Die Stereolithografie (Abkürzung: SLA) ist heute eines der geläufigsten 3D-Druckverfahren mit flüssigem Kunstharz und verdankt seine Beliebtheit der Möglichkeit, hochgenaue, isotrope, wasserdichte Prototypen oder Endverbrauchsteile in verschiedenen fortschrittlichen Materialien mit feinen Details und einer glatten Oberfläche zu fertigen.

In diesem umfassenden Leitfaden erfahren Sie, wie SLA-Technologien funktionieren, warum tausende Fachleute heutzutage dieses Verfahren nutzen und was Sie wissen müssen, um vom Einstieg in den SLA-3D-Druck profitieren zu können.

Einführung in den Stereolithografie-3D-Druck (SLA)

Suchen Sie nach einem 3D-Drucker, der Ihre Modelle in hoher Auslösung umsetzt? Laden Sie unser umfassendes Whitepaper über SLA herunter und erfahren Sie, wie SLA-Verfahren funktionieren, warum tausende Fachleute heutzutage diesen Prozess nutzen und was Sie wissen müssen, um bei Ihrer Arbeit von SLA-3D-Druck profitieren zu können.

Was ist Stereolithografie-3D-Druck?

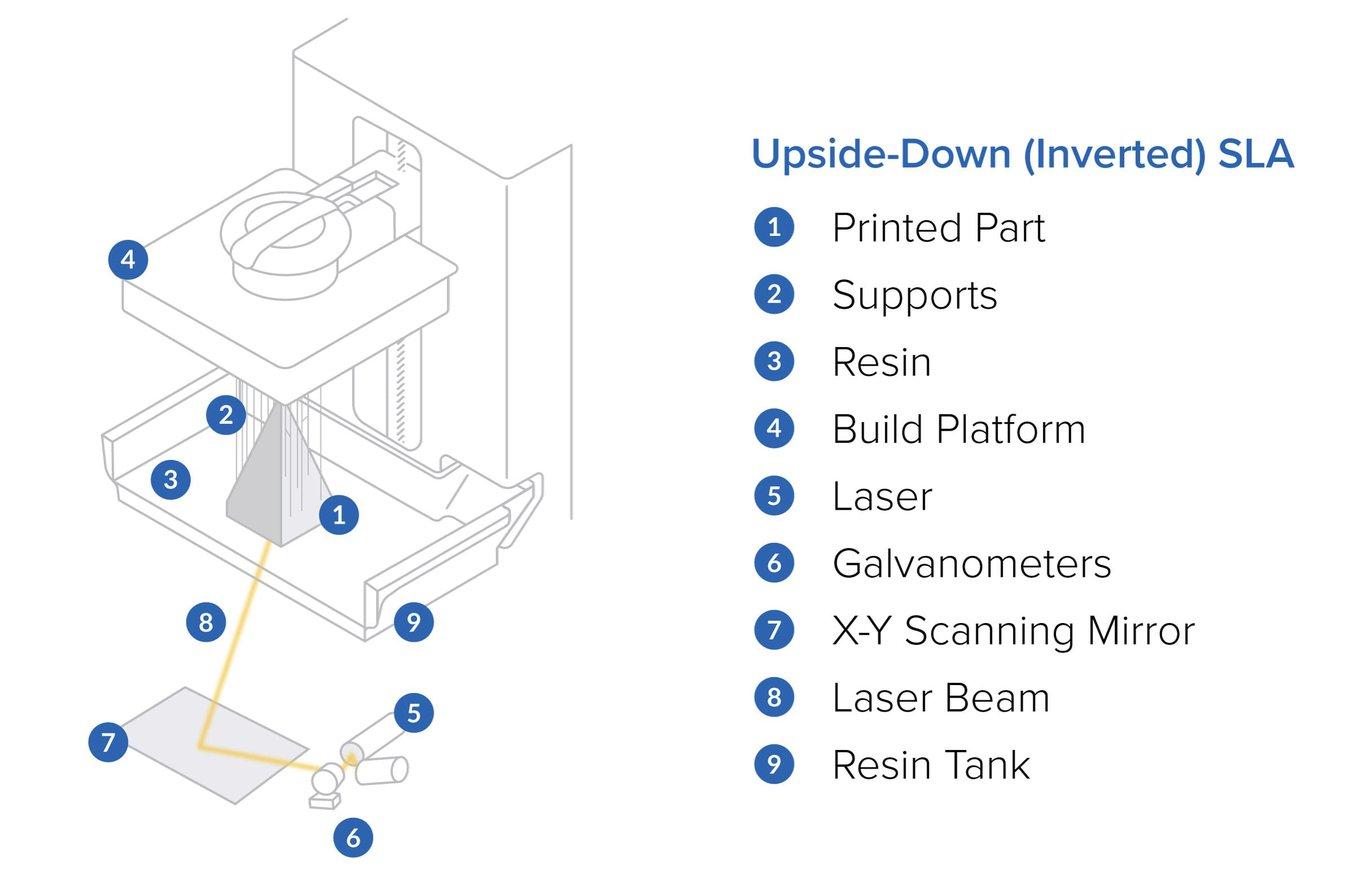

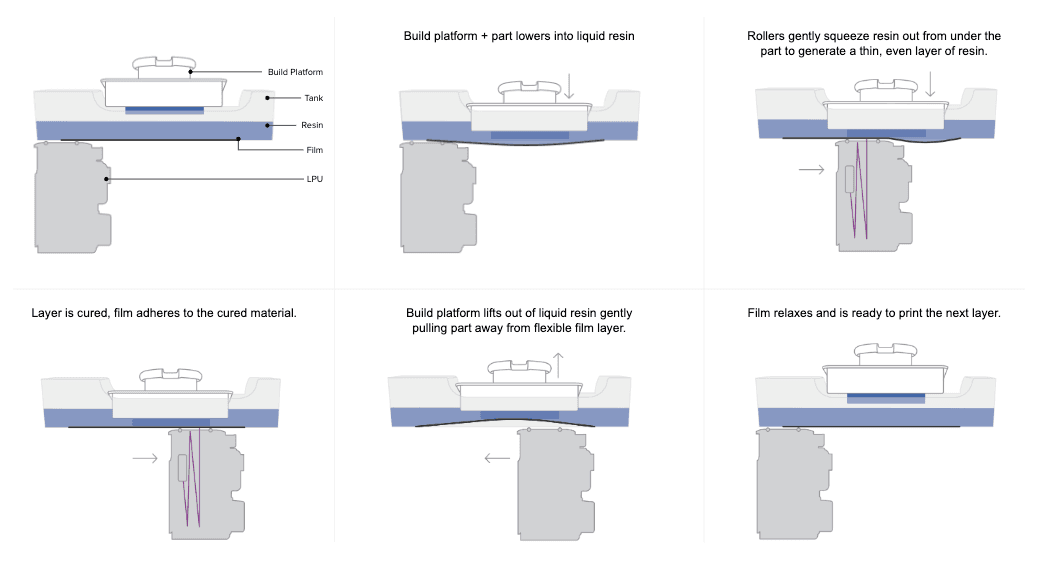

Die Stereolithografie gehört zu einer Familie von additiven Fertigungstechnologien, die allgemein als 3D-Druck aus Kunstharz (auch Resin genannt) bekannt ist. Diese Maschinen sind alle nach dem gleichen Prinzip aufgebaut und verwenden eine Lichtquelle - einen Laser oder Projektor -, um flüssiges Harz in ausgehärteten Kunststoff zu transformieren. Die wichtigste physikalische Unterscheidung liegt in der Anordnung der Kernkomponenten wie der Lichtquelle, der Bauplattform und des Harztanks.

Sehen Sie, wie der 3D-Druck mit Stereolithografie (SLA) funktioniert.

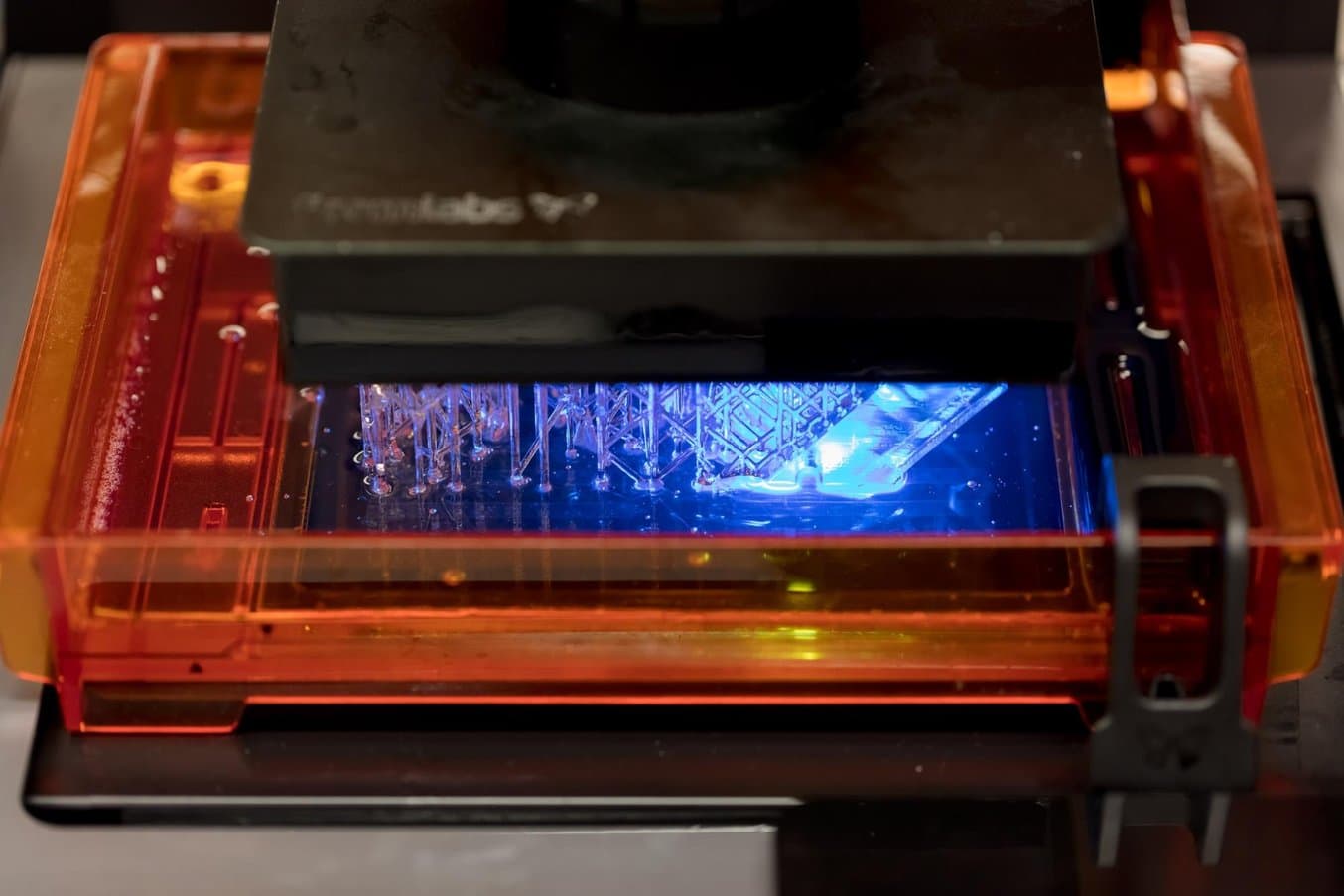

Bei SLA-3D-Druckern für den Desktop kommt ein Harztank mit durchsichtigem Boden und nicht haftender Oberfläche zum Einsatz. Sie dient als Substrat, an dem das flüssige Kunstharz aushärtet. Auf diese Weise können neu gebildete Schichten behutsam abgelöst werden.

Eine grafische Darstellung der grundlegenden Mechanik des 3D-Stereolithografie-Drucks.

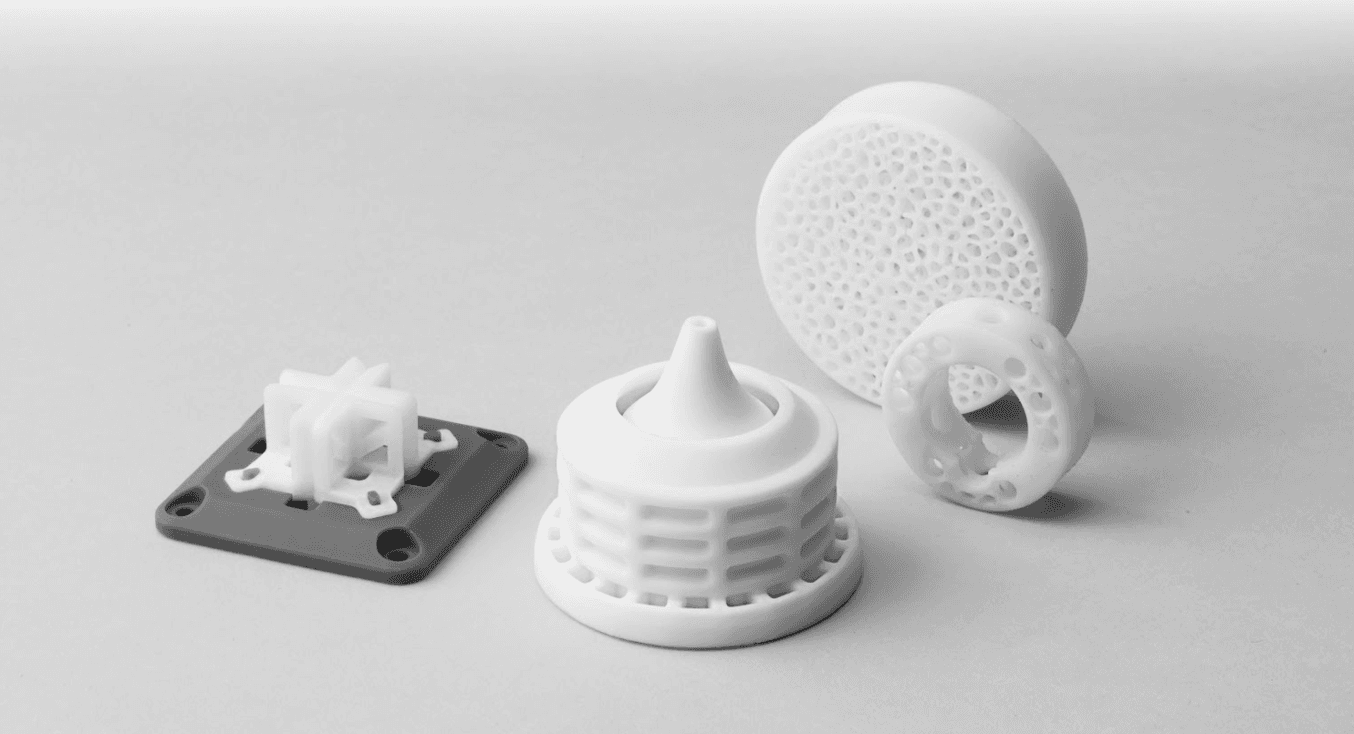

SLA-Teile haben die höchste Auflösung und Genauigkeit, die schärfsten Details und die glattesten Oberflächengüten aller 3D-Drucktechnologien, aber der Hauptvorteil der Stereolithografie liegt in ihrer Vielseitigkeit.

Materialhersteller haben innovative SLA-Harzformulierungen mit einem breiten Spektrum optischer, mechanischer und thermischer Eigenschaften entwickelt, die denen von Standard-, technischen und industriellen Thermoplasten entsprechen.

Fortschritte beim 3D-Druck verändern kontinuierlich die Art und Weise, wie Unternehmen an die Prototypenfertigung und die Produktion herangehen. Da die Technologie immer zugänglicher und günstiger wird und Hardware und Materialien sich weiterentwickeln, um die Chancen und Anforderungen des Marktes zu erfüllen, integrieren Fachleute in den Bereichen Design, Maschinenbau und Produktentwicklung die additive Fertigung in die Arbeitsprozesse in verschiedenen Entwicklungszyklen.

Besonders bei der Stereolithografie hat sich ein großer Wandel vollzogen. Ursprünglich waren SLA-Drucker unflexibel und unerschwinglich. Es waren geschultes technisches Personal und teure Wartungsverträge erforderlich. Heute können kleinformatige Desktop-Drucker Teile mit industrieller Qualität zu einem Bruchteil der Kosten und mit einer nie dagewesenen Vielseitigkeit fertigen.

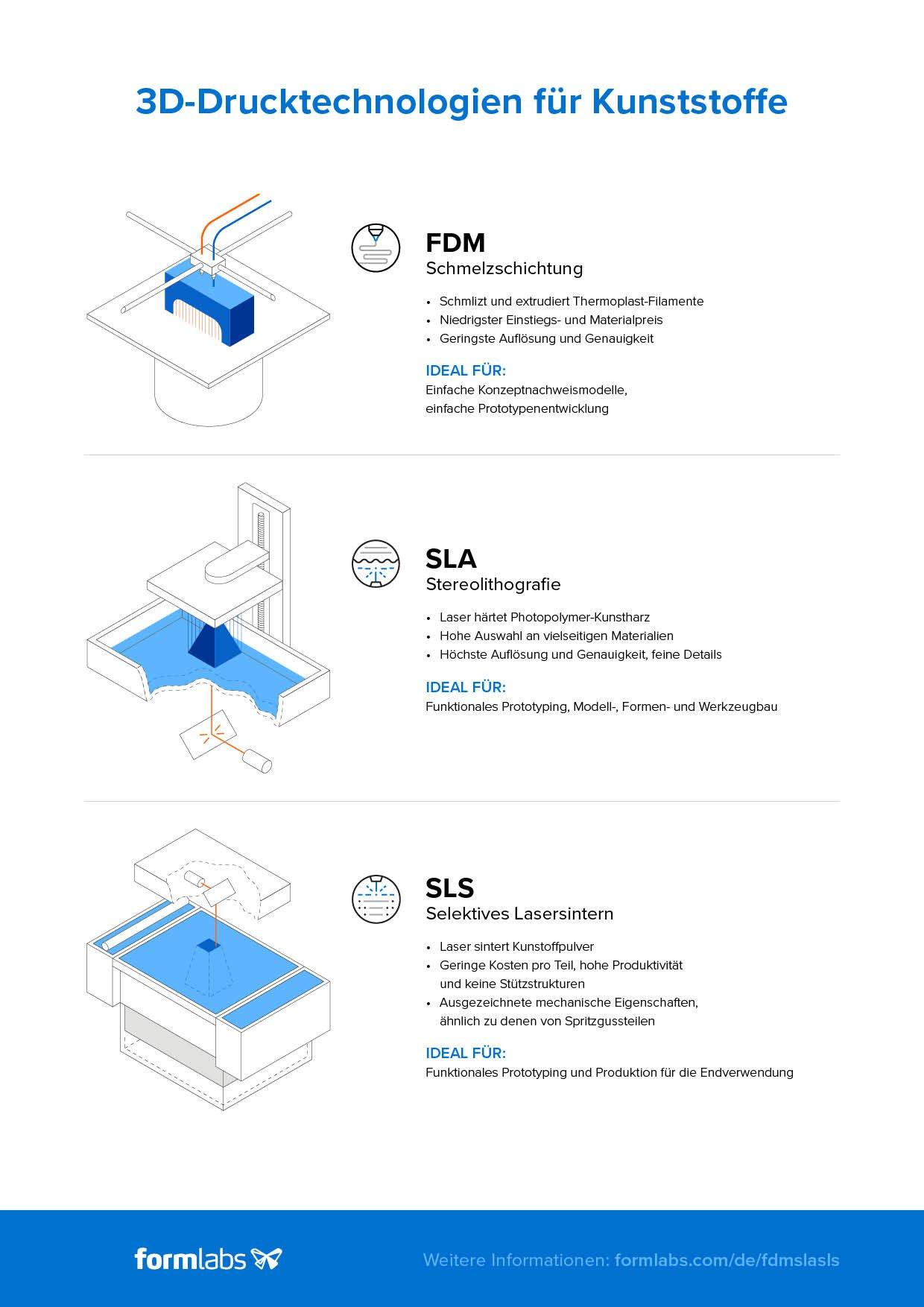

Vergleichen Sie den 3D-Stereolithografie-Druck mit zwei anderen gängigen Technologien zur Herstellung von Kunststoffteilen: Fused Deposition Modeling (FDM) und Selektives Lasersintern (SLS).

Kostenlosen Probedruck anfordern

Sehen und fühlen Sie die Qualität von Formlabs selbst. Wir senden Ihnen einen kostenlosen Probedruck an Ihren Arbeitsplatz.

Der Arbeitsprozess beim SLA-3D-Druck

Erfahren Sie, wie Sie mit dem SLA 3D-Drucker Form 3 vom Design zum 3D-Druck übergehen. In diesem 5-minütigen Video werden die Grundlagen der Verwendung des Form 3 von der Software und den Materialien bis zum Drucken und Nachbearbeiten erläutert.

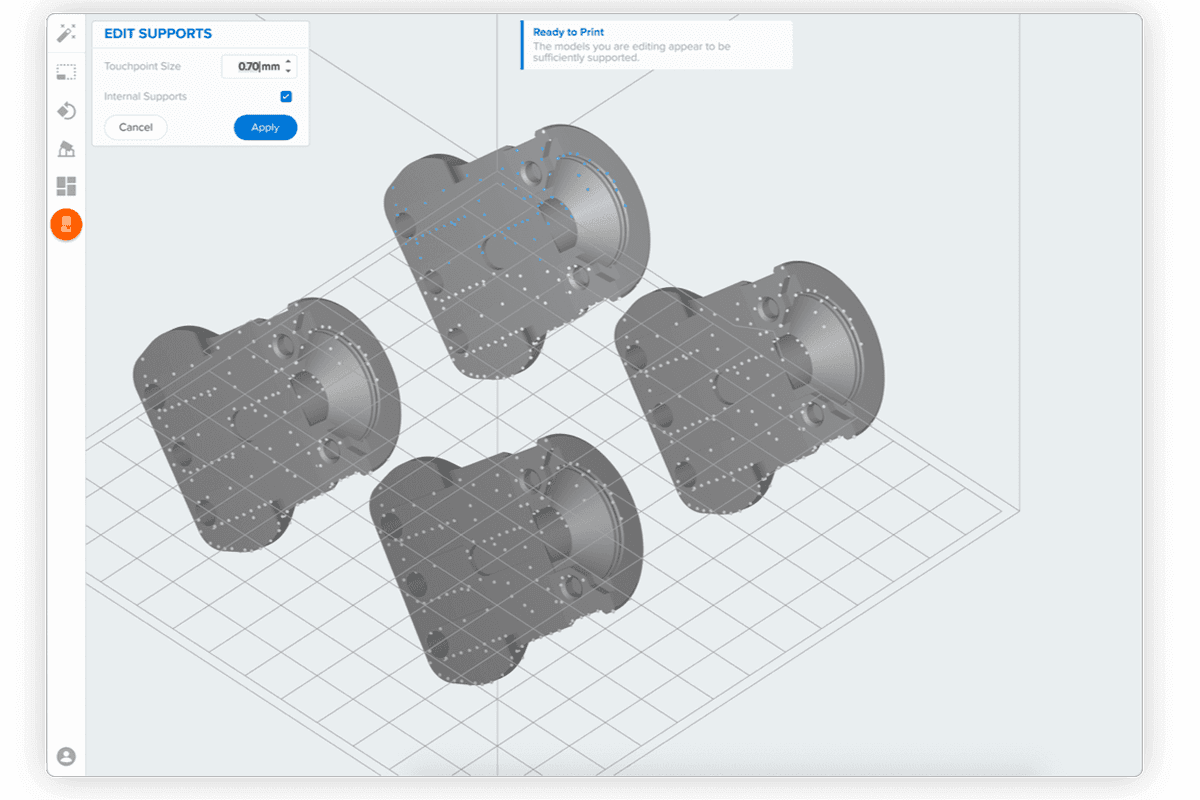

1. Design

Konstruieren Sie Ihr Modell mit einer beliebigen CAD-Software oder 3D-Scandaten und exportieren Sie es in einem für den 3D-Druck geeigneten Dateiformat (STL oder OBJ). Jeder SLA-Drucker verfügt über Software, um die Druckeinstellungen zu konfigurieren und das digitale Modell in Schichten aufzuteilen, die horizontale Querschnitte des Teils darstellen. Nach der Einstellung sendet die Druckvorbereitungssoftware die Vorgaben per WLAN- oder Kabelverbindung an den Drucker.

Fortgeschrittene Nutzer können Modelle speziell für den SLA-Prozess entwerfen, oder Methoden wie hohle Teile nutzen, um Material zu sparen.

2. Druck

Nach einer raschen Bestätigung der korrekten Einrichtung beginnt der Druckvorgang und das Gerät kann bis zu dessen Abschluss unbeaufsichtigt laufen. Bei Druckern mit Kartuschensystem wird das Material automatisch vom Gerät nachgefüllt.

Mit dem Online Dashboard von Formlabs können Sie aus der Ferne Drucker, Materialien und Teams managen.

3. Nachbearbeitung

Nach Abschluss des Druckvorgangs müssen die Druckteile in Isopropylalkohol (IPA) gespült werden, um alle unausgehärteten Harzablagerungen von den Oberflächen zu entfernen. Nachdem die gespülten Teile getrocknet sind, müssen manche Materialien nachgehärtet werden. Bei diesem Prozess lässt sich die höchstmögliche Festigkeit und Stabilität erreichen. Entfernen Sie abschließend die Stützen vom Teil und schleifen Sie die verbleibenden Stützspuren sauber ab. SLA-Teile können leicht für spezifische Anwendungen oder Oberflächengüten spanend bearbeitet, grundiert, lackiert und montiert werden.

Nachhärten ist besonders wichtig bei funktionalen Kunstharzen für technische Anwendungen und Pflicht bei einigen Materialien und Anwendungen in den Bereichen Zahntechnik und Schmuck.

Live-Demo: Der neue Form 3+ und die Build Platform 2

Effizienterer 3D-Druck mit noch einfacherer Nachbearbeitung: In diesem kostenlosen Online-Webinar stellt Jakob Dobberow, Pro Services Trainer bei Formlabs, bei einer Live-Demonstration die neuen Funktionen unserer verbesserten SLA-Drucker Form 3+ und Form 3B+ vor.

Eine kurze Geschichte der Stereolithografie

Stereolithografie (SLA) wurde in den frühen 1980er Jahren erfunden, als der japanische Forscher Dr. Hideo Kodama den modernen Schichtaufbau für die Stereolithografie erfand und dabei UV-Licht nutzte, um lichtempfindliche Polymere zu härten. Der Begriff Stereolithografie wurde von Charles (Chuck) W. Hull erfunden, der die Technologie 1986 patentieren ließ und das Unternehmen 3D Systems gründete, um sie zu kommerzialisieren. Hull beschrieb die Methode als das Herstellen von dreidimensionalen Modellen durch das aufeinanderfolgende „Drucken“ dünner Schichten aus einem Material, das sich durch ultraviolettes Licht härten lässt.

SLA-3D-Druck war jedoch nicht die erste 3D-Drucktechnologie, die sich großer Beliebtheit erfreute. Als die Patente Ende der 2000er Jahre abliefen, wurde die additive Fertigung durch Einführung des kleinformatigen Desktop-3D-Drucks immer breiteren Anwenderkreisen zugänglich gemacht. Dabei kam zunächst das Fused Deposition Modeling (FDM, Schmelzschichtung) auf Desktop-Plattformen zum Einsatz.

Zwar trug diese erschwingliche Extrusionstechnik zur zunehmenden Verbreitung des 3D-Drucks bei, doch die Qualität der gefertigten Teile hat den Einsatz von FDM-Druckern begrenzt, da für professionelle Anwendungszwecke wie bei biokompatiblen Materialien in der Zahntechnik wiederholbare Ergebnisse von hoher Präzision unerlässlich sind. Hinzu kommen die Anforderungen der Schmuckherstellung und der Millifluidik, bei denen filigrane Details gefertigt werden müssen.

Prototypen des Form 1, des ersten SLA-3D-Druckers für den Desktop.

Desktop-SLA führt zur Disruption auf dem Markt

SLA wurde kurz nach FDM für den Desktop eingeführt, als Formlabs die Technologie 2011 anpasste. Kleinformatiger SLA-Druck versprach hochauflösende 3D-Druckergebnisse, die zuvor nur von industriellen Systemen erzielt worden waren, im Rahmen einer weitaus kleineren und kostengünstigeren Konfiguration und mit einer breiten Palette an Druckmaterialien. Diese Eigenschaften machten den Einstieg in den 3D-Druck für eine Vielzahl verschiedener Spezial- und Hochpräzisionsanwendungen zugänglich, z. B. im Bereich des Ingenieurwesens, des Produktdesigns und der Fertigung sowie in der Dental- und Schmuckbranche und anderen Industriezweigen.

Im Jahr 2015 führte Formlabs seinen SLA-Drucker der nächsten Generation ein, den Form 2, der bald zum branchenführenden Desktop-3D-Drucker avancierte. In der Praxis ließen sich nun Teile wie günstige maßgefertigte Prothesen oder individuelle Rasierergriffe fertigen.

Der Form 2 brachte frischen Wind in die Diskussion um die Stereolithografie, indem er ein „verteiltes“ Produktionsmodell einführte, mit dem Unternehmen ihre Fertigung schrittweise skalieren konnten. So ließen sich kleinformatige Drucker mit wachsender Nachfrage hinzufügen und auf jedem Drucker konnte nun mit einem anderen Material gedruckt werden. Die Reife der Materialien hat nur zu immer umfassenderer Nutzung dieses Modells geführt, da durch fortschrittliche Kunstharze Anwendungen jenseits der Prototypenfertigung wie etwa Produktion und Fertigteile in verschiedenen Branchen erschlossen wurden.

Im Jahr 2019 sorgte Formlabs mit der Einführung des Form 3 und des Form 3L für den nächsten Quantensprung in der Branche. Die beiden neuen Hardwareprodukte setzen einen neuen Standard für SLA mit Systemen, die auf einem vollständig neuen Druckprozess basierten.

Der Form 3 und der Form 3L von Formlabs basieren auf der neuen Low Force Stereolithography (LFS) 3D-Drucktechnologie, einer fortschrittlichen Form der Stereolithografie, die einen flexiblen Tank und lineare Beleuchtung nutzt, um aus flüssigem Kunstharz makellose Teile zu formen.

Dank des modularen Designs der LPU, der gleichmäßigen linearen Beleuchtung und der durch den flexiblen Tank reduzierten Kräfte lässt sich die Technologie der Low Force Stereolithography problemlos auf eine größere Konstruktionsplattform skalieren, unter Nutzung desselben leistungsstarken Drucksystems.

Der erste erschwingliche Kunstharz-Drucker im Großformat, der Form 3L, liefert auch große Teile in kürzester Zeit, mithilfe zweier versetzter LPUs, die simultan entlang eines optimierten Druckpfads arbeiten. Dadurch drucken Unternehmen erstmals auch großformatige Teile betriebsintern in hoher Qualität, bei geringen Stückkosten und kurzer Durchlaufzeit.

Das Ecosystem des Form 3L und Form 3BL

Möchten Sie mehr über die neuen Drucker Form 3L und Form 3BL sowie unsere großformatigen Nachbearbeitungsgeräte erfahren?

Unser Pro Service Engineer Jacob Naumann stellt Ihnen den Form 3L vor und erklärt, wie die LFS-Technologie auf Großformat-SLA-Druck skaliert werden kann.

Das nächste Kapitel für SLA: Low Force Stereolithography 3D-Druck

Low Force Stereolithography (LFS) Technologie ist die neueste Entwicklung beim SLA-3D-Druck und erfüllt die Anforderungen des heutigen Markts an skalierbaren, zuverlässigen 3D-Druck in industrieller Qualität.

Bei dieser fortschrittlichen Form des SLA-Drucks kommen ein flexibler Tank und lineare Beleuchtung zum Einsatz, wodurch die auf die Teile wirkenden Kräfte deutlich reduziert und eine unglaubliche Oberflächenqualität und Druckgenauigkeit erzielt werden. Durch die geringeren Druckkräfte lassen sich berührungsempfindliche Stützstrukturen einsetzen, die leicht abgelöst werden können. Zusätzlich eröffnet der Prozess eine Vielzahl von Möglichkeiten bei der Entwicklung fortschrittlicher, produktionsreifer Materialien.

Die umgekehrte SLA sorgt für Abzugskräfte, die auf das Druckteil wirken, wenn es von der Tankoberfläche getrennt wird. Darum ist das Fertigungsvolumen begrenzt und robuste Stützstrukturen sind erforderlich. Der Form 2 ist genau kalibriert, um die Kräfte beim Ablöseprozess zu berücksichtigen und hochwertige Teile zu liefern. Erfahren Sie mehr über die Unterschiede zwischen dem Form 2 und dem Form 3, bei dem LFS-Technologie eingesetzt wird.

Beim LFS 3D-Druck kommen ein flexibler Tank und lineare Beleuchtung zum Einsatz, wodurch die auf die Teile wirkenden Kräfte deutlich reduziert und eine unglaubliche Oberflächenqualität und Druckgenauigkeit erzielt werden. Erfahren Sie mehr über die Funktionsweise von LFS in diesem detaillierten Video.

Der Form 3 auf einen Blick

In dieser Produktvorführung führt unser Experte Sie Schritt für Schritt durch die Verwendung unseres Form 3 sowie die Technologie dahinter. Sie erhalten außerdem Einblicke in Anwendungsbeispiele aus der Praxis sowie die dazugehörigen, gedruckten Teile.

Wieso SLA-3D-Druck?

Ingenieure, Designer, Hersteller und weitere Profis wählen SLA-3D-Druck wegen der feinen Merkmale, der glatten Oberfläche, der vollendeten Teilepräzision und -genauigkeit und den mechanischen Eigenschaften wie Isotropie, Wasserdichtigkeit und Vielseitigkeit der Materialien.

Isotropie

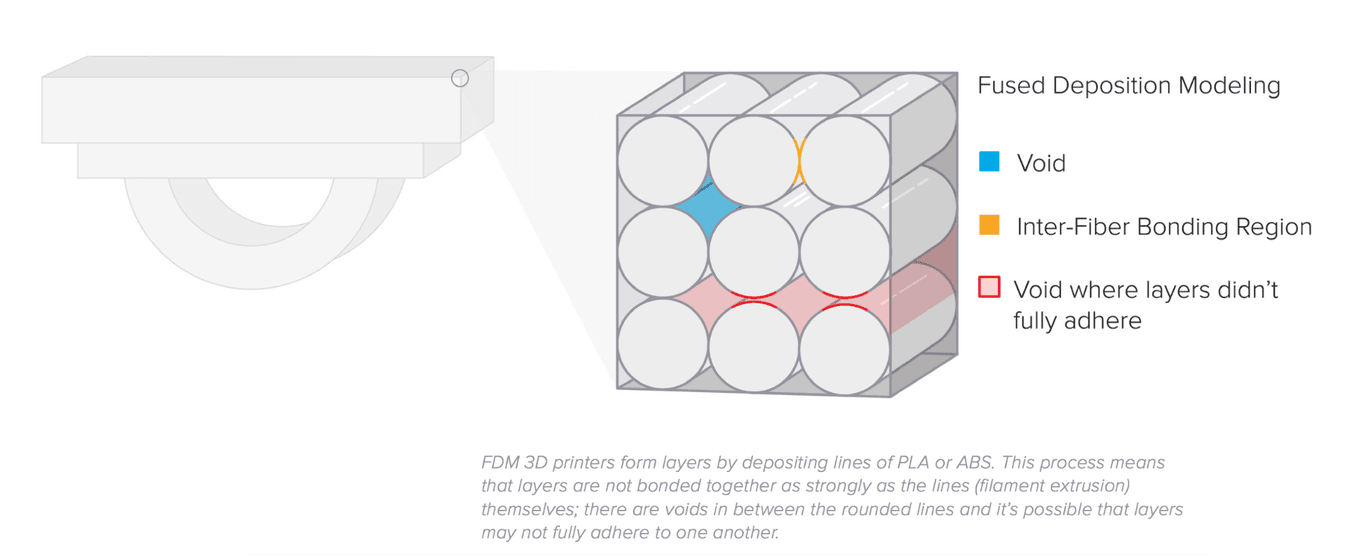

Da beim 3D-Druck die Teile schichtweise gefertigt werden, gibt es bei fertigen Druckteilen abhängig von der Ausrichtung des Teils zum Druckprozess möglicherweise Unterschiede in Sachen Festigkeit. Dabei treten unterschiedliche Eigenschaften in den X-, Y- und Z-Achsen zu Tage.

Druckprozesse wie Schmelzschichtung (FDM) sind aufgrund der beim Druckprozess entstehenden Unterschiede von Schicht zu Schicht als anisotrop bekannt. Diese Anisotropie begrenzt die Nutzbarkeit von FDM bei bestimmten Eigenschaften oder macht zusätzliche Anpassungen bei der Druckgeometrie erforderlich, um sie zu kompensieren.

Lesen Sie unsere ausführliche Anleitung zu FDM- und SLA-3D-Druckern und erfahren Sie, wie sie sich im Hinblick auf Druckqualität, Materialien, Anwendungen, Workflow, Geschwindigkeit, Kosten und unterscheiden.

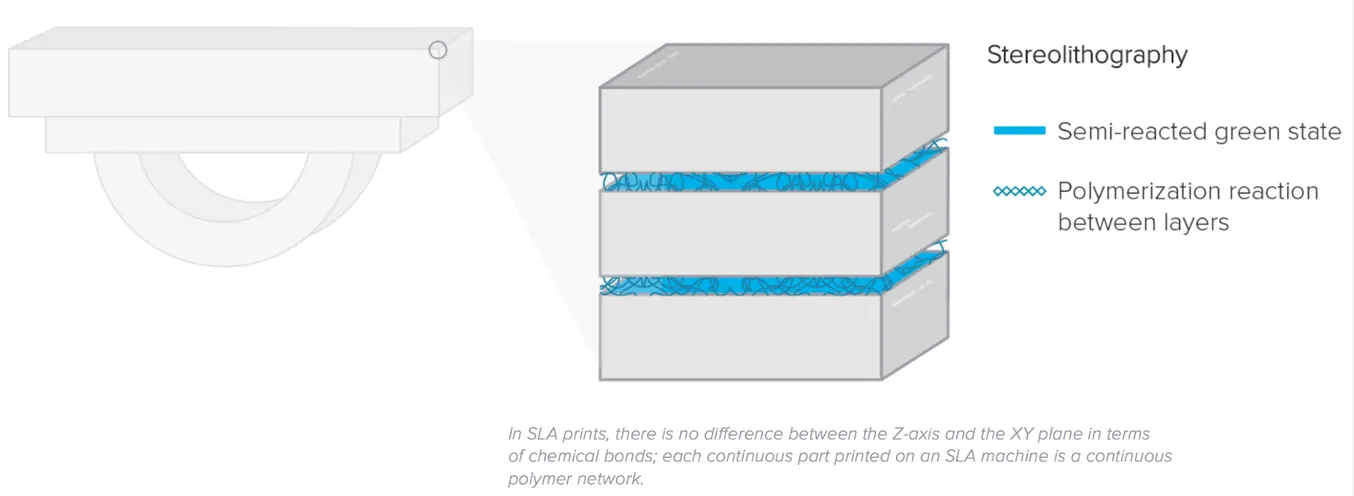

Im Gegensatz dazu sorgt SLA-Druck für hochgradig isotrope Teile. Die Erzielung von Teileisotropie hängt von verschiedenen Faktoren ab, die genau gesteuert werden können, indem die Materialchemie für den Druckprozess genutzt wird. Während des Druckvorgangs bilden die Harzbestandteile kovalente Bindungen, doch von Schicht zu Schicht bleibt das Teil ein halb reagiertes „Grünteil“.

In diesem Grünteilzustand bleiben im Kunstharz polymerisierbare Gruppen zurück, die Verbindungen über Schichten hinweg eingehen können. Bei der endgültigen Aushärtung werden dem Teil so Isotropie und Wasserdichtigkeit verliehen. Auf molekularer Ebene gibt es keine Unterschiede zwischen den X-, Y- oder Z-Schichten. Dies führt zu Teilen mit vorhersehbaren mechanischen Eigenschaften, die für Anwendungen wie Vorrichtungen, Fertigteile und funktionsfähige Prototypen erforderlich sind.

SLA-Druckteile sind im Vergleich zu FDM-Druckteilen hochgradig isotrop.

Da sie isotrop sind, halten SLA-Druckteile wie diese Vorrichtung von Pankl Racing Systems Kräften aus unterschiedlichen Richtungen stand, denen sie bei Fertigungsschritten mit hohen Belastungen unterworfen sind.

Wasserdichtigkeit

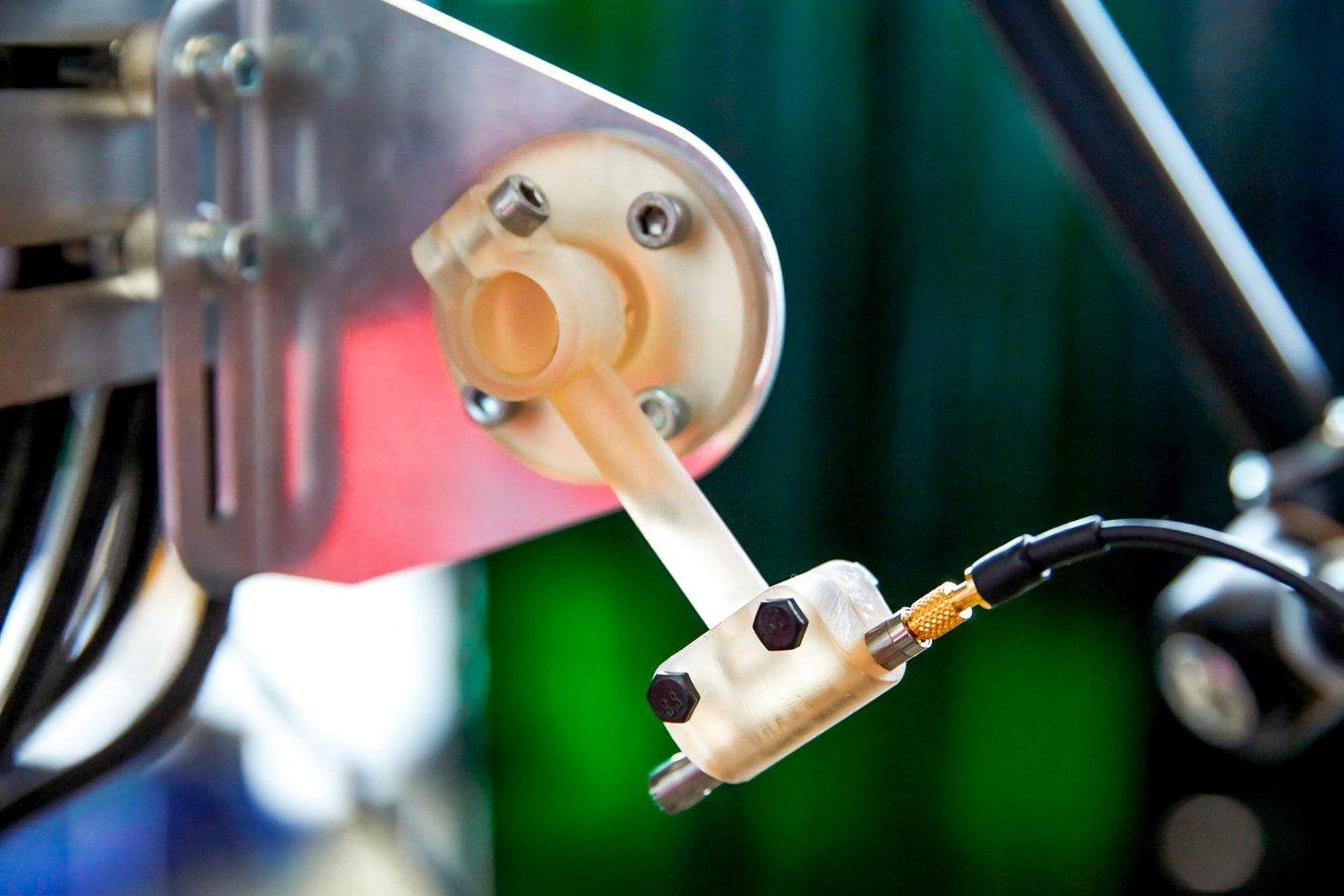

SLA-Druckteile sind durchgehend, unabhängig davon, ob Geometrien mit massiven Details oder internen Kanälen erzeugt werden. Die Wasserdichtigkeit ist wichtig für ingenieurtechnische und fertigungstechnische Anwendungen, bei denen der Luft- oder Fluidfluss kontrolliert und vorhersehbar sein muss. Ingenieure und Designer nutzen die Wasserdichtigkeit von SLA, um Herausforderungen bei Luft- und Flüssigkeitsströmen in den Bereichen Automobiltechnik und biomedizinische Forschung zu lösen und Teiledesigns für Produkte wie Küchengeräte zu validieren.

OXO verlässt sich auf die Wasserdichtigkeit von SLA-Druck, um robuste funktionsfähige Prototypen für Produkte mit Luft- oder Fluidfluss wie dieser Kaffeemaschine zu fertigen.

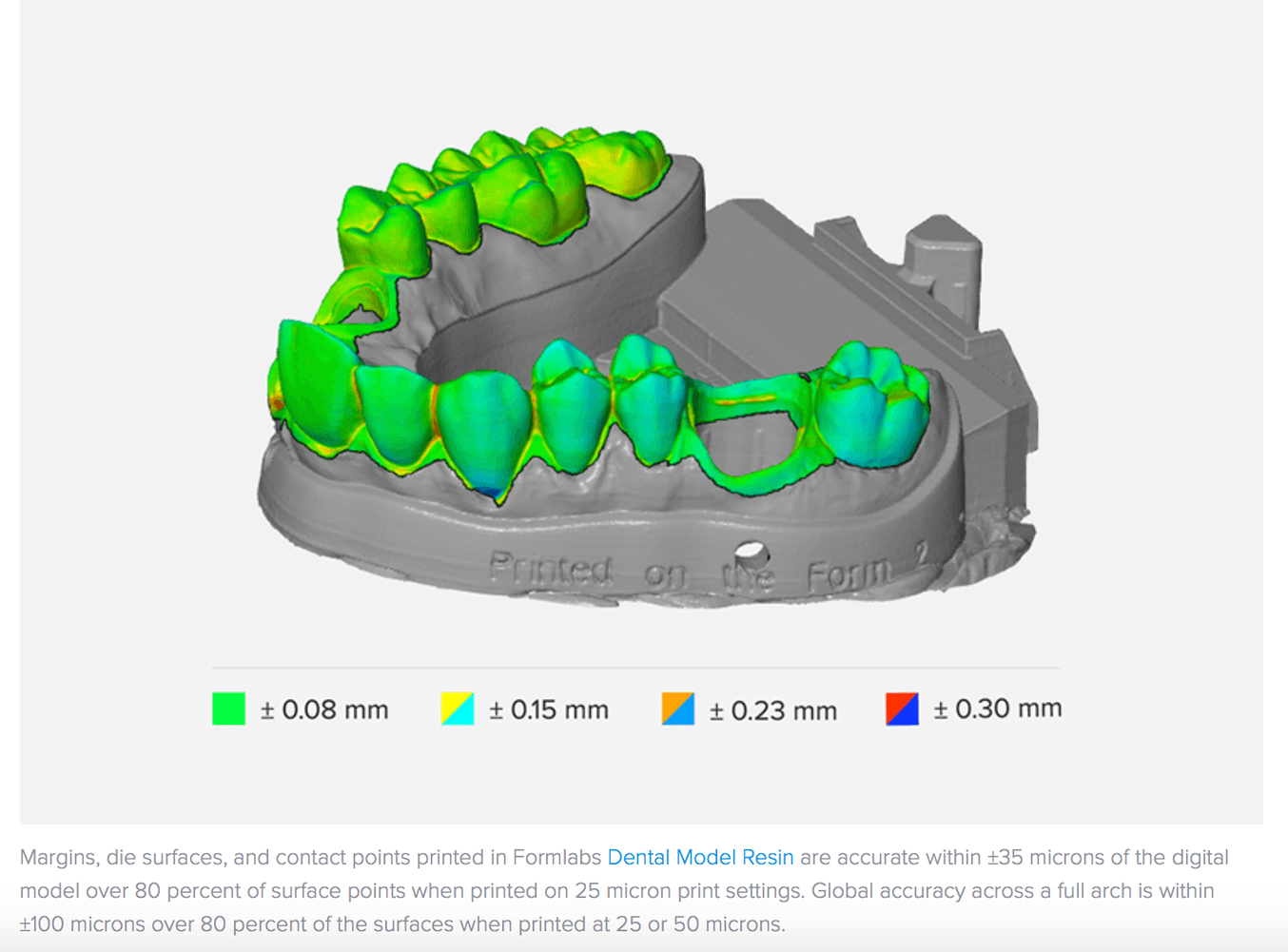

Genauigkeit und Präzision

Branchen von der Zahnmedizin bis zur Fertigung verlassen sich auf SLA-3D-Druck, um wiederholt genaue, präzise Komponenten zu fertigen. Damit ein Druckprozess genaue und präzise Teile herstellen kann, müssen mehrere Faktoren genau gesteuert werden.

Im Vergleich zur Genauigkeit der spanenden Bearbeitung liegt der SLA-3D-Druck zwischen der Standardbearbeitung und der Feinbearbeitung. SLA hat die engsten Toleranzen aller kommerziell verfügbaren 3D-Technologien. Erfahren Sie mehr über Genauigkeit, Präzision und Toleranz im 3D-Druck.

Die Kombination aus beheiztem Harztank und geschlossener Konstruktionsumgebung gewährleistet nahezu identische Bedingungen für jeden Druckauftrag. Die höhere Genauigkeit lässt sich darauf zurückführen, dass mit niedrigeren Drucktemperaturen gearbeitet wird als bei Thermoplasttechnologien, bei denen das Rohmaterial geschmolzen wird. Da SLA statt Wärme Licht einsetzt, erfolgt der Druckvorgang nahezu bei Raumtemperatur. Aus diesem Grund kommt es bei den Druckteilen nicht zu Artefakten durch Wärmeausdehnung und Kontraktion.

Beim Low Force Stereolithography (LFS) 3D-Druck befindet sich die Optik in einer Light Processing Unit (LPU), die sich in der X-Richtung bewegt. Ein Galvanometer positioniert den Laserstrahl in der Y-Richtung und lenkt ihn dann über einen Faltspiegel und einen Parabolspiegel, um einen Strahl zu erzeugen, der stets senkrecht auf die Druckebene fällt. So bewegt er sich immer in einer gerade Linie und sorgt für noch mehr Präzision und Genauigkeit. So kann die Gleichmäßigkeit ermöglicht werden, wenn Hardware auf größere Formate skaliert wird, wie den großformatigen SLA-Drucker Form 3L. Die LPU nutzt auch einen Raumfilter, um einen scharfen Laserstrahl mit größerer Präzision zu erzeugen.

Die Eigenschaften der individuellen Materialien sind ebenfalls wichtig, um einen zuverlässigen, wiederholbaren Druckprozess zu ermöglichen.

Formlabs Rigid Resin weist einen hohen Grünmodul oder Modul vor dem Nachhärten auf, was bedeutet, dass sehr dünne Teile präzise und mit höherer Erfolgsrate gedruckt werden.

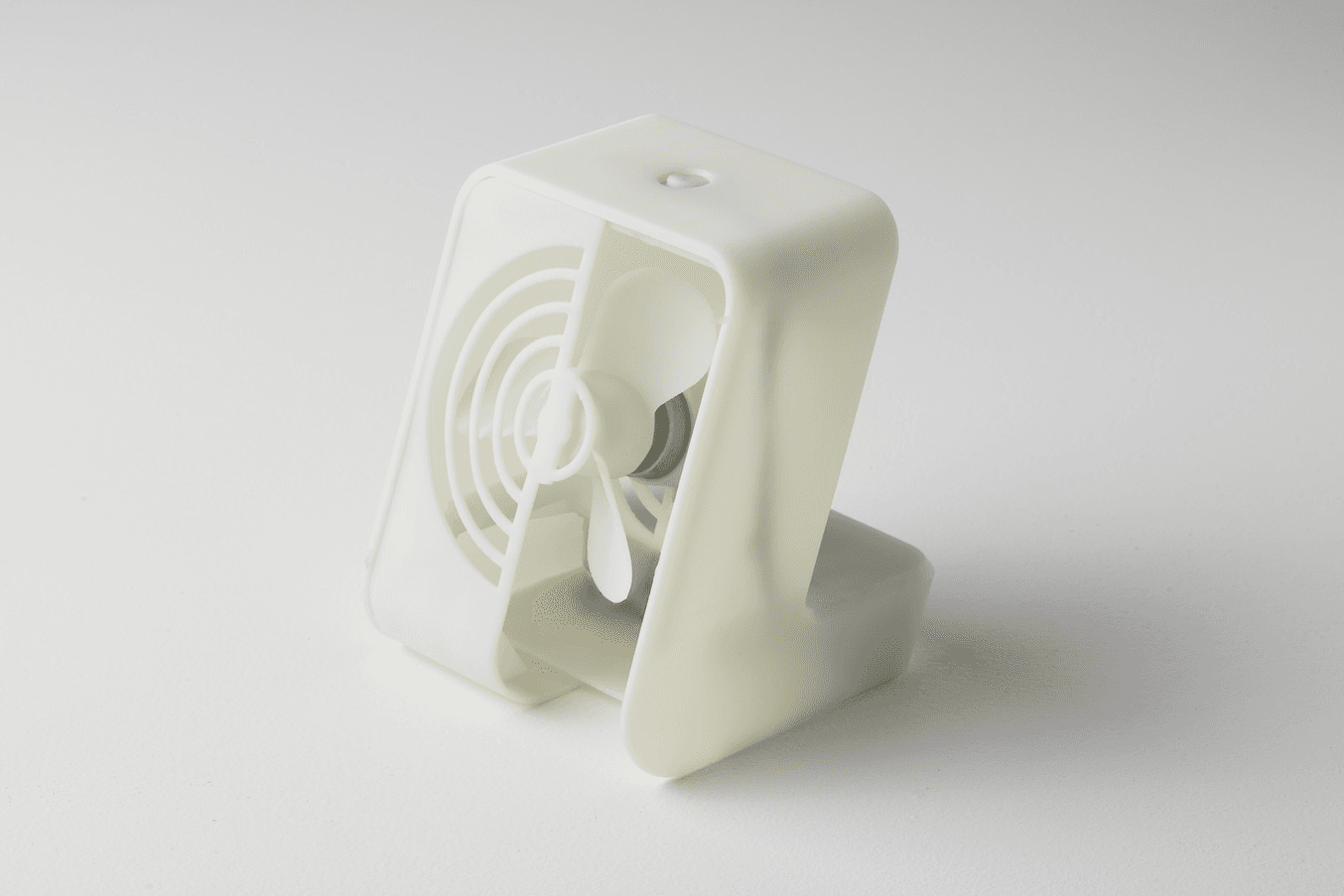

Filigrane Details und makellose Oberflächenbeschaffenheit

SLA-Druck gilt als der Maßstab für die Erzielung einer glatten Oberfläche. Es lassen sich Oberflächenbeschaffenheiten erreichen, die denen bei traditionellen Fertigungsverfahren wie Bearbeitung, Spritzguss und Extrusion ähneln.

Diese Oberflächenbeschaffenheit ist für Anwendungen ideal, die makellose Oberflächen erfordern, und spart außerdem Zeit bei der Nachbearbeitung, da die Teile problemlos abgeschliffen, poliert und lackiert werden können. Beispielsweise nutzen Marktführer wie Gillette SLA-3D-Druck, um fertige Konsumprodukte wie 3D-gedruckte Rasierergriffe für seine Razor Maker Produktplattform zu drucken.

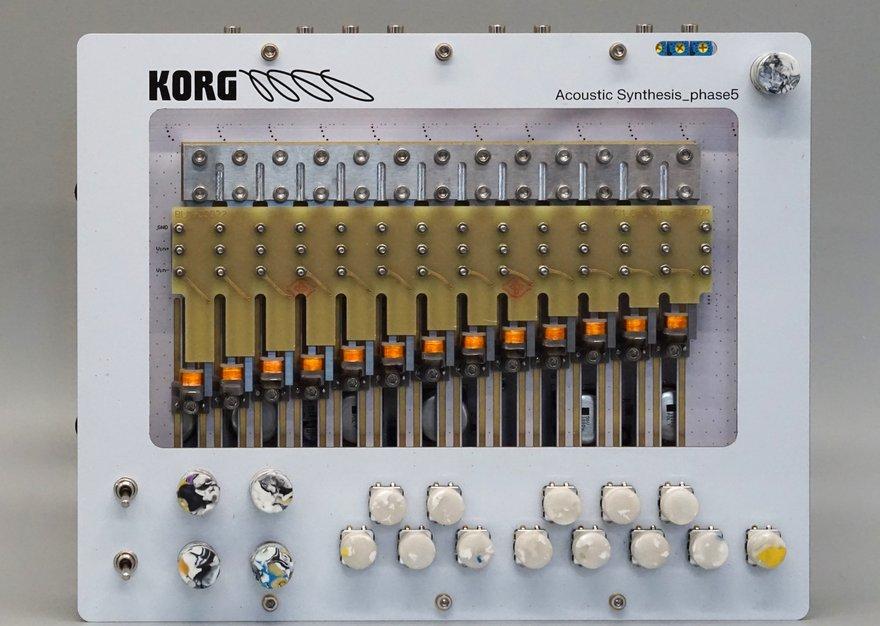

Marktführer wie Gillette nutzen SLA-3D-Druck, um fertige Konsumprodukte wie 3D-gedruckte Rasierergriffe für seine Razor Maker Produktplattform zu drucken.

Die Schichthöhe der Z-Achse wird häufig genutzt, um die Auflösung eines 3D-Druckers zu definieren. Sie kann bei Formlabs' SLA-3D-Druckern zwischen 25 und 300 Mikrometern angepasst werden, wobei sich ein Kompromiss zwischen Geschwindigkeit und Qualität ergibt.

Im Vergleich dazu drucken FDM- und SLS-Drucker für gewöhnlich Z-Achsenschichten zwischen 100 und 300 Mikrometern. Jedoch unterscheidet sich ein Teil, das mit 100 Mikrometern auf einem FDM- oder SLS-Drucker hergestellt wurde, von einem Teil, das mit derselben Auflösung auf einem SLA-Drucker gedruckt wurde. SLA-Drucke haben eine glattere Oberfläche, wenn sie aus dem Drucker kommen, da die äußeren Begrenzungswände gerade sind, und die neu gedruckte Schicht mit der vorherigen Schicht interagiert, sodass der „Treppeneffekt“ geglättet wird. FDM-Drucke haben für gewöhnlich deutlich sichtbare Schichten, während die Oberfläche beim SLS-Verfahren aufgrund des gesinterten Pulvers körnig ist.

Beim SLA-Druck werden außerdem selbst winzigste Details weitaus genauer wiedergegeben. Grund hierfür ist die Tatsache, dass der Form 3 mit einer Laserspotgröße von 85 Mikrometern arbeitet, wohingegen industrielle SLS-Drucker Düsen von 350 Mikrometern verwenden und FDM-Maschinen Düsen von 250 bis 800 Mikrometern einsetzen.

Materialvielfalt

SLA-Kunstharze bieten eine große Anzahl an Formulierungskonfigurationen: Die Materialien können weicht oder hart, stark mit sekundären Materialien wie Glas oder Keramik gefüllt sein, oder über mechanische Eigenschaften wie eine hohe Wärmeformbeständigkeitstemperatur oder Schlagzähigkeit verfügen. Die Materialien reichen in ihren Anwendungen von branchenspezifisch wie jene für Zahnersatz bis hin zu Kunstharzen, die bei der Prototypenfertigung dem Endprodukt sehr ähneln, und formuliert sind, um umfangreichen Tests standzuhalten und unter Belastung zu funktionieren.

Mit Ceramic Resin können Sie 3D-Druckteile fertigen, deren Oberfläche Stein ähnelt. Sie können zu vollwertigen Keramikteilen gebrannt werden.

In manchen Fällen ist es diese Kombination aus Vielseitigkeit und Funktionalität, die Unternehmen dazu bewegt, SLA firmenintern zu nutzen. Nachdem eine Anwendung mit einem spezifischen funktionsfähigen Material gelöst wurde, dauert es häufig nicht lange, bis weitere Möglichkeiten gefunden werden und der Drucker zu einem Werkzeug wird, mit dem die verschiedenen Eigenschaften der unterschiedlichen Materialien genutzt werden können.

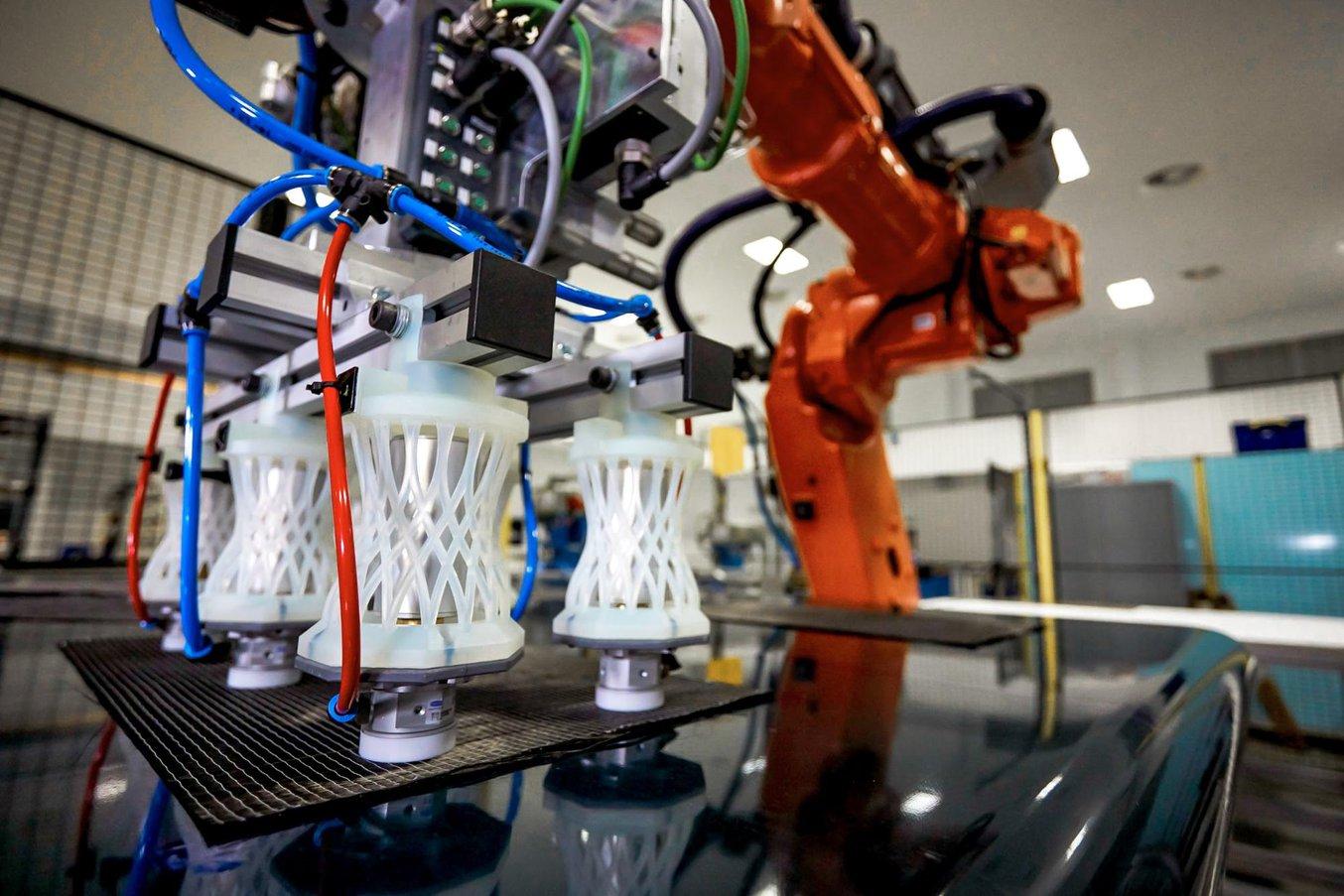

Beispielsweise verlassen sich hunderte Ingenieure der Design and Prototyping Group des Advanced Manufacturing Research Centre (AMRC) an der University of Sheffield auf den freien Zugang zu einer Flotte aus 12 SLA 3D-Druckern und einer Vielzahl an technischen Kunstharzen, um vielfältige Forschungsprojekte mit Industriepartnern wie Boeing, Rolls-Royce, BAE Systems und Airbus zu unterstützen. Das Team nutzte High Temp Resin, um Unterlegscheiben, Halterungen und ein Sensorhalterungssystem zu bauen,das hohen Temperaturen standhält. Es setzte außerdem Durable Resin ein, um maßgefertigte filigrane Federkomponenten für einen Pick-and-Place-Roboter zu fertigen, der die Herstellung von Verbundwerkstoffen automatisiert.

Ingenieure am AMRC nutzen eine Flotte aus 12 SLA 3D-Druckern und eine Vielzahl an technischen Materialien, um maßgefertigte Teile für diverse Forschungsprojekte herzustellen, darunter Halterungen für einen Pick-and-Place-Roboter (links) und Halterungen für Sensoren in einer Umgebung mit hohen Temperaturen (rechts).

Finden Sie das richtige Material für Ihre Anwendung

Benötigen Sie Hilfe bei der Auswahl des richtigen 3D-Druckmaterials? Mit unserer neuen, interaktiven Materialhilfe treffen Sie im wachsenden Angebot unserer Kunstharze die richtige Entscheidung basierend auf Ihrer Anwendung und den für Sie wichtigsten Eigenschaften.

Anwendungen für SLA-3D-Druck

SLA-3D-Druck beschleunigt die Innovation und unterstützt Unternehmen in vielen verschiedenen Branchen wie Maschinenbau, Fertigung, Zahnmedizin, Gesundheit, Bildung, Unterhaltung, Schmuck, Hörakustik und mehr.

Maschinenbau und Produktdesign

Rapid Prototyping mit 3D-Druck gibt Ingenieuren und Designern die Möglichkeit, Ideen in realistische Proof-of-Concept-Modelle zu verwandeln, diese Konzepte zu hochpräzisen Prototypen weiterzuentwickeln, die aussehen und funktionieren wie die Endprodukte, und Produkte durch eine Reihe von Validierungsschritten zu führen, die in der Serienproduktion enden.

Fertigung

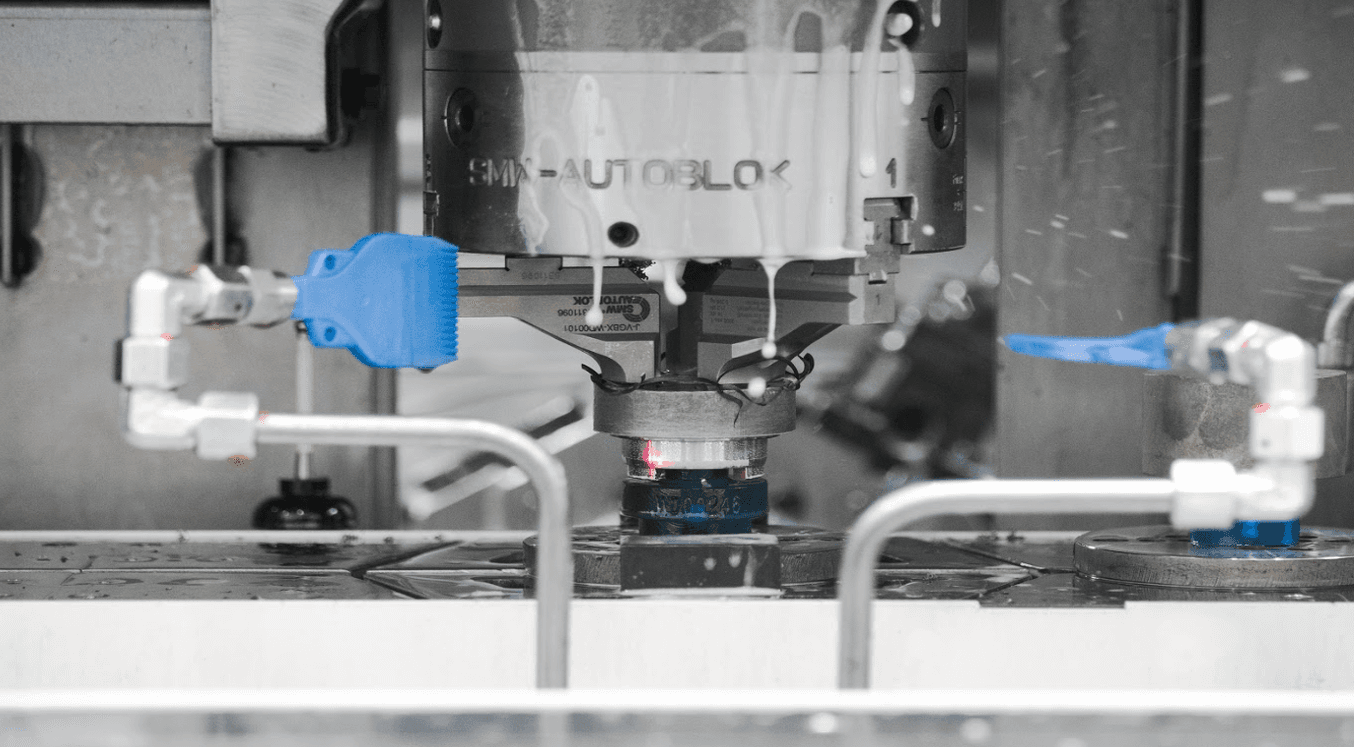

Fertigungsunternehmen automatisieren Produktionsprozesse und rationalisieren Arbeitsabläufe, indem sie Werkzeugprototypen entwickeln und per 3D-Druck maßgefertigte Werkzeuge, Formen und Produktionshilfen deutlich kostengünstiger und schneller als traditionelle Fertigungsverfahren herstellen. Damit sparen sie Fertigungskosten ein, senken die Fehlerquote, steigern die Qualität, beschleunigen die Montage und nutzen Arbeitskraft optimal aus.

Zahnmedizin

Digitale Zahnmedizin senkt das Risiko menschlichen Versagens und liefert gleichmäßigere Produkte und eine höhere Genauigkeit und Präzision bei jedem Arbeitsschritt. So erhält der Patient die bestmögliche Behandlung. 3D-Drucker können eine breite Spanne hochwertiger, maßgefertiger Produkte und Dentalvorrichtungen bei geringen Stückkosten herstellen. Dabei werden zudem eine exzellente Passform und wiederholbare Ergebnisse gewährleistet.

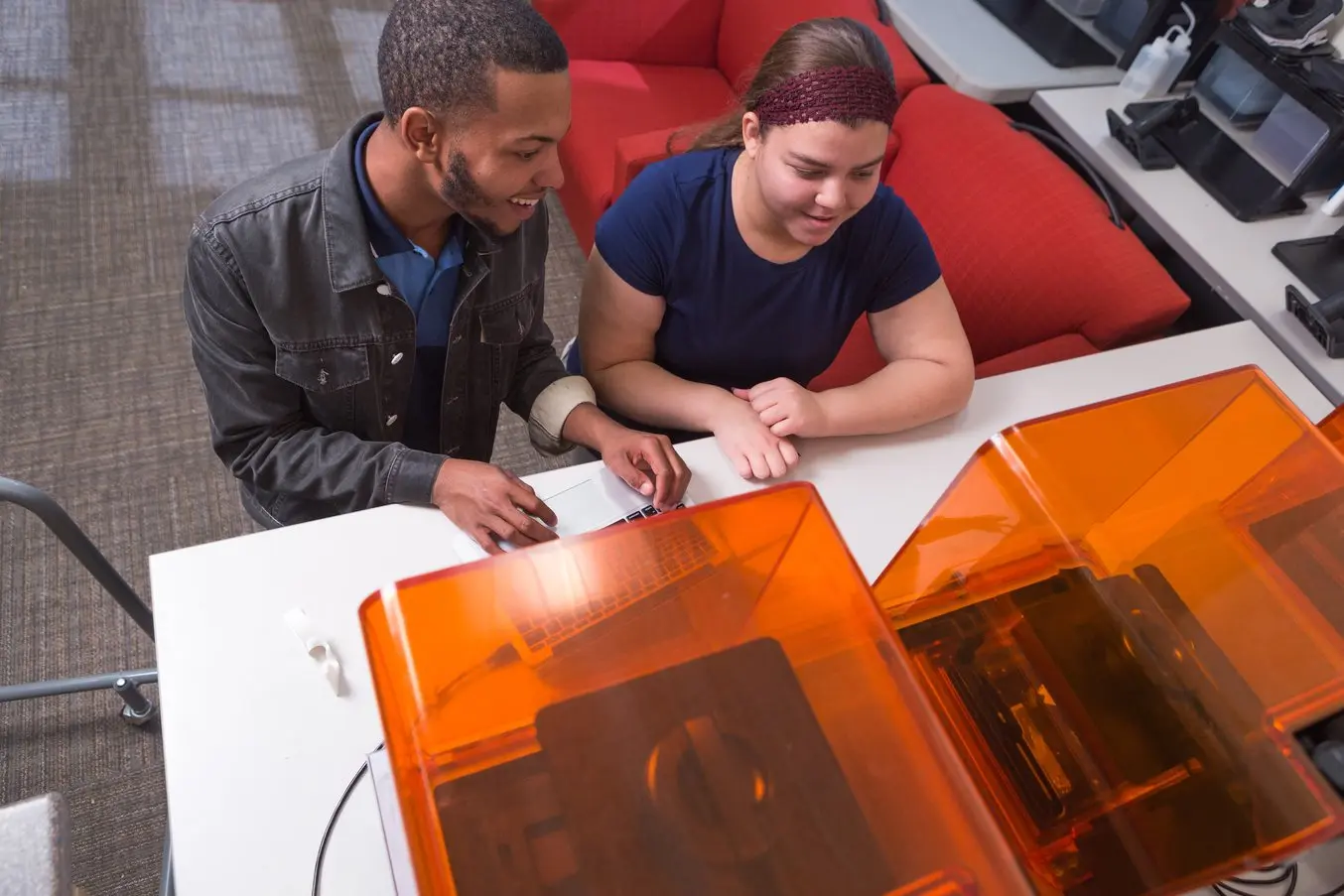

Bildung

3D-Drucker sind multifunktionale Werkzeuge für immersives Lernen und innovative Forschung. Sie können die Kreativität fördern, Schülern und Studenten professionelle Technologie näherbringen und MINT-Kenntnisse in den Wissenschaften, Technik, bildenden Künsten und Design vermitteln.

Gesundheitswesen

Erschwinglicher, professioneller Desktop 3D-Druck eröffnet Ärzten neue Wege, Behandlungen und Medizinprodukte zu bieten, die besser auf die einzelnen Patienten abgestimmt sind. So können sie leistungsstarke medizinische Anwendungen bereitstellen und gleichzeitig maßgeblich Zeit und Kosten einsparen – in der Behandlung ebenso wie im Labor.

Unterhaltung

Hochaufgelöste physische Modelle kommen in der Bildhauerei, der Charaktermodellierung und der Herstellung von Requisiten häufig zur Anwendung. 3D-gedruckte Teile kamen bereits für Stop-Motion-Filme, Videospiele, maßgeschneiderte Kostüme und Special Effects in Blockbuster-Filmen zum Einsatz.

Schmuck

Schmuckhersteller verwenden CAD- und 3D-Druck, um schnell Prototypen ihrer Designs anzufertigen, sie Kunden anprobieren zu lassen und große Chargen an gussbereiten Teilen herzustellen. Digitale Tools erlauben die Fertigung gleichmäßiger, detaillierter Schmuckstücke ohne die mühselige Kleinarbeit und die Abweichungen, die mit Wachsmodellierung einhergehen.

Audiologie

Hörakustiker und -labore nutzen digitale Workflows und 3D-Druck, um hochwertige Otoplastiken gleichmäßiger und mit höheren Stückzahlen herzustellen. Anwendungsmöglichkeiten umfassen HDO-Hörgeräte, Hörschutz und maßgefertigte Ohrstöpsel und Ohrhörer.

Betriebsinterner SLA-3D-Druck

Viele Unternehmen nutzen 3D-Druck zunächst durch Outsourcing an Dienstleister oder Labore. Das Outsourcing der Produktion kann eine sehr gute Lösung für Teams sein, die 3D-Druck nur gelegentlich benötigen, oder bei Unikaten mit einzigartigen Materialeigenschaften oder Anwendungszwecken. Dienstleister können ebenfalls Ratschläge zu verschiedenen Materialien geben und bieten Mehrwertleistungenwie Design oder fortschrittliche Fertigstellung.

Die wichtigsten Nachteile des Outsourcings sind Kosten und Durchlaufzeiten. Häufig ist Outsourcing der erste Schritt zum betriebsinternen 3D-Druck, wenn der Bedarf zunimmt. Einer der größten Vorteile des 3D-Drucks ist seine Schnelligkeit im Vergleich zu herkömmlichen Fertigungsmethoden, der jedoch schnell an Relevanz verliert, wenn ein ausgelagertes Teil erst Tage oder gar Wochen später ankommt. Mit der wachsenden Nachfrage und Produktion wird das Outsourcing auch schnell teuer.

Durch die Verfügbarkeit von günstigem 3D-Druck mit Industriequalität entscheiden sich immer mehr Unternehmen dafür, sofort auf firmeninternen 3D-Druck zu setzen. Sie integrieren ihn vertikal in bestehende Werkstätten oder Labore oder in Arbeitsplätze von Ingenieuren, Designern und anderen Profis, die von der Umsetzung digitaler Designs in physische Teile profitieren könnten, oder die an der Herstellung kleiner Produktionsreihen beteiligt sind.

Kleinformatige Desktop-SLA-3D-Drucker sind eine ideale Lösung, wenn Sie Teile schnell benötigen. Abhängig von der Anzahl der Teile und des Druckvolumens kann sich die Investition in einen kleinformatigen 3D-Drucker schon innerhalb von Monaten amortisieren. Außerdem ist es bei kleinformatigen Geräten möglich, nur für die Kapazität zu zahlen, die ein Unternehmen benötigt, und die Produktion durch zusätzliche Drucker zu skalieren, wenn die Nachfrage wächst. Der Einsatz mehrerer 3D-Drucker bietet auch die Flexibilität, gleichzeitig Teile aus verschiedenen Materialien zu drucken. Dienstleister können diesen flexiblen Arbeitsprozess immer noch bei größeren Teilenoder ungewöhnlichen Materialien unterstützen.

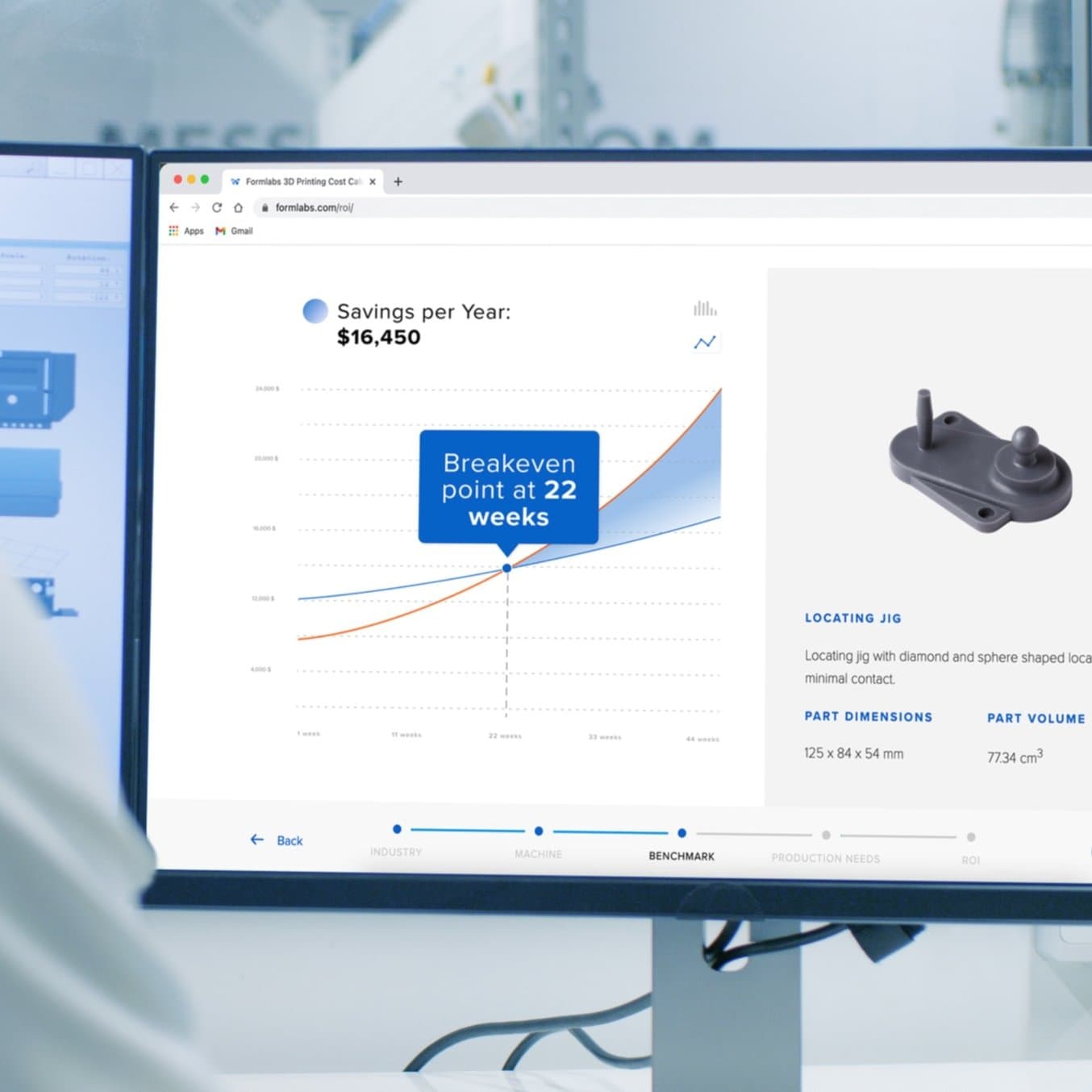

Ihre Zeit- und Kosteneinsparung berechnen

Nutzen Sie unser interaktives ROI-Hilfsmittel zur Berechnung Ihrer Zeit- und Kostenersparnis beim 3D-Druck mit einem Formlabs-3D-Drucker.

Kurze Durchlaufzeiten und schnelle Designänderungen

Kurze Durchlaufzeiten sind ein großer Vorteil für Eigentümer von Desktop 3D-Druckern. Bei der Arbeit mit einem Druckdienstleister sorgen Durchlaufzeiten, Kommunikation und Lieferung für Verzögerungen. Mit einem Desktop 3D-Drucker wie dem Form 3 halten Sie das Teil nach wenigen Stunden in den Händen. So können Designer und Ingenieure mehrere Teile an einem Tag drucken, was schnellere Iterationen ermöglicht und die Produktentwicklungszeit reduziert. Mechanismen und Baugruppen können schnell getestet werden, um kostenspielige Werkzeugänderungen zu vermeiden.

Kosteneinsparungen

Ein eigener Desktop 3D-Drucker bietet erhebliche Einsparungen gegenüber 3D-Druckdienstleistern und traditionellen Bearbeitungsverfahren, da diese Alternativen mit zunehmender Nachfrage und wachsender Produktion schnell teuer werden.

Ein Beispiel: Um enge Produktionsfristen zu erfüllen, haben ein Prozessingenieur und sein Team bei Pankl Racing Systems den SLA-3D-Druck eingeführt, um maßgefertigte Halterungen und andere Kleinserienteile direkt für die Fertigungslinie herzustellen. Obwohl man im Unternehmen dem betriebsinternen SLA-Druck zunächst skeptisch gegenüberstand, erwies er sich bald als ideale Alternative zur spanenden Fertigung verschiedener Werkzeuge. In einem Fall wurde die Durchlaufzeit von Haltevorrichtungen um 90 Prozent von zwei bis drei Wochen auf weniger als ein Tag reduziert. Die Kosteneinsparung lag zwischen 80 und 90 Prozent.

Kostenvergleich: Maßgefertigte Haltevorrichtung bei Pankl Racing Systems

| Kosten | Durchlaufzeit | |

|---|---|---|

| Firmeninterner SLA-Druck | 9-28 USD | 5 bis 9 Stunden |

| CNC-Bearbeitung | 45-340 USD | 2 - 3 Wochen |

Pankl Racing Systems hat die Durchlaufzeiten und Kosten durch den firmeninternen 3D-Druck maßgefertigter Haltevorrichtungen bedeutend reduziert.

Nach Bedarf skalieren

Bei kleinformatigen Geräten ist es möglich, nur für die Kapazität zu zahlen, die ein Unternehmen benötigt, und die Produktion durch zusätzliche Drucker zu skalieren, wenn die Nachfrage wächst. Der Einsatz mehrerer 3D-Drucker bietet auch die Flexibilität, gleichzeitig Teile aus verschiedenen Materialien zu drucken.

Die Design and Prototyping Group des Advanced Manufacturing Research Centre (AMRC) der University of Sheffield betreibt eine additive Fertigungsstation mit einer Flotte von 12 Stereolithografie-3D-Druckern (SLA) des Typs Form 2, die hunderten von Ingenieuren am Standort freien Zugang zum 3D-Druck bei ihren verschiedenen Projekten bietet.

Einstieg in den SLA-3D-Druck

Formlabs bietet zwei hochpräzise SLA-3D-Drucksysteme, eine wachsende Bibliothek an spezialisierten Materialien, intuitive Druckvorbereitungs- und Managementsoftware und professionelle Dienstleistungen – alles in einem Paket.

Um den SLA-3D-Druck noch näher kennen zu lernen, verschaffen Sie sich selbst einen Eindruck der Qualität des SLA-Verfahrens: Fordern Sie einen kostenlosen Probedruck aus Ihrem Wunschmaterial an, der direkt an Ihre Haustür geliefert wird.