Food-safe powder for selective laser sintering (SLS) 3D printing. Implant grade polymers for stereolithography (SLA) 3D printing. What do these materials all have in common? They were developed on Formlabs printers with Open Material Mode (OMM).

In October 2024, Formlabs announced that we are open with the release of OMM, which gives expert users the ability to print with any 405 nm photopolymer resin or 1064 nm powder on Formlabs 3D printers. Since then, hundreds of companies have purchased and used OMM to unlock their printing capabilities including research organizations, material manufacturers, and companies looking to unlock new applications.

The heater, mixer, and level sense of Form 4 Series 3D printers combined with OMM give material developers the tools they need to create novel materials. In combination with the 10 new parameters we’ve added since initial release, Formlabs printers are an optimal platform for cutting-edge material development.

Three companies, Henkel Corporation, Poly-Med, and Fabulous, have developed novel materials using OMM, revolutionizing just what it’s possible to print.

Talk to Our Sales Team

Whether you need to prototype at speed, or are producing end-use parts, we’re here to help. The Formlabs Sales team is composed of dedicated specialists who know exactly how to support you and your company's needs.

How Henkel Brings Loctite® 3D Resins to Form 4 With Custom Print Settings

“Formlabs has built an ecosystem that makes resin printing easy and accessible. With strong customer demand from their user base, it was a natural choice to validate Loctite® 3D resins on the Form 4. Today, more than a dozen of our materials are qualified, giving users reliable workflows from start to finish.”

Andrew Baggen, Head of Business Development – North America 3D Printing, Henkel Corporation

(Image: Henkel)

Henkel Corporation produces Loctite® 3D printing resins, designed for a wide range of end-use applications. OMM makes it faster and easier for Henkel Corporation to develop Form 4 settings for their resins, which, in turn, enables more customers to print with Loctite® 3D Resins. Using OMM, they were able to quickly release settings for more than 12 of their resins including tough, heat-resistant, and elastomeric materials.

With OMM, Henkel Corporation could use Print Settings Editor to develop the optimal print settings for each resin on Form 4, as well as post-processing workflows. Each setting requires end-to-end validation from printing through post-processing in order to guarantee consistent mechanical performance, dimensional accuracy, and surface quality.

“Open Material Mode gives us the flexibility to optimize print settings directly, which speeds up profile development and validation. It allows us to fine-tune mechanical performance, dimensional accuracy, and surface quality so customers can get the best out of Loctite® resins.”

Dr. Daniel Rothfuss, Head of Product Development and Application Engineering 3D Printing, Henkel Corporation

The high exposure power of Form 4 enabled Henkel Corporation to develop settings for resins that often can only be printed on industrial 405 nm 3D printers, giving their customers a greater variety of choice. With OMM on Form 4, these high-performance resins are more accessible. Baggen added, “We’re already seeing innovative applications with customers like Air Down Gear Up and Forerunner 3D, who are using Loctite® 3D resins to produce functional end-use parts.”

Printing Implant Grade Polymers in High-Precision Geometries at Poly-Med

Poly-Med, Inc., a contract development and manufacturing organization (CDMO), develops biomaterials including Photoset® 023 resin, a material designed for non-loading bearing and low modulus requiring applications. Aaron Vaughn, Ph.D., Manager of Material Science and Technology at Poly-Med, uses OMM on Formlabs SLA 3D printers in the development of biomaterials. Currently, he and the Poly-Med team are nearing the end of a feasibility project for a novel resorbable medical device, a 3D printed, lattice-based implantable medical device that can be used for production of customized soft-tissue grafts, wound matrices, and burn matrices.

An example of Poly-Med’s Photoset® 023 resin as printed on Formlabs 3D printers. (Image: Poly-Med)

In the development of this resin, Poly-Med utilized OMM on both Form 3 and Form 4 3D printers. In particular, the heater, squish and lift capabilities, and mixer speed control of Form 4 were important features for development.

“In developing materials for bioresorbable applications, we wanted to exclude solvents and reactive monomers which are typically used to reduce the viscosity of a resin. The printer heater became a critical printer feature in enabling our biocompatible resorbable resins to be printed without these chemicals. In addition to the heater, we wanted the printer to include a wiper that could serve to mix any additives that we included in the resin.”

Aaron Vaughn, Ph.D., Manager of Material Science and Technology, Poly-Med

With the control of PreForm’s Print Settings Editor, Vaughn could control exposure, layer height, heating, layer thickness, XYZ correction factors, and more, developing the precise settings needed for printing.

Since we last spoke with Poly-Med, Vaughn says, “we have purchased two Form 4 printers to meet the demand of our current printing projects. These two Form 4 printers have expedited our process and product development work.”

Unlocking Food Safety With Fabulous’s Food Safe SLS Powder

“OMM and the Fuse 1+ 30W transformed our approach to material development. Thanks to this open platform, we validated DETECT in record time and provided our customers with a reliable industrial solution — without the constraints of traditional systems.”

Arnault Coulet, CEO and Founder, Fabulous

Fabulous, a company that specializes in high-end materials for SLS, designed and validated their PA11 DETECT powder on Fuse 1+ 30W. The company FABULOUS is renowned for being the first to develop patented materials compliant with food contact regulations for powder bed technologies. These materials also feature detection functionalities essential for safety in food and pharmaceutical production lines: optical detection with a blue safety indicator within the material’s mass and metal detection using a composite polymer magnetite material. The DETECT material is developed from bio-based PA11, granting the highest food contact certifications. The accessibility of the Fuse Series ecosystem made it possible for Fabulous to validate a specialized material like DETECT without resorting to expensive high-end SLS systems.

DETECT sample illustrating food industry safety requirements: blue optical detection combined with magnetizable metal detection.

In validating their powder, Fabulous has achieved isotropic mechanical properties for the material. Additionally, thanks to OMM and the Fuse ecosystem’s reliability, Fabulous confirmed DETECT with EU 1935-2004 / 10-2011 and FDA CFR 21 migration tests on parts printed directly from the Fuse 1+ 30W.

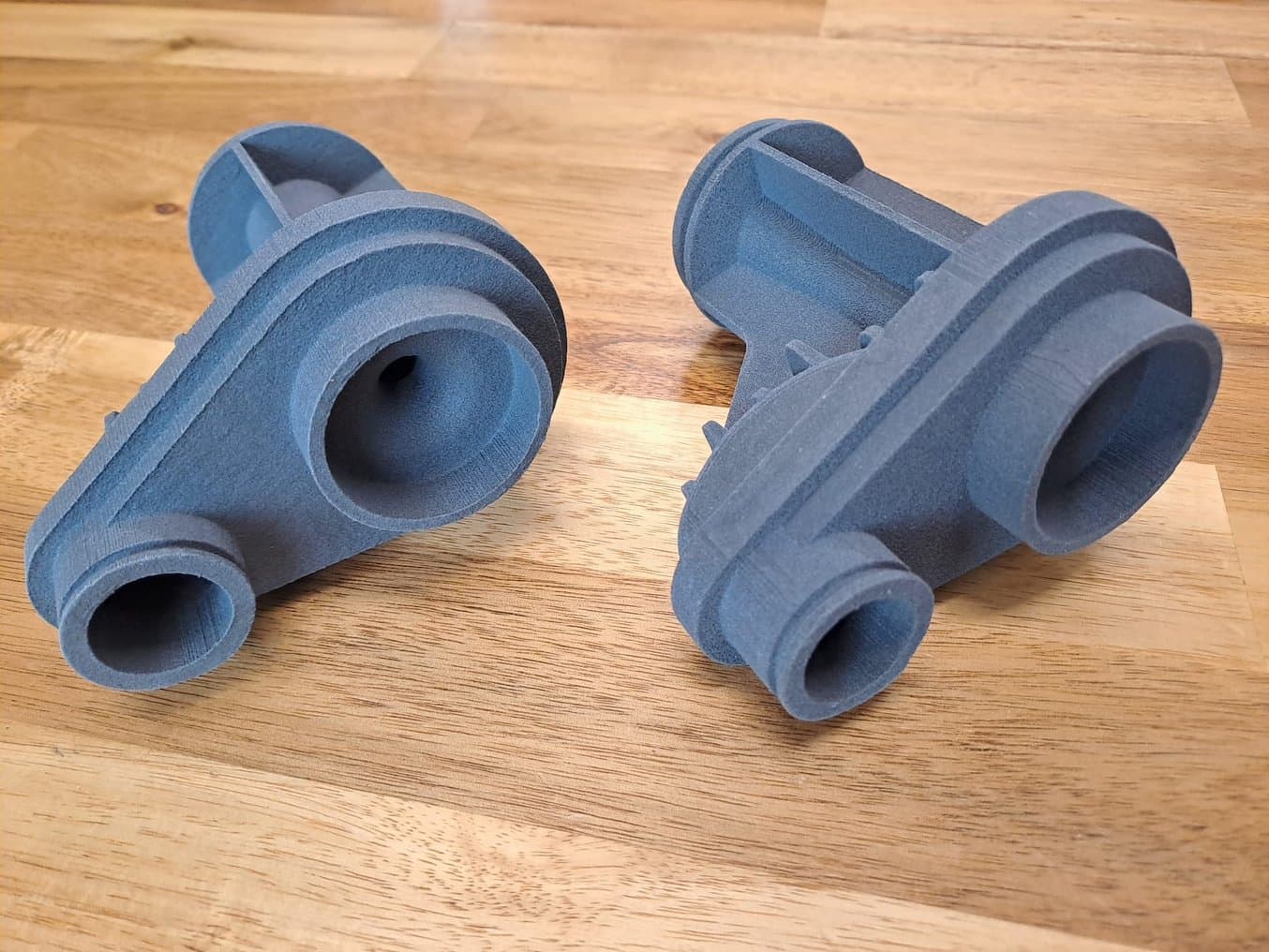

The Ice Extruder printed in DETECT on Fuse 1+ 30W, is now used in production, replacing traditional machined and molded parts. This part showcases the surface finish, geometric complexity, and industrial applicability to food and pharma industries. (Image: Fabulous)

Fabulous provides a ready-to-use FPS file that can be uploaded to PreForm. Additionally, a detailed user guide for printing DETECT on the Fuse 1+ 30W is also available and includes recommended settings and post-processing protocols.

A parter before Fuse Blast (at left) and after (at right). (Image: Fabulous)

Fuse Blast is a fully automated cleaning and polishing solution to achieve parts with a semi-gloss surface finish. (Image: Fabulous)

Printing DETECT on Fuse 1+ 30W makes printing food-safe parts more accessible, overcoming the high costs of industrial SLS systems and the long lead times associated with outsourcing.

Join Formlabs

Do you want to help equip every designer, engineer, researcher, artist, and healthcare professional in the world with high-quality, in-house production?

The Tools To Make Anything

From food-safe powders to bioresorbable resins, OMM on Formlabs printers is giving researchers on the cutting-edge of materials science access to the tools they need to push the boundaries of what it’s possible to print.

While OMM and Print Settings Editor are unparalleled tools for tuning printing processes, they can be difficult to navigate. For those exploring OMM, resources are available. A forum page dedicated to sharing FPS files is available here. Additionally, the following resources are available for SLA and SLS 3D printing.

SLA

SLS

To start pushing the boundaries of what it’s possible to print, or to use third-party materials, get OMM. Or learn more about Formlabs 3D printers to see how our technology can empower your research and development.