Improve Efficiency With 3D Printed Manufacturing Aids

3D printed manufacturing aids, such as custom jigs, fixtures, tools, and replacement parts on the shop and factory floors, are vital tools for addressing common problems that arise during manufacturing. Bring 3D printing in-house to improve the efficiency of your manufacturing process, reduce costs, shorten lead times, and enhance production quality.

Why Go Digital?

Lower Costs

Faster Turnaround Time

Flexible Manufacturing

Design Freedom

Precision and Repeatability

Lightweight and Ergonomic

Leverage 3D Printed Tools at Every Manufacturing Step

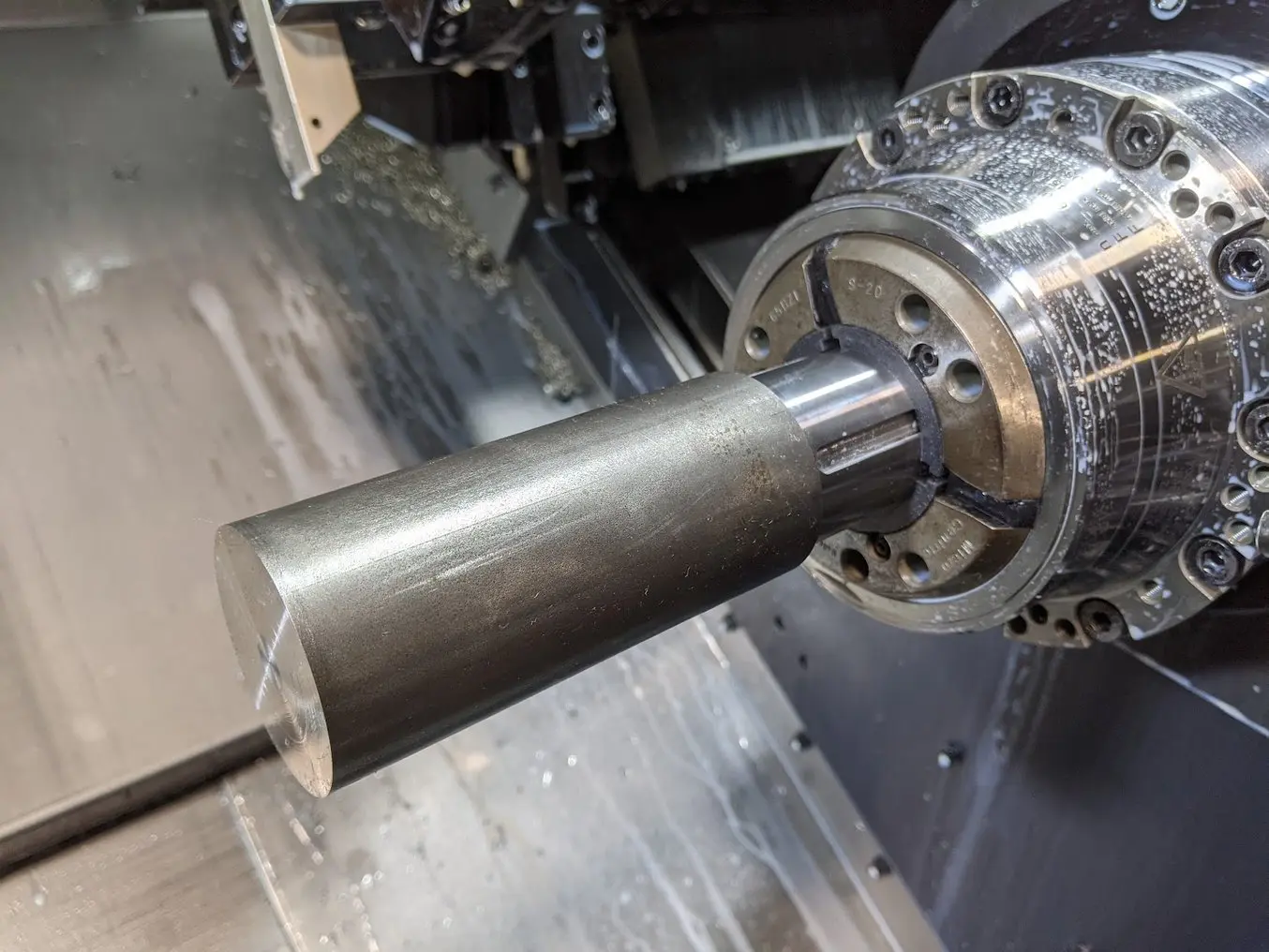

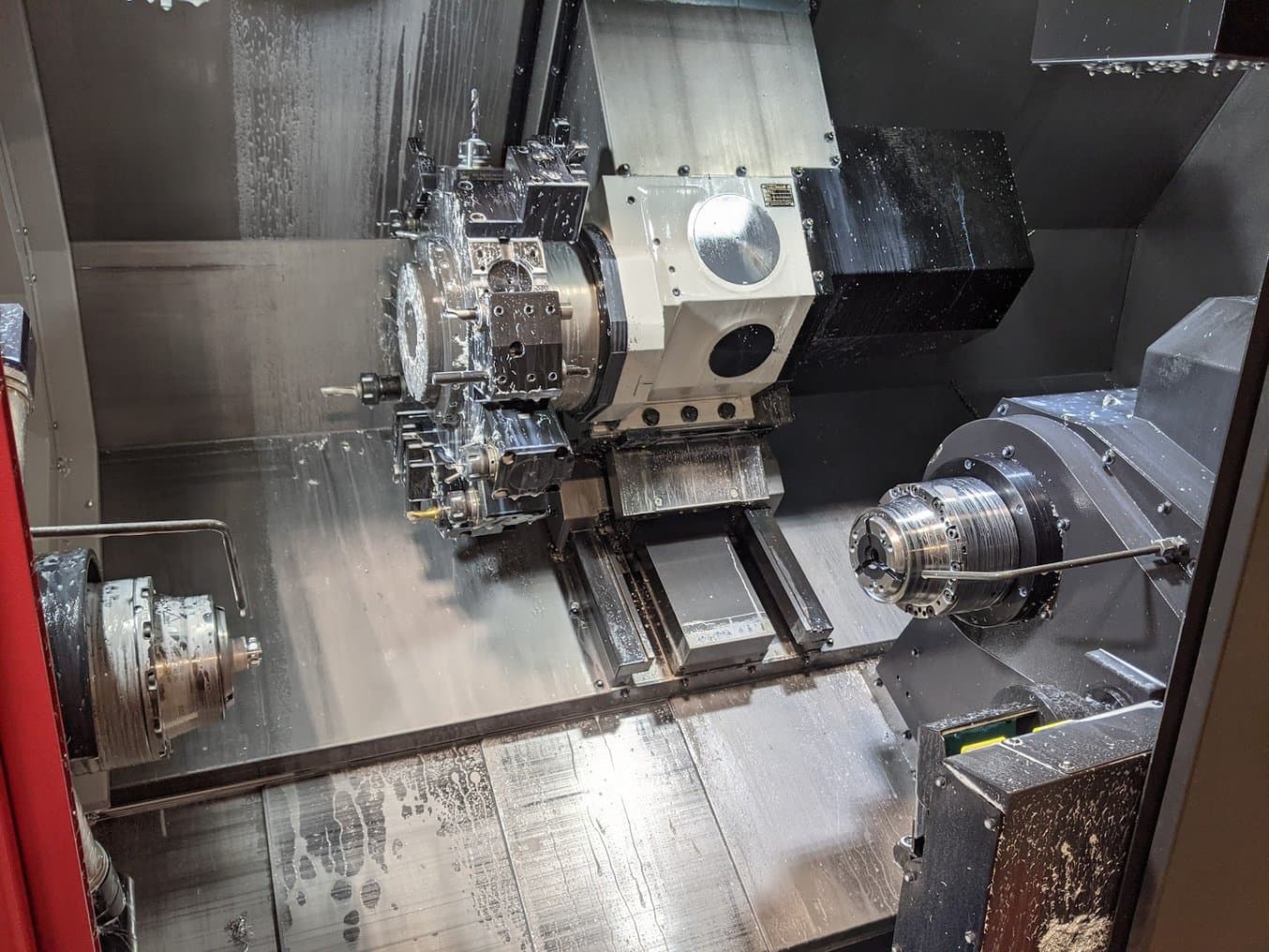

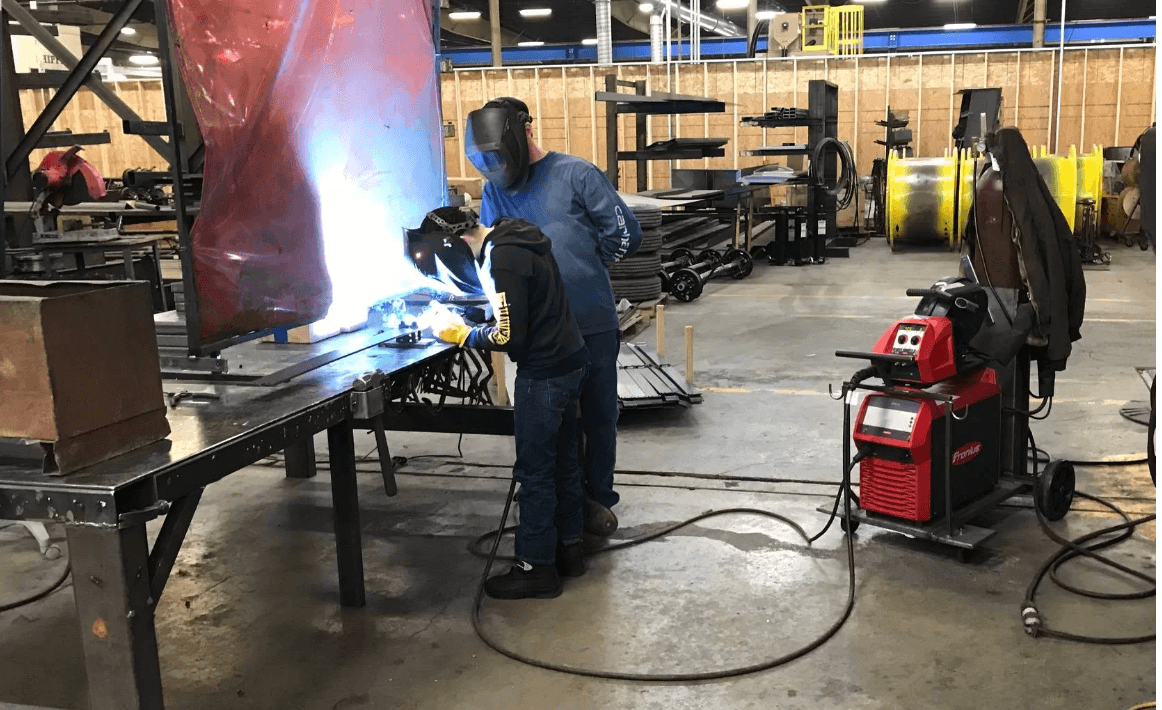

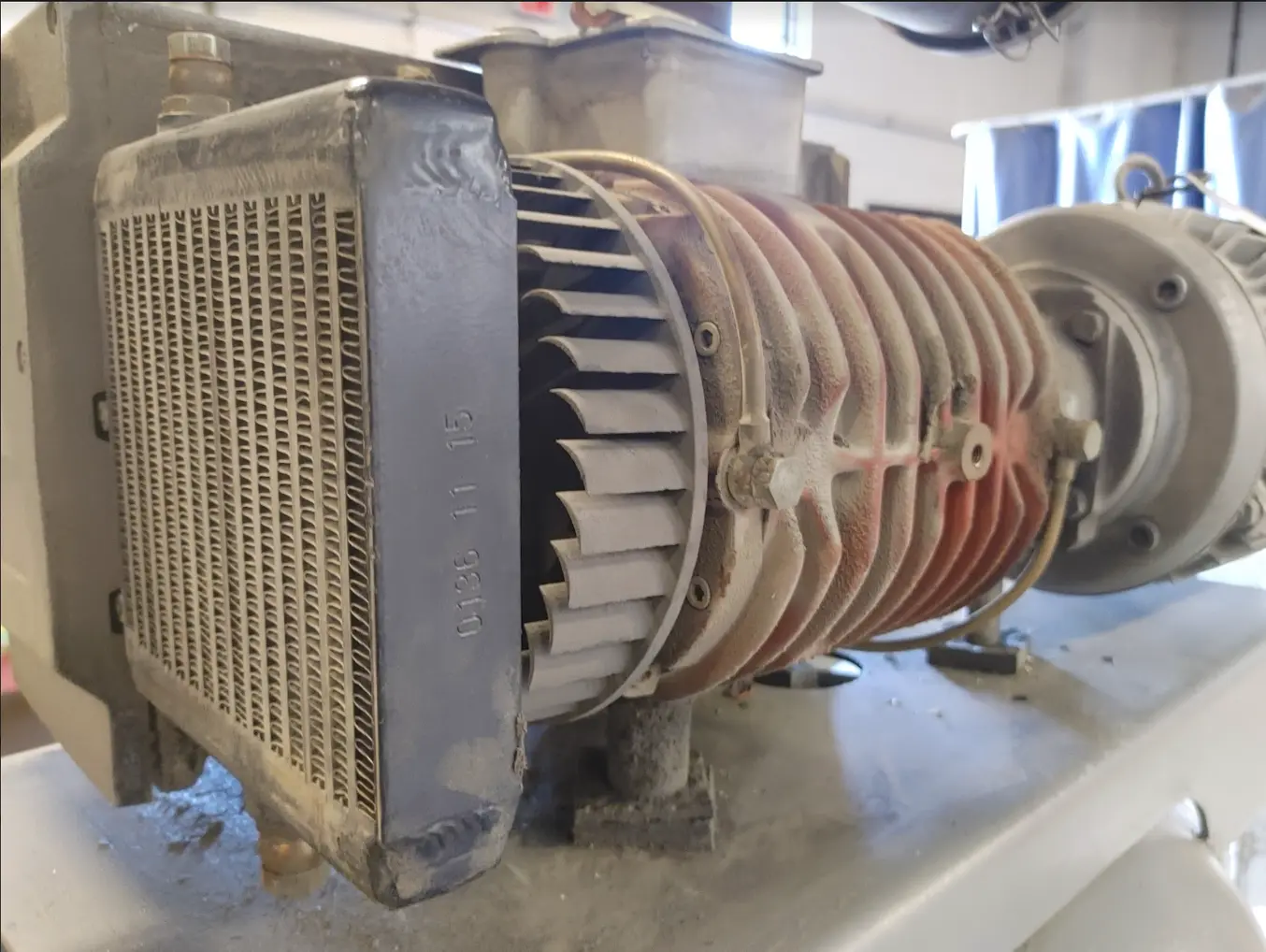

Metalworking Operations

Bring manufacturing flexibility in-house and produce robust and precise tools that withstand demanding environments such as welding or machining. 3D printing introduces a new level of efficiency to metalworking by cutting costs, reducing lead times, and allowing for rapid customization of jigs and fixtures.

See Also

Reduce Costs and Lead Times in Metalworking With On-Demand Jigs and Fixtures

How Brose Leverages SLA and SLS Technology to Bolster Automotive Production

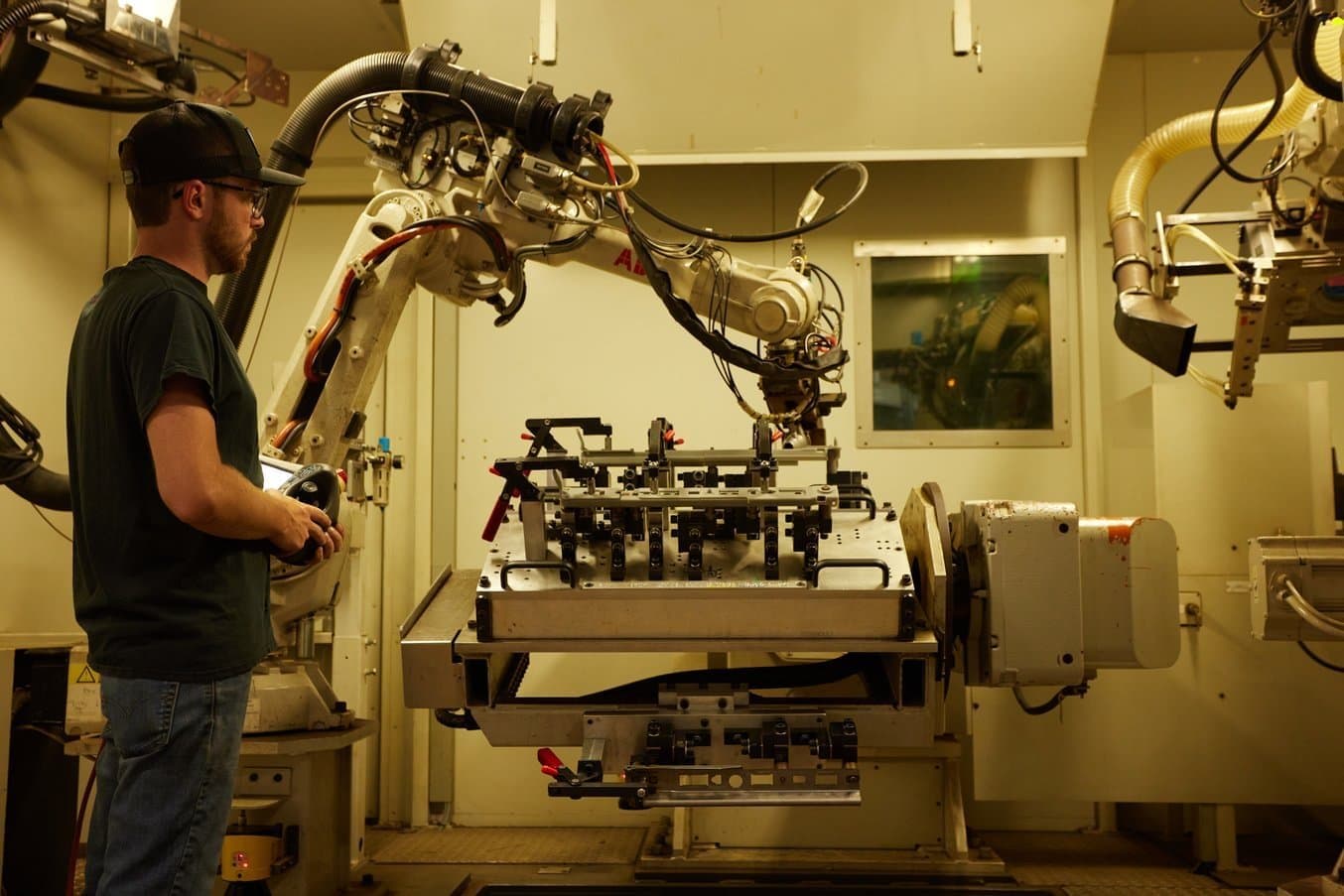

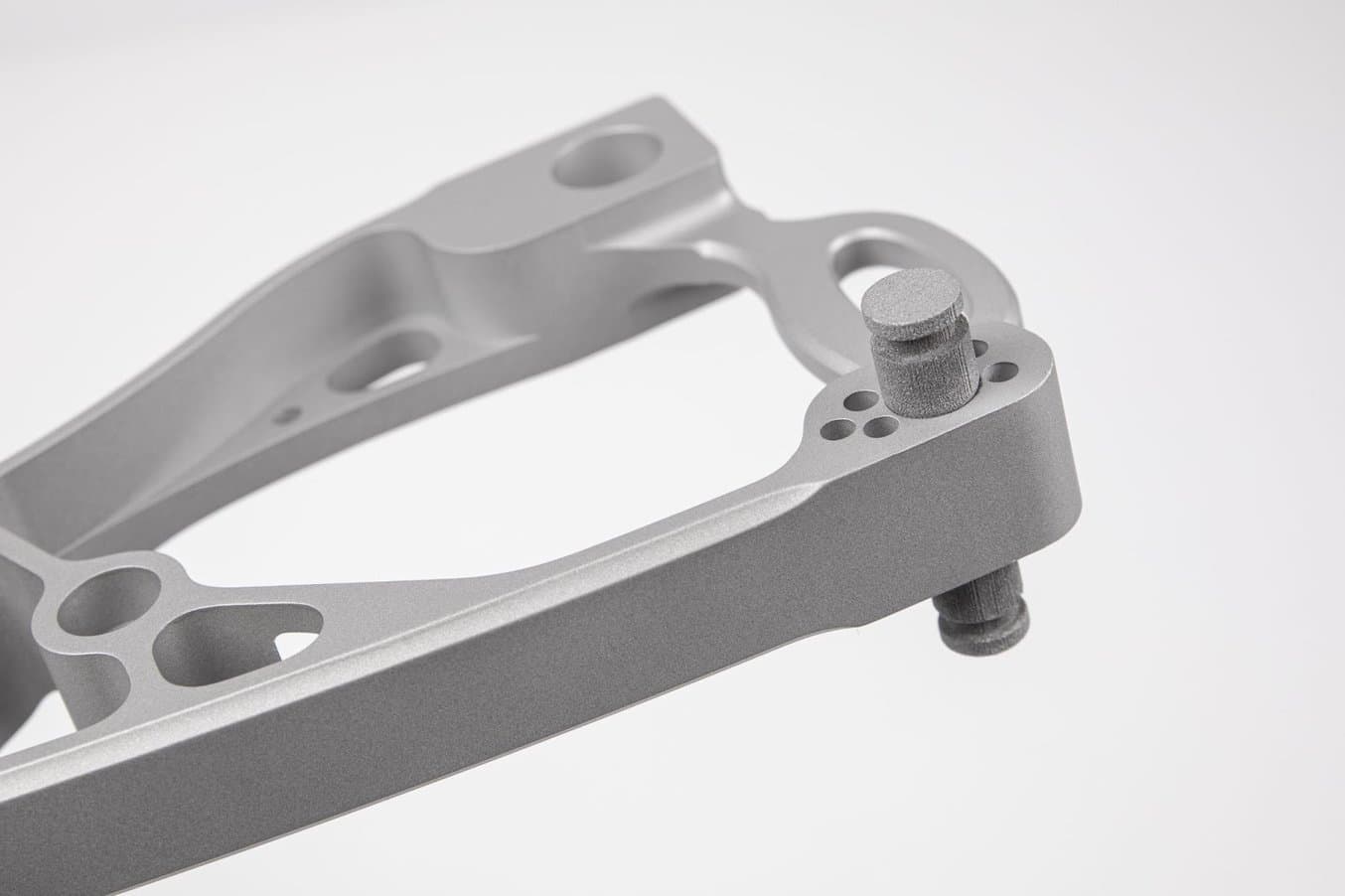

Tooling and Replacement Parts

Manufacture custom tooling within 24 hours and reduce machine downtime by producing on-demand replacement parts in-house. 3D printed polymer parts offer almost unlimited design freedom, light weight, a wide range of material options, and durability to stand in or even replace metal parts in many applications.

See Also

Printing Presses, Empowered by 3D Printing: Robotics Applications and Replacement Parts at HEIDELBERG

Problem Solving on the Factory Floor: Manufacturing Aids at Productive Plastics

How Rosenberger Optimizes Traditional Manufacturing and Lead Times With 3D Printed Tooling and End-Use Parts

3D Scanning and 3D Printing for Reverse Engineering and Other Applications

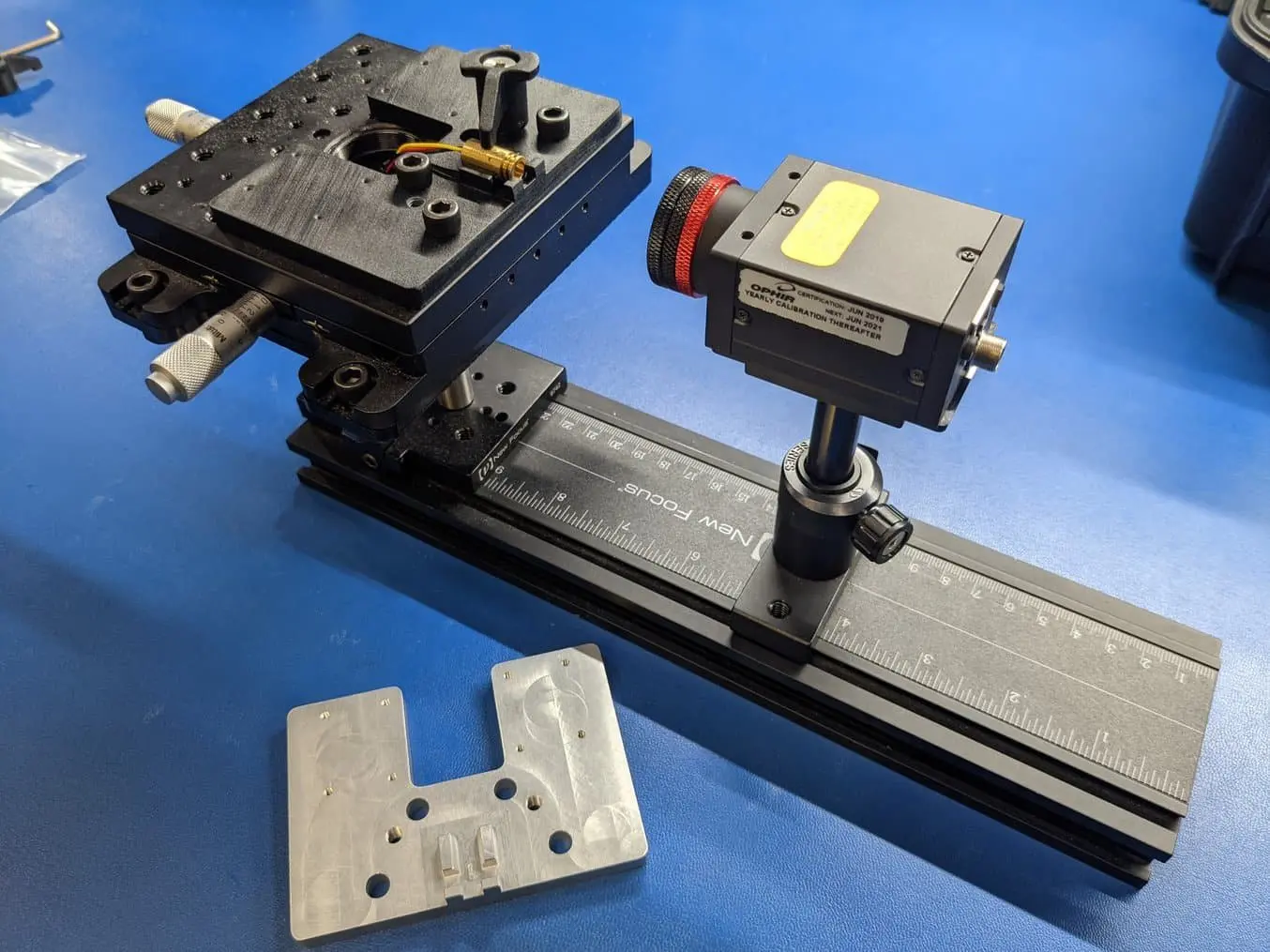

Assembly and Inspection

Improve manufacturing efficiency with custom assembly and alignment jigs, component trays, testing fixtures and rigs, and more. From flexible to ESD-safe, 3D printing offers a material for any solution.

See Also

Controlling the Automotive Supply Chain: 3D Printing at Jasper Engines & Transmissions

SLS 3D Printed Tools Help Digitalize Oil Pipeline Operations and Maintenance

3D Printing Fast and Cost-Effective Manufacturing Tools for Watchmaking

Finishing and Masking

3D printing presents a cost-effective means of creating customized masking parts that can fit complex geometries and be used repeatedly, reducing the need for hours of manual labor during post-production workflows.

See Also

How Deutsche Bahn Uses 3D Printed Manufacturing Aids to Streamline Vehicle Maintenance

How Figure Engineering Developed an Advanced SLA Material for the Department of Defense

Powerful and Versatile 3D Printing Solutions to Streamline Tooling Processes

Form 4

Precise, smooth, and ergonomic tools with fine details

Wide range of material properties

Fast and easy for low-volumes

Accessible entry price points

Form 4L

Mid to large-size parts

Precise, smooth, and ergonomic tools with fine details

Wide range of material properties

Fast and easy for mid and high-volumes

Fuse 1+ 30W

Strong, durable, and heavy-duty tools

Chemical-resistant and environmentally stable tools

Lightweight tools with complex design

Cost-efficient for large volumes

Save Time and Money

Your printer pays for itself in a matter of weeks or months, accelerating the pace of work along the way.

Curious to see how much you can save? Try our interactive ROI tool to calculate cost per part and lead time when 3D printing on Formlabs 3D printers.

Cut Tool-Making to 24 hours

Stop waiting weeks for tools to arrive from a service provider or for your CNC machine to free up. With in-house 3D printing, you can create custom jigs and fixtures within a day, run tests, tweak your design, and print again.

3D Print

Post-Process

Test and Integrate

Get Started 3D Printing for Manufacturing Aids

Contact a Formlabs Solution Specialist to get started with manufacturing aids production powered by 3D printing.