Compression molding is a versatile manufacturing process used by small and large production companies alike for creating a wide variety of parts, from large airplane parts to small baby-bottle nozzles.

In this guide, we’ll provide an introduction to compression molding, its benefits, and applications. Then, we’ll show how anyone can use this process to create prototypes, mass produce parts, and everything in between.

Silicone Part Production With 3D Printed Tools

Download this report for a step by step guide on 3D printed tooling for silicone part production, with mold design best practices and customer case studies.

What Is Compression Molding?

Compression molding is a manufacturing process where a measured amount of molding material that’s generally preheated (typically referred to as a charge) is compressed into the desired form using two heated molds.

How Does Compression Molding Work?

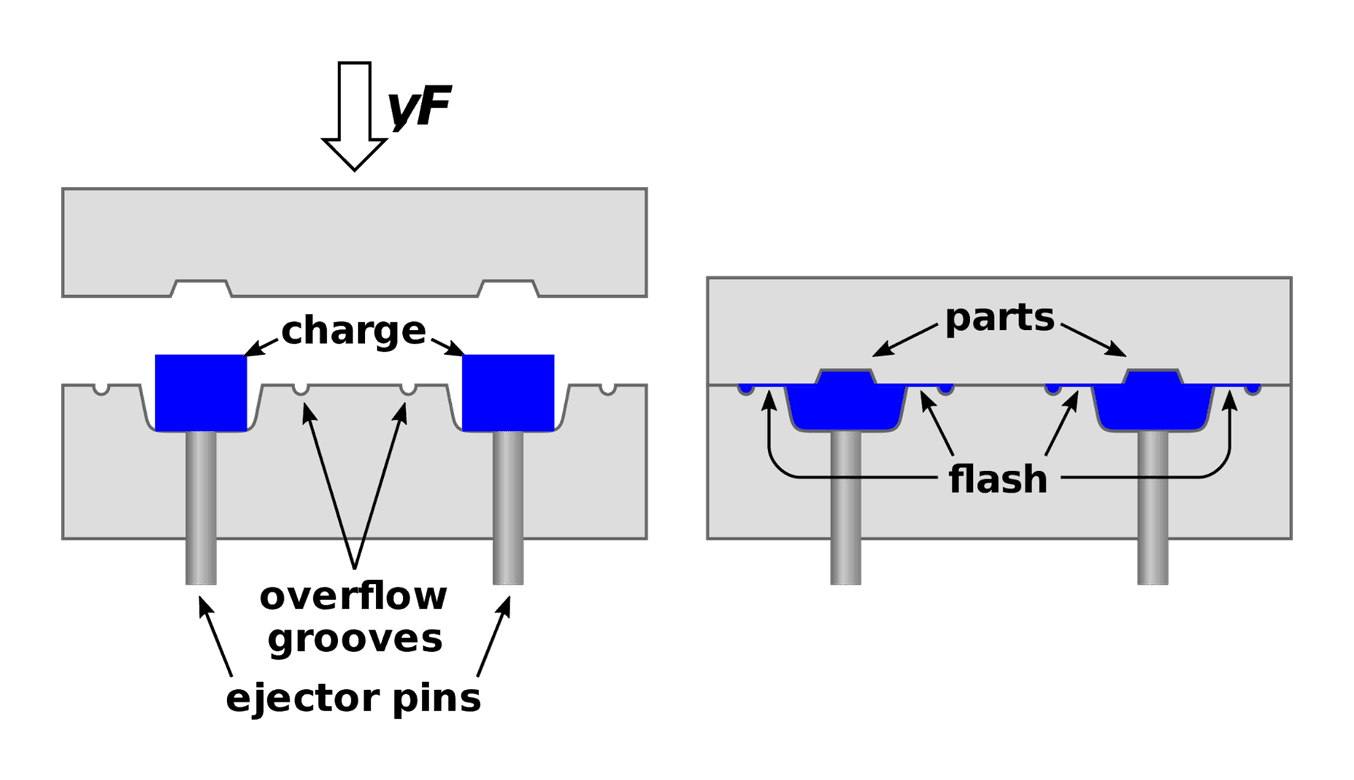

A simplified diagram of the compression molding process. (image source)

The step-by-step compression molding process works as follows:

-

Create molds - Tooling can be produced in a number of ways, including machining, die casting, 3D printing.

-

Set up the machine - Depending on the specific machine or device you’re using, this may include cleaning the mold, turning on the heat, and other set-up processes.

-

Prepare charge - Selected the type of material you want to use and determine the proper amount of material. If your charge is too big, excess material will seep out of the mold and result in flash that you will need to manually cut off.

-

Insert charge - Place the charge in the center of the bottom mold.

-

Compress part - Close the top mold, apply pressure, and wait for your piece to form. Many manufacturers also use heat during the compression process, which softens the raw materials and can help speed up production.

-

Release part - Remove the finished piece.

-

Clean part - Resin flash around the edges must be manually cut off or removed, and the part may need to be cleaned before the final assembly.

Compression Molding vs. Injection Molding

Compression molding and injection molding are very similar, but they have one major difference. In compression molding, molds are closed around the charge, and in injection molding, the charge is injected into a closed mold cavity.

Today’s manufacturers frequently use both compression and injection molding but for different types of parts. Injection molding is typically a better choice for more complex parts, while compression molding is a great option for relatively simple designs, including ultra-large basic shapes that cannot be produced using extrusion techniques.

Injection molding requires a shorter cycle time than compression molding, so it’s often faster and more cost-effective if you need to produce a large number of parts. However, compression molding is a lower-pressure production method, so the tooling costs are often lower. It also wastes little material, providing an advantage when working with expensive materials.

As a general rule of thumb, high volume production is better suited for injection molding, while compression molding is used rather for low and medium series of part production.

Low-Volume Rapid Injection Molding With 3D Printed Molds

Download our white paper for guidelines for using 3D printed molds in the injection molding process to lower costs and lead time and see real-life case studies with Braskem, Holimaker, and Novus Applications.

The Pros and Cons of Compression Molding

Now that we’ve discussed the differences between compression molding and injection molding, let’s take a deeper look at the unique benefits and limitations of this manufacturing process.

Cost-Effective

Compression molding is often the most cost-effective manufacturing method if you need to produce simple, mostly flat, large parts. Some curves and pockets in designs are acceptable, but extreme angles and deep draws can be challenging to achieve through compression molding. Due to the lower pressures, tooling costs are affordable, and molds typically last a long time without warping or needing to be replaced. To offset the cost associated with compression molding’s long cycle times, manufacturers can use a mold with multiple cavities to produce multiple parts in the same cycle.

Produces Strong Parts

Compression molding produces solid parts that are free of flow and knit lines. The structural stability of compression molded parts is very high. Compression molding is also used to manufacture parts using composite materials, which means that durable, corrosion-resistant parts and products can be produced easily through this method.

Flexibility in Design

Compression molding is also a great manufacturing tool for engineers and product developers. For example, prototyping can be done using low-cost compression molding. Simple compression molds can be designed in computer-aided design (CAD) software, 3D printed, and then used to form various types of materials with a simple tabletop vise. You’ll find an example of how OXO does prototyping this later on in this article.

Limitations

While there are many benefits to using compression molding, it does have its limitations. Compression molding doesn’t work well for manufacturing complex parts, such as those with severely slanted angles or small details. The cycle time, which can be several minutes long, is slow in comparison to high-volume molding methods. Injection molding, for example, often has cycle times of just seconds.

The labor cost associated with compression molding can be relatively high as well due to the slow cycle time that correlates with more working hours. Flash and burrs need to be manually removed from compression-molded parts, which takes up more time and creates waste. All these limitations aside, compression molding is still an important manufacturing method that is used to produce a wide range of products that we use every day.

The Applications of Compression Molding

Compression molding has a myriad of applications. Here are some of the many parts and products we interact with that have compression molded parts:

-

Vehicle parts - Many large parts and panels for cars, tractors, and other vehicles are made using compression molding. Many plastic parts used in vehicle interiors as well as engine components can be compression molded, too.

-

Computer and gaming devices - Components of video game controllers, keypads, and more can be compression molded.

-

Kitchenware - Many kitchen tools, utensils, and appliances have parts that are compression molded. Dinnerware, including bowls, cups, plates, and more, especially those made out of melamine, is often manufactured using compression molding.

-

Electrical components - Compression molding is often used to manufacture electrical sockets, switches, faceplates, and metering devices.

-

Medical and dental device parts - Many plastic and silicone parts used in the medical industry are compression molded, including syringe stoppers and respirator masks.

Kitchen tools manufactured using compression molding.

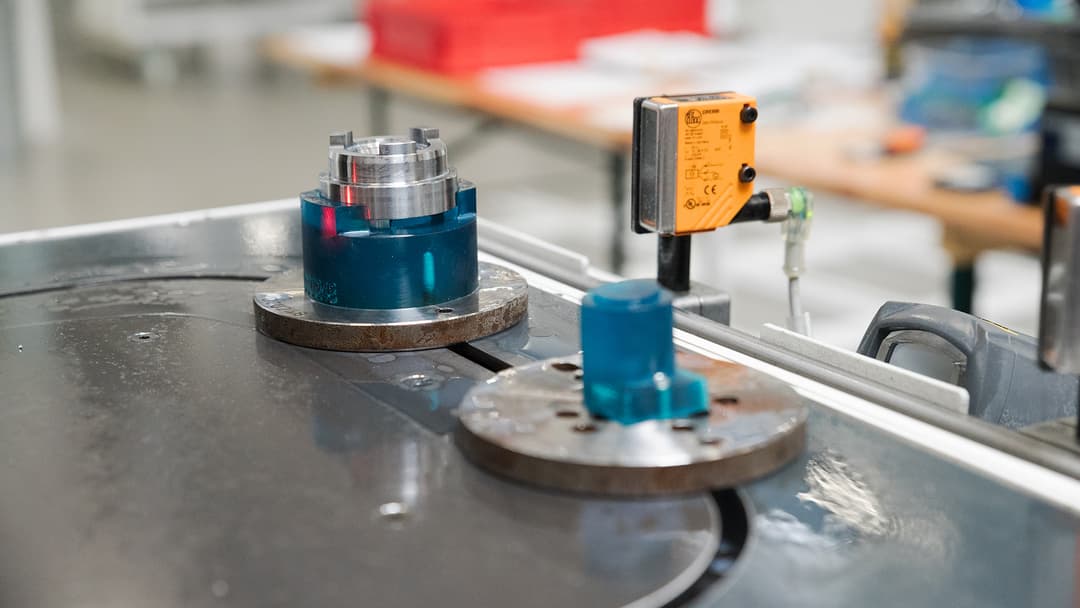

Types of Compression Molding Machines

Compression molding machines range in size from large industrial machines to small DIY creations. Much like the parts they produce, compression molding machines are as varied as the engineers and designers who create them. Let’s go through a few examples in the next section.

Industrial Hydraulic Compression Molding Machines

Large industrial compression molding machines are best for producing large commercial parts.

Hydraulic lift systems make it possible to achieve a high level of pressure for manufacturing and producing large, uniform parts while workers can oversee the process from a separate control panel.

Benchtop Presses

Smaller benchtop compression machines are ideal for manufacturing small- to mid-size parts and products. Beckwood’s benchtop presses take up less space than large industrial compression machines but are well suited for large runs. Multiple access points give engineers the flexibility to easily remove processed parts and flash, and the smaller footprint makes it easier to incorporate these machines into smaller warehouses or production facilities.

Cold (Heatless) Compression Molding Machines

As a reminder, compression molding can be done with or without heat. This is true for compression molding machines of all sizes. Some manufacturers will even use a cold compression machine but heat the charge or raw materials before placing them into the mold. You can control the way a finished product cures and shorten production cycles by introducing heat at specific times.

Wet Compression Molding Machines

Wet compression molding machines are used to combine resins, epoxies, and other liquid substances with solid fabrics.

Wet compression has become a common process for manufacturing durable car parts and components. BMW and other major corporations have incorporated wet compression molding machines into their production lines.

DIY Compression Molding Devices

Compression molding is also a great tool for at-home designers and DIY’ers. Soft materials, such as urethane, can be compression molded with relatively low pressure. Even complex molds can be easily fabricated using a 3D printer and CAD software. For many small projects, you can achieve compression using a simple tabletop vise or lever system.

Materials for Compression Molding

Both thermoplastics and thermosets are compatible with compression molding. Thermoplastic materials are types of plastics that become soft and pliable when heated and harden when cooled. Thermoplastics can be heated and cooled (or reshaped) numerous times.

Thermoset materials, on the other hand, include plastics and other polymers that become irreversibly cured when exposed to heat—meaning they can only be molded or shaped once. The compression molding process causes thermosets to change on a chemical level in a way that cannot be undone or repeated.

Common materials used in compression molding include:

-

Diallyl phthalate (DAP)

-

Epoxy

-

High-density polyethylene (HDPE)

-

Melamine

-

Polyamide-imides (PAIs)

-

Polyether ether ketone (PEEK)

-

Polyurethane (PU)

-

Polyphenylene sulfide (PPS)

-

Phenolic resins (PF)

-

Polytetrafluoroethylene (PTFE)

-

Silicone

-

Urea-formaldehyde (UF)

-

Urethane

How to Create Molds for Compression Molding

Depending on the material or charge you will be compression molding, you have several options for creating molds. The key is that your molds need to be able to withstand the compression molding process, so if you are using heat, you will need to create molds that can handle dramatic temperature changes. Molds will also need to be able to withstand the amount of pressure applied during compression.

Die Casting

Die casting is one of the most popular ways to create molds for compression molding as well as other methods of manufacturing. Die casting remains a top choice because it delivers durable metal parts at a more affordable cost than alternative manufacturing methods. It should be noted that the dies for die casting are often made using CNC machining, and these two manufacturing methods often go hand-in-hand.

CNC Machining

CNC machining is an optimal choice for more detailed compression molds. The computerized component of CNC machining gives engineers more control over design; however, it can be expensive for creating tooling. Some manufacturers will use a combination of die casting, followed by CNC machining to produce molds that are more cost-effective.

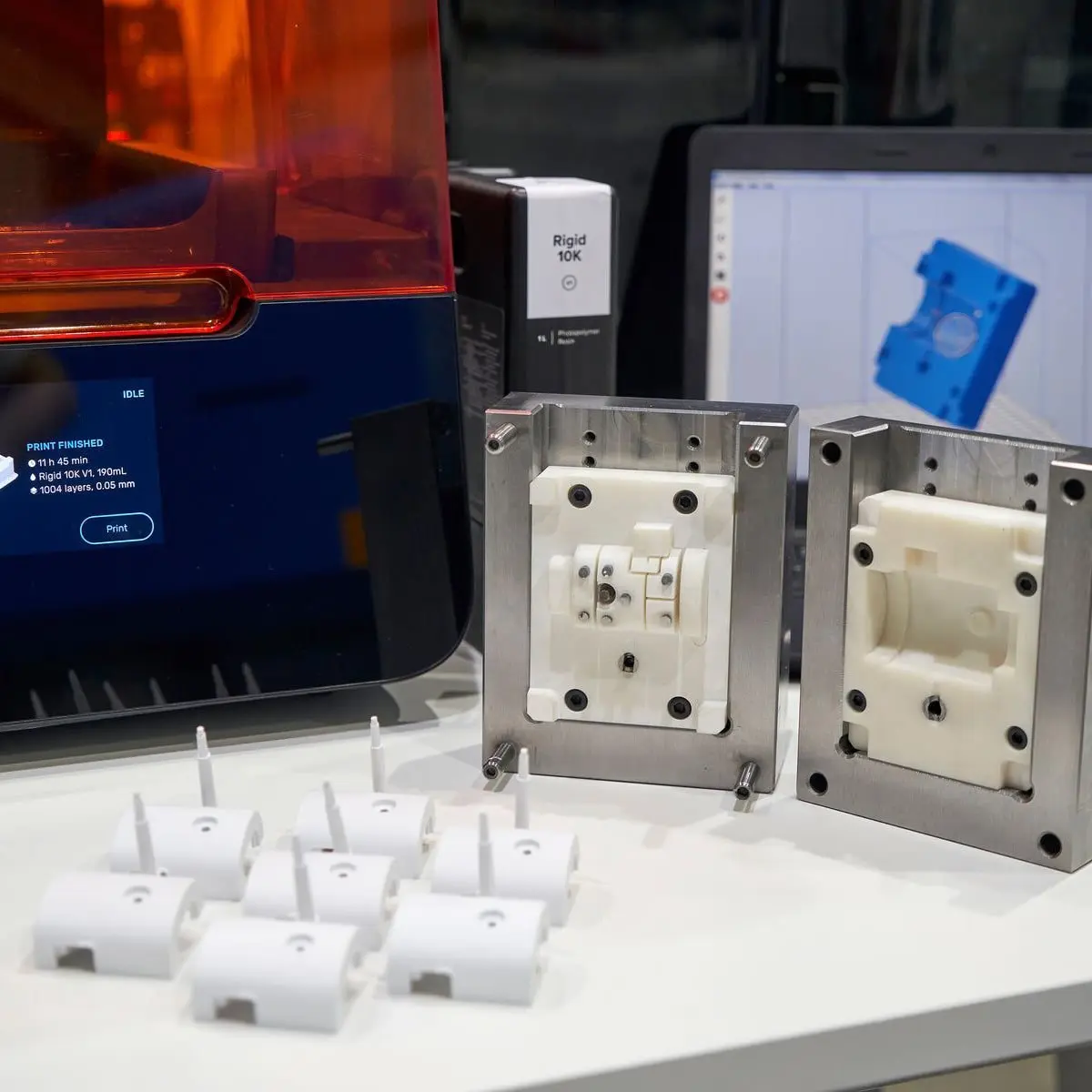

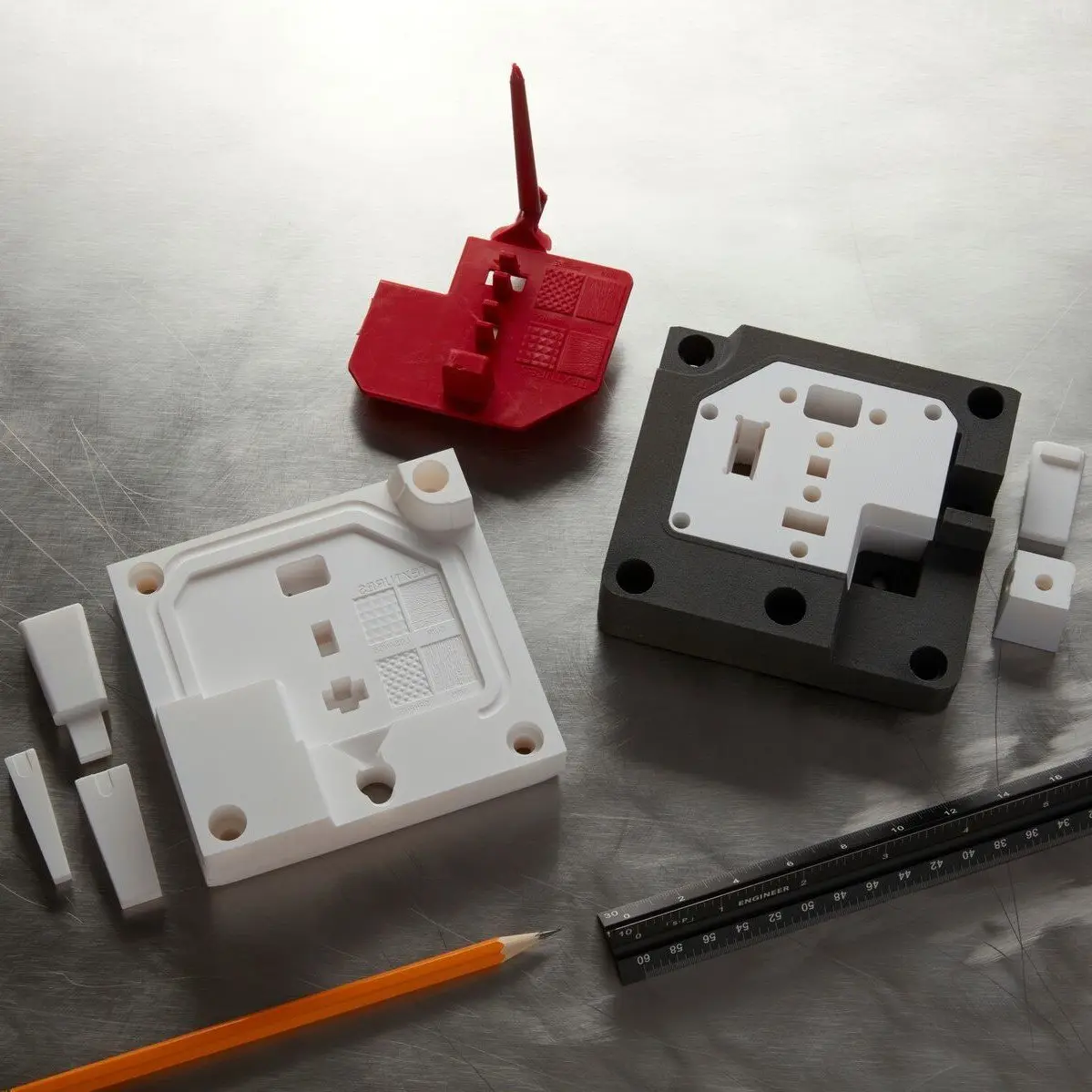

3D Printing

Tooling for compression molding can also be made using 3D printing. If you are prototyping smaller parts, 3D printing may be the cheapest and fastest method for creating molds. Multiple iterations can be made quickly with CAD software, reprinted, and then tested. 3D printing is most commonly used for compression molds intended for heatless applications.

3D printing is a fast and cheap method for creating molds for compression molding.

Guide to Rapid Tooling

In this white paper, learn how to combine rapid tooling with traditional manufacturing processes like injection molding, thermoforming, or casting.

How OXO Used Compression Molding for Prototyping

OXO is a U.S.-based brand that creates ergonomic and practical items for the home, including some iconic kitchen gadget designs. Product developers at OXO use stereolithography (SLA) 3D printing for form and function prototyping, but hybrid methods are essential for prototyping rubbery components, such as gaskets.

OXO engineers needed to produce a functional prototype for a cocktail shaker gasket that had watertight seals between parts. After testing many available silicones, they determined that compression molding two-part silicone putty Castaldo Quick-Sil was ideal for creating a watertight prototype that mimics the production gasket. In fact, the prototype compression mold is a good representation of the method and mold design used in gasket manufacturing.

OXO engineers used their Formlabs SLA 3D printer to create their molds out of Clear Resin. Once the molds were washed and cured, they were prepared for compression molding. A mold release was applied to the interior surfaces. Next, their silicone putty was prepared and placed into the bottom mold.

Left: The silicone mixture being placed into the 3D printed mold. Right: The mold being compressed in a tabletop vise.

The top mold was then closed into place, and engineers were able to achieve their desired level of pressure by compressing the two molds in a tabletop vise. Once the part was fully cured, it was released from the mold and trimmed. You can adapt this process easily for your own purposes using the step-by-step guide in our white paper.

The final functional prototype of the cocktail shaker gasket.

How to Produce Silicone Parts With 3D Printed Tools

In this webinar, you get to learn from a detailed example of a gravity-filled injection overmold printed with Formlabs Clear Resin. We also discuss how to select a mold type for your application, as well as silicone-resin compatibility and other silicone casting best practices.

Compression Molding, Injection Molding, Vacuum Forming, and Silicone Molding With 3D Printing

If you are interested in the step-by-step workflows for creating molds with 3D printing, watch our free educational webinars and download our free white papers:

-

Watch our webinar for the basics of mold design and how they apply to 3D printed molds, as well as real-world examples of prototype molding and 3D printed molds in production.

-

Download our white paper for a step by step guide on 3D printed tooling for silicone part production, with mold design best practices and customer case studies.

-

Download this white paper to learn about six mold making strategies for prototyping and production: injection molding, thermoforming, and casting elastomers.