Urban air mobility (UAM) is a transportation system that moves people and cargo above cityscapes and includes helicopters, vertical-takeoff-and-landing aircraft (VTOL), and unmanned aerial vehicles (UAVs). Teranova, based in Incheon, South Korea, develops and services UAM for logistics delivery, relying on 3D printing to produce prototypes and develop advanced motor technologies.

Teranova has set its sights on delivering up to one ton of cargo via UAM vehicles by 2026, a goal that demands constant prototyping and iteration. By embracing in-house 3D printing as a critical tool, Teranova has lowered costs and decreased times.

FDM vs. SLA for 3D Printing Drone Prototypes

Initially, Teranova used fused deposition modeling (FDM) 3D printers due to their cost-effectiveness, but these printers fell short in delivering market-ready prototypes due to limitations in speed, material variety, and surface finish quality.

Teranova’s team then looked to stereolithography (SLA) 3D printers. SLA can achieve smoother finishes and tighter tolerances than FDM, as the technology uses a light source to cure liquid resin layer by layer.

While the finer finishes and improved accuracy of SLA 3D printers helped achieve higher quality prototypes, the 3D printers Teranova was using had high failure rates, which slowed timelines and wasted material.

The company needed a solution that could provide speed, part quality, and reliability at low costs. Enter Form 4.

Product Demo: Form 4

See how Form 4 can enable new levels of productivity and innovation through its unmatched speed, accuracy, and reliability.

Adding Form 4

"LFD technology has been a game-changer for us, delivering stable and reliable performance. In aircraft manufacturing, where precision is everything, it ensures error-free production every time."

Kim Ji Hwan, CTO, Teranova

Form 4 is a masked stereolithography (MSLA) 3D printer powered by a Low Force Display™ (LFD) Print Engine that turns liquid resin into printed parts at blazing fast print speeds and delivering excellent print quality and accuracy anywhere on the Build Platform.

From set up, Ternova’s team appreciated the intuitive user experience of Form 4, including the large touch screen and built-in leveling system. For printing, automated resin handling and heating speed up the print process while the mixer ensures consistent printing without adding to print time.

With Form 4, Teranova achieves precise, accurate 3D printed parts with fine details and smooth surface finishes.

"The most impressive thing about the Form 4 is its high print success rate. With the resin 3D printer we were using before, we only had about a 70% success rate. Form 4 has consistently delivered over 90%. This has reduced material waste, sped up production, and accelerated our project timelines."

Kim Ji Hwan, CTO, Teranova

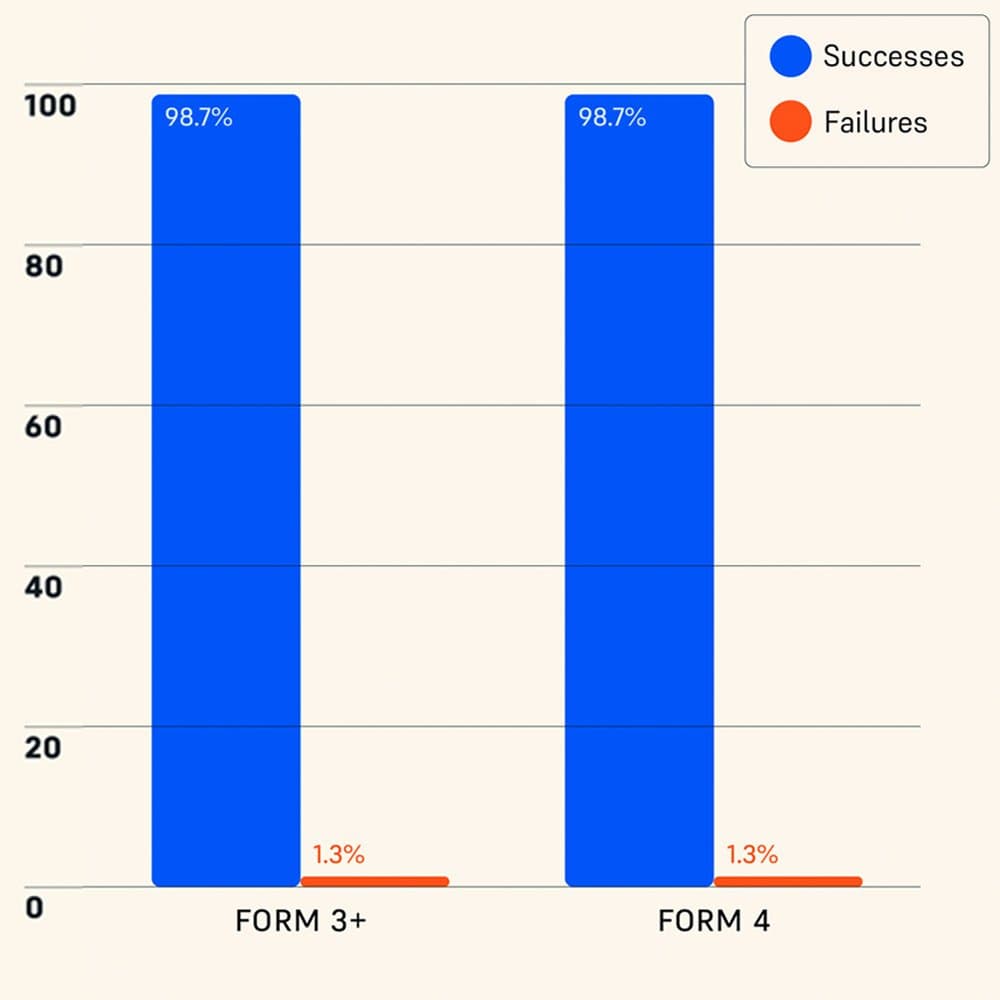

For Teranova, Form 4’s standout feature is its exceptional success rate, with the few failures largely due to user errors rather than hardware issues. Recent testing by an independent, third-party lab has shown that Form 4 delivers a print success rate of 99%. This improved reliability reduces material waste and accelerates part production, enabling faster project completion for Teranova’s team at lower costs.

Independently Tested Reliability of Form 4 and Other Resin 3D Printers

Formlabs Form 4 was measured to have a 98.7% print success rate by an independent global leader in product testing. Read a complete description of the test methodology and see the results in our white paper.

Robust, Presentation-Ready Prototypes With Formlabs Resins

Teranova’s team uses Tough 2000 Resin for printing robust, functional prototypes, and Black Resin for looks-like prototypes. Tough 2000 Resin has a similar strength and stiffness to ABS plastics, making it ideal for tough and durable functional parts that need to hold up to extended use.

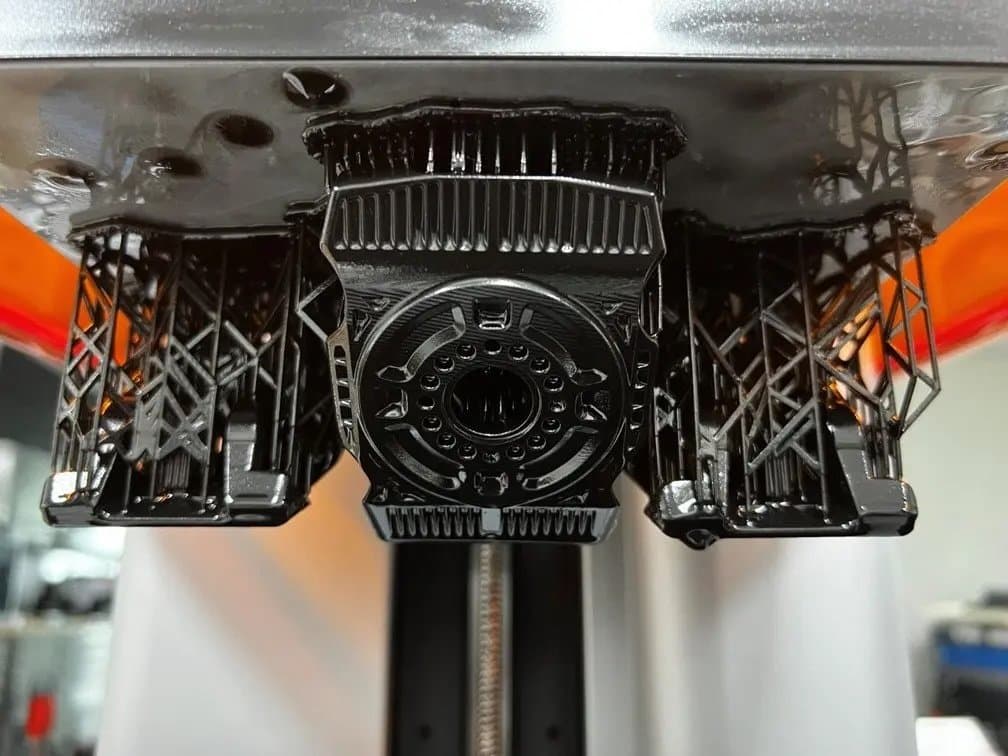

Parts printed in Black Resin on the Form 4 Build Platform before post-processing.

Black Resin utilizes the technology of Form 4, delivering fast printing and a presentation-ready appearance. With Form 4 and Black Resin, the Teranova team delivers prototypes that look like they are injection molded three times faster than with their previous FDM and SLA 3D printers.

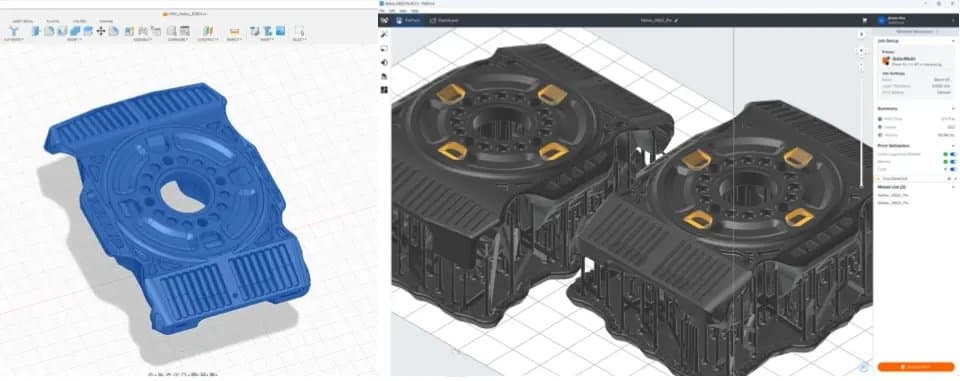

Before printing, thrust vectoring distributed electric propulsion system parts are set up using PreForm, Formlabs’ free print preparation software.

However, plans for 3D printing with Form 4 go beyond prototyping. Next, the team plans to start printing molds for production with Rigid 10K Resin.

Request a Free Sample Part

See and feel Formlabs quality firsthand. We’ll ship a free 3D printed sample part to your office.

Harnessing In-House 3D Printing for Aerospace Innovation

As a forward-thinking aerospace company, Teranova is vertically integrated, managing everything from research and development to design and manufacturing in-house. With a meticulous, step-by-step approach, the company is targeting the launch of its prototype aircraft by 2026.

The company has embraced 3D printing as a cornerstone of its production process, with in-house production enabling control over developmental timelines and decreased costs compared to outsourcing. With the print speed of Form 4, the Teranova team can print multiple prototypes a day.

Looking ahead, Teranova plans to expand its use of Formlabs ecosystems, bringing a Fuse 1+ 30W into its production line. The Fuse ecosystem will allow Teranova to independently produce critical components including landing gear parts.

Explore Form 4 to learn more about fast, accurate SLA 3D printing, or contact a Formlabs expert to discuss the best solutions for your business.