54minBenchmark FDM3h37minBenchmark SLA8h31minForm 3+RightHand Robotics, Robotic Finger Overmolds

- 1h37minForm 4

5h32minBenchmark FDM4h38minBenchmark SLA4h29minForm 3+

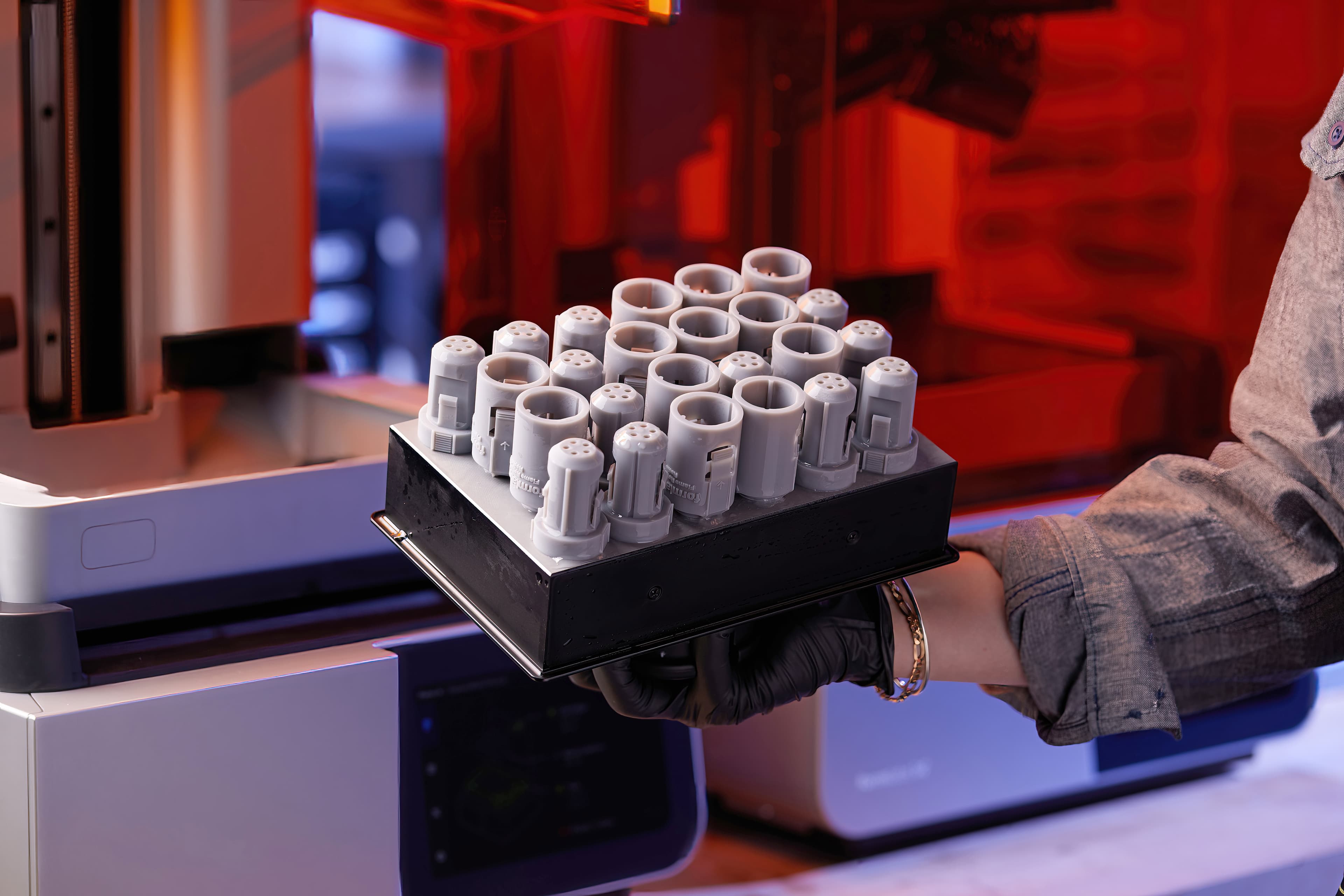

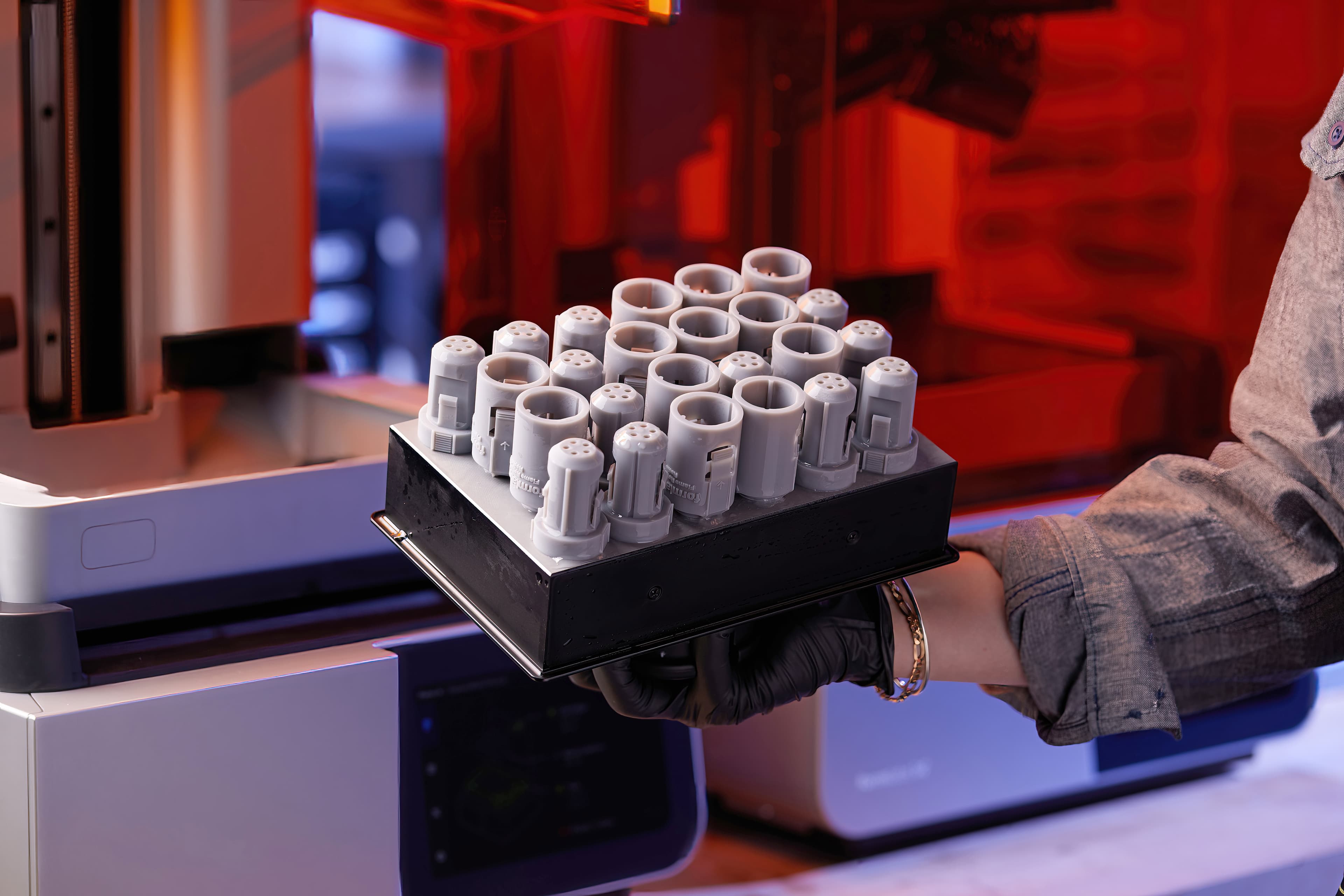

5h32minBenchmark FDM4h38minBenchmark SLA4h29minForm 3+Formlabs Form 4, Tower Cap

- 1h28minForm 4

9h12minBenchmark FDM2h16minBenchmark SLA9h43minForm 3+

9h12minBenchmark FDM2h16minBenchmark SLA9h43minForm 3+Electrical Connector

Produce stunning parts that always fit, rivaling injection molded parts.

Sharpest Details

Highly collimated light and 50 µm pixel size with pre-tuned anti-aliasing for subpixel resolution

Smoothest Surfaces

Lower peel forces, light touch supports, and 50 µm pixel size with pre-tuned anti-aliasing

Most Accurate Assemblies

±0.15% XY dimensional tolerances so assemblies always fit.

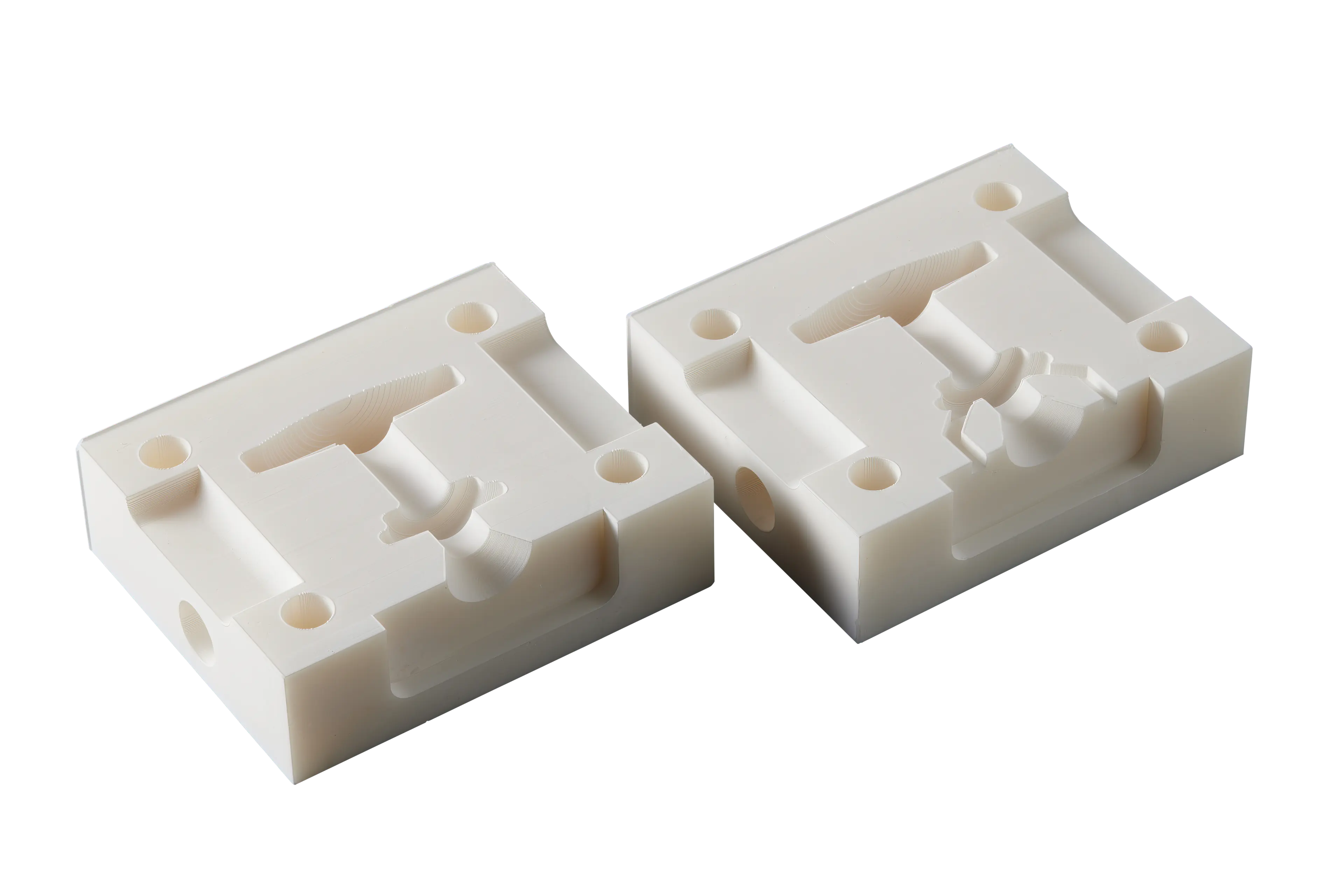

INJECTION MOLD

INJECTION MOLDSharpest Details

Highly collimated light and 50 µm pixel size with pre-tuned anti-aliasing for subpixel resolution

Smoothest Surfaces

Lower peel forces, light touch supports, and 50 µm pixel size with pre-tuned anti-aliasing

Most Accurate Assemblies

±0.15% XY dimensional tolerances so assemblies always fit.

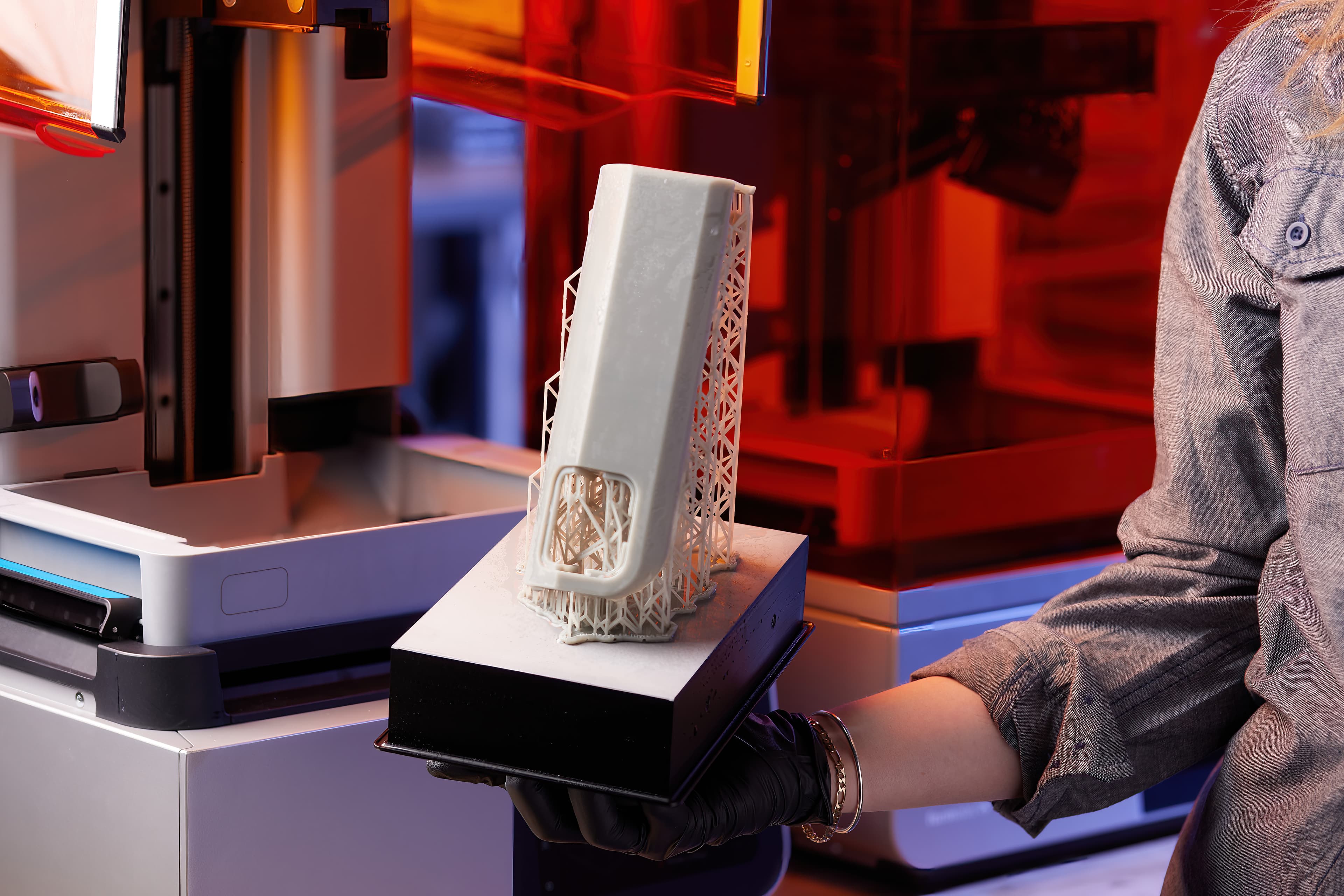

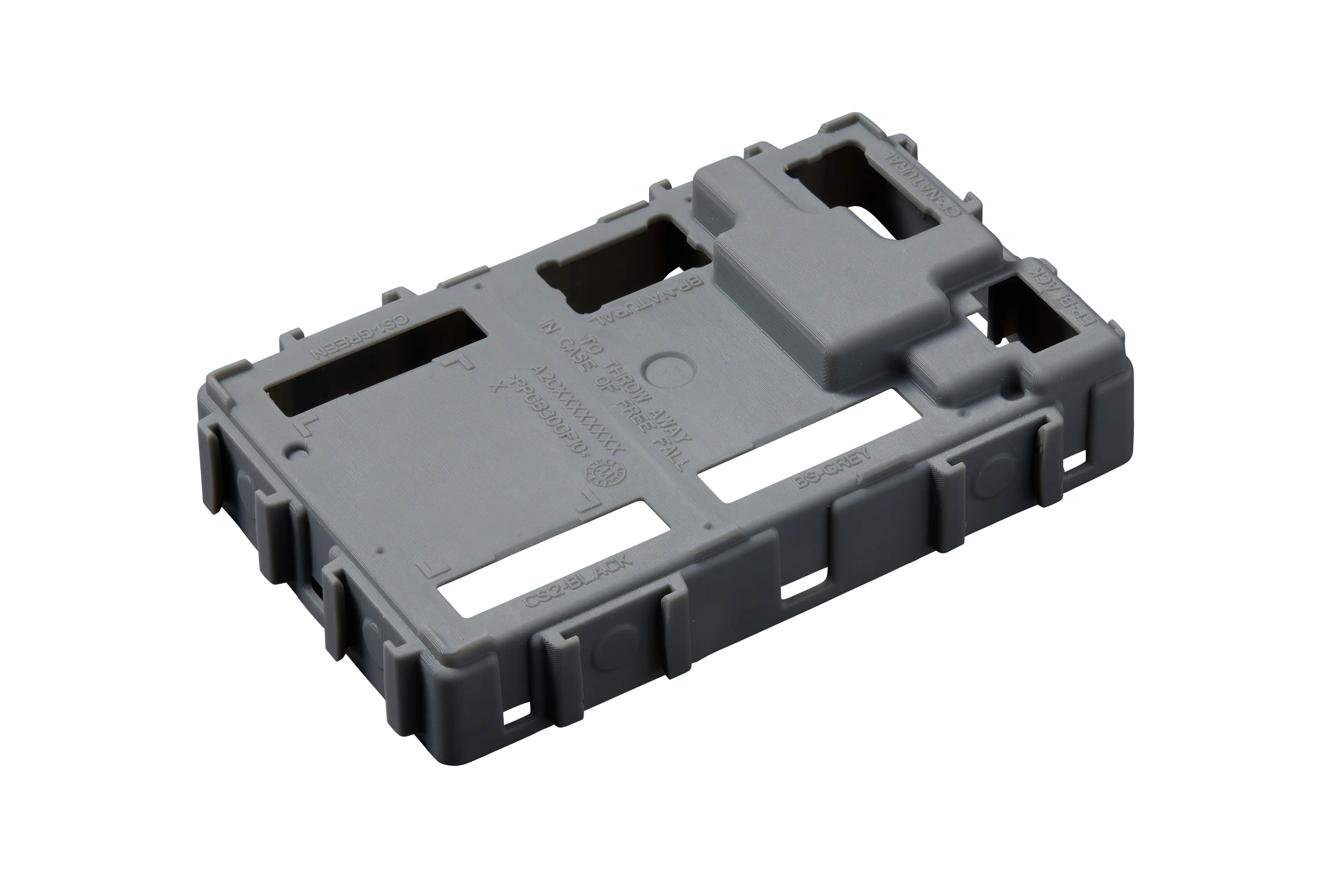

Injection MoldManufacturing JIG

JIGSharpest Details

Highly collimated light and 50 µm pixel size with pre-tuned anti-aliasing for subpixel resolution

Smoothest Surfaces

Lower peel forces, light touch supports, and 50 µm pixel size with pre-tuned anti-aliasing

Most Accurate Assemblies

±0.15% XY dimensional tolerances so assemblies always fit.

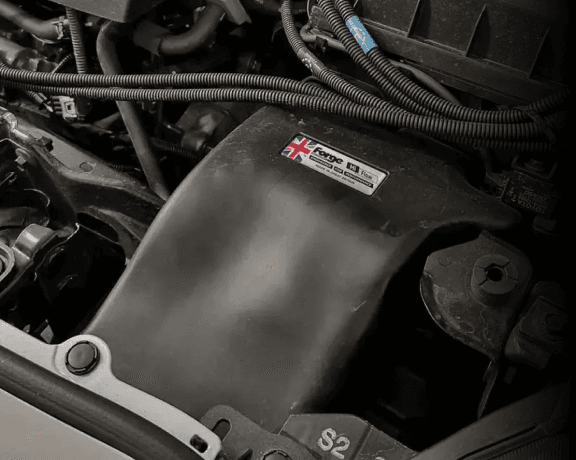

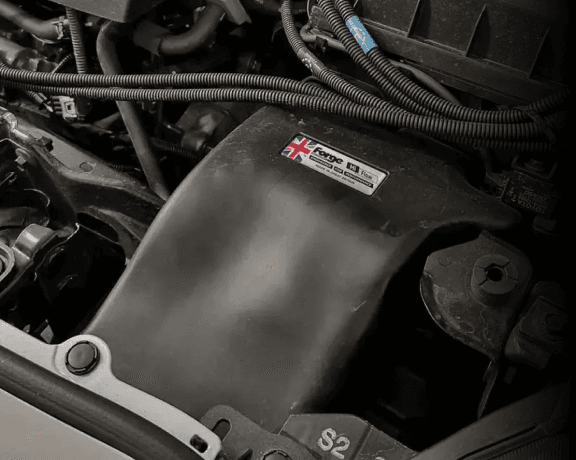

JigAutomotive HEAT SINK AND SHIELD

HEAT SINK AND SHIELDSharpest Details

Highly collimated light and 50 µm pixel size with pre-tuned anti-aliasing for subpixel resolution

Smoothest Surfaces

Lower peel forces, light touch supports, and 50 µm pixel size with pre-tuned anti-aliasing

Most Accurate Assemblies

±0.15% XY dimensional tolerances so assemblies always fit.

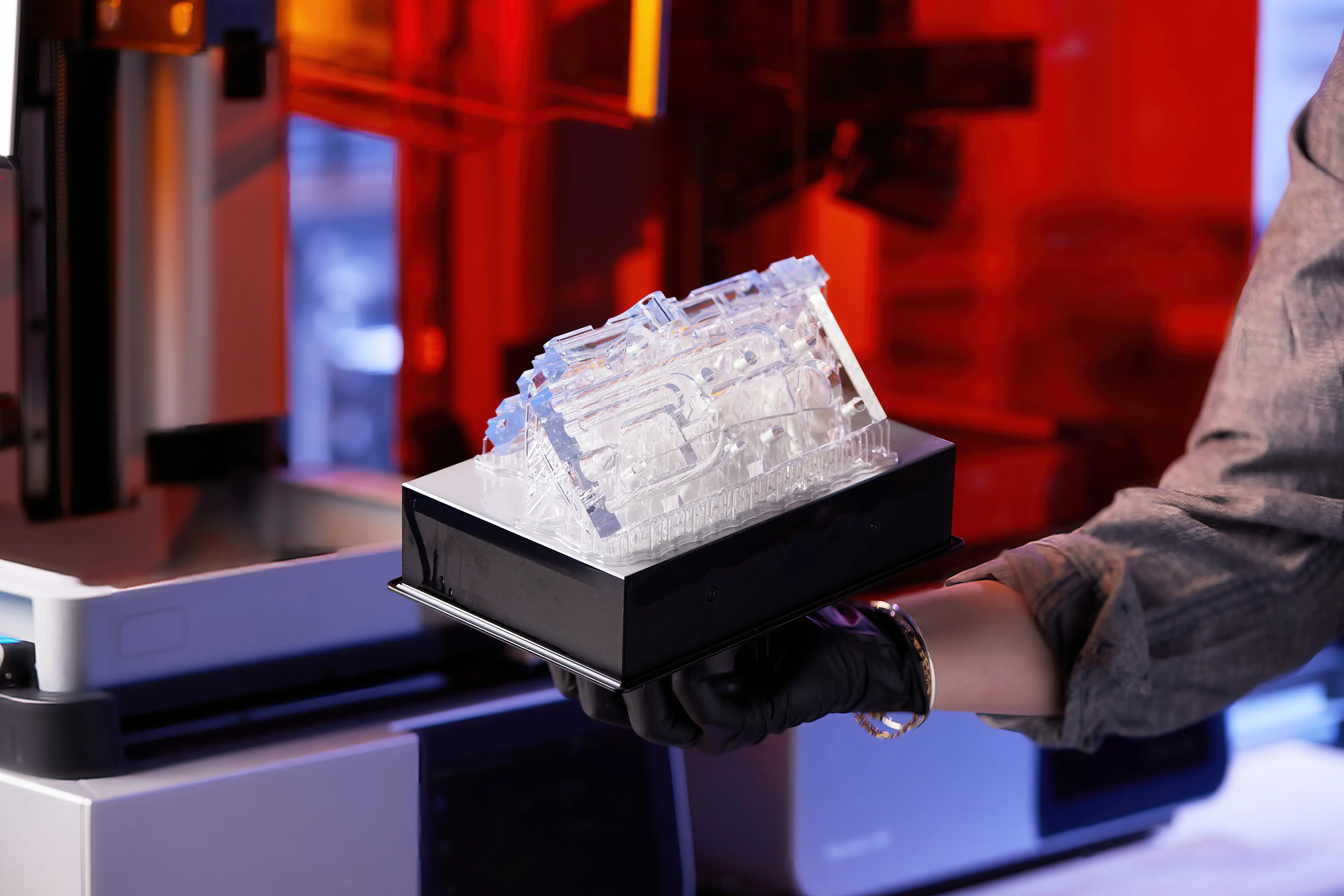

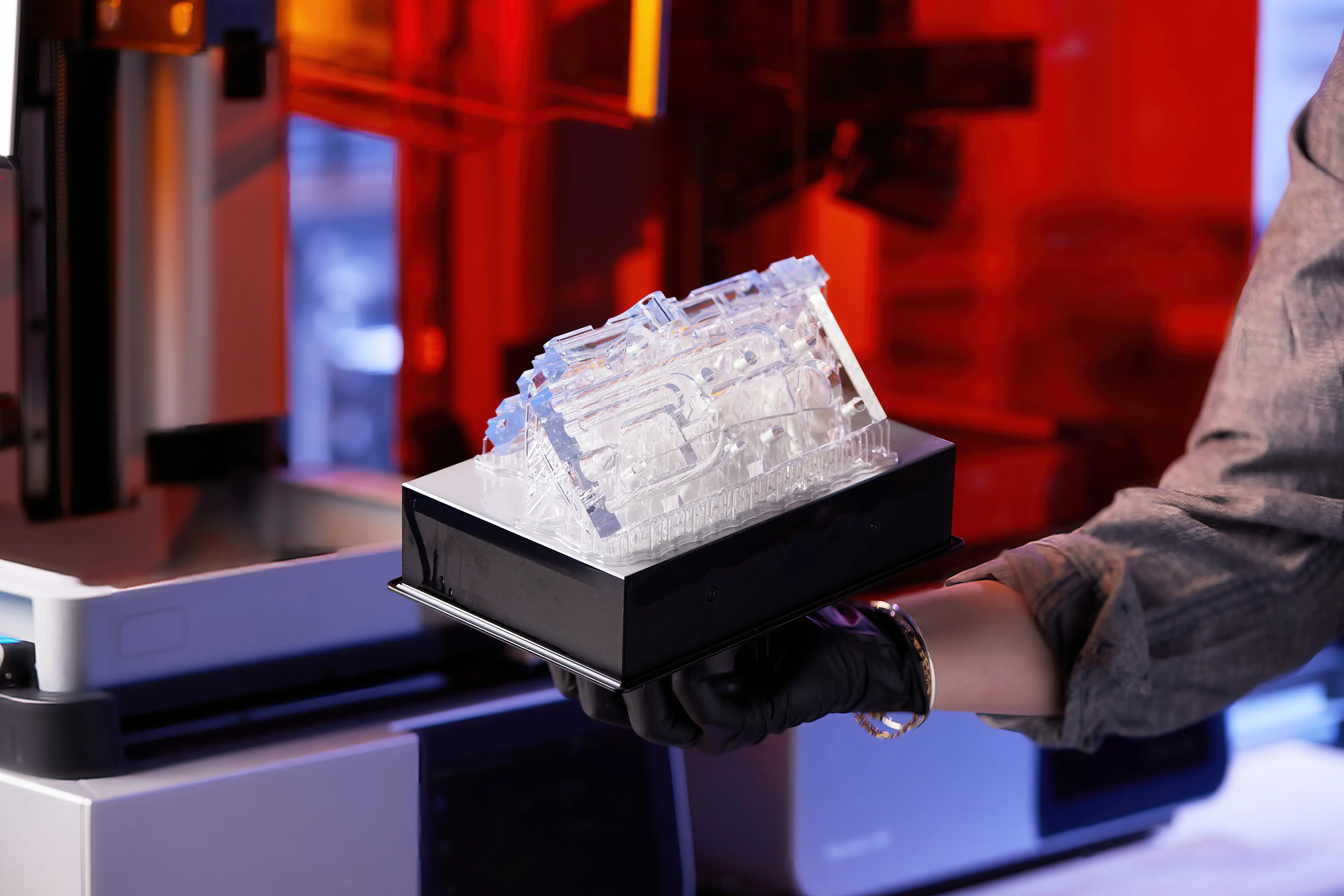

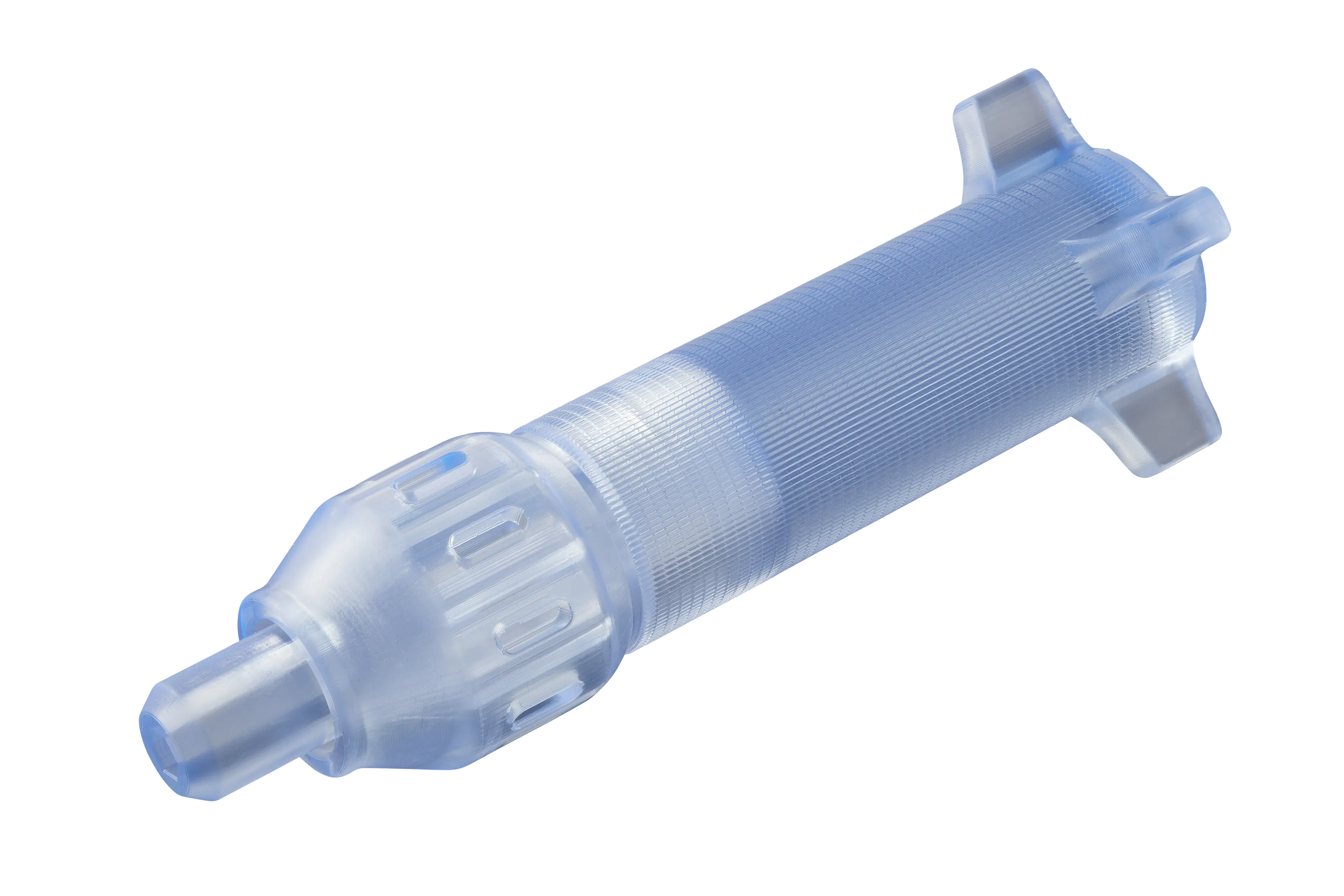

Heat Sink and ShieldConsumer Products FLUIDIC DEVICE

FLUIDIC DEVICESharpest Details

Highly collimated light and 50 µm pixel size with pre-tuned anti-aliasing for subpixel resolution

Smoothest Surfaces

Lower peel forces, light touch supports, and 50 µm pixel size with pre-tuned anti-aliasing

Most Accurate Assemblies

±0.15% XY dimensional tolerances so assemblies always fit.

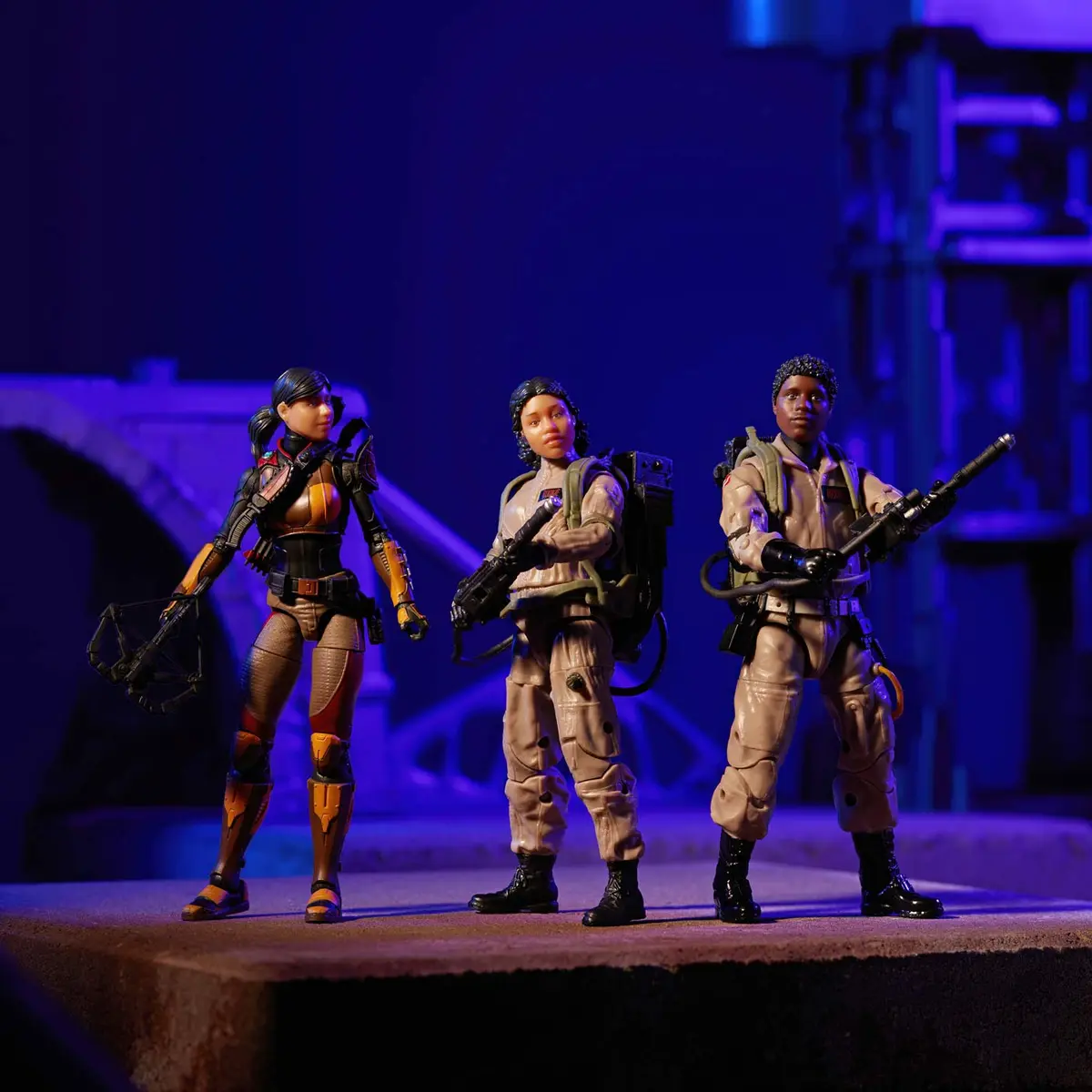

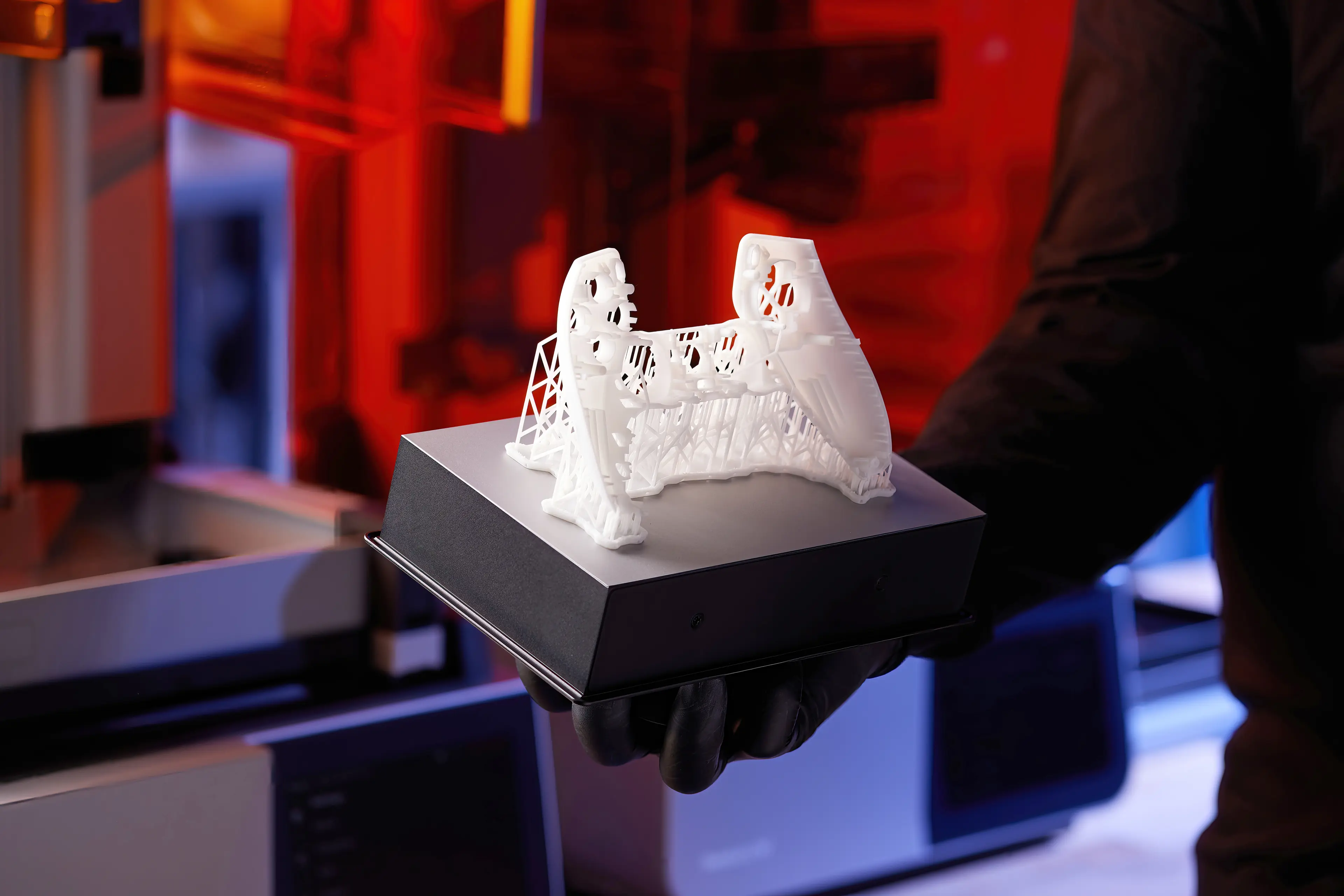

Fluidic DeviceFluidics GAMER CONTROLLER

GAMER CONTROLLERSharpest Details

Highly collimated light and 50 µm pixel size with pre-tuned anti-aliasing for subpixel resolution

Smoothest Surfaces

Lower peel forces, light touch supports, and 50 µm pixel size with pre-tuned anti-aliasing

Most Accurate Assemblies

±0.15% XY dimensional tolerances so assemblies always fit.

Gamer ControllerConsumer Products SURGICAL RATCHET

SURGICAL RATCHETSharpest Details

Highly collimated light and 50 µm pixel size with pre-tuned anti-aliasing for subpixel resolution

Smoothest Surfaces

Lower peel forces, light touch supports, and 50 µm pixel size with pre-tuned anti-aliasing

Most Accurate Assemblies

±0.15% XY dimensional tolerances so assemblies always fit.

Surgical RatchetMedical

Unmatched reliability. Stop coming back to failed prints.

Form 4 was measured to have a 98.7% print success rate by an independent global leader in product testing. Read a complete description of the test methodology and see the results in our white paper.

Unmatched reliability. Stop coming back to failed prints.

Form 4 was measured to have a 98.7% print success rate by an independent global leader in product testing. Read a complete description of the test methodology and see the results in our white paper.

So intuitive that anyone can learn to print in 15 minutes.

- 1

Import your model and prepare your print.

- Smart auto-orientation

- Advanced support generation

- Live printability checks

- 2

Load a material and click print.

- Validated print settings

- No-hassle cartridge and tanks

- Automatic resin dispensing

- 3

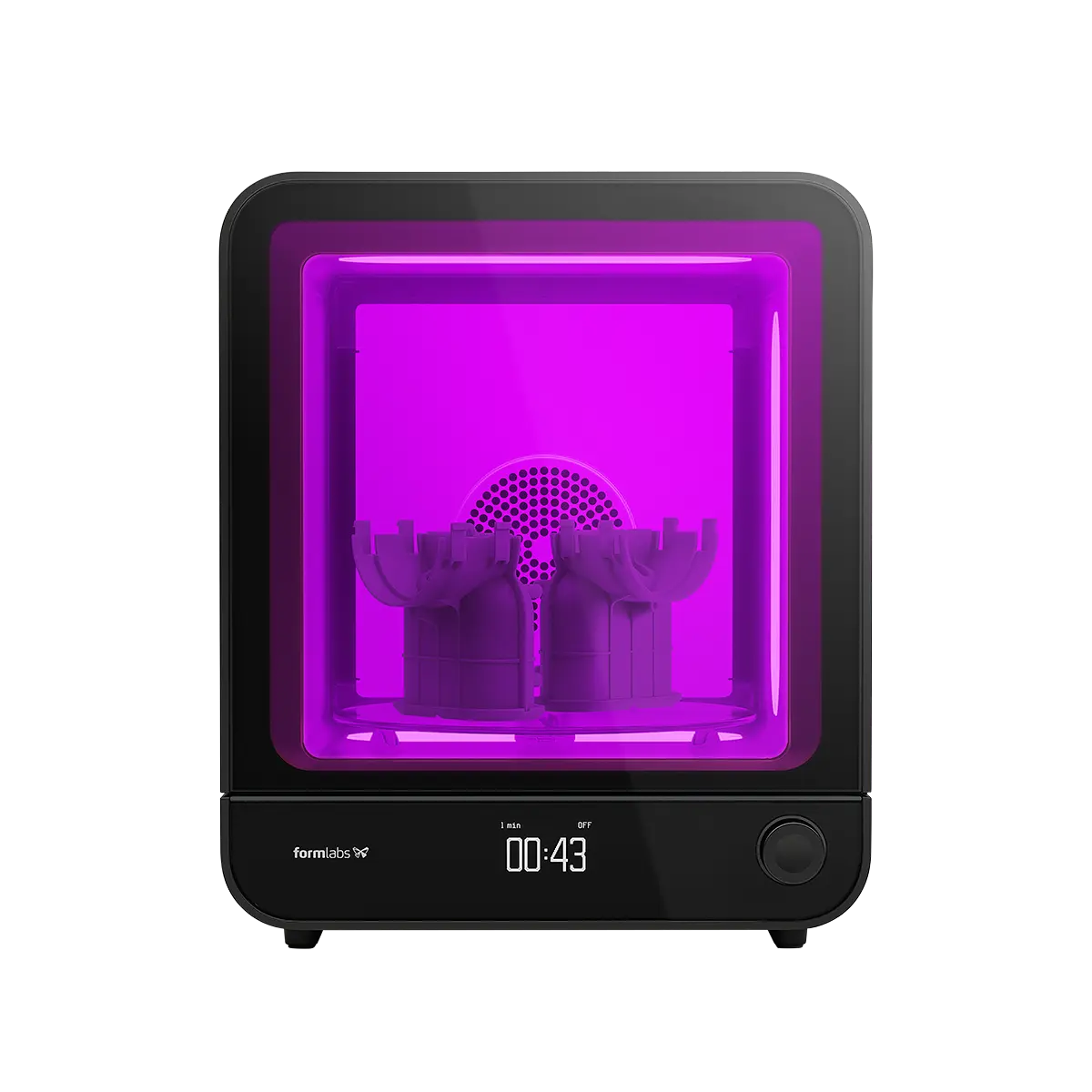

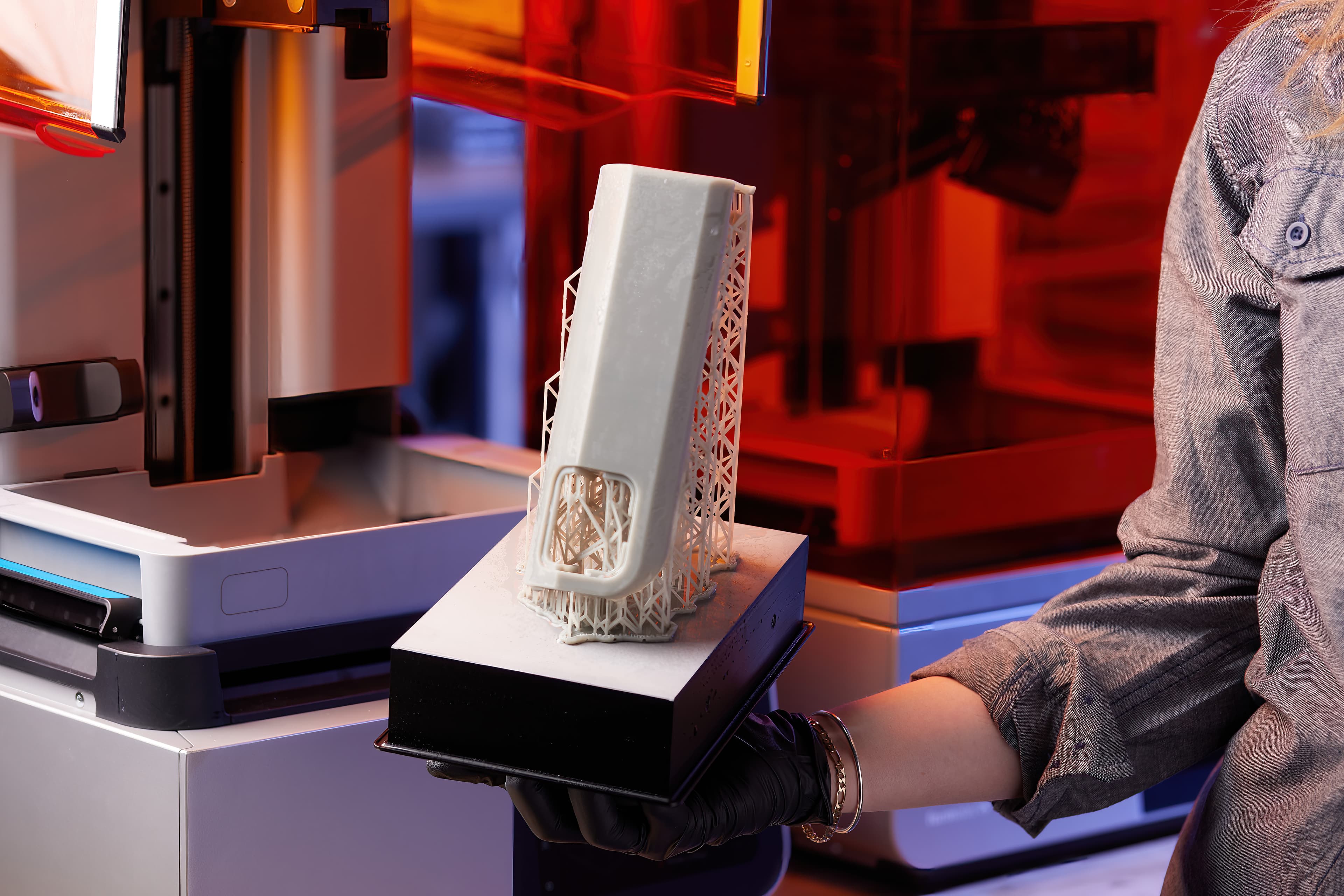

Remove, wash, cure.

- Quick release part removal

- Automatic part cleaning

- Precision post-curing for peak material properties

- 4

Finish your part.

- Light touch supports for quick, clean support removal

- Optional sanding, coating, or painting

Low Force Display™ (LFD)

The Power Behind Form 4Low Force Display™ (LFD)

The Power Behind Form 4A wide range of applications to help you excel in your work.

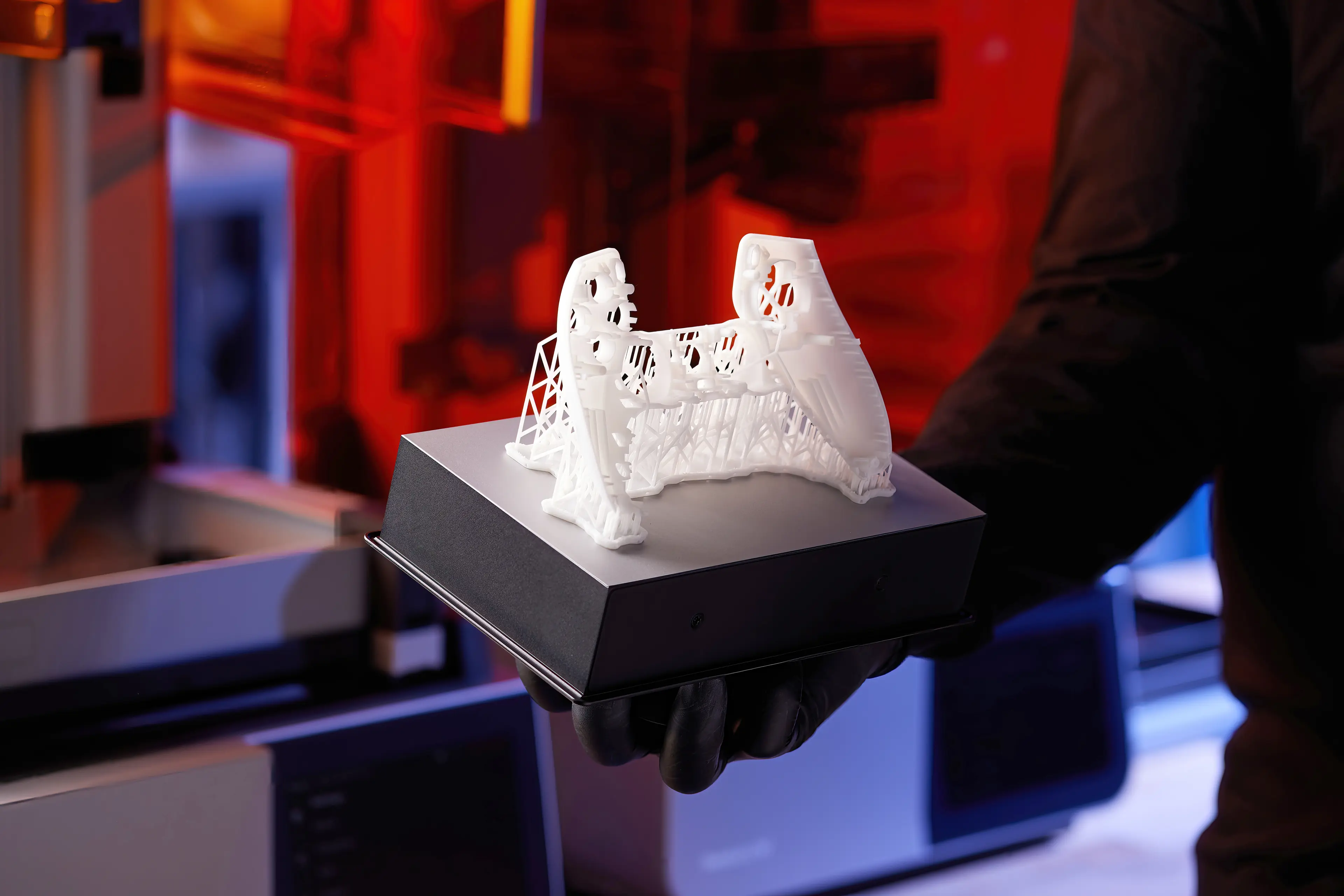

Forge Motorsport reverse-engineered an underperforming part, 3D printed a new design, and tested it on a vehicle for five months before committing to tooling.

Forge Motorsport reverse-engineered an underperforming part, 3D printed a new design, and tested it on a vehicle for five months before committing to tooling.

Speed That Scales

Powered by the same groundbreaking LFD technology, Form 4L can complete large prints the size of the entire build volume in under 6 hours with unmatched reliability and accuracy, empowering you to solve big problems with big parts.

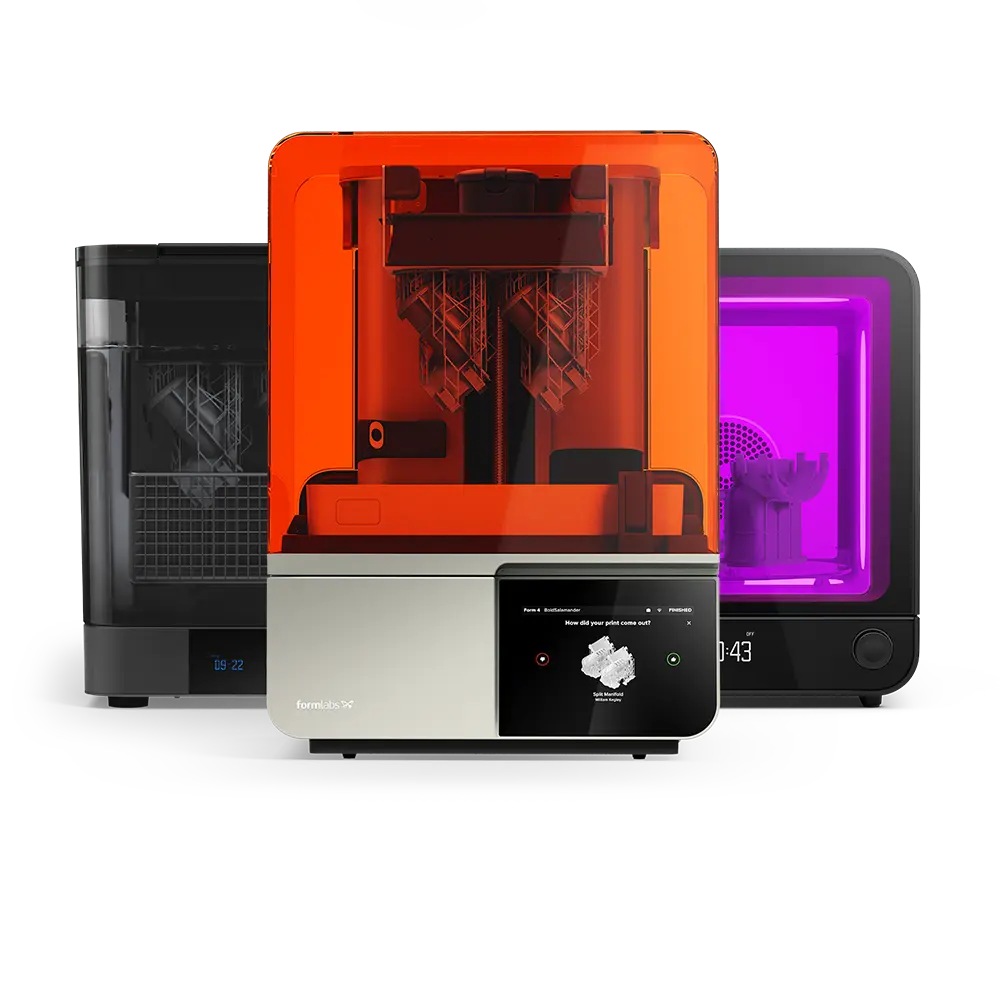

The Form 4 Ecosystem

Complete Your 3D Printing Experience

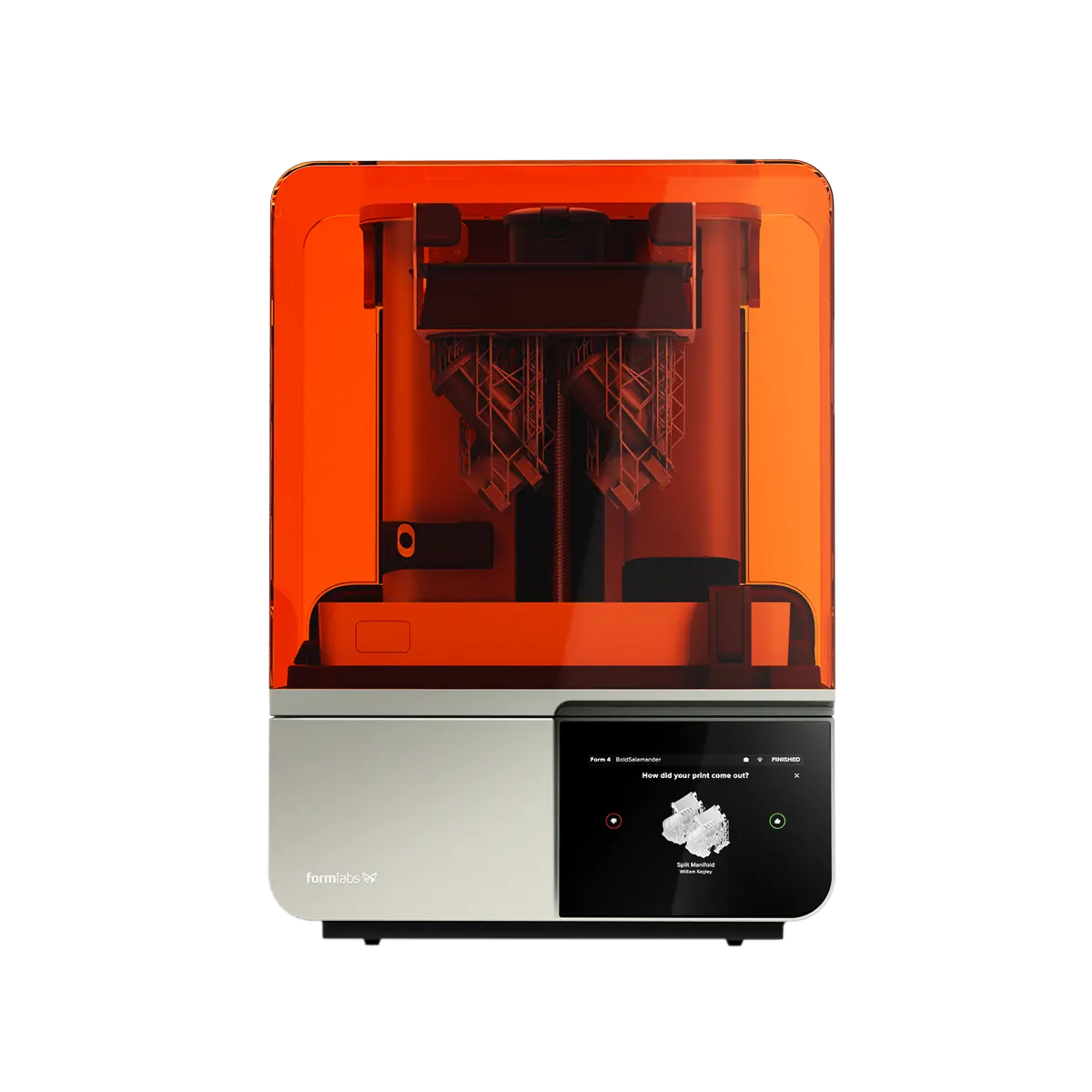

Form 4