“This will make the diagnosis of tumors or diseases easy and precise and will change the way we diagnose and treat diseases in the long run.”

Sheng Liu, Development Director at Pixelbio

DNA-specific genetic testing and detection are some of the most rapidly developing fields in research and medicine. Thanks to their ability to quickly produce custom biomolecular-chips at an affordable price, 3D printers have been playing a growing role in empowering these innovations.

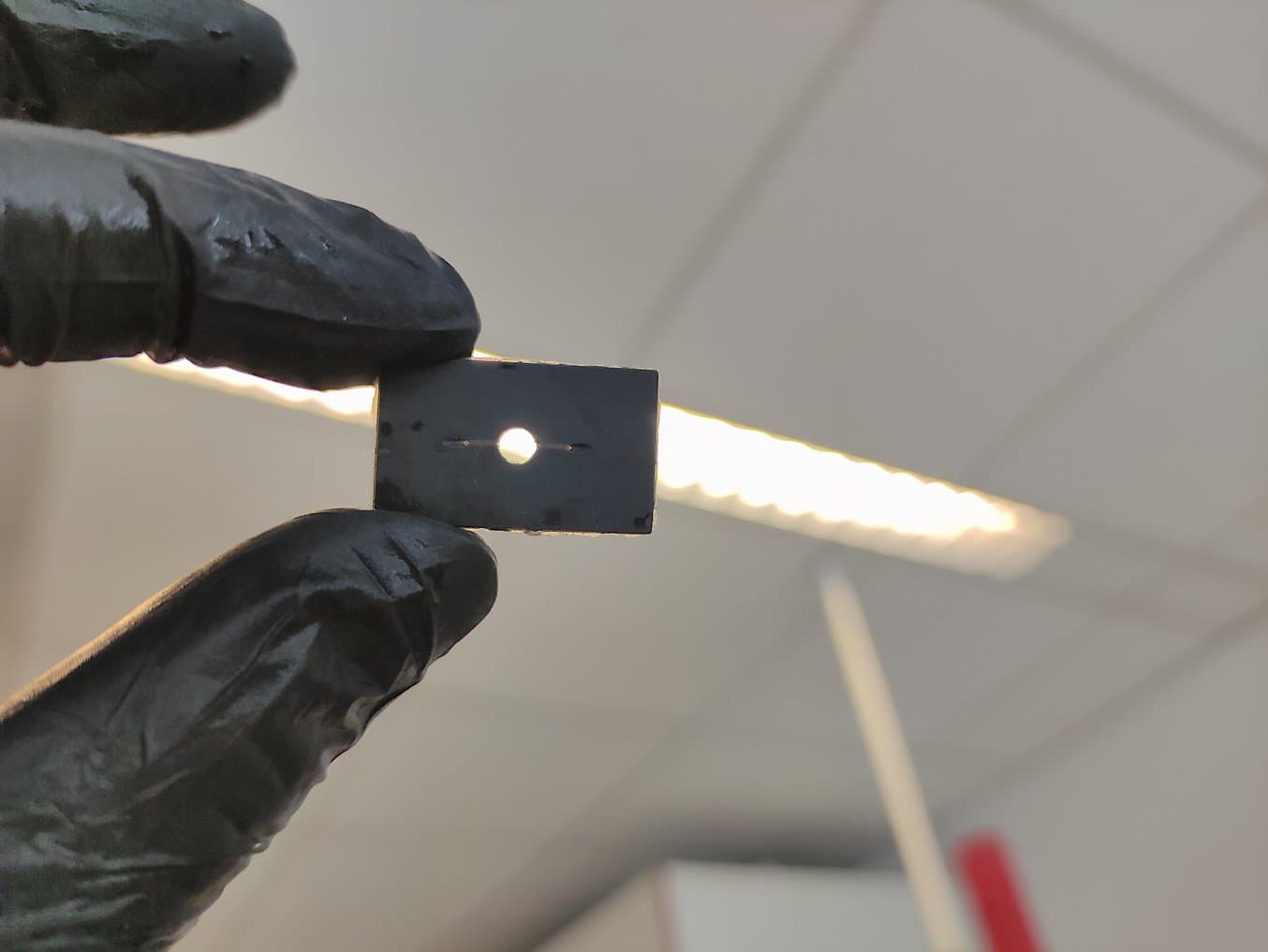

Pixelbio is one of the pioneers of this approach. Based in Heidelberg, Germany, Pixelbio specializes in single-molecule genetic testing and has found a way to change the medical and diagnostic field with genetic research using 3D printed molecular biochips. Through their singular molecule fluorescence in situ hybridization application HuluFISH, they promise an easy and fast detection of genes through multi-color-labeled probes—all of which takes place in a 3D printed molecular biochip created using Black Resin.

The molecular chip contains multiple labeled probes and can recognize up to 7 different genes in a single reaction. The different types of color combinations are used as barcodes, which can then be read under the microscope, or Pixelbio's AI-driven software.

Since the early 1960s, in situ hybridization has found applications in a variety of industries due to its ability to directly locate and detect specific nucleic acids, DNA and RNA, in tissues, cells, cell compartments as well as chromosomes. The method generally involves the use of chemical or radioactive probes to make the targeted genes visible in human, animal, or plant cells.

However, it is also possible to use fluorescent substances—the so-called fluorescence in situ hybridization or FISH method. This technique, as the name suggests, uses fluorescent markers that dock onto the targeted gene making it visible under the microscope. Although the method has been supplemented by single molecular detection, making it possible to study gene expressions in a single cell by detecting individual RNA molecules, the FISH method has,until now, always been limited to detecting one singular gene.

Pixelbio has now changed that: With their product HuluFISH, they offer the industry's first individualizable multiplex smFISH solution, allowing a large number of genes to be detected simultaneously with a 3D printed molecular biochip manufactured with the Form 3 stereolithography (SLA) 3D printer.

By detecting and identifying a large number of samples simultaneously, Pixelbio has the potential to change the medical and diagnostic field. "[HuluFISH] will make the diagnosis of tumors or diseases easy and precise, and will change the way we diagnose and treat diseases in the long run," Sheng Liu, Development Director at Pixelbio predicts.

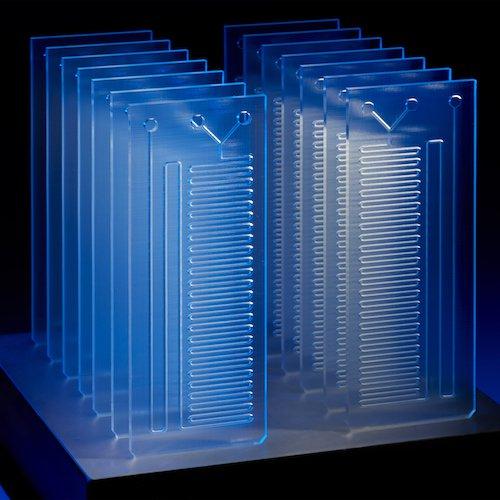

From Pixelbio’s ever-growing library of detectable genes, customers are able to assemble the probes that they require, making HuluFISH not only innovative but also highly customizable and suitable for a wide range of testing. Upon ordering, customers not only receive the marked genes of their choice but also the corresponding 3D printed molecular biochips to perform the test.

The 3D printed molecular biochips from Pixelbio offer opportunities for a variety of new applications and rapid research.

3D Printing Molecular Biochips

Molecular biochips are used for simultaneous measurement of biochemical samples at high throughput. During the process, liquids are introduced through channels with diameters of 0.8-1.2 mm, and are combined in the chamber in which they are then detected and identified with a laser. The requirements of these chips depend on the type and amount of liquids to be tested as well as the desired result, and can thus be difficult and time-consuming to manufacture.

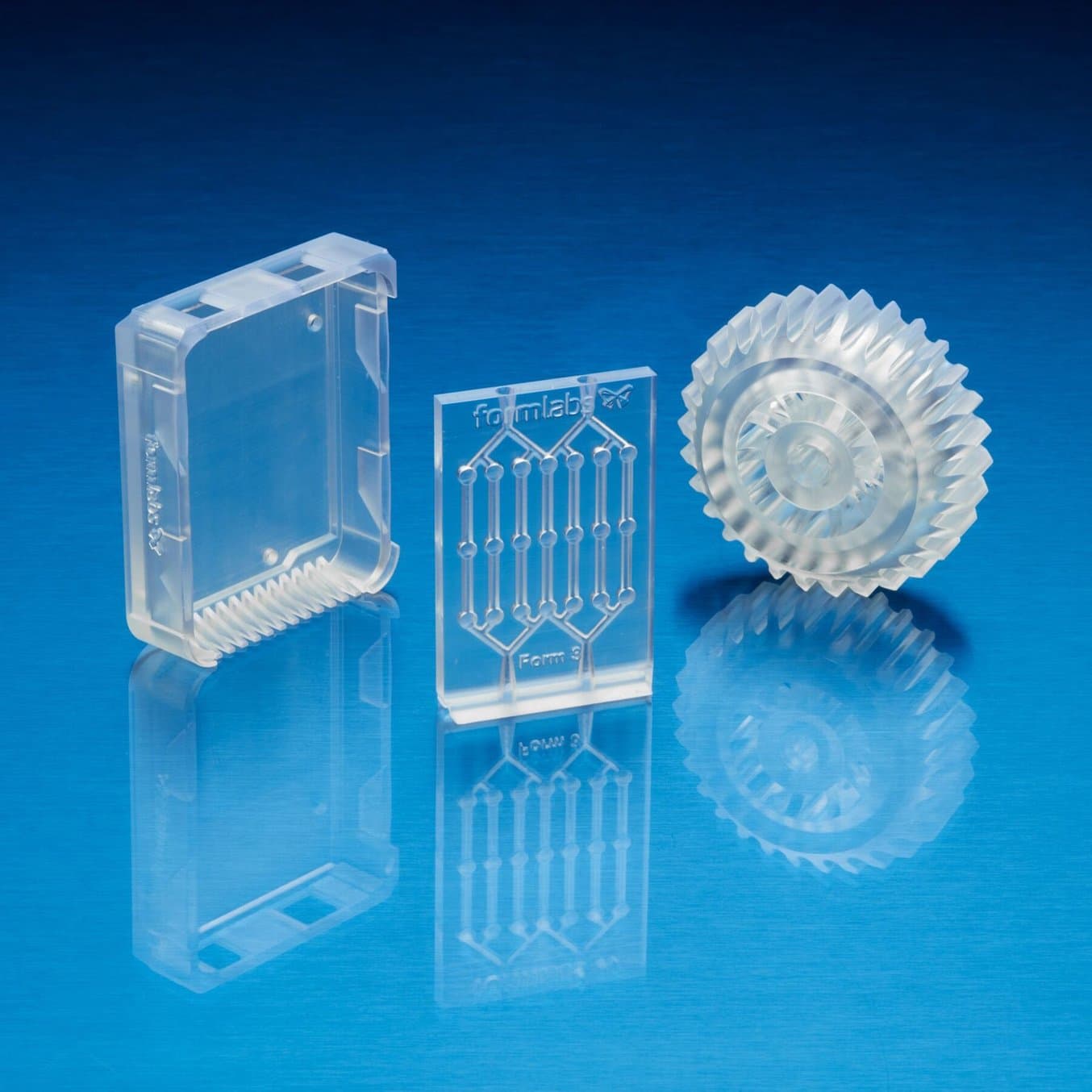

Desktop Millifluidics With SLA 3D Printing

This white paper delves into the implementation of millifluidic geometries using stereolithography (SLA) 3D printing and best practices for fabricating millifluidic chips in-house.

Development Director at Pixelbio, Sheng Liu, who is responsible for the design and production of the biochips faced the same issue with HuluFISH. Due to the different types of probes, the chip's specifications are constantly changing, and finding the right prototype takes multiple weeks or even months.

“We need to be more efficient when developing new molecular probes, and thanks to the Form 3’s high precision and printing speed, we are able to use it to print tubes smaller than 1 mm into a tiny space.”

Sheng Liu, Development Director at Pixelbio

Prototypes for their molecular biochips can now be produced and printed directly on site. Liu and his team have been able to save a significant amount of time as well as costs. In addition, using in-house SLA 3D printing has enabled them to reduce the size of the channels to 0.8 mm from the original 1.2 mm, making their chips more efficient.

Pixelbio is working with two Form 3 SLA 3D printers in their R&D center in Heidelberg, Germany.

Due to its properties, such as low opacity, Black Resin has proven to be highly effective in the creation of molecular biochips. In fact, Formlabs Black Resin has shown such impeccable results in the manufacturing of Pixelbio's molecular biochips that it has led them to use the 3D printed chips to test new ideas. As a result, they were able to save time and costs as well as carry out a large number of tests with new designs within just a few days.

“We found that once the design was right, we could produce the part we needed quickly and on a large scale with Formlabs products, which would have been very expensive per unit and not necessarily suitable for our needs [with traditional methods].”

Sheng Liu, Development Director at Pixelbio

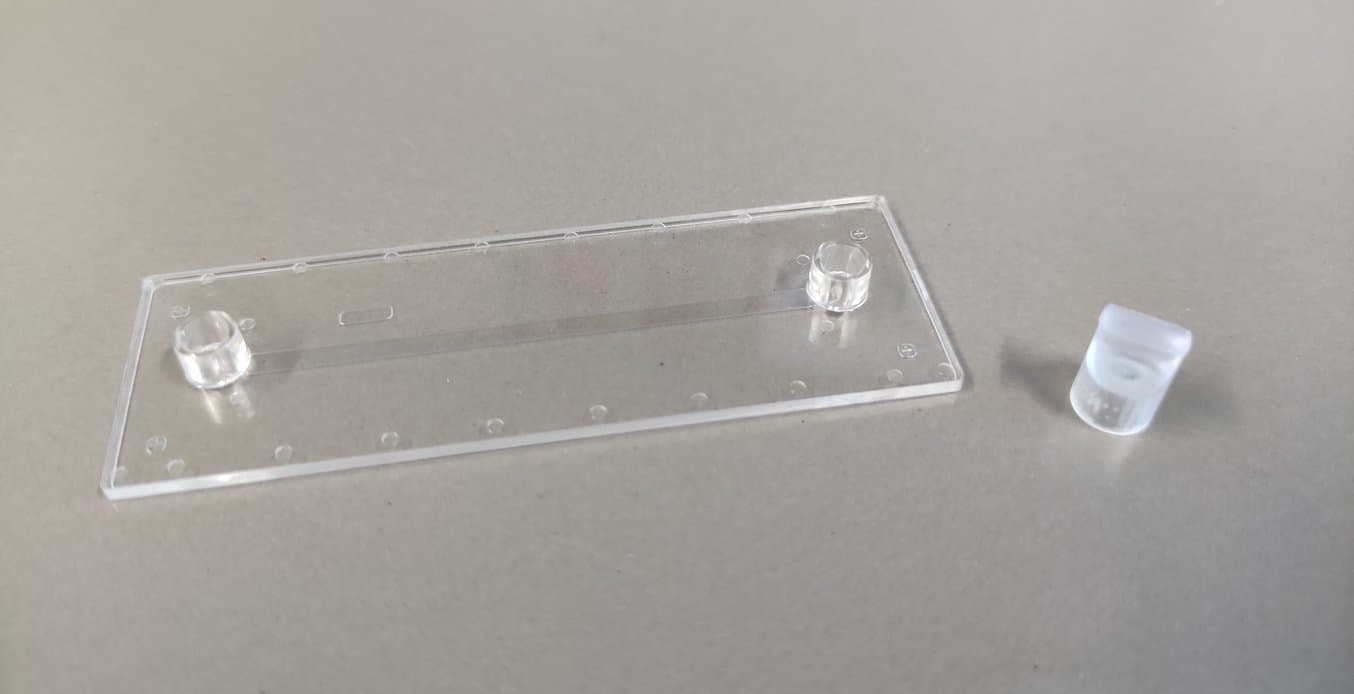

In addition to the production of the molecular chips, the Form 3 has also found application for the production of other components in Pixelbio's laboratory. "In the process of developing the automated staining system, some of the small necessary parts can be produced by printing them ourselves, so that we don't need to search or order—which usually takes several days to reach us—3D printing only takes a few hours," said Sheng Liu. As a result, they are now producing precision-fit closures for the liquid inlets of their chips with Formlabs Clear Resin, which not only save time and costs, but also allow them to stay independent and flexible in the development and design of their chips.

Pixelbio is also using the Form 3 and Formlabs Clear Resin to 3D print precision-fit closures for their liquid inlets - which not only saves time and costs but also allows them to stay independent and flexible in the development and design of their chips.

HuluFISH for a Rapid COVID-19 Response

The customizability of HuluFiSH and its ability to detect multiple genes simultaneously has also made it suitable for the targeted detection of the SARS-CoV-2 virus. The probes within the chip can be specified to not only detect but also directly determine all publicly available strains of the virus in infected tissue or cells.

This provides not only the ability to identify the virus itself but also shows potential for further analysis on the progression of the SARS-CoV-2 as well as the discovery of additional vaccines. "We are confident that our HuluFISH probe can accelerate the development of drugs and vaccines by enabling the detection of SARS-CoV-2 and its receptor ACE2 mRNA at the single-cell molecule level."

Due to their promising product in the fight against COVID-19, Pixelbio is currently participating in an international competition of the National Institutes of Health. The NIH has launched a Rapid Acceleration of Diagnostics (RADxSM) initiative in 2020 with the purpose of identifying and funding companies which exhibit promising technologies for rapid COVID-19 testing. Pixelbio is currently in the second phase of the competition after having been selected out of 100 competitors worldwide.

Request a Free Sample Part

See and feel the quality of SLA 3D printing firsthand. Request your sample and we’ll ship a free 3D printed Clear Resin sample to your office.

The Future of 3D Printed Molecular Biochips

With the opening of the second laboratory in Hamburg, Pixelbio now has a Form 3 at both locations. The printer in Hamburg is being used to 3D print the chips, their Research and Development Center will remain in Heidelberg, where Pixelbio plans to expand the number of accessible probes and develop more spectrale separable fluorophores, including the development of more 3D printed biochips.

The company is exploring new ways to use their 3D printers: They are currently in the process of developing microarray chips using the Form 3—another method of gene detection in which DNA spots are pressed onto a 3D printed biochip.

If you want to ready more about biochips read our article on microfluidic chips.

Note: Users involved in the pharmaceutical manufacturing of tubing, fittings, and other fluid-contact devices may be interested in BioMed Clear, which is USP Class VI certified.