Today’s customer increasingly strives to fulfill their individual needs and requirements when making purchases. According to a study by Deloitte, in some categories, more than 50% of consumers expressed interest in purchasing customized products or services, with the majority of them willing to pay more for a customized product or service. But with the vast majority of products around us being mass produced, how can companies provide customized products and experiences to wider audiences at an affordable price?

Manufacturing customized products requires paying exclusive attention to specific customer requirements, but applying this to potentially thousands of orders would drastically increase production costs and delivery timelines using traditional methods. Mass customization is a process that combines the individuality of customization and the advantages of mass production to meet changing customer requirements.

This guide will provide manufacturers with insights into the different approaches to customization, how to choose the most applicable approach, and which advanced technologies can enable your business to implement mass customization.

How to Make Mass Customization a Reality?

Learn how to achieve true mass customization quickly and cost-effectively with 3D printing. Formlabs experts will guide you through different workflows, share recommendations, and delve into real-life examples from innovative companies using 3D printing for mass customization.

What is Mass Customization?

Mass customization is a marketing and manufacturing technique that combines the flexibility and personalization of custom-made products with the low unit costs associated with mass production.

Traditional mass production involves the manufacturing of large quantities of standardized products in an efficient process. The continuous production of standardized products was made possible by the discovery of electricity and the invention of the assembly line, which marked the beginning of the second industrial revolution. With the assembly line, production moved to large, centralized facilities to aid the mass production of goods. The third industrial revolution began around 1970 with the increasing automation of entire production processes, progressively removing human assistance and replacing it with robotics and automated manufacturing tools. The current period, Industry 4.0, is characterized by the application of information and communication technologies to industry.

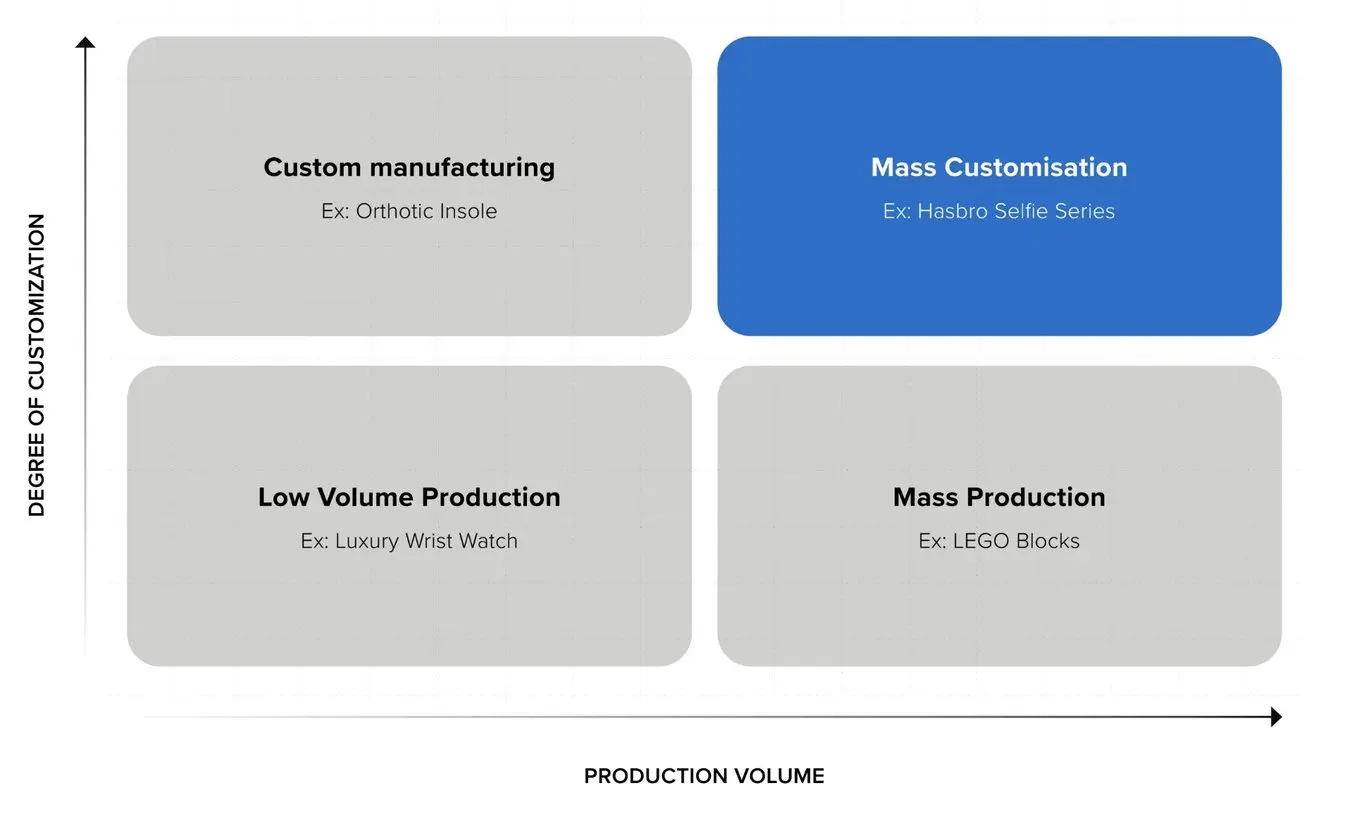

While mass production is all about producing a large number of goods at the lowest possible cost, custom manufacturing is the opposite end of the spectrum, defined as the process of designing, engineering, and producing goods based on a customer’s unique specifications. Traditional custom manufacturing is usually applied on a small scale or in short production runs to meet niche customer requirements and is traditionally associated with higher costs.

In today’s market, in which a large number of customers desire customized goods, neither mass production nor traditional custom manufacturing can fulfill that need. Mass customization enables manufacturers to implement the holy grail of producing customized products in large volumes for a growing market.

Here’s a high-level comparison of the different terms and their most important features:

| Mass Production | Custom Manufacturing | Mass Customization | |

|---|---|---|---|

| Cost per Part | Low | High | Affordable |

| Manufacturing Volume | Large-scale production | Small-scale production | Medium to large-scale production |

| Production Approach | Make-to-stock | Make-to-order Assemble-to-order | Make-to-order Assemble-to-order |

| Variability of Products | Very Limited | Unlimited | Slightly limited to unlimited |

| Manufacturing Speed Per Part | Fast | Slow | Medium to fast |

| Time to Introduce New Product Iterations | Slow | Fast | Fast |

| Common Production Tools and Processes | Injection molding, casting, metal forming, stamping, assembly lines, robotics and automation | Manual labor, machining, and fabrication tools | 3D scanning, 3D printing, digital fabrication tools, rapid tooling for traditional manufacturing tools, robotics and automation |

Beyond the volume and cost, one of the biggest differences between these terms is the production approach:

-

Make-to-stock is a manufacturing strategy in which production plans are made based on forecasted demand. In this scenario, the manufacturer tries to predict the consumers' demand cycles and specific requirements, and then produces goods to meet them. Make-to-stock is the go-to approach for mass production. Manufacturing products in large batches allows the producer to keep initial production costs low, but keeping large inventories is expensive and there’s excessive waste when demand projections go wrong.

-

Assemble-to-order involves the stocking up of the components required to assemble an end-use product. The manufacturer then assembles the components according to customers’ order requests and customization requirements. Assemble-to-order strategies are common for both custom manufacturing and mass customization, with the latter generally using more advanced product configuration and production processes to keep costs low.

-

Make-to-order involves comprehensive collaboration between consumers and the manufacturer. The manufacturer develops the product following the exact specifications provided by the customer, which means that the variability of products can be unlimited. This strategy is common for both custom manufacturing and mass customization, with the latter relying on more advanced processes to gather the data for customization, produce the custom components, and assemble the final products, all at scale to keep costs low.

As the three concepts have different goals, the production tools and processes, and their characteristics differ as well:

-

Traditional mass production relies on traditional manufacturing processes like injection molding, casting, forming, or stamping that require expensive tooling and many months of lead time to create, set up, and dial in. Assembly lines and automation can be leveraged to further improve efficiency. Once set up, the production can churn out thousands of products in a short period of time and the fixed costs get distributed among these parts, resulting in low unit costs. Mass production processes are rigid and design changes are expensive as they require adapting tooling and the manufacturing process.

-

Traditional custom manufacturing leverages processes like manual labor, machining, and a variety of fabrication tools. There’s limited or no tooling and the workflow is more flexible, which makes it easier to introduce new products and customize designs. The manual production process has low throughput and cannot be easily scaled.

- Mass customization relies on innovative and emerging technologies to collect data, create designs, manufacture parts, and assemble products. It uses manufacturing processes that require no tooling or leverages low-volume rapid tooling for traditional processes to reduce costs. Depending on the development needed and the complexity of the product, time to market can be even longer than with mass production, but changes to the design of the product are inexpensive and easy, which enables customization and makes it easier to adapt to the market needs. Many enterprises also utilize the concept of modularity, using a variety of standard mass-produced components that can be assembled in different patterns, modified, and combined with custom parts to produce the final product, in order to increase throughput and keep costs manageable.

Mass Customization Advantages and Disadvantages

Mass customization has its unique benefits, but it’s not a good fit for all applications. Here’s a brief overview of the advantages and disadvantages to help you decide:

| Advantages | Disadvantages | ||

|---|---|---|---|

| Businesses can charge a premium for a customized product, which can often be substantially higher than the costs of incorporating customized parts into a product. | Higher manufacturing costs compared to the traditional mass production of standardized goods. | ||

| Direct-to-customer business models eliminate middlemen, increase margin, and empower enterprises to build lasting relationships with their customer base. | Viability is dependent on the product type and the willingness of customers to pay for customization. Mass customization is better suited to luxury than to basic products. | ||

| Customization helps to differentiate a brand from competitors and can even be a unique selling proposition (USP), making a company more competitive. | Customization often leads to increased delivery timelines as the products have to be manufactured and shipped post-purchase. | ||

| Flexible production processes make it easier to adapt products to customers' needs and don’t require businesses to invest in costly tooling upfront. | Relatively lower throughput for customized goods compared to the volumes associated with traditional mass production. | ||

| Improved inventory management can reduce overhead costs and waste, contributing to sustainability, which is increasingly valued by the customer base. | Increased or unplanned demand for customized goods can lead to supply chain challenges. Product returns are complex or not feasible. | ||

| Customization options and enhanced customer relationships improve customer satisfaction and reduce customer churn, increasing customer lifetime value. |

Types of Mass Customization

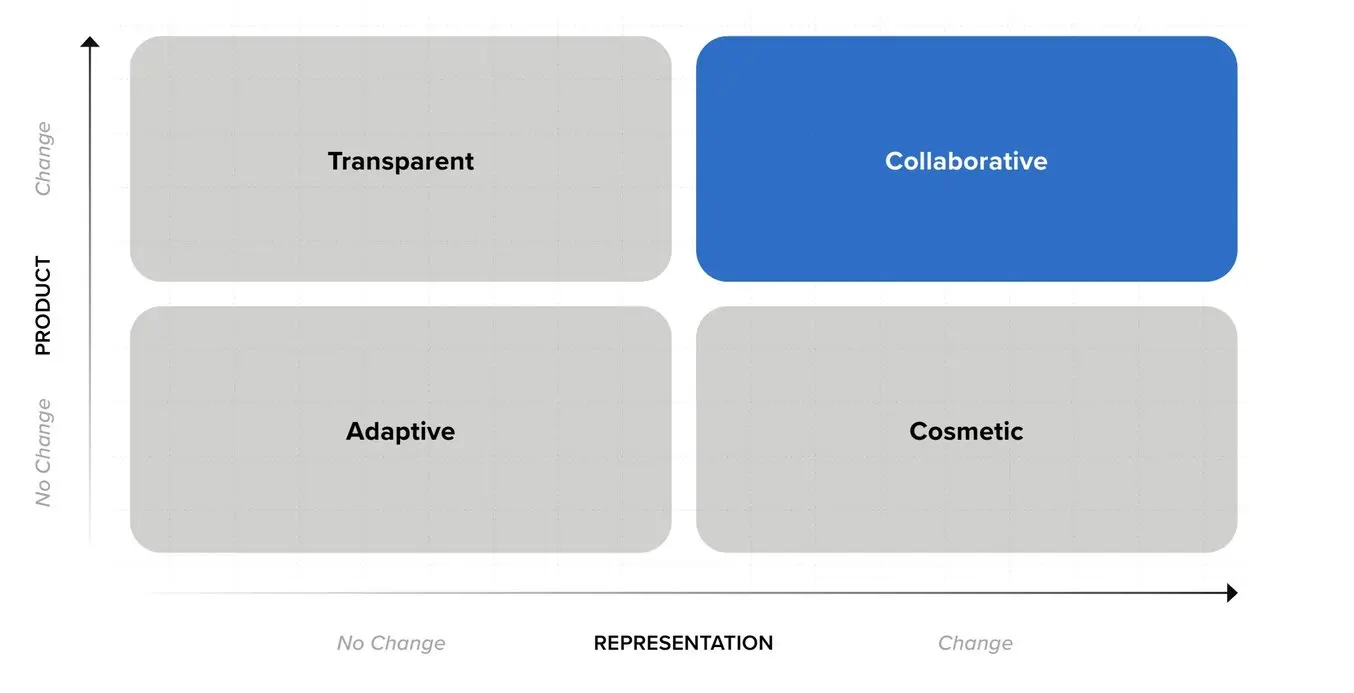

Pine and Gilmore (1992) defined four distinct approaches to mass customization, which can be used individually or combined to best serve a particular set of customers.

These four approaches are as follows:

-

Collaborative Customization (Co-creation): Collaborative customizers conduct a dialogue with individual customers to help them articulate their needs, identify the precise offering that fulfills those needs, and make customized products for them. This approach is most often associated with the term mass customization and is applied primarily by manufacturers with a large customer base that requires customized products. It also provides clients who struggle with decision-making or have sensitive requirements with a platform to detail their exact needs.

The Nike by You (formerly Nike ID) shoe customization program is an excellent example of the collaborative approach. The customization process gives design control to consumers looking to customize shoe designs. The online platform provides consumers the tools to iterate products virtually, while the final product is produced and shipped directly to the customer.

-

Adaptive Customization: Adaptive customizers offer one standard but customizable product that is designed so that users can alter it themselves upon receipt. These customization options enable the customer to use the product in different ways to meet diverse needs. The adaptive approach integrates easy-to-use features to ensure the customer can customize product usage with relative ease.

Internet of things (IoT) systems provide an excellent example of adaptive customization. For example, customers can install IoT-enabled devices in their homes to control lights, heating/cooling, curtains, window opening/closing, speakers, and domestic appliances, and more, all according to their preferences.

-

Cosmetic Customization: Cosmetic customizers present a standard product differently to different customers. With this approach, customization does not require extensive changes to the product sold to individual customers, but standard product offerings are merely packaged using customized presentation tools that appeal to individual customers. Cosmetic customization may be done according to the request of the customer, discreetly using customer information, or randomly.

The popular “Share a Coke” campaign by Coca-Cola is a great example of cosmetic customization and how it can bolster sales and satisfy the personalized requirements of consumers without changing a standard product. This campaign changed the traditional wrapping or packaging on the standard Coke can or bottle to include the most common first names in specific regions. Customers could choose to request their branded Cokes or simply enjoy the thrill of searching for their personalized bottle in any market.

-

Transparent Customization: Transparent customizers provide individual customers with unique goods or services without letting them know explicitly that those products and services have been customized for them. Enterprises that utilize transparent customization employ this process when the specific requirements for customers are readily accessible within their databases or the customer’s needs are predictable through the analysis of behavioral patterns that provide insight into their requirements.

Transparent customization is often done discreetly without explicitly informing the client about the ongoing customization activities. This approach is common with online services and platforms, such as personalized feeds on Facebook, personalized music recommendations by Spotify, or personalized ads by Google. The beauty industry provides examples of the successful application of transparent customization for products, as in the case of L’Oreal. The beauty products manufacturer launched an application that allowed its dedicated customers to detail their beauty routines and skin-care goals. Leveraging the data from the app, the company provides customized skin-care products in different quantities and packaging for individuals and beauty salons using its products. In this case, prior data of customer behavioral patterns enables L’Oreal to implement mass customization and the customer benefits from the transparent customization process by receiving renewed products tailored to their skin-care routines and location without having to make new requests.

To provide an overview, the following graph highlights the four different approaches to customization and how they affect an enterprise’s standard products:

Mass Customization vs. Mass Personalization

With mass customization, specifically collaborative customization or co-creation, the customer manually makes changes to the item to meet their needs or requirements, selecting from a preset number of configurations. Customization is implemented using paint finishes and customized fabrics, but very few offer physical geometries that are unique to the user. Most of the truly personalized goods in the world today are either luxury goods or healthcare devices, both with very high price tags.

Mass personalization is the action of creating or modifying an item using customer data to meet an individual’s needs, creating a completely unique product. Historically, there haven’t been good manufacturing options for creating these physical products, but advanced manufacturing processes like 3D printing are now transforming the way customization is delivered, enabling the manufacturing of truly personalized goods at scale.

Technologies for Mass Customization

How can mass customization bridge the gap between mass production and custom manufacturing? By using innovative and emerging technologies to collect data, create designs, manufacture parts, and assemble products. Let’s look at some of the most common technologies that enable mass customization and real-life examples.

Product Configurators

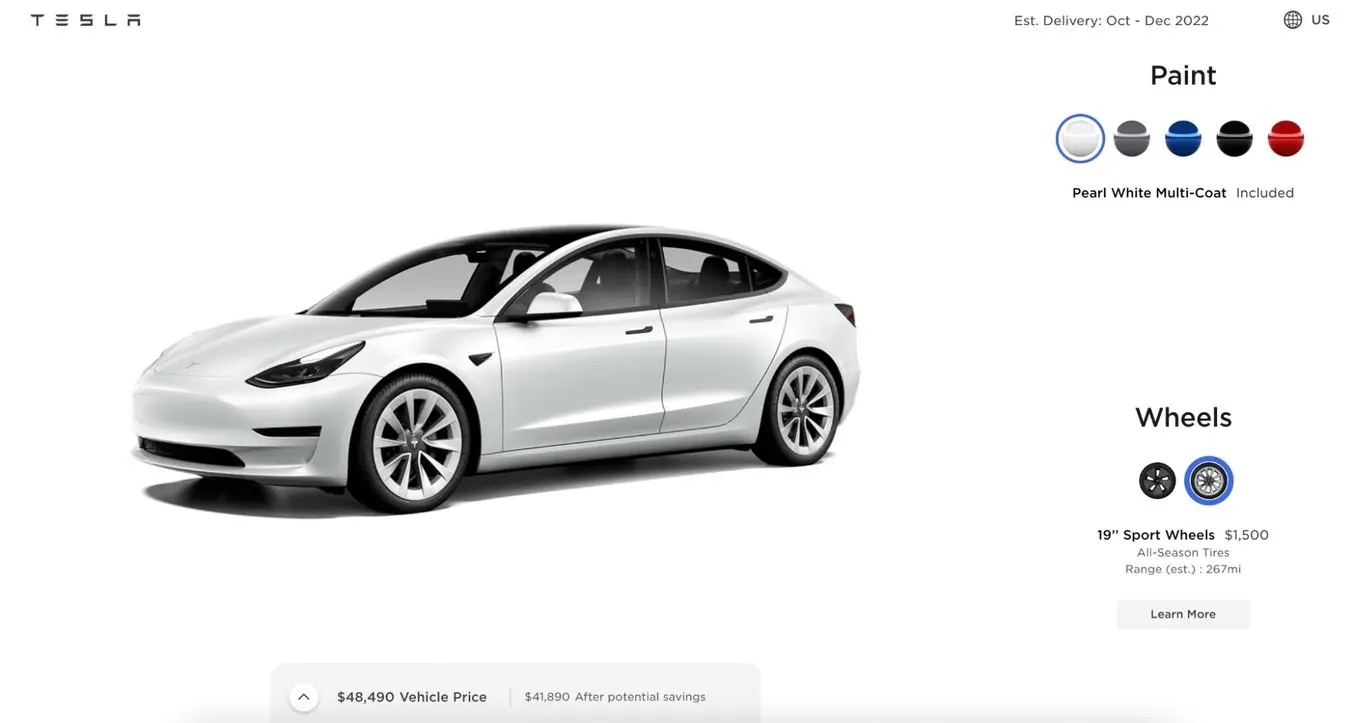

Online, app, or software-based product configurators make it possible to add and/or change functionalities of a core product, modify the design/looks, or create custom designs or features from scratch. They’re some of the most common co-creation tools that are valuable for marketing as well as for directly capturing customer preferences that can be turned into customized products.

Some examples of product configurators include automotive configurators that allow customers to view the given car model in different colors, rims, and interiors; sunglass configurators that let customers virtually try on different frames and lenses, and more. Recently, new configurators have appeared that use augmented reality to make the experience even more realistic.

Tesla Motors’ product configurator lets customers customize their car and order it directly online, without ever having to visit a showroom.

CAD Design

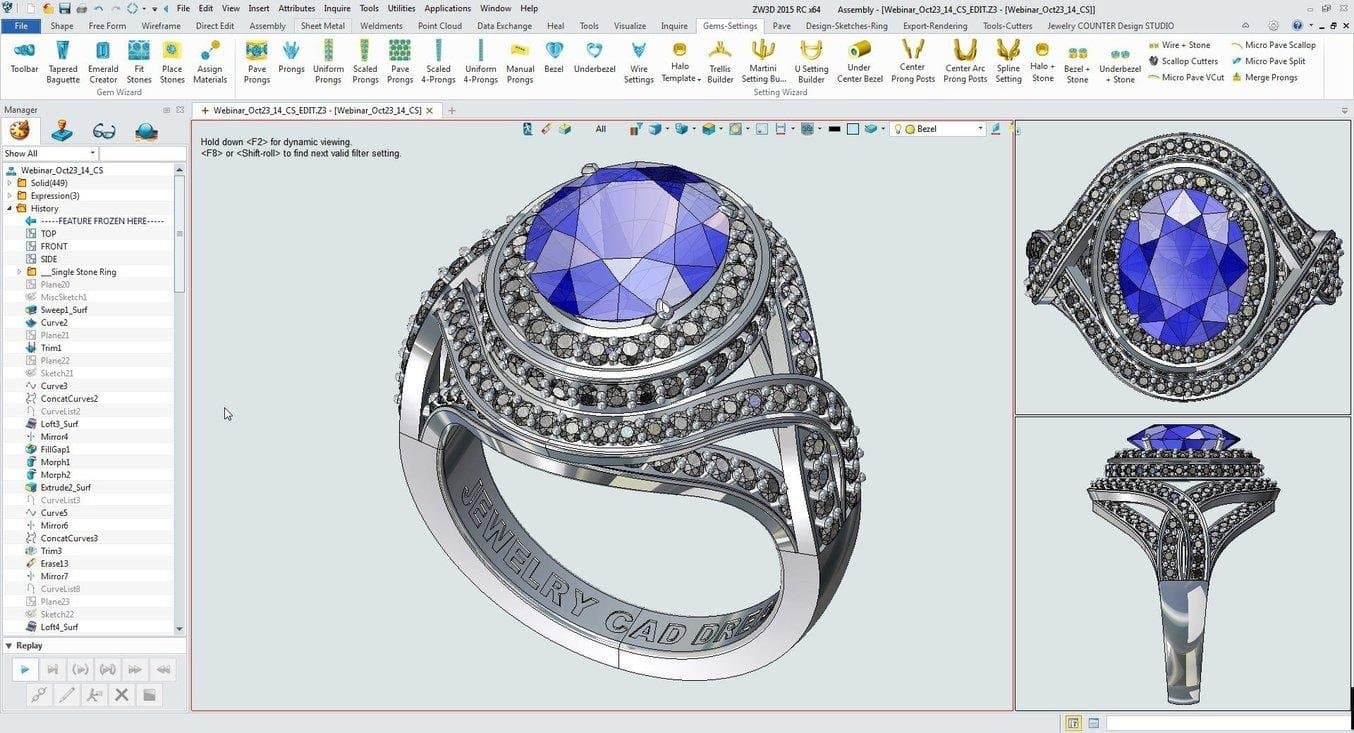

Computer-aided design (CAD) is a method to digitally create 2D drawings and 3D models that has replaced manual drafting across a wide range of industries. The majority of products around us today are already being created with CAD design, and integrated tools specifically to enable mass customization are also rapidly emerging.

Traditional CAD software is like a combination of a Swiss Army knife and a digital drawing board, offering a wide range of tools that allows designers to create anything. However, these tools have a steep learning curve and the pool of designers is limited. Consequently, CAD tools for mass customization are often tailored to specific workflows, thus decreasing the complexity of digital design, so trained personnel or customers can intuitively create or modify designs.

For example, specialized CAD software tools are now available to design dental appliances, like aligners treatment, dentures, or crowns based on intraoral scan data of patients. Medical CAD tools empower healthcare professionals to design anatomical models, prosthetics, or surgical guides. Jewelry CAD tools let jewelry designers create new custom designs on their computers, which is infinitely easier to do at scale than hand carving traditional wax patterns.

Customizing jewelry digitally is infinitely easier than hand carving new wax designs.

3D Scanning

3D scanning is the process of analyzing a real-world object or environment to collect data on its shape and/or appearance. The collected data can then be used to construct digital 3D models.

3D scanners and their uses are proliferating today, and they’re key tools for capturing data for mass customization. They’re often indispensable for mass personalization, where they’re used for referencing the exact shape of the human body, that can be used to create custom-fit products and appliances. While some applications require dedicated 3D scanners, smartphone scanning (photogrammetry and LiDAR) has developed rapidly, so billions of customers already have a scanner in their pocket capable of gathering data that can be used as an input for mass customization.

For example, 3D scanners can be used to scan customers’ faces to create customized glasses, ear canals to make custom-fit earphones, teeth to produce a range of dental appliances, and more.

Dental intraoral scanners are an increasingly common sight in dental practices, replacing traditional, uncomfortable impressions. The digital data they gather can be used for designing dental appliances.

3D Scanning and 3D Printing for Reverse Engineering and Other Applications

3D scanning and 3D printing workflows can be applied to replication and restoration, reverse engineering, metrology, and more. Download our white paper to explore these applications and learn how to get started.

3D Printing

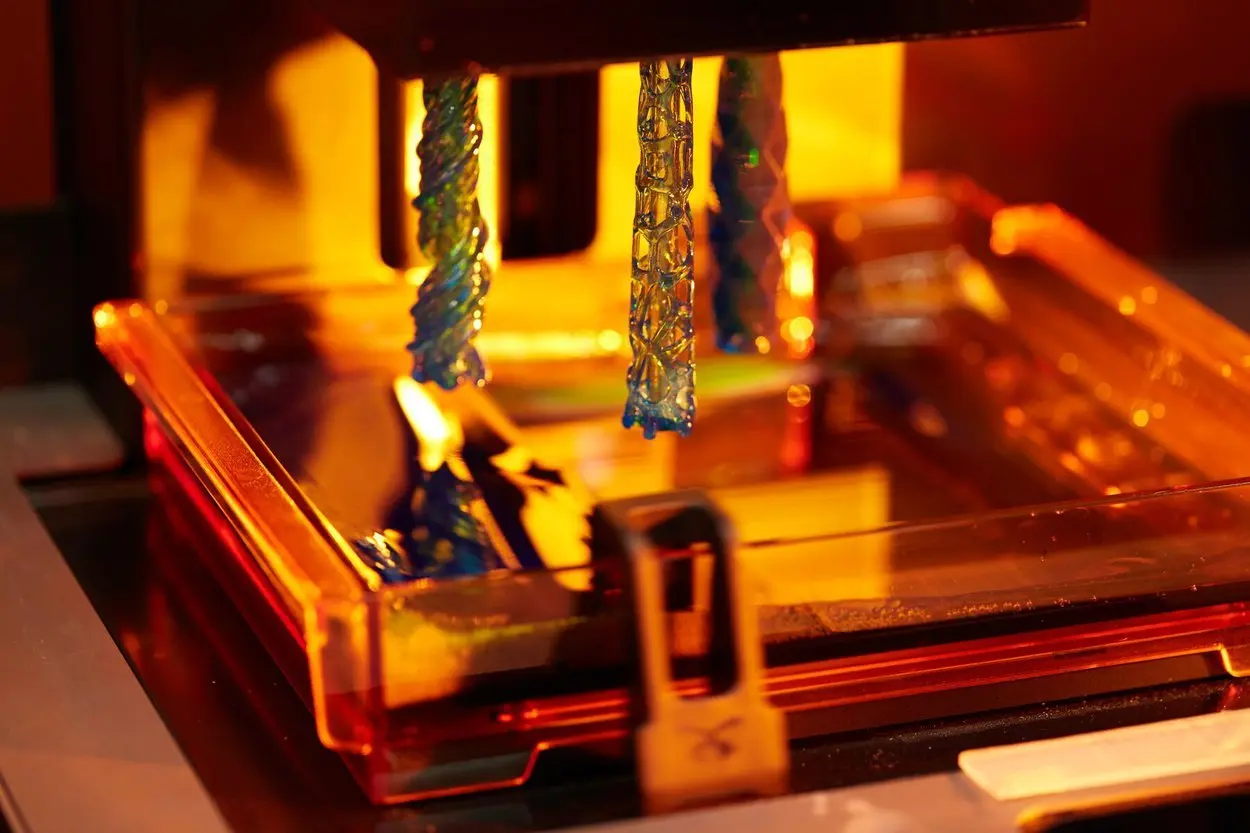

3D printing or additive manufacturing (AM) technologies create three-dimensional parts from computer-aided design (CAD) models by successively adding material layer by layer until the physical part is created.

While 3D printing technologies have been around since the 1980s, recent advances in machinery, materials, and software have made 3D printing accessible to a wider range of businesses and enabled more applications, including the manufacturing of end-use parts.

As professional 3D printers require no tooling, only the digital design needs to be changed to tailor each product to the customer without additional tooling costs. 3D printing also offers practically unlimited design freedom, as it can create complex shapes and parts, such as overhangs, microchannels, and organic shapes, that would be costly or even impossible to produce with traditional manufacturing methods.

Additive manufacturing is one of the most widely used production technologies for mass customization, offering solutions for medical, dental, and audio appliances, manufacturing consumer goods, and more.

Hasbro’s Selfie Series line of products introduces the personalization of action figures on a large scale to its customer base. Customers can scan their faces using their smartphones, pick a hairstyle, and configure a customized action figure. The customized heads are assembled with a standard/off-the-shelf action figure body made with traditional tools to keep the prices affordable and the customized action figure is shipped to the customer.

Gillette developed the Razor Maker concept that provides a direct-to-consumer customization workflow. Customers can use an online configurator to pick from a range of razor handle designs and colors, and choose to add their name to the design. The handles are produced with 3D printing and assembled with standard razor components.

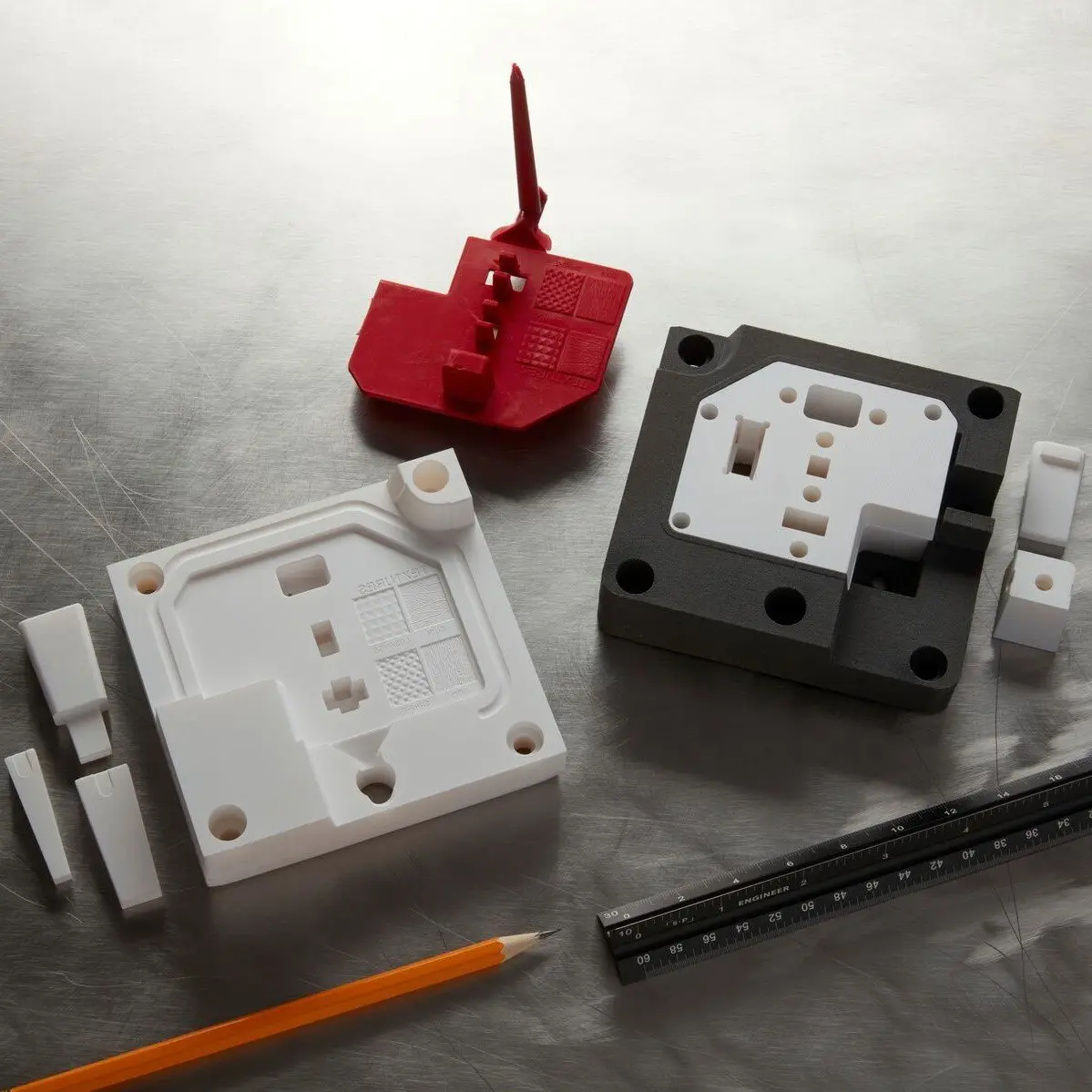

Beyond directly manufacturing end-use parts, 3D printing can also be used to produce rapid tooling and manufacturing aids that can both support mass customized production.

How to Unlock Low Volume Production and Custom Manufacturing with 3D Printed End-Use Parts

Watch this webinar to learn how to achieve custom manufacturing and low volume production of end-use parts quickly and cost-effectively with 3D printing.

24/7 Production With Formlabs Automation Ecosystem

Reach new levels of productivity with a fully automated resin 3D printer fleet that you can operate at any place and from anywhere.

Rapid Tooling

Rapid tooling is the group of techniques used to fabricate tooling fast, at low cost, and efficiently for traditional manufacturing processes like injection molding, thermoforming, or compression molding, to create parts on a slim timeline or in lower quantities.

Conventional tooling is most commonly produced out of durable metals using technologies such as machining and metal casting. However, these processes are expensive and better suited for large-scale production cycles. Rapid tooling provides means to produce custom or limited series of end-use parts using traditional manufacturing processes that would be prohibitively expensive using conventional tooling. This allows manufacturers to test the market for new products, offer a wider range of products, or customize parts based on customer needs.

The most popular common methods for producing rapid tooling are 3D printing and machining, with the former being most suited for mass customization.

Looking at real-life examples, vacuum forming over 3D printed models designed based on intraoral scans of patients is the go-to method for producing clear aligners in orthodontics.

Jewelers also use CAD design to create patterns that can be cast directly to create customized jewelry. Traditionally, patterns for direct investment casting are carved by hand or machined if the part is a one-off or expected to be only a handful of units. With 3D printing, however, jewelers can directly 3D print the patterns, removing the design and time constraints common in other processes.

Custom-fit ear devices such as in-ear monitors, hearing aids, or noise protection used to be labor-intensive and expensive to make, which means that they were only accessible to a few niche audiences. Now, 3D scanning can be used to scan someone’s ears and molds for casting silicone ear tips can be 3D printed, empowering audiologists to produce affordable custom-fit devices at scale.

Silicone ear molds can be 3D printed to produce custom-fit ear devices.

Guide to Rapid Tooling

In this white paper, learn how to combine rapid tooling with traditional manufacturing processes like injection molding, thermoforming, or casting.

Robotics and Automation

Robotics and automation are the hallmarks of the third industrial revolution. The next generation of robots is practical for applications well beyond traditional strongholds like the automotive industry and they have an important place in many mass customization workflows.

Advancements in computer vision, sensor technology, embedded processors, and artificial intelligence are making robots better at gripping irregular objects, navigating crowded industrial environments, and interacting with human workers.

While conventional industrial robots are isolated on the factory floor with cages, barriers, or safety enclosures, and are programmed to avoid contact with humans, collaborative robots promise to reshape automated factories, allowing for much more interaction between robots and humans.

Robots at every level are becoming easier to program, so companies don’t always need to depend on costly integrators. This makes industrial automation accessible to smaller manufacturers and those that need flexible production environments, which is essential for customization.

Connected factory assets, such as robots, sensors, and assembly stations, can also now be integrated through data platforms to inform not only day-to-day operations, but every stage of the product lifecycle, from ideation, design, and engineering, through distribution, sales, and service. This is essential for mass customization as job and part tracking are more complex and error-prone when every part is different.

Collaborative robots can work alongside humans and are easier to program for flexible production environments like mass customization.

Mass Customization Workflows

As we already saw in the previous examples, mass customization workflows are incredibly diverse, mixing and matching innovative technologies and combining them with traditional tools and processes.

Here’s a high-level overview of the most common steps:

1. Design

Provide configuration options to customers, create a customizable design in CAD, or create a custom-fit design based on a 3D scan of an existing model, an MRI scan, or an intraoral scan.

2. Manufacture

Produce end-use parts directly with 3D printing or utilize 3D printed rapid tooling with your traditional manufacturing methods. Post-processing and finishing can add additional personalization options and enable longer-lasting products.

Forget about the design restrictions of traditional processes—custom parts and complex designs can be produced with 3D printing in a cost-efficient manner.

3. Assemble

Use the customized part as a component or sub-assembly in manufacturing, or as an individual product, just as you'd use a part produced with traditional tools.

Combine the custom part with off-the-shelf components to keep costs at bay and leverage robotics and automation tools to improve the efficiency of production.

4. Scale Up and Be Agile

Scale up as the demand grows without excessive equipment costs, diversify your operations, and answer to the market and your customers faster than your competition without needing to invest in costly tooling changes.

Leverage customization and new direct-to-customer business models to increase margins and build a stronger relationship with your customers.

Get Started With Mass Customization

The market for customized products and services is undergoing continuous growth. Businesses that understand and embrace new business models will thrive, while those that don’t risk being left behind.

Have an idea for leveraging mass customization at your business, but don’t know where to start? Get in touch with a Formlabs Solution Specialist to discuss how you can piece together an ideal workflow ensuring a smooth transition into mass customization.