“As soon as the Form 4L was announced, I immediately started putting the numbers together. I was able to use PreForm to start simulating the prints and saw that I could achieve a project I had just quoted 6x faster than on the Form 3L, and decided to buy two printers ASAP. The difference in cost and time is staggering — that single job paid for both of the printers in full, it was worth it from day one!”

Matthew Deutsch, Co-Founder and Head of Design, Facto Nova

Facto Nova provides comprehensive design and product engineering services to companies, including Disney, Universal, Siemens Energy, and the Department of Transportation. Matthew Deutsch, Co-Founder and Head of Design at Facto Nova, uses a range of fabrication methods for projects spanning from entertainment to engineering.

“Our bread and butter is being quick, nimble, reactive. We're able to have somebody walk in on a Monday with a problem and have a solution to it before the end of the week.”

Hanari Solomon, Fabricator, Facto Nova

Deutsch has used fused deposition modeling (FDM) as well as resin 3D printers for his work, including Form 3L. But with the release of Form 4L and updated General Purpose Resins, Deutsch realized, “The parts are going to be cheaper and faster, and the savings in time will pay for the machine in short order.”

Deutsch shares his cost-savings breakdown of Form 4L and General Purpose Resins, ultimately drawing the conclusion that “these machines were paid off the day they arrived.”

Talk to Our Sales Team

Whether you need to prototype at speed, or are producing end-use parts, we’re here to help. The Formlabs Sales team is composed of dedicated specialists who know exactly how to support you and your company's needs.

Competitive Cost Per Part With Form 4L and General Purpose Resins

“We were quoting work in PreForm using Form 4L versus the Form 3L to say, okay, this job doesn't make sense if we're using the 3L. But it makes all the sense in the world, even if we just had one Form 4L.”

Matthew Deutsch, Co-Founder and Head of Design, Facto Nova

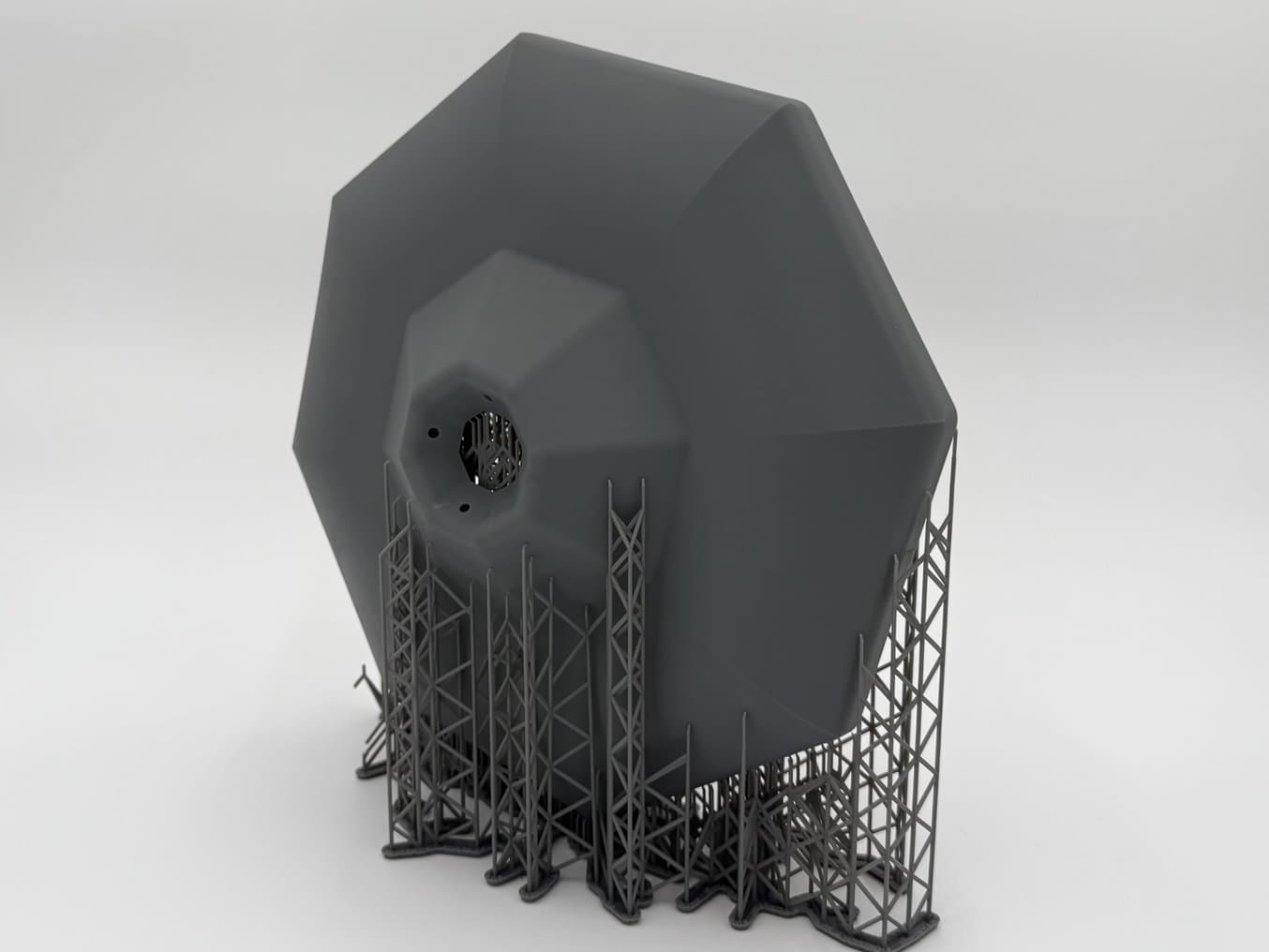

Facto Nova has done multiple projects for some of the largest theme parks. Soon after Form 4L was released, Deutsch designed a part to be assembled onto an installation to house cameras in a new theme park. When the order first arrived, Deutsch had a Form 3L. He prototyped the part on the Form 3L, but realized that with one part per build and a 29-hour print time, the cost was going to be prohibitive. He then set up the parts in PreForm, Formlabs’ print preparation software, and changed the printer to Form 4L.

“With Form 4L, we were able to fit two parts on a build plate and it printed in less than a third of the time. So, it quite literally took that project from being a non-starter — we wouldn't be able to have come in at a good price — to it being a no-brainer.”

Yousuf Abdeltawab, Fabricator, Facto Nova

This part prints in 8.5 hours on Form 4L, less than a third of the time it takes to print on Form 3L.

With Form 4L, two parts per build could be printed in eight and a half hours, for a part every four hours and 15 minutes, versus every 29 hours on Form 3L. Lower costs for Grey Resin also more than halved the cost per part.

| Number of parts per build | Resin | Print time | Time per part | Cost of materials per part | |

|---|---|---|---|---|---|

| Form 3L | 1 | Grey Resin V4 | 29 h | 29 h | $94 |

| Form 4L | 2 | Grey Resin V5 | 8.5 h | 4 h 15 min | $49* |

*Bulk resin discounts are available and can further reduce cost per part.

“The speed and the cost of material have really changed the game. Formlabs shakes up SLA in the same way that Bambu Lab is shaking up FDM, where 3D printing is rapidly becoming strictly a tool and an appliance, not a project.”

Matthew Deutsch, Co-Founder and Head of Design, Facto Nova

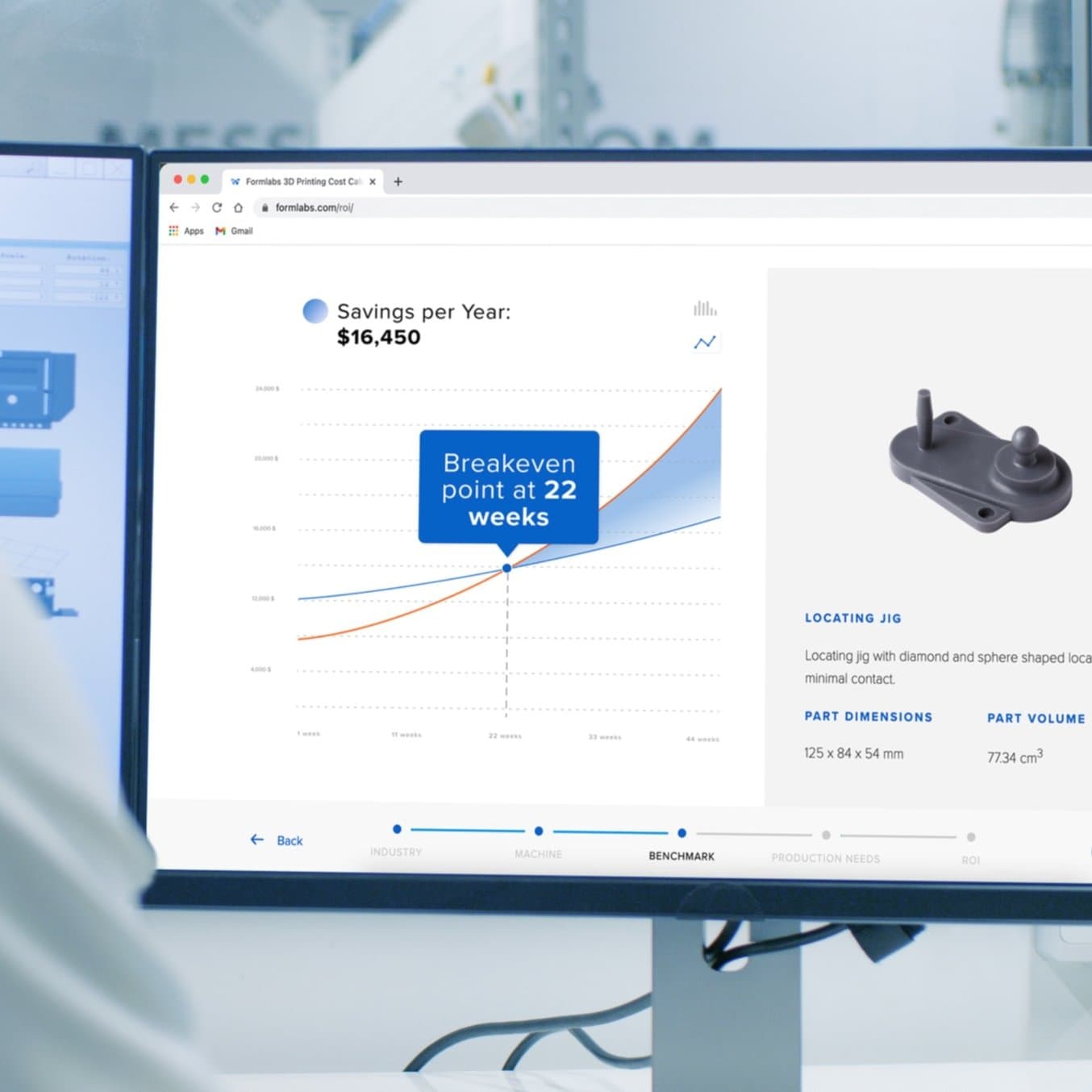

Calculate Your Time and Cost Savings

Try our interactive ROI tool to see how much time and cost you can save when 3D printing on Formlabs 3D printers.

Minimizing Post-Processing

With the release of Form 4 Series 3D printers came updates to General Purpose Resins, including Clear Resin and Grey Resin. Deutsch says, “Materials like Grey and Clear have been constant staples in our work for companies like Universal Studios.” The updates improve mechanical properties, clarity of color, and enhance aesthetics.

Among Facto Nova’s projects are animatronics that are painted with automotive paint, which require a smooth surface for application. “Surface quality and finish minimize the amount of labor that needs to be put into post-processing,” says Deutsch, “and Form 4L is a godsend for that.”

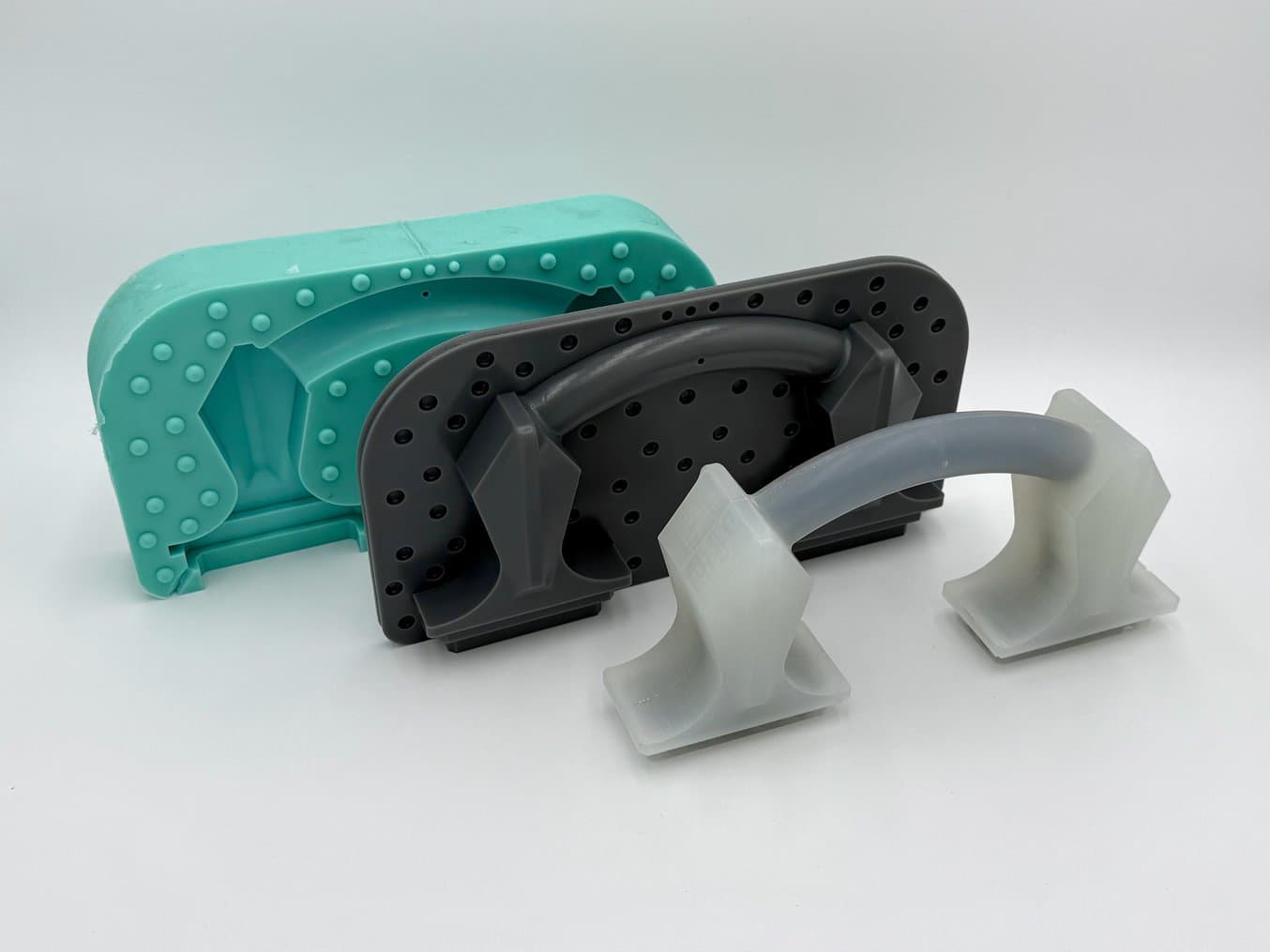

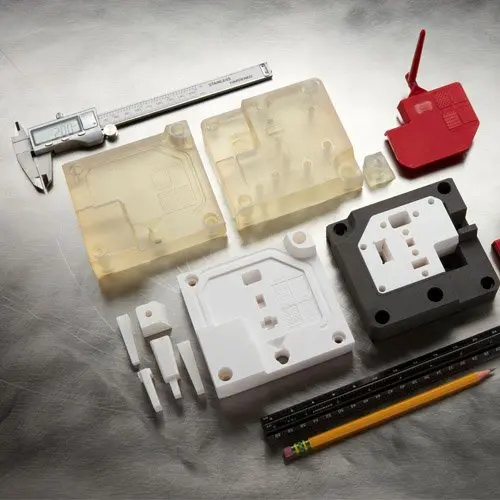

In addition to printing end-use parts, Deutsch has been 3D printing molds. For a while, he’d moved away from molds due to the workflow and results, but 3D printing molds on Form 4L “is, beyond a shadow of a doubt, easier. This is one of the best molds that I have ever made in my life. All of the surface finishes took almost no post-processing.”

Printing molds on Form 4L makes for an easier workflow and parts with a fine surface finish.

Preparing the 3D printed part.

Making the mold.

In addition to the fine finishes on parts from Form 4L, Deutsch orients parts in PreForm so that supports are on the inside or, in the case of molds, avoid placements in the areas where a part will be cast. This further minimizes post-processing and finishing time, for additional time savings.

Moldmaking with 3D Prints: Techniques for Prototyping and Production

Download our white paper to learn about six moldmaking processes that are possible with an in-house SLA 3D printer, including injection molding, vacuum forming, silicone molding, and more.

Speeding Ahead With Form 4L

Deutsch says that people often ask him which is better: FDM or SLA. “They’re not better, they’re different,” he says, “typically I'm using SLA whenever I need to do something that is higher detail or where we need to reduce the amount of labor hours we’re putting into post-processing.”

The print speed, resin costs, and print volume of Form 4L have enabled an increase in production volume.

However, the print speed and resin costs of Form 4 Series 3D printers have changed Deutsch’s decision-making process. It used to be that he’d select resin printing only if he could wait a few hours for a part and wanted it to look nice. “Now that the material is cheaper and the prints take half as much time, it's almost more convenient to do it in resin,” says Deutsch.

“Overall, I am thoroughly impressed with the Form 4L and Formlabs' direction as a whole. The machines perform beautifully and open doors to a higher volume of work than we previously had.”

Matthew Deutsch, Co-Founder and Head of Design, Facto Nova

In addition to the higher volumes of work enabled by Form 4L, Deutsch would like to add selective laser sintering (SLS) to his offerings, with the printers housed in their own area. But while Deutsch intends to expand the size and scope of Facto Nova, he says, “I want to maintain the reason why we started, which is to be quick and reactive.”

Explore Formlabs 3D printers or contact sales to learn more.