Working for yourself and making a profit from a passion project aren’t guarantees for anyone, much less those just thinking about entering the workforce. But for brothers Renfield and Arren Cudal, the dream has become a highly profitable reality in just a few years.

By bringing manufacturing in-house and creating an agile, on-demand workflow with Fuse Series selective laser sintering (SLS) 3D printers, Renfield and Arren have gone far beyond just getting a product to market. In just three years, they’ve built a catalog of over 2,500 unique SKUs and bootstrapped their business, Tapp Airsoft, from the ground up.

“The Fuse is one of the best investments for small businesses, one of the crucial elements to being a US manufacturer in a growing industry. Before technology like this, you had to think about tooling, injection molding from China. Now, for us, we can just think about development and how to create new products.”

Arren Cudal, Co-Founder, Owner, Tapp Airsoft

Request a Free Nylon Powder Sample Part

Formlabs offers seven SLS powders with a range of mechanical and visual properties. Choose a free sample printed on the Fuse 1+ 30W to see them for yourself.

Business Majors With a Better Plan

While in college studying for a business degree, the Cudal brothers were spending their free time playing airsoft, a team-based game where players use plastic projectiles to eliminate their opponents, much like paintball, but without the messy cleanup. There are two types of airsoft replicas — those powered by an electric motor to expel the BBs and those that use pressurized gas, which are typically more expensive but make the game more exciting due to the increased recoil and live-action feel.

“When we got our first gas-powered platform, it immediately ran out of ammo and interrupted the game,” says Renfield. In facing that one inefficiency, Tapp Airsoft was born. Though they didn’t have an engineering background, they were able to create their own adaptor by connecting a paintball gas canister to a 2,000-round drum magazine, and immediately saw the difference. You could play for much longer without having to reload, making the game more fun and streamlining the whole experience. Their adapter didn’t start out as sophisticated tech, but the process showed Renfield and Arren how they could go from idea to solution under their own steam. “We literally used a hacksaw to cut magazines in half, then epoxy-glued everything together. But then we started modeling things in CAD, figuring out how to 3D print parts, and we went from there,” says Renfield.

Airsoft Means Air-Tight: The Pitfalls of Prototyping

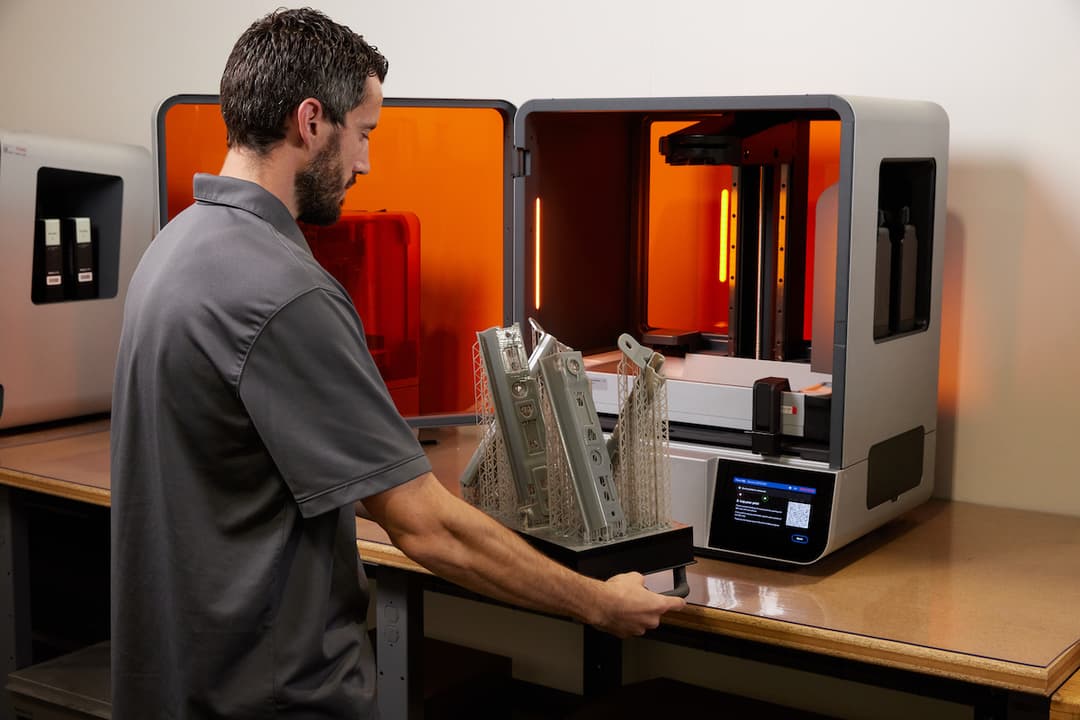

After starting off with hacksawed prototypes, bringing the Fuse Series printer in-house enabled the development of a sophisticated solution like this SLS 3D printed part in Nylon 11 CF Powder.

With hundreds of different attachments and OEM models possible, Tapp needs a manufacturing solution that can move quickly and produce end-use parts without the overhead and long timelines of traditional tooling.

After immediately loving their new, 2,000-rounds-at-a-time experiences, Arren and Renfield got to work learning how to make more parts, without the hacksaw and glue. “We were playing airsoft and we knew we wanted to get these without having to carve or drill them out of wood. 3D printing is the simplest way to get a physical part. We started with Autodesk Inventor, and then when we switched to Autodesk Fusion, it was like going from Hot Wheels to an actual car,” says Arren.

They started out with just one design, the lower half of the magazine that could hold and power more rounds, with the customer having to attach and combine it with their current magazine. After first getting parts printed on fused deposition modeling (FDM) 3D printers, they started outsourcing to powder bed fusion technology printers. “The FDM parts just couldn’t stand up to the conditions and tolerances we needed, and they weren’t airtight, so the pressurized gas could leak out,” says Renfield.

In 2017, they put a reservation down for a Fuse 1 to bring their production in-house, but quickly canceled, needing all their available funds to purchase more magazines so they could make the bottom half adaptors. Working with 3D printing service bureau Jawstec, Tapp was placing huge orders and worked out a tiered bulk pricing model, enabling them to keep inventory constantly turning over and customers happy.

Manufacturing in Palm Beach

In just 1,000 square feet of manufacturing space, Tapp Airsoft started producing thousands of individual SKUs in end-use carbon fiber-reinforced nylon powder.

Keeping a stocked inventory is easier said than done with so many unique SKUs, but Tapp's customer service record is proof that it can be done by a small team: customers can receive an update or replacement part in just 48 hours, typically.

After a couple of years of successfully working in that model, though, a design change necessitated a change in their manufacturing workflow. “We took and combined the top and bottom parts of the magazine so it’s all one piece. We’re 3D printing the whole thing but offering multiple models, and that’s what gives it the modularity,” says Arren.

With the number of unique models necessary to provide a solution to a large part of the market, Tapp would have to offer hundreds, if not thousands, of unique SKUs. Very quickly, outsourcing became a bottleneck. “The reason we got the printer in-house was this new invention, where we could print the whole magazine,” says Renfield.

Tapp figured out a design to hold all the air inside the fully 3D printed magazine and adapter, printing it as a single unit with slightly altered designs for the thousands of different platform setups out there. “We realized, now that we’re printing this whole thing instead of buying the OEM part to mate to, we needed to change,” says Arren.

Though printing on industrial multi jet fusion (MJF) or legacy SLS machines through a service bureau can be cost-efficient, with a minimum $300,000 price tag and the infrastructure demands of those printers, Tapp needed an alternative solution. They had purchased a house in West Palm Beach, where they grew up, before 2020, and were working out of a 1,000 square foot space, growing from a hundred SKUs to nearly 2,500 in a short time. Their in-house manufacturing solution needed to be compact, fast, capable of high-volume printing, and easy to maintain.

“When we first got the Fuse, it was a complete game-changer. We could get parts the same day.”

Renfield Cudal, Co-Founder and Owner, Tapp Airsoft

Insane Customer Service, Powered by Fuse

With their prototyping and production system all in one workflow and at their fingertips, and a lower cost per part, Tapp was able to quickly expand their offerings. When a customer reaches out with a new model or a customization feature, Tapp is able to respond immediately and deliver a working prototype within days. “We can make anything that we can scan. With the Fuse, we can make all current and future products. Our product catalog grew by 10x within a year of having the Fuse,” says Renfield. They’ll purchase or get a scan of the model in question, reverse engineer an assembly and magazine, and then print out a prototype in under 24 hours.

“We have the flexibility to make one product on demand, and then change it by one millimeter for someone else, and ship it to them in three days. They’ll tell us, ‘this is insane customer service,’ and well, it’s because we have an insane back-end.”

Arren Cudal, Co-Founder, Owner, Tapp Airsoft

New Fuse Series updates helped them push the limits even further. Though they were considering adding another printer when their demand grew exponentially, a PreForm update that optimized speed settings completely negated the need. “With that speed update, we were able to print full builds overnight and have them cooled and ready to go in the morning. We didn’t even need another build chamber,” says Renfield.

The Preform 3.46 update went a step beyond with the ‘Add to Running Job’ feature. Tapp can start a job earlier in the day, and throughout the day, as new orders come in, they’ll add them to the printing build chamber, ensuring that they’ll be ready to go in the morning for post-processing.

Having the Fuse Series in-house enables Tapp to respond to customer feedback immediately, often answering a forum question or customer service email with a new, updated product within days.

With constant production and the continuous up-time of their printer, Tapp is operating as a completely on-demand manufacturing system. “We’re able to keep all of our ‘stock’ in powder form. We don’t have to commit to anything or keep track of inventory. We don’t have to print extras of anything. As soon as we make a new part, we put it in a bin. When someone buys that one, the bin is empty, and we print one to refill it,” says Arren. With the Fuse Series in-house, Tapp can always offer the latest version. Small updates and tolerance changes could be the breaking point for most aftermarket manufacturers, but with SLS in-house, Tapp can adapt and react to OEM changes on the same day they’re released.

This print-as-they-sell approach has enabled the Cudal brothers to stay incredibly lean while offering over 2,500 unique SKUs. They eliminated their inventory tracking software, they have one other employee who works as a CNC machinist, and yet they’re manufacturing at a scale that typically requires a plant and teams of workers. Looking forward, Tapp is excited to start manufacturing other products within the airsoft industry. Because they’ve proven their business model, low-volume manufacturing with an on-demand production platform, expansion doesn’t carry any overhead or risk.

“We are 100% dependent on the Fuse. This business would not exist without it.”

Renfield Cudal, Co-Founder and Owner, Tapp Airsoft

To learn more about the Fuse Series, contact our experts. To test the end-use quality of Nylon 11 CF Powder for yourself, request a free 3D printed sample.