Begin Your Manufacturing Learning Pathway

Find opportunities to use 3D printing to reduce costs and lead times in manufacturing–from small-batch production to tackling inefficiencies on the production line.

Follow along step-by-step for thorough instruction, or pick and choose individual resources most relevant to your needs or learning style.

Choose the Right Materials

Gain a deeper understanding of the properties and functions of each Formlabs resin and learn which are best for your applications.

Learn to:

- Identify the resins you will use most frequently

- Understand the material properties of individual resins

- Understand the printing and post-processing requirements of each resin you use

Material Guide: Tough Resin

Learn to print parts in Tough Resin for prototyping strong, functional parts and assemblies that will undergo brief periods of stress or strain.

Learn to:

- Choose suitable applications for Tough Resin

- Print successfully with Tough Resin

- Post-process and post-cure Tough Resin

Material Guide: Rigid Resin

Learn to use glass-reinforced Rigid Resin to produce parts requiring high stiffness, resistance to deformation, and a polished finish.

Learn to:

- Choose suitable applications for Rigid Resin

- Print successfully with Rigid Resin

- Post-process and post-cure Rigid Resin

Material Guide: Durable Resin

Learn to use Durable Resin to print parts with a smooth, glossy finish and high resistance to deformation.

Learn to:

- Choose suitable applications for Durable Resin

- Print successfully with Durable Resin

- Post-process and post-cure Durable Resin

Material Guide: Flexible Resin

Learn to use Flexible Resin to print parts that bend and compress, simulate soft-touch materials, and more.

Learn to:

- Choose suitable applications for Flexible Resin

- Print successfully with Flexible Resin

- Post-process and post-cure Flexible Resin

Material Guide: High Temp Resin

Learn to use High Temp Resin to print models for environmental testing, or create molds and masters for production processes like casting and thermoforming.

Learn to:

- Choose suitable applications for High Temp Resin

- Print successfully with High Temp Resin

- Post-process and post-cure High Temp Resin

Material Guide: Grey Pro Resin

Learn to use Grey Pro Resin to print high precision concept models and functional prototypes, or for parts that will be handled repeatedly.

Learn to:

- Choose suitable applications for Grey Pro Resin

- Print successfully with Grey Pro Resin

- Post-process and post-cure Grey Pro Resin

Jigs and Fixtures

Read this guide to understand the basics of designing jigs and fixtures with 3D printing, and the opportunities for reducing costs and cycle times.

Learn to:

- Design mechanisms for locating, supporting, fixtures, and clamping

- Take advantage of 3D printing’s design freedom to build better jigs and fixtures

- Leverage the unique benefits of 3D printing materials in manufacturing

Reducing Costs in Manufacturing with 3D Printing

Learn how Pankl Racing Systems employed 3D printing to rapidly manufacture hundreds of custom jigs for a fraction of the cost and lead time of outsourcing.

Learn to:

- How Pankl uses 3D printed parts directly on their production line to drastically reduce costs and lead times

- How parts printed in Formlabs Engineering Resins fulfilled the requirements of Pankl’s demanding manufacturing environment

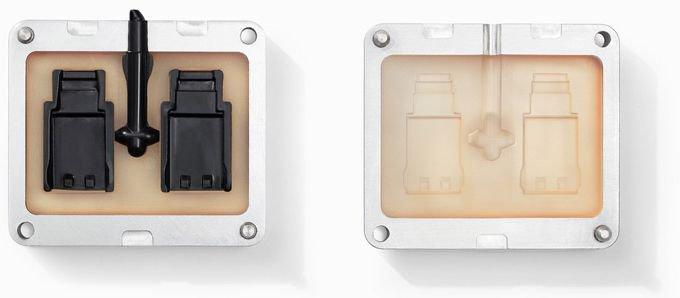

Making Molds with 3D Printing

Learn to speed up prototyping, save money, and help bring products to market faster by combining 3D printing and moldmaking in this webinar.

Learn to:

- Understand the advantages and disadvantages of current mold production techniques

- Apply the basics of mold design to 3D printed molds

Agile Manufacturing at RightHand Robotics

Watch this short video to learn how RightHand Robotics uses the Form 2 to improve their products with agile manufacturing.

Learn to:

- The benefits of a flexible design and production process

- How Righthand Robotics uses 3D printing to create molds for casting final materials

Look Inside Formlabs Manufacturing Processes

Watch this webinar to learn how we use our own desktop 3D printers in production, from prototyping for manufacturability to printing functioning end-use parts used on the line.

Learn to:

- Use 3D printing to reduce prototyping costs and delays in manufacturing

- Create agile manufacturing conditions

- Change designs as needed during the production process

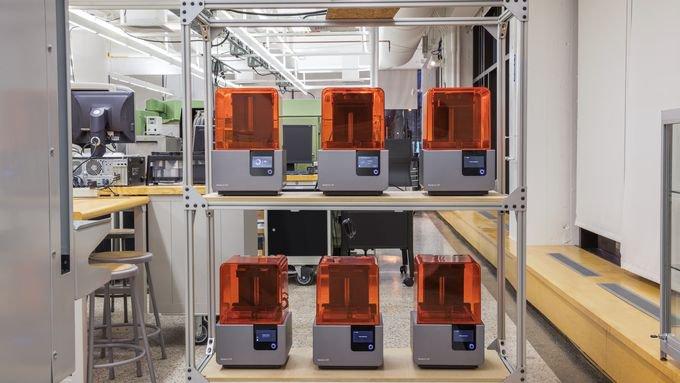

Manage Multiple 3D Printers

Learn the unique demands of managing multiple 3D printers to increase productivity while growing your 3D printing capacity.

Learn to:

- Configure a multi-printer lab or workspace

- Acquire and manage consumables and essential supplies

- Understand the 3D printing process at scale