As anyone in the packaging industry can tell you, sometimes it really is what’s on the outside that counts. TLM is an Italian manufacturing company that designs and produces flow-pack machines — the large pieces of machinery that take goods like chocolate bars, soft bread rolls, or cosmetics, and wrap them in packaging for preservation and ease of handling.

For every consumer goods manufacturer, packaging is an integral part of the assembly process, and the quality of that packaging can make or break a consumer’s experience. To stay at the top of the global packaging industry, TLM leveraged Italy’s Industry 4.0 incentives program and brought the Fuse Series selective laser sintering (SLS) 3D printer in-house.

“TLM decided to adopt the Fuse Series immediately, because it met our technical needs, first of all due to its ease of use, and secondly due to the type of material, which was perfect for our needs….Furthermore, it allowed us to reduce costs by printing replacement parts for metal and aluminum components.”

Davide Camoletto, Mechanical Designer at TLM

Request a Free Nylon Powder Sample Part

Formlabs offers seven SLS powders with a range of mechanical and visual properties. Choose a free sample printed on the Fuse 1+ 30W to see them for yourself.

Precision Machining for Customization Demands

An air intake accessory with integrated support and laser-engraved text, printed on the Fuse Series SLS 3D printer in Nylon 12 Powder.

An air suction accessory with integrated support, used to reduce air inside the packages and make them fit more snugly around the packaged product, printed on the Fuse Series in Nylon 12 Powder.

TLM’s customers range from local mom-and-pop chocolatier shops to globalized cosmetics manufacturers. Even when two customers may produce a similar product, their packaging has to set them apart, and they’ll need a differently configured machine from TLM.

For over 45 years, TLM has responded to demands for customization by bringing as much of the design and fabrication of flow pack machines in-house as possible. “Having our own machine shop in-house allows us to devote resources to every single detail of the machine, from design to the end result and flow. For such a small company, we have more advanced technology in-house than our competitors,” says Camoletto.

TLM’s machines have to be easy to use and accessible for small artisanal producers as well as those capable of large-scale production by businesses churning out thousands of products each day. “Our customers, the manufacturers, buy flowpack machines because they want their product to be enhanced and of the highest quality, and the packaging is very important,” explained Camoletto. TLM has historically produced these customized components by machining metal, sending out for plastic injection molded parts, and building as much as possible in-house. During the COVID-19 pandemic, however, much of their typical supply chain was completely disrupted, and TLM had to scramble to find a new solution.

Deciding Between HP and Formlabs Fuse

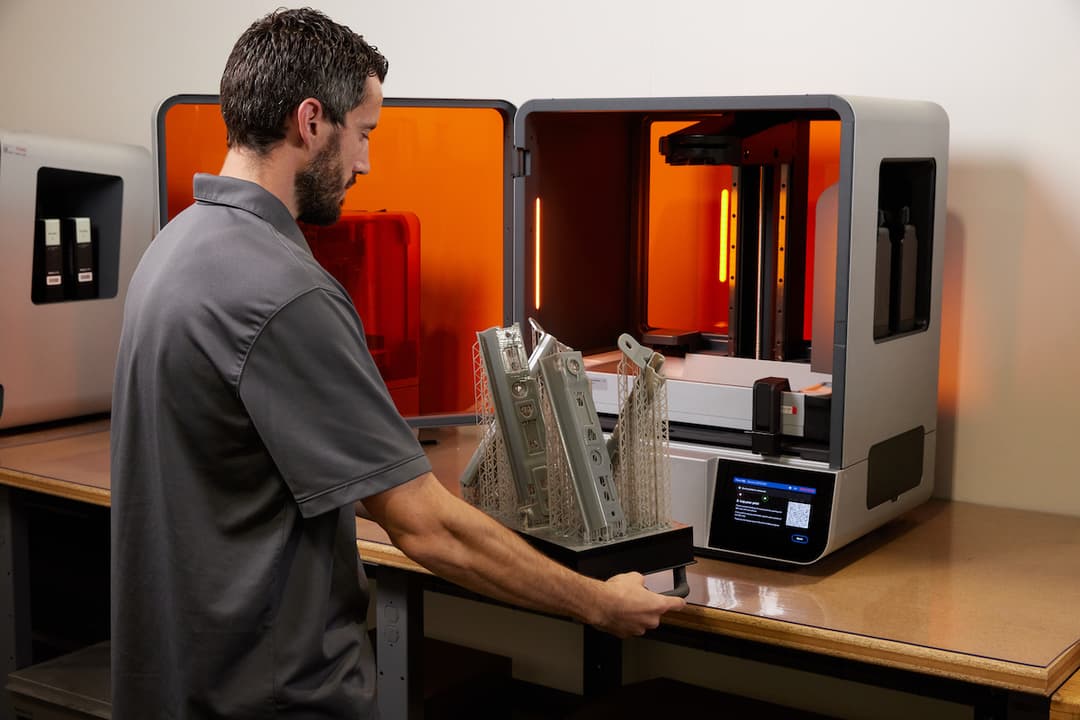

The accessibility, ease-of-use, and affordability were major factors in TLM choosing the Fuse Series over a secondhand large-format HP machine.

When the Italian government introduced Industry 4.0 incentives, in part to help stimulate the economy in the wake of pandemic-era shutdowns, TLM began to evaluate the feasibility of bringing an industrial 3D printing solution in-house.

Though the incentives included tax breaks and funding for R&D, even with these incentives, the cost of the used HP machine they were considering was far too high. “With the cost of the HP, we could have purchased two new work centers,” explained Camoletto. A meeting with Formlabs partner 3DZ convinced them that the Fuse Series ecosystem could deliver the industrial, end-use parts they needed without the high cost of other systems. “The Fuse Series is perfect for us because it was a relatively small investment. With the 4.0 incentives, it became a very attractive solution. We were finally able to find a cost-effective solution.”

Fuse Series SLS Printers vs. Traditional Powder Bed Fusion Systems

This comparison guide will cover the main differences between compact SLS printers such as Formlabs Fuse Series and traditional large footprint machines.

SLS End-Use Production and Replacements

These Fuse Series SLS 3D printed parts help support this tension belt system, and were 3D printed for a much lower price than the original OEM parts would be repurchased for.

This custom SLS 3D printed brackets supports this sensor, one of the many ways 3D printing enables a higher level of customization.

After three years with the Fuse Series, TLM has printed thousands of end-use parts in flow-pack machines sent to customers around the world, often printing four or five days a week with 40+ parts packed into each build. “We print a bit of everything, from supports to casings, objects with internal mechanisms,” says Camoletto.

SLS technology’s self-supporting powder bed makes it possible to streamline some designs that would otherwise be molded or machined in multiple pieces and then assembled. The TLM team has been able to redesign certain components for simplicity, Camoletto explains. “For example, a simple relay, which previously consisted of two or three parts, from a piece of sheet metal, a milled aluminum block, we grouped everything into a single code and created a unique relay.”

For internal components, the TLM team will simply use the Fuse Sift to unpack and depowder the parts and then run them through a quick sandblasting cycle. For others that are higher profile, they’ve devised a dyeing workflow using black pigment that leaves a smooth, end-use quality surface finish. On other parts, they’ll add custom texturing using Formlabs Texture Engine in PreForm to increase the grippiness of a hand-held part.

Dyeing SLS parts with black pigment helps TLM produce end-use parts that are aesthetically pleasing and fit right in on any factory floor.

Larger parts like this could distract from the machine’s appearance, but dyeing helps them blend in with the industrial feel.

For other parts, on their own equipment as well as for their customers’ purchased machines, TLM can now own more of their supply chain for replacements. “We were purchasing some components from a manufacturer, and we realized that it was no longer economically viable to buy them as standard purchases, the kind found in industrial component catalogs, but we found that we could easily print them in-house,” says Camoletto.

A Simple Workflow for Near-Constant Uptime

Even thicker parts, like this component, print reliably on the Fuse Series, and can handle thousands of repeated cycles of wear.

Adding screws and bolts to Fuse Series printed parts makes them easy to assemble (and switch in and out interchangeably) onto existing machinery.

The Fuse Series’ ease of use has been an important part of ramping up volume for TLM. Though sometimes the machinist team runs their own builds, more often than not, any operator can start a build with parts from multiple designers. Their typical workflow involves collecting parts throughout the day and running the machine overnight, then sifting, blasting, and dyeing the parts the next day.

For parts that aren't integral to the functioning of the machine, but would take weeks or months to make tooling for, like this electrical box cover, SLS provides an easy in-house option.

Other parts, like this component, are small and simply designed, but provide an important function in keeping the packaging running smoothly through the flow pack machine.

The quick turnaround for parts has enabled TLM to deliver custom solutions faster to its diverse set of customers as well as work on new, innovative solutions for the packaging industry as a whole. Camoletto says, “As a company, we can't stand still; we're constantly developing new systems, new approaches to our machines for the future. We recently presented two new machines, a new requirement that will be the future of packaging: moving from plastic packaging to bagging in paper film.” With multiple designers able to print parts overnight, new iterations can be tested daily, and TLM is confident that their ideas will be part of a more sustainable future for the packaging industry.

To learn more about the Fuse Series, contact our team. To test the mechanical properties of Nylon 12 Powder for yourself, request a free SLS 3D printed sample.