Accelerated Weathering Study of Formlabs SLS Powders

This white paper summarizes the results of an accelerated weathering study conducted on Formlabs Nylon 12 Powder and Nylon 12 Tough Powder, tested under ASTM D4329-21, Cycle A, using Xenon arc exposure for 1000 hours. Mechanical, visual, and dimensional properties were evaluated at 200-hour intervals to assess the materials' performance for long-term and outdoor applications. Additional low-temperature testing was performed to evaluate performance in extreme cold environments. Results show consistent mechanical stability with predictable aging behavior, making these selective laser sintering (SLS) 3D printing materials well-suited for outdoor end-use parts and tooling applications.

The results show that both powders maintain mechanical stability throughout the exposure period, with material properties after exposure retaining 90% of their original value

Accelerated Weathering Study of Formlabs SLS Powders

This white paper summarizes the results of an accelerated weathering study conducted on Formlabs Nylon 12 Powder and Nylon 12 Tough Powder, tested under ASTM D4329-21, Cycle A, using Xenon arc exposure for 1000 hours. Mechanical, visual, and dimensional properties were evaluated at 200-hour intervals to assess the materials' performance for long-term and outdoor applications. Additional low-temperature testing was performed to evaluate performance in extreme cold environments. Results show consistent mechanical stability with predictable aging behavior, making these selective laser sintering (SLS) 3D printing materials well-suited for outdoor end-use parts and tooling applications.

The results show that both powders maintain mechanical stability throughout the exposure period, with material properties after exposure retaining 90% of their original value

Introduction

Selective laser sintering (SLS) is a prominent 3D printing technology that uses a laser to sinter powdered material, building parts layer by layer. SLS is particularly valued for its ability to produce durable, functional parts with intricate designs, making it ideal for end-use applications across various industries.

As SLS 3D printing is increasingly used for end-use production, understanding the long-term performance of printed parts becomes crucial. End-use components are often subjected to harsh environmental conditions, including exposure to ultraviolet (UV) radiation, temperature fluctuations, and mechanical stress. Assessing how materials respond to these factors is essential to ensure reliability and safety.

This study evaluates the long-term environmental durability of Formlabs Nylon 12 Powder and Nylon 12 Tough Powder using accelerated weathering. The goal is to simulate prolonged exposure to UV light, heat, and moisture to assess how mechanical, visual, and dimensional properties change over time. This approach follows standard test methods used across industries, making the results comparable to conventional thermoplastics.

Book a Consultation

Get in touch with our 3D printing experts for a 1:1 consultation to find the right solution for your business, receive ROI analyses, test prints, and more.

Methodology

Accelerated Weathering

Test Standard and Procedure

The aging was performed by Applied Technical Services (ATS), a certified independent laboratory, using ASTM D4329-21, Cycle A. This standard outlines procedures for accelerated weathering of plastics using a Xenon arc light source, which simulates the full spectrum of sunlight (UV, visible, and infrared) and includes moisture cycles via water spray. This test cycle is widely recognized across the plastics and automotive industries as a validated method for predicting long-term outdoor durability. The aged samples were then tested at Formlabs by a calibrated automatic tensile tester, as well as measured and analyzed with a spectrophotometer for color changes.

Exposure parameters per ASTM D4329-21, Cycle A:

-

Typical Irradiance at 340 nm is 0.89 W/(m2.nm)

-

8-hour UV with an uninsulated black panel temperature controlled at 60 °C

-

4-hour condensation with an uninsulated black panel temperature controlled at 50 °C

Equipment

-

ATS: Ultraviolet chamber (Q-Lab), clock wall, radiometer

-

Formlabs: Labscubed Automated Tensile Tester, X-Rite Spectrophotometer

Sample Preparation

48 samples were 3D printed on Formlabs Fuse Series 3D printers, using standard ASTM Type I tensile bar geometry. 24 samples were printed with Nylon 12 Powder and 24 with Nylon 12 Tough Powder, using Formlabs’ default print settings.

To ensure consistency, all samples were printed in the same orientation and processed under identical conditions, including depowdering and media blasting. For each material, four replicates were tested per time interval. The following table summarizes the exact processing parameters:

|

Parameter |

Nylon 12 Powder |

Nylon 12 Tough Powder |

|---|---|---|

|

Powder Refresh Rate |

30% |

20% |

|

Build Packing Density |

6.5% |

6.5% |

|

Build Settings Version |

v4.1 |

v1.1 |

|

Depowdering Method |

Fuse Sift and Fuse Blast |

Fuse Sift and Fuse Blast |

|

Blast Time |

20 min |

20 min |

|

Blast Pressure |

60 psi |

60 psi |

Measured Properties

Mechanical Testing:

Mechanical properties were tested at six intervals: 0, 200, 400, 600, 800, and 1000 hours of exposure. Four samples of each powder were removed at each interval. Each test measured the following properties, with all parts printed in the X direction in the same build from the same batch of powder to remove potential lot-to-lot variation:

-

Tensile Modulus (MPa): measures the material’s stiffness and how much it can resist deformation under stress.

-

Ultimate Tensile Strength (UTS) (MPa): reflects the material’s strength and measures the maximum stress a material can withstand while being stretched before it starts to break.

-

Elongation at Break (EAB) (%) (X/Y): measures the material’s ductility and how far it can stretch before it fractures.

Testing was conducted at room temperature following standard tensile protocols. An automated tensile tester was used to minimize operator error, and parts were conditioned at 25 °C, 50% relative humidity for two days prior to testing to ensure test reliability.

Visual and Spectrographic Inspection

Each sample was photographed before and after exposure to document visible changes such as yellowing or discoloration and surface texture changes. This qualitative data supplements the mechanical test results and helps determine part aesthetics over time.

The color of all of the samples was measured using an X-Rite Spectrophotometer. Color measurements are taken in a CIELAB (L*a*b*) color space, and a Delta E 2000 difference is calculated between the original printed part and the aged sample. Delta E 2000 (DE00) is the most advanced mathematical approximation of color difference, providing a very close approximation of what the human eye can perceive. Generally, a DE00 of 1 is the limit of color difference perceptible by the human eye.

Dimensional Properties

Dimensional changes were measured without any specific standard. The results are reported as percentage changes across both build directions.

Low Temperature Testing

In addition to UV weathering, low temperature performance is a key consideration for end-use applications, especially in cooled or extreme outdoor applications, i.e. spaceflight or cryogenic equipment. A separate lab performed low-temperature testing on Nylon 12 Powder to evaluate material performance in extreme cold. The testing was ISO 170250-2017 compliant, following the ASTM D638-22 standard test method. Type 1 tensile bars were conditioned for over four hours and tested at -60 °C to assess changes in mechanical behavior, following the same protocols used for room-temperature testing (crosshead speed at 0.2 inches per minute).

Results

Mechanical Properties Retention Over Time

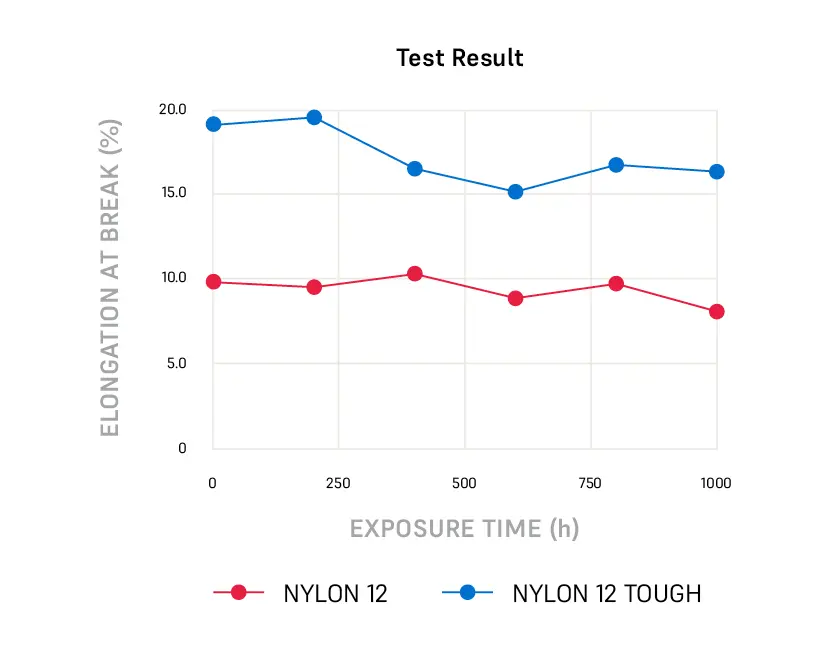

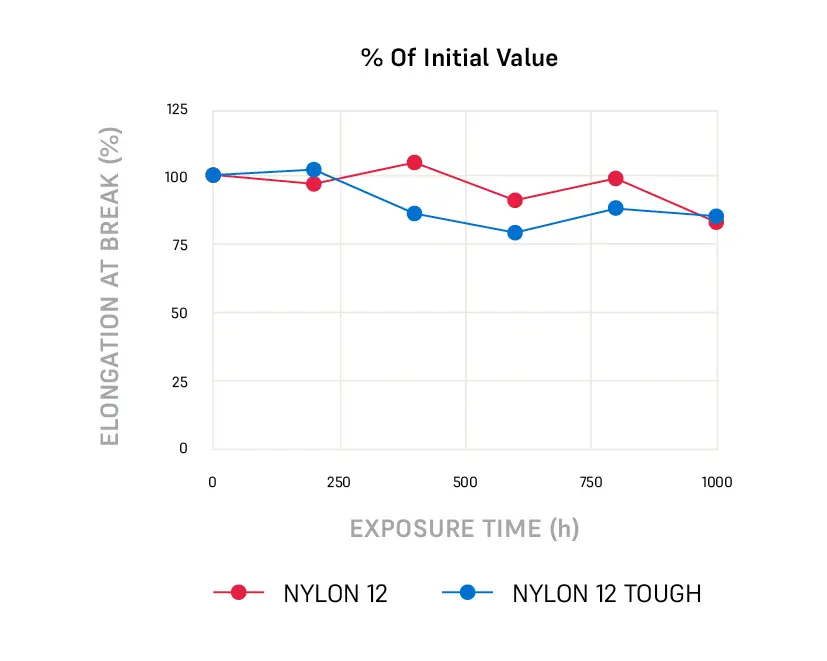

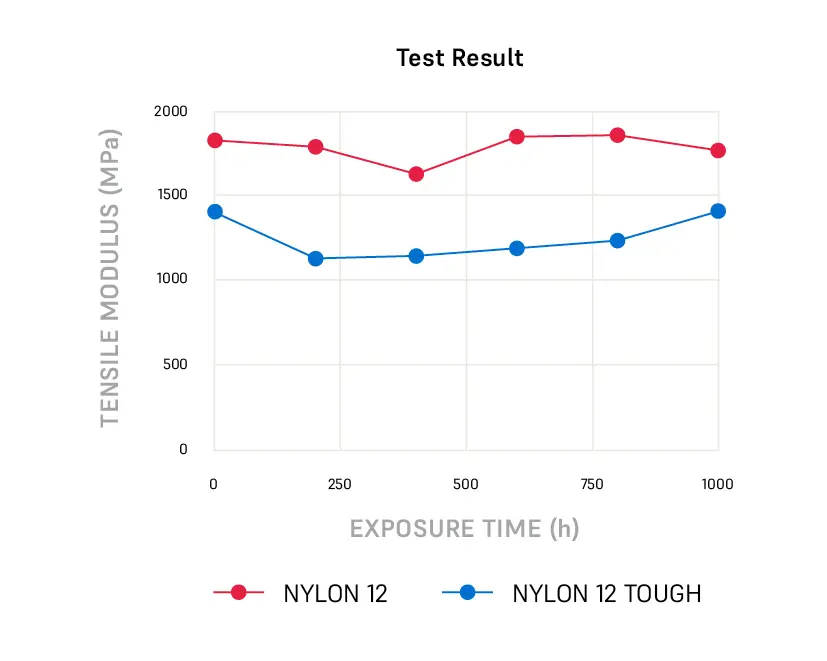

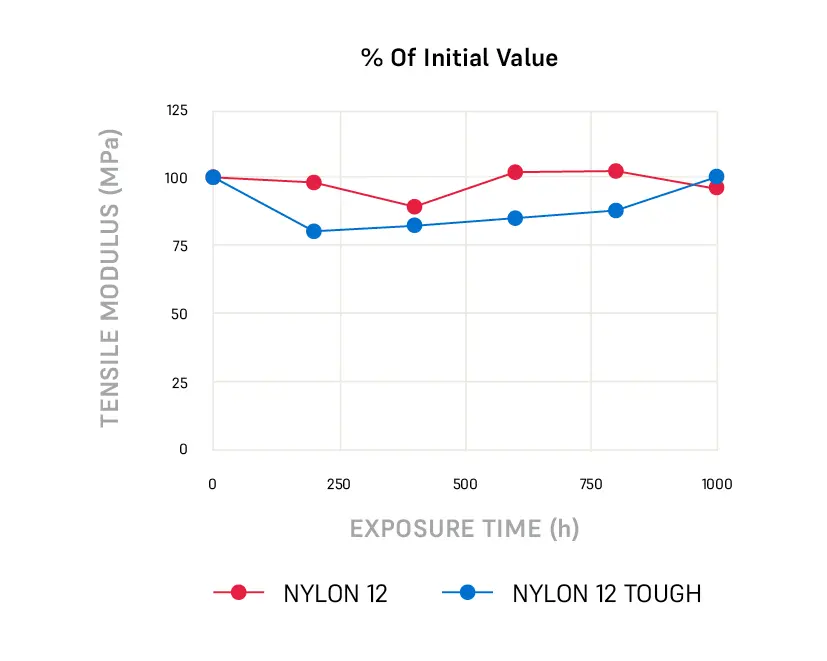

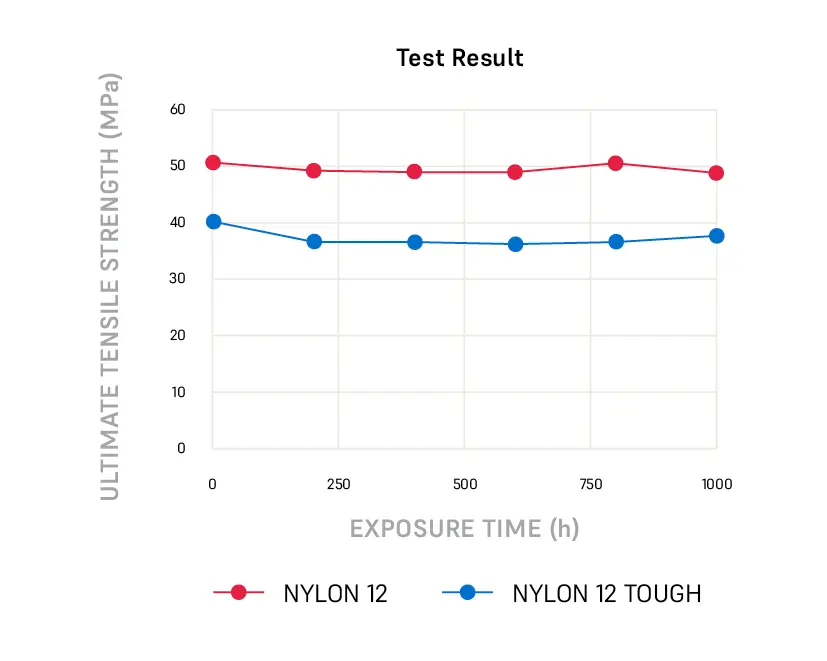

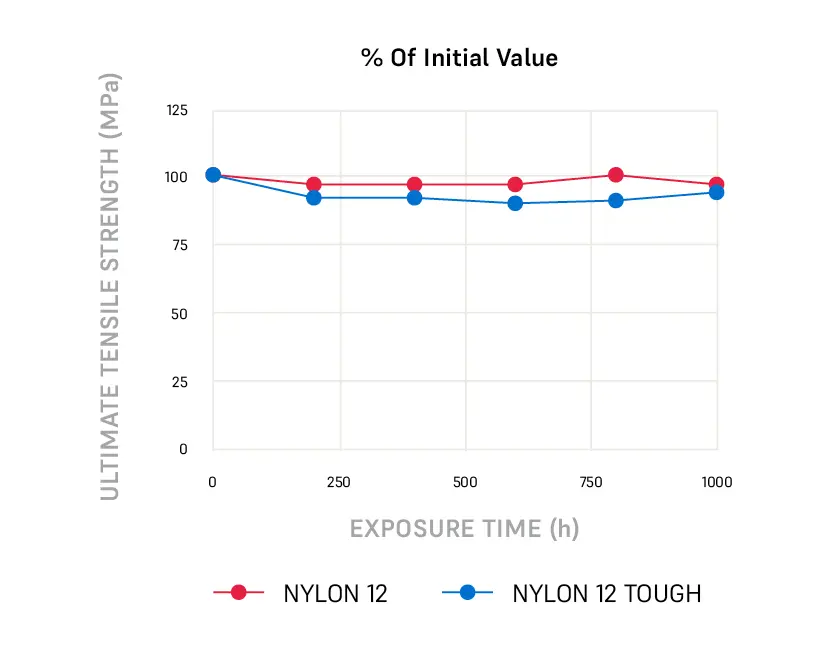

The graphs above show for each powder and measured mechanical property the normalized value (%) of the measured mechanical properties, which is the percentage of change relative to its original value.

While there is no single universal standard to define what is an acceptable property evolution under accelerated aging for all polymers, there are industry guidelines and best practices to interpret the results. According to studies of common non-3D printed thermoplastics, the industry-accepted definition of stability can typically be defined as less than 10% change in modulus and strength, and less than 20% change in elongation. This definition is also commonly adopted in the additive manufacturing industry for SLS 3D printing.

Nylon 12 Powder exhibits excellent mechanical retention throughout the 1000-hour exposure. Tensile modulus only decreases by about 4%, and ultimate tensile strength declines by only 3.3%, both of which fall within the threshold typically considered as stable (less than 10% change). Elongation at break decreases by approximately 17%, a common trend for thermoplastics exposed to prolonged UV light, but still within acceptable bounds for industrial applications.

Nylon 12 Tough Powder also performs well. Its tensile modulus initially declines but recovers by the end of the cycle, ending at just 0.5% below the original value. Ultimate tensile strength was similarly consistent with only a 6% reduction. Elongation at break drops by 14.7%, which is aligned with expectations for flexible polyamides subjected to UV exposure.

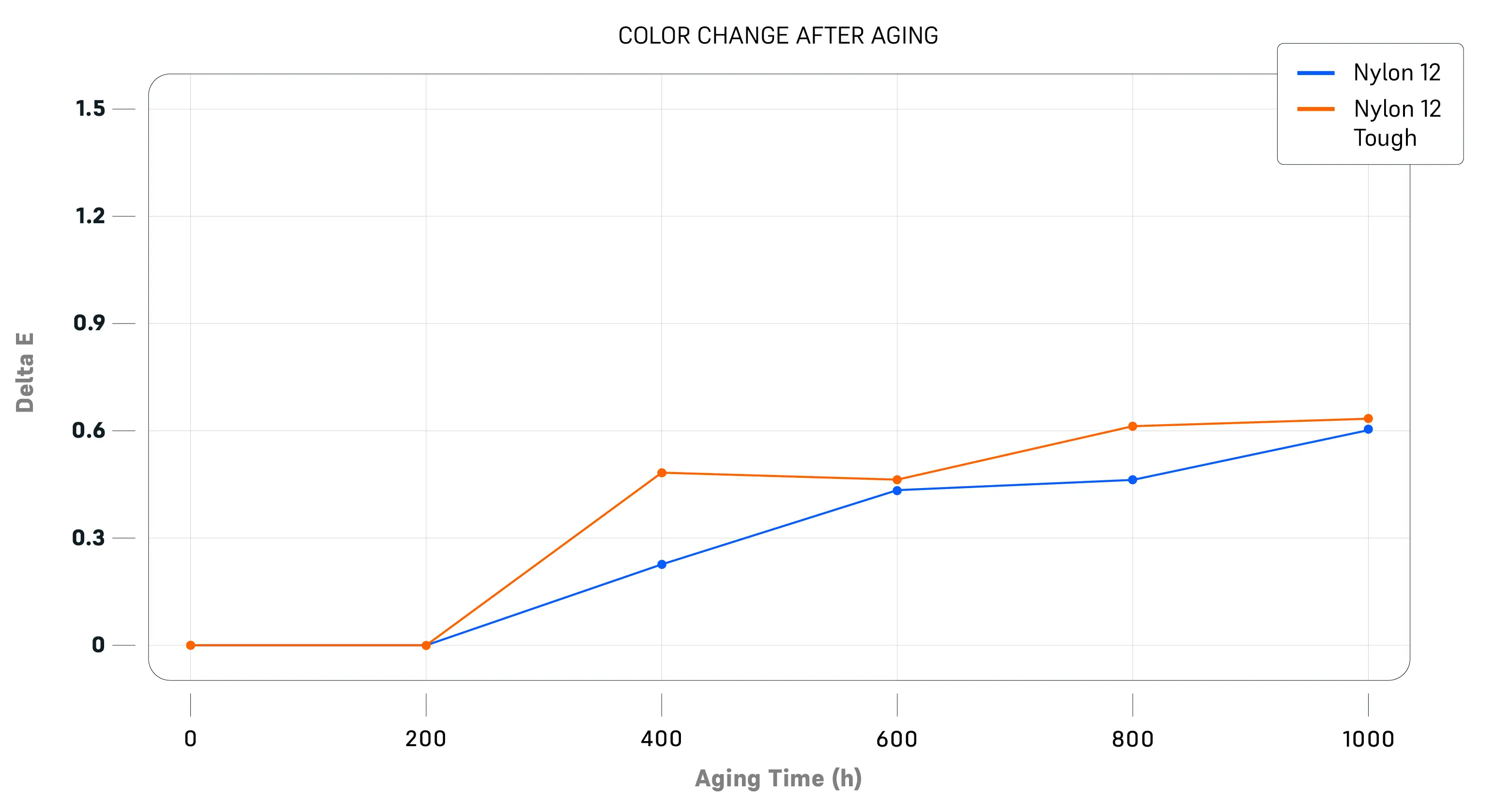

Color Changes

The graph below shows the visual evolution of each material over time. Measurements using dE00 to calculate the color shift show minimal change: 0.60 for Nylon 12 Powder and 0.63 for Nylon 12 Tough Powder. These results fall below 1.0, typically considered the threshold of perceptibility by the human eye, indicating excellent color retention over time.

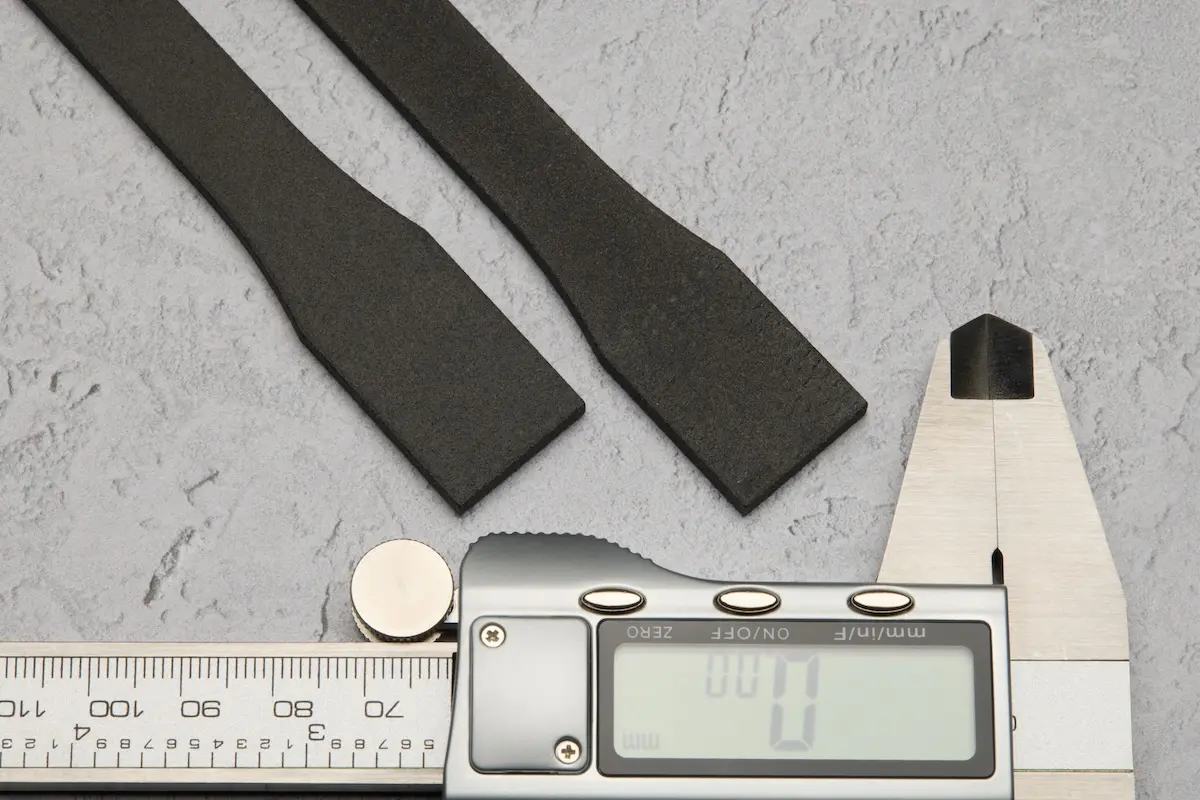

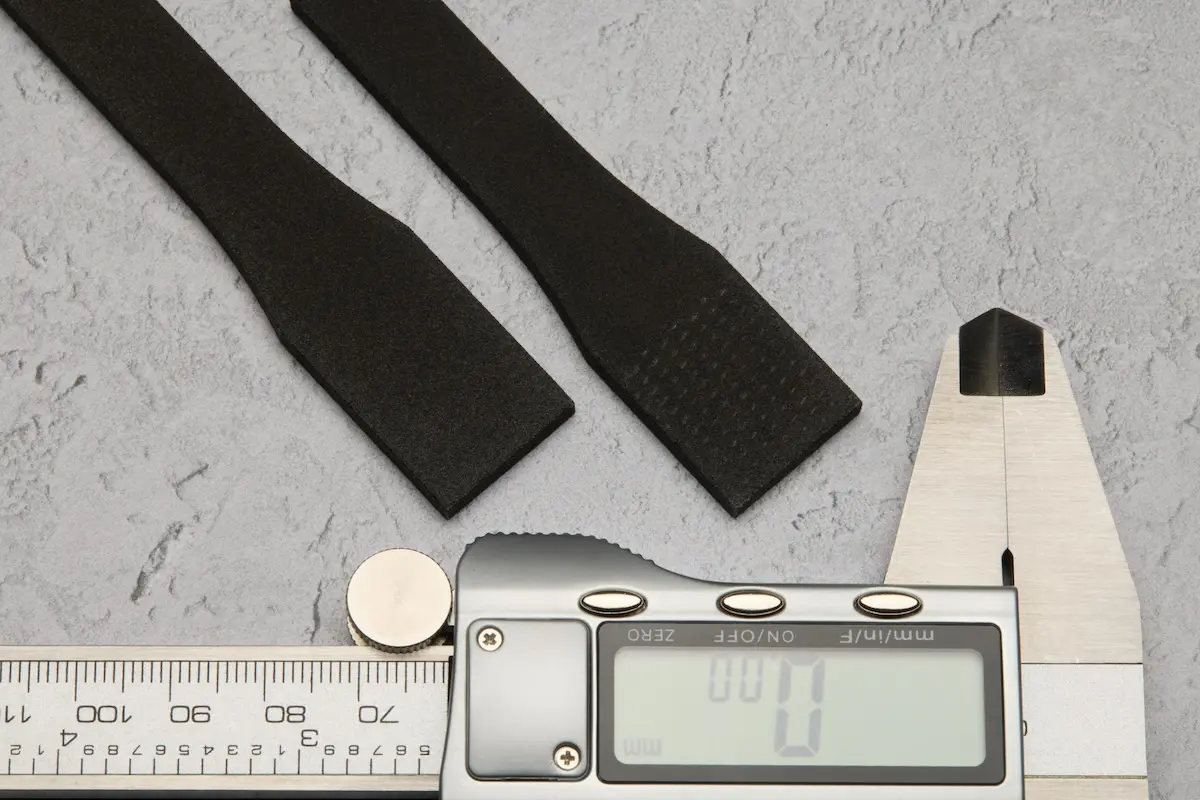

ATS photos of Nylon 12 Powder samples at 0 hour (left) and 1,000 hours (right) exposure. (Clamp marks on right-hand sample are from being held in place in the weathering chamber).

ATS photos of Nylon 12 Tough Powder samples at 0 hour (left) and 1,000 hours (right) exposure. (Clamp marks on right-hand sample are from being held in place in the weathering chamber).

Summary of the Data

The tables below summarize the results after 1,000 hours of accelerated weathering testing.

Nylon 12 Powder

| Exposure Time | 0 hrs | 1,000 hrs | Change |

|---|---|---|---|

|

Ultimate Tensile Strength |

50.8 MPa |

48.9 MPa | -3.7% |

| Tensile Modulus |

1832 MPa |

1764 MPa | -3.7% |

| Elongation at Break (X/Y) | 9.78% | 8.13% | -16.9% |

| ΔE | / | / |

0.6 |

Nylon 12 Tough Powder

| Exposure Time | 0 hrs | 1,000 hrs | Change |

|---|---|---|---|

|

Ultimate Tensile Strength |

40.5 MPa |

38 MPa |

-6.1% |

| Tensile Modulus |

1399 MPa |

1402 MPa | 0.2% |

| Elongation at Break (X/Y) | 19.2% | 16.4% | -14.7% |

| ΔE | / | / |

0.63 |

These changes are well within the industry-accepted definition of stability, typically defined as less than 10% change in modulus and strength, and less than 20% change in elongation. Both powders show excellent long-term mechanical and visual stability under Xenon arc accelerated weathering. These results suggest that both powders are suitable for outdoor and end-use applications where aging and exposure matter.

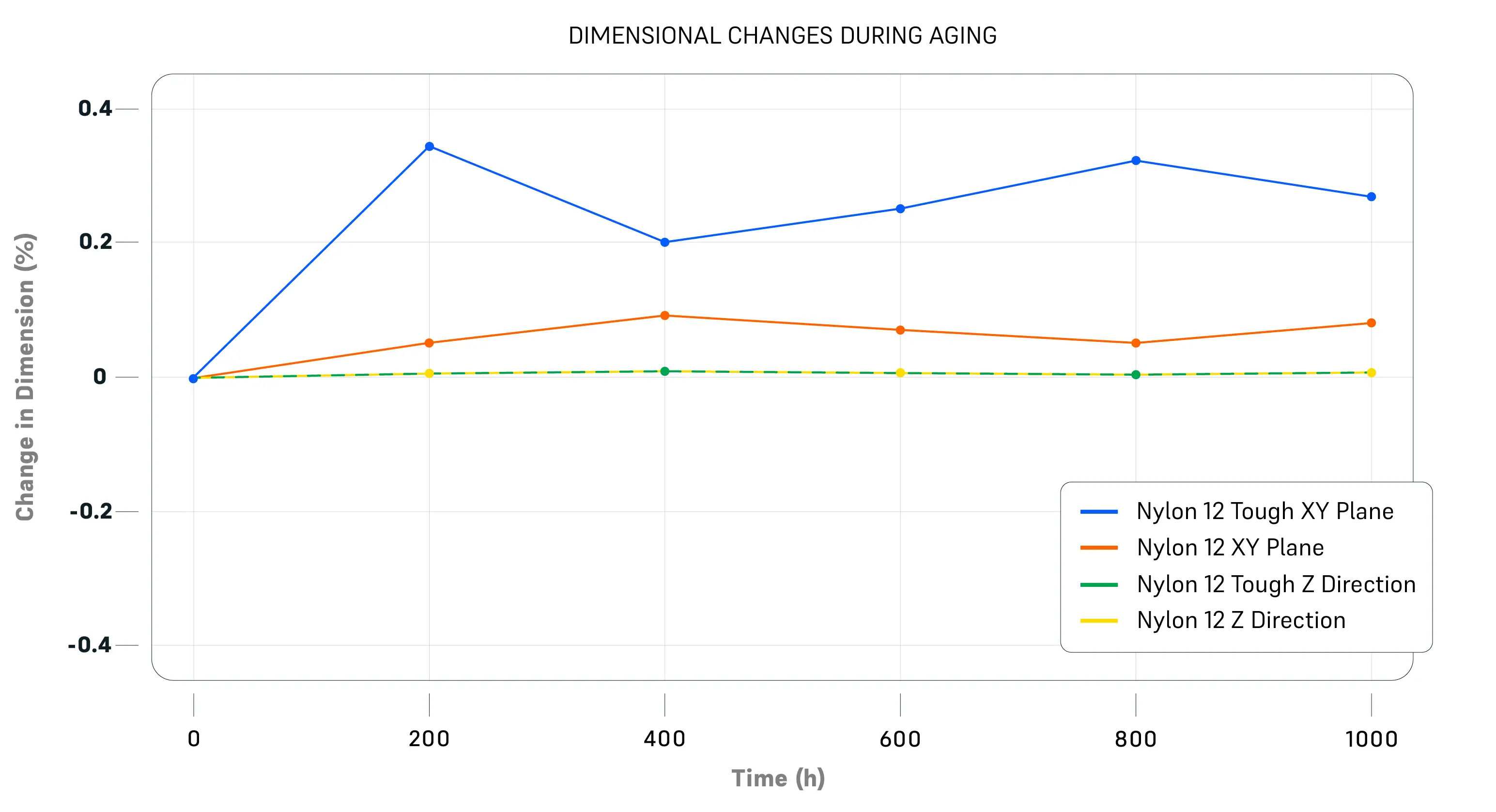

Dimensional Changes

The graph below shows the percentage of dimensional changes of the samples over time, across both powders and build directions. The results demonstrate minimal dimensional change, typically within ±0.5%, for both Nylon 12 Powder and Nylon 12 Tough Powder. This is consistent with normal variation from the printing process itself. These results indicate good dimensional stability under long-term weathering conditions.

Dimensional changes over time for each powder.

Mechanical Properties at Low Temperature

In addition to accelerated weathering, Formlabs' R&D team performed low-temperature tensile testing on Nylon 12 Powder to evaluate part behavior in extreme cold.

|

Temperature |

Room Temp | -60 °C | % Change |

|---|---|---|---|

|

Ultimate Tensile Strength |

50 MPa |

67 MPa | +34% |

|

Tensile Modulus |

1850 MPa |

2650 MPa | +43% |

| Elongation at Break | 11% |

3.4% |

-69% |

These results show higher strength and stiffness but lower ductility at sub-zero temperatures, which is consistent with typical thermoplastic behavior. This trend is expected to extend to other nylon-based SLS powders, such as Nylon 12 Tough Powder.

Request a Free Sample Part

See and feel Formlabs quality firsthand. We’ll ship a free 3D printed sample part to your office.

Conclusion

This white paper summarizes the results of an accelerated weathering study conducted on Formlabs Nylon 12 Powder and Nylon 12 Tough Powder, tested under ASTM D4329-21, Cycle A, using Xenon arc exposure for 1000 hours. This standard procedure simulates long-term exposure to sunlight and moisture. Mechanical and visual properties were evaluated to assess the materials' performance for long-term and outdoor applications.

The results show that both powders maintain mechanical stability throughout the exposure period, with material properties after exposure retaining 90% of their original value. Tensile modulus and ultimate tensile strength varied by less than 10%, a threshold commonly used in polymer aging studies to indicate stable performance. Elongation at break declined, as expected, but within an acceptable range for nylon-based thermoplastics. Color shift remained below the perceptibility threshold. Additional low-temperature testing was performed at -60 °C to evaluate performance in extreme cold environments. The results indicate an increased stiffness and reduced ductility, which is an expected behavior for common thermoplastics.

Together, these findings confirm that both powders are viable candidates for long-term, indoor and outdoors end-use applications. These powders are ideal for production parts, jigs, fixtures, housings, and tooling that require strength, stability, and visual consistency over time. Customer examples of real-world use are included in the appendix. Advanced post-processing methods like vapor smoothing and coatings can further enhance the performance of SLS parts by improving surface finish, reducing moisture absorption, and increasing durability, making them suitable for even more demanding applications.

Disclaimer: These results are based on test conditions described above. Material properties may vary with part geometry, print conditions, and temperature.

Appendix - Customer Case Studies

The results presented in this white paper show that Formlabs Nylon 12 Powder and Nylon 12 Tough Powder maintain excellent mechanical and aesthetic performance over time, even under accelerated aging conditions and extreme cold. These findings are consistent with how Formlabs customers are already using these materials in demanding, long-term applications. The following case studies illustrate how companies rely on SLS 3D printed parts for production, validating their durability with in-house or third-party testing.

Notes on Other Formlabs SLS Powders

While this white paper focuses on Nylon 12 Powder and Nylon 12 Tough Powder, it is important to note that other Formlabs SLS powders are also being tested by customers for long-term, outdoor applications. Several companies have reported successful outcomes using these materials in aging and weathering use cases, though formalized data may not yet be published.

Micromobility Charging Hubs Withstand Daily Use and Weathering

KUHMUTE designs and manufactures universal charging hubs for shared electric scooters, bikes, and wheelchairs. To scale their operations and improve design flexibility, KUHMUTE transitioned from outsourced injection molding to in-house production with the Formlabs Fuse 1 and Nylon 12 Powder. By 3D printing structural and functional components, such as parking guides, electrical enclosures, and bracketry, they reduced part costs by over 60% and accelerated product iteration cycles.

These parts are exposed to outdoor environments in cities across the U.S., where they endure rain, UV radiation, impacts, and daily mechanical use. The team reports that SLS 3D printed parts withstand real-world stressors with minimal wear, maintaining mechanical integrity and appearance over time. This aligns directly with the performance observed in Formlabs’ weathering and low-temperature tests, which demonstrated stable mechanical properties and minimal color change under UV and cold exposure.

Functional End-Use Camera Accessories in the Field

XSPECTER designs and manufactures rugged camera tripods and accessories used by photographers, filmmakers, and emergency services. To reduce tooling costs and improve design freedom, they integrated both SLA and SLS 3D printing into production, using Formlabs Nylon 12 Powder for durable end-use components that must endure impact, vibration, and weather exposure during outdoor use. Parts like custom tripod feet and modular housing units are now printed in-house, enabling faster iterations and small-batch production without compromising reliability. This field deployment reinforces the material’s mechanical stability in real-world, outdoor environments.

Field-Ready, Weather-Exposed Components for Water Utilities

Next Meters manufactures connected water meters and needed to create customized adapters for a wide range of utility installations. For low-volume variants, they used the Fuse 1 and Formlabs Nylon 11 Powder to print end-use mounting rings exposed to environmental stress.

To validate durability, they performed a three-month accelerated environmental test in a Thermotron chamber simulating 15 years of weather exposure, including heat, cold, humidity, and water immersion. Parts were also subjected to UV and rain chamber testing. The SLS 3D printed components exhibited no mechanical or aesthetic degradation during testing and are now deployed in the field.

These results directly align with the findings of this white paper’s accelerated aging tests, demonstrating that SLS materials retain both function and appearance under prolonged environmental stress. This makes them a robust solution for outdoor utility and infrastructure components.

Housing for camera tripod

XSPECTER

SLS Nylon 12 Powder

Low volume production

1500 parts per year

Adapter for power charging station

KUHMUTE

SLS Nylon 12 Powder

Custom manufacturing

Mounting ring for outdoor water meter

NextMeters

SLS Nylon 11 Powder

Custom manufacturing

250+ parts

Drone base end-use parts

Boresight

SLS Nylon 12 Powder

Low volume production

End-use impeller components

Foil Drive

SLS Nylon 12 Powder

Low-volume manufacturing

Drone functional prototypes

PMR Robotics

SLS Nylon 12 Powder

Custom manufacturing

Lateral thruster for jet boat’s pump

JetBoatPilot

SLS Nylon 12 Powder

Aftermarket parts

Air Duct for race cars

GreenTeam University of Stuttgart

SLS Nylon 12 Powder

On-Demand

UUV End-Use Components

Nakai Robotics

SLS Nylon 12 Powder

Low-volume manufacturing

300+ parts

Eyewear

Marcus Marienfeld AG

SLS Nylon 11 Powder

Custom manufacturing

Prothesis

Partial Hand Solutions

SLS Nylon 12 Powder

Custom manufacturing

Housing for a vehicle’s control system

IBL Hydronic

SLS Nylon 11 Powder

Low volume production

100-250 parts per batch

Book a Consultation

Get in touch with our 3D printing experts for a 1:1 consultation to find the right solution for your business, receive ROI analyses, test prints, and more.

Request a Free Sample Part

See and feel Formlabs quality firsthand. We’ll ship a free 3D printed sample part to your office.

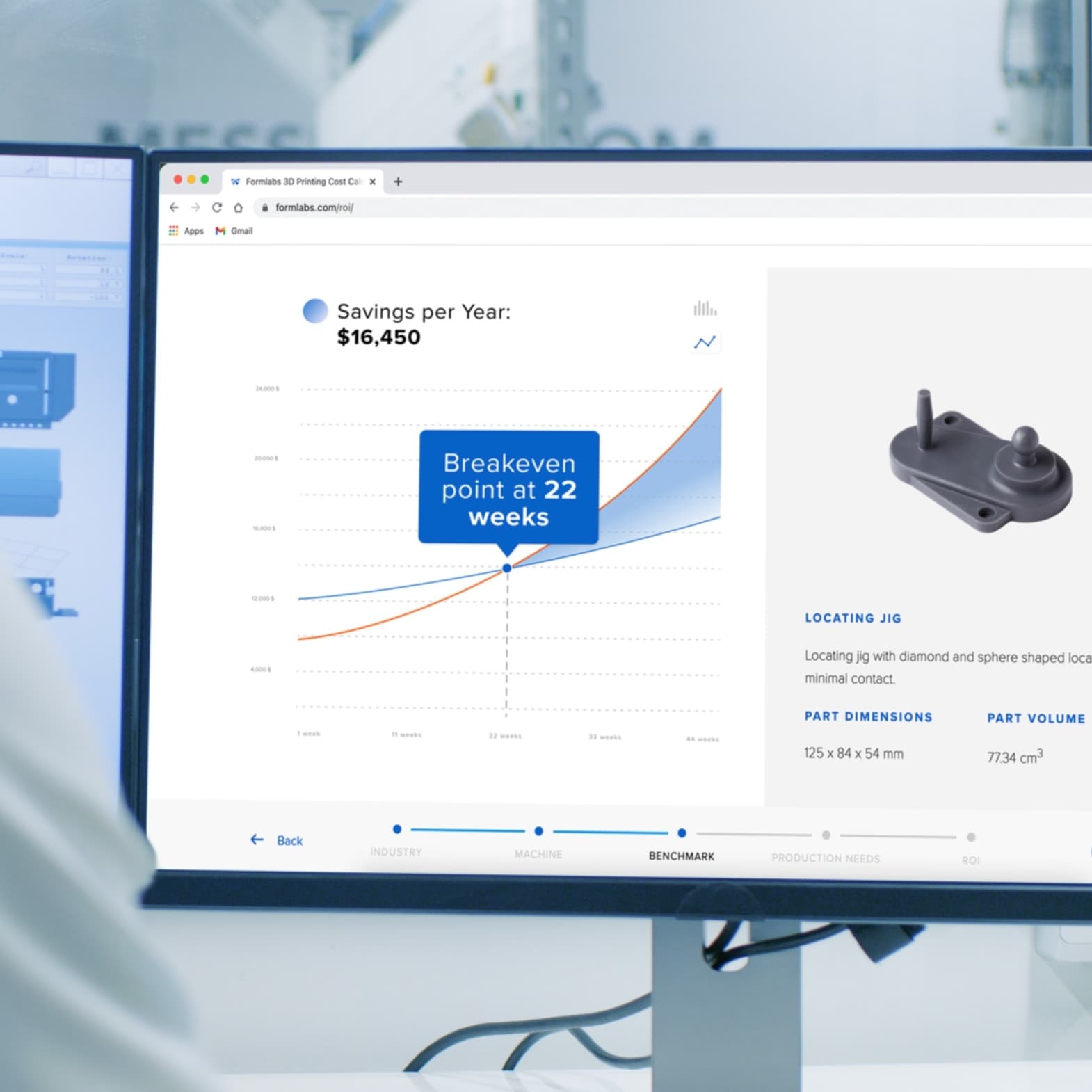

Calculate Your Time and Cost Savings

Try our interactive ROI tool to see how much time and cost you can save when 3D printing on Formlabs 3D printers.