The availability of low-cost resin 3D printers over the past few years has increased accessibility, especially in the hobbyist space. However, while it has expanded who and what can be printed, low-cost resin printers often come at a cost.

Low-cost resins often contain 4-Acryloylmorpholine (ACMO), a harmful and hazardous chemical, lack or misrepresent safety information, and come with no customer support. Workflows of low-cost resin 3D printers are also more manual and prone to user error, leading to an increased risk of exposure to resin and isopropyl alcohol (IPA).

We’ve developed the following to improve the safety and experience of users of Formlabs resin 3D printers:

- Resin cartridge and tank designed to minimize resin exposure

- Automatic resin dispensing and smart sensors

- No ACMO in our resin formulations

- Contained post-processing solutions

- An IPA alternative, Formlabs Resin Washing Solution

- Extensive documentation

- Robust sales and service support

In designing our 3D printers, documentation, support, and services with an eye to user experience, Formlabs resin 3D printers offer safer workflows than low-cost resin printers.

Product Demo: Form 4

See how Form 4 can enable new levels of productivity and innovation through its unmatched speed, accuracy, and reliability.

Resin Safety

Auto-Dispensing Resin Cartridges

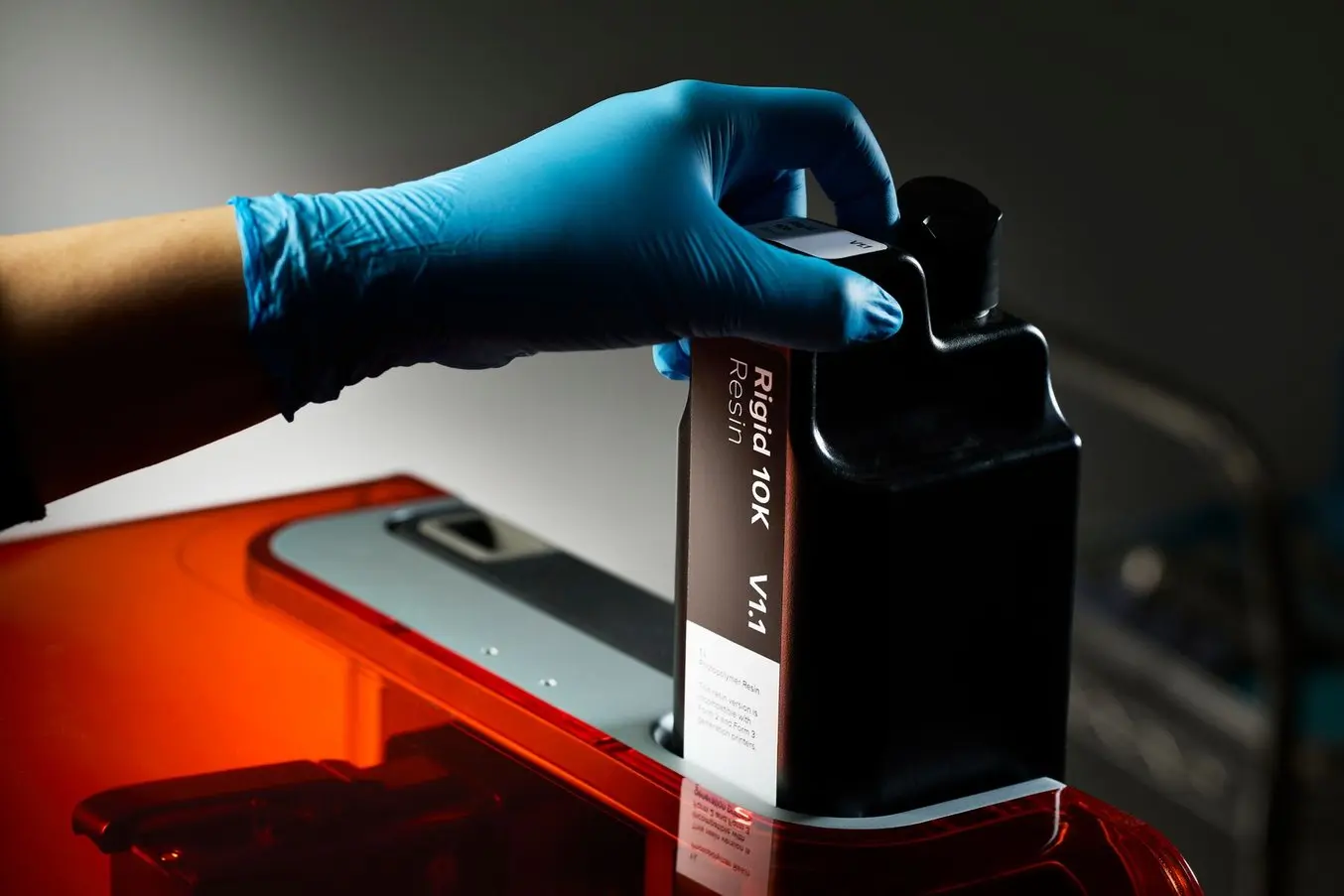

Formlabs resin cartridges are designed to minimize spills and potential skin contact, though gloves should always be worn when handling resin and resin cartridges. Once a resin cartridge is installed in a Formlabs 3D printer, resin will automatically dispense, reducing possible spills and any need to clean up resin.

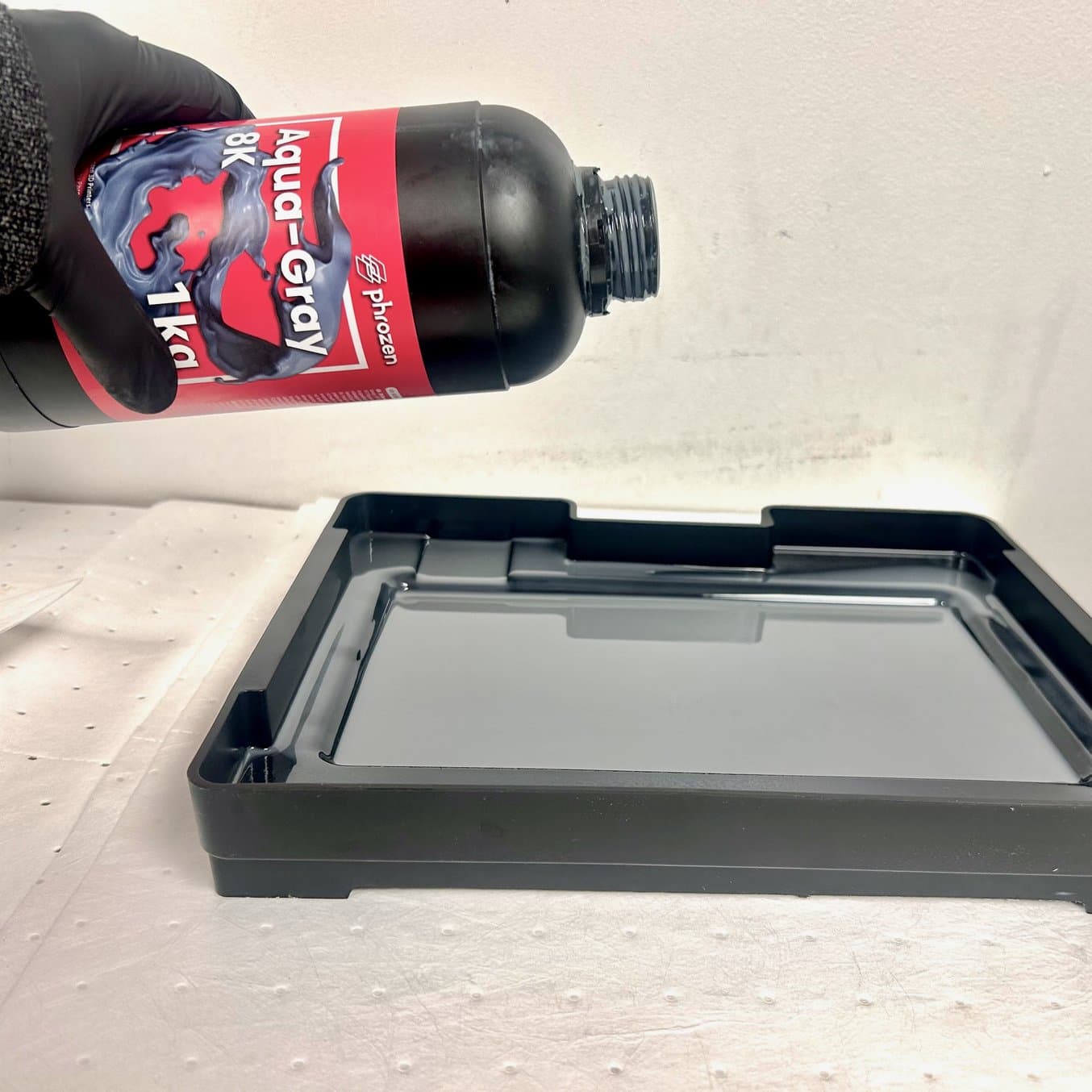

In contrast, low-cost resin is packaged in bottles and must be manually poured into the resin tray, increasing the likelihood of a spill and potential skin contact with resin.

Resin cartridges for Form 4 Series printers contain 1 L of resin, but with 63% less plastic and a 30% smaller footprint than Form 3 Series cartridges, for less waste and more efficient storage. Once installed in the printer, a cartridge load cell weighs how much resin is in the cartridge, giving a clear picture of how much resin remains so it’s easy to plan ahead on resin quantities. Plus, automatic resin dispensing eliminates the need to top off resin while printing, further reducing the chance of resin spills.

Formlabs resin cartridges were developed to minimize spills while automatic resin dispensing and smart sensors inside Form 4 series printers make for a streamlined printing process.

Resin Tank Design

Most low-cost resin tanks have a bare-bones design and don’t include a lid or box, leading many users to store them in cardboard boxes or tupperware. This can also make storage cumbersome.

Formlabs resin tanks for Form 4 Series printers come with lids and areas for labeling the tank with the date and contents. Tanks store information; when a tank is installed in a printer, the touch screen will display resin and lifetime information. Lids are designed to allow stacking of resin tanks for efficient storage.

Handles make it easy to pick up a Formlabs resin tank while a raised bottom protects the film from debris and damage. Low-cost resin tanks typically don’t have handles, making it more likely that the resin tank film will be touched or dirtied. Additionally, Formlabs resin tanks are designed to be robust and long-lasting, preventing potential workflow disruptions like resin spills.

Low-cost resin has to be poured into the resin tank, increasing the risk of resin spills and skin exposure.

Formlabs resin tanks have lids and are easily stacked for space-efficient storage.

Resin Formulations

Low-cost resins often use cheap and volatile chemicals to cut costs and increase print speeds. While some of these additives are safe, some of these chemicals produce noxious odors and fumes, sometimes leading to complaints of eye and throat irritation and headaches, and can pose longer term health risks.

One component commonly used in low-cost resins is 4-Acryloylmorpholine or ACMO. ACMO is inexpensive and highly reactive, enabling manufacturers to cut costs and decrease print times. The EPA has issued a SNUR, or a significant new use regulation, for ACMO because of the potentially dangerous effects of breathing in its vapors and its ability to quickly sensitize skin. The SNUR requires manufacturers to report ACMO on material safety data sheets (SDS). Unfortunately, not all resins that contain ACMO adhere to the safety labeling requirement. Resins containing ACMO should list it on their SDS sheet along with the health hazard statements, “May cause damage to organs through prolonged or repeated exposure” and “May cause reproductive effects.”

The EPA has issued a significant new use regulation for ACMO. Resins containing ACMO should list it on their MSDS sheet, though not all do.

ACMO also presents an ecological threat. The limit for releasing ACMO into waste water streams is limited at 100 parts per billion. To put this in perspective, the amount of water needed to dilute one liter of a resin formulation containing 50% ACMO is about five million liters of water, or roughly the size of two Olympic swimming pools. This is especially concerning since many resins marketed as “water-washable” contain high levels of ACMO.

Formlabs resins never contain ACMO and SDSs are available for all resins, so users know what they are working with. Our SDSs are always available and up-to-date with resin safety information. SDSs from low-cost resin manufacturers are often hard or impossible to find, and lack the appropriate information to safely use the resins.

To mitigate the hazards of low-cost resins, many users must print with an enclosed ventilation system. Formlabs resins can typically be printed without such a system.

Clearly Indicated Skin Safety and Biocompatibility

The Formlabs resin library includes a comprehensive selection of biocompatible resins. Parts printed with biocompatible resins, called BioMed Resins, have been tested for skin and/or mucosal membrane contact. Testing by Nelson Labs and NAMSA is well documented. Materials in our BioMed Resin family are developed and manufactured in an ISO 13485-certified facility and are compatible with common disinfection and sterilization methods.

In comparison, almost no low-cost resin manufacturers have any type of skin safety or biocompatibility testing, and it can be hard-to-impossible to access safety data sheets.

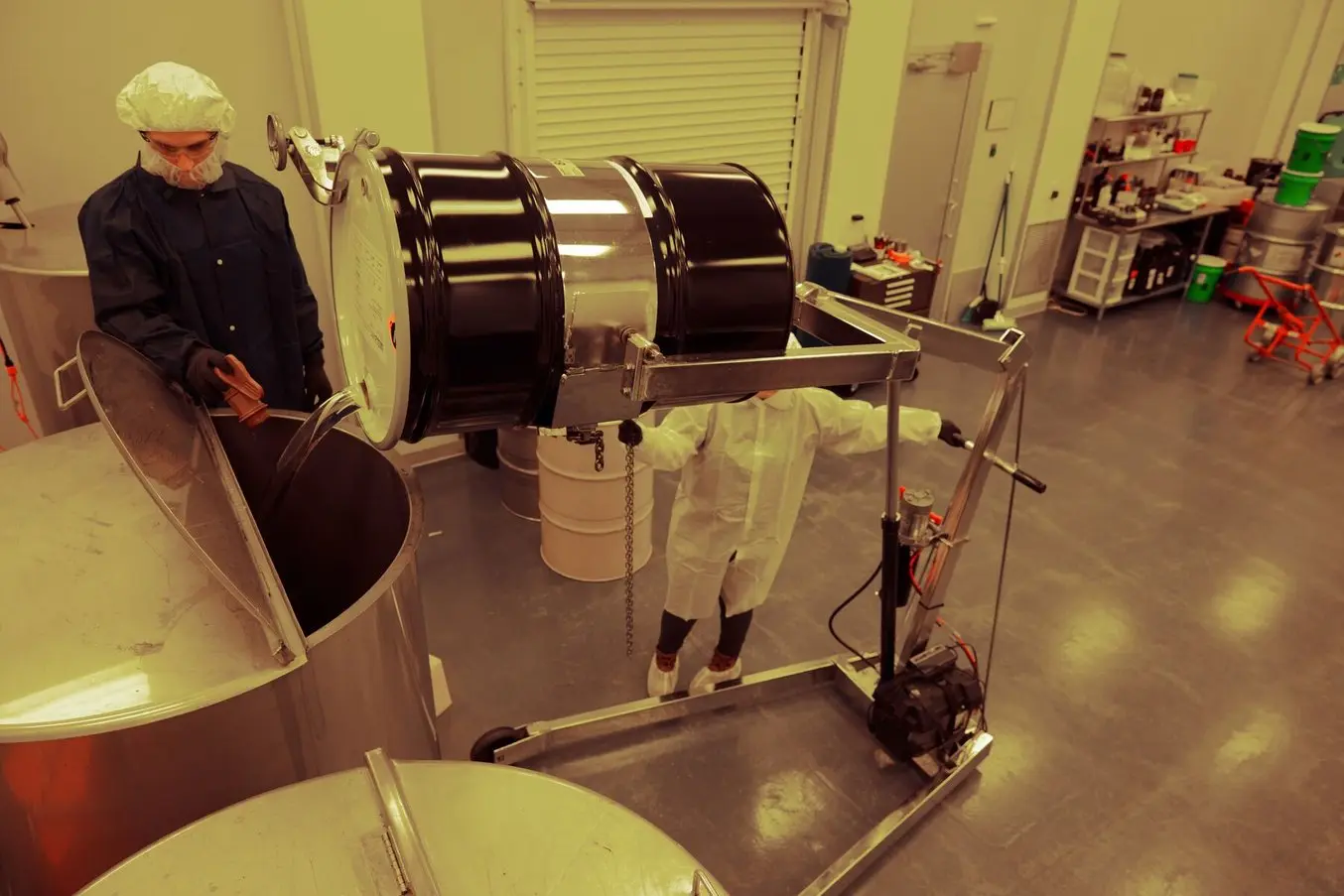

Formlabs resins are developed and manufactured in-house at Spectra. Here, BioMed Resins are manufactured inside a certified ISO Class 8 clean room.

Formlabs resins undergo thorough testing throughout development and manufacturing.

Every Formlabs resin, whether biocompatible or not, has clearly marked wash and cure times specific to that material, resulting in a part that is safe to handle. Most low-cost resins do not provide information on how to best wash or cure their parts. This means users waste time and material with trial and error as wash and cure settings are dialed in.

“Our customers can trust that the development and manufacturing of our resins have undergone the highest levels of scrutiny and quality.”

Bradley Heil, Global Regulatory and Compliance Leader, Formlabs

Learn how Formlabs develops and ensures compliance for biocompatible materials in our story, or download safety and technical data sheets for Formlabs materials.

Request a Free Sample Part

See and feel Formlabs quality firsthand. We’ll ship a free SLA sample part to your office.

Build Platform Optimization

Formlabs build platforms include a lip to catch resin.

Even build platforms can be designed with safety in mind. Formlabs build platforms have a small, extended lip, which catches resin dripping down the sides, helping to prevent drips.

Additional risk can come from scraping parts off build platforms. Build Platform Flex and Build Platform Flex L (for large-format 3D printers) feature patented Quick Release technology, making it easy to remove parts without tools, preventing possible injury or damage to the surface of the build platform.

When printing, many low-cost resin printers fully submerge the build platform into the resin tank. This causes resin drips upon removal and more cleanup, as well as resin waste. Formlabs resin printers do not fully submerge the build platform into the resin tank, reducing resin drips and spills when removing parts, and minimizing potential resin waste.

Post-Processing Safety Considerations

The Benefits of Separating and Containing Washing and Curing

Integrated wash/cure combos are attractively priced. However, they require users to move the bucket of IPA in and out of the wash/cure unit every time a print needs to be post-processed. Any time this exchange happens, there is a risk of an IPA spill, increasing the likelihood of accidents and IPA exposure.

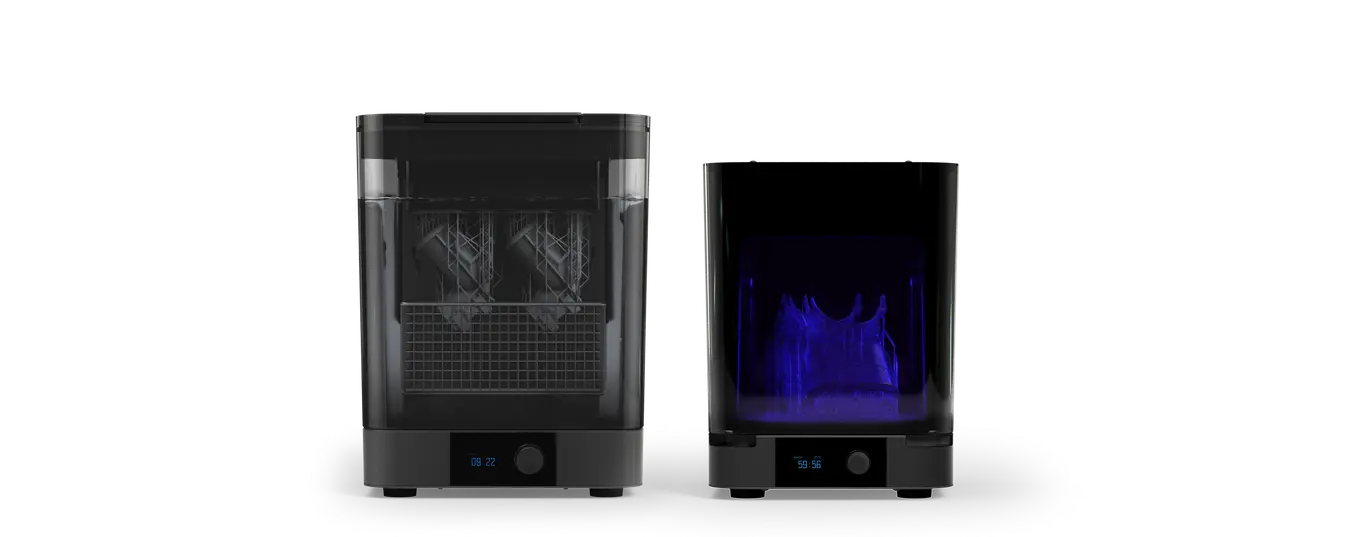

Separate wash and cure units eliminate the need to move buckets of IPA, streamlining post-processing and significantly reducing the risk of IPA exposure. Form Wash, Form Wash L, Form Cure, and Form Cure L are separate and contained wash and cure solutions.

Individual Form Wash (2nd Generation) and Form Cure mean parts are moved from wash to cure, for an intuitive and efficient workflow.

Additionally, the lid of Form Wash and Form Wash L are sealed, reducing IPA fumes and exposure. When washing, the build platform can be put into a holder in the Form Wash. Note that the Form Wash and Form Wash L can fit build platforms from multiple companies.

With the push of a button, the build platform is then lowered into the wash, reducing the potential contact of the user with both resin parts and IPA. Programmed settings for each Formlabs resin time the wash, automatically lifting the build platform out of the wash once the cycle is complete. An integrated cover goes over the IPA bath, minimizing exposure to IPA and preventing accidental part damage from leaving it in the wash for too long, which can happen with low-cost wash units.

Most low-cost washing systems are just baskets to put parts into, though a few do have the capability to insert a build platform into the wash. Without timed washes and automated raising and lowering of build platforms, users risk both exposure to IPA due to splashing and leaving parts in IPA for too long.

Form Wash above, and Form Wash L for large parts, feature auto-rise, and a lid to reduce IPA fumes and exposure. Form Wash and Form Wash L are also compatible with Resin Washing Solution.

IPA vs. Resin Washing Solution

While IPA washes well, odor, flammability, sourcing, and storage are concerns for some users. Formlabs Resin Washing Solution is a lower-odor washing solution that’s non-flammable per GHS classification and cleans as well as IPA. It has twice the longevity of IPA and minimal evaporation, leading to less frequent top-offs and fewer full changeouts of washing solution. While IPA has a saturation limit of 10%, Resin Washing Solution’s saturation limit is 20%, meaning it can dissolve twice as much resin before becoming saturated.

“Formlabs Resin Washing Solution is key in my 3D printing workflow. It washes my models completely and I can go much longer without worrying about replacing solvent. It doesn't have a strong smell and isn't a flammability risk, which I appreciate for my small workspace.”

Kristine Paxon, Beam Orthodontics

For small workspaces or spaces where odor and flammability are concerns, Resin Washing Solution offers a safer alternative to IPA washes. Read our blog to learn more about Formlabs Resin Washing Solution, or buy now to start washing.

Resin Washing Solution is not compatible with Flexible and Elastic Resins, or resins that require a validated workflow (including Biocompatible Resins). View the complete list of compatible resins here.

Robust Sales and Service Support

Companies that don’t have dedicated sales and service teams have less overhead, meaning they can charge less for their products. However, this means that user questions remain unanswered or entirely crowd-sourced, and that there’s less access to safety information and issues.

Companies producing low-cost resin printers sometimes have email support, but you’ll often have a 12-hour delay between North America and China, less prompt replies, and, often, a language barrier. This means your concerns go unaddressed, or you have to rely on message boards and the advice of people whose knowledge base and experience are unknown.

Dedicated sales and support teams, including medical and dental specialists, help Formlabs users with everything from questions and training to issues and troubleshooting.

We pride ourselves on the ease with which potential users can speak with sales, and with our responses to support requests. We are continuously shortening the time it takes to resolve support requests, ensuring any potential safety issues are addressed promptly and effectively. Additionally, regular maintenance checks help prevent issues from occurring in the first place.

“We are really happy with the technical support we receive from Formlabs, the service is excellent. Responses are quick and helpful and when we had an issue that we couldn’t resolve ourselves, we were able to get a hot swap printer as part of our Pro Service Plan membership.”

Kals Wilde, Director, JR Design + Fabrication

Resin 3D printers for healthcare applications, including medical and dental applications where biocompatible resins are being utilized, have additional considerations. Dedicated medical and dental service plans and staff ensure concerns are promptly addressed by knowledgeable individuals, so that patients receive the best care.

“The support service I received was outstanding. I had an urgent problem and it was solved unbelievably quickly.”

Luke Smith, Medical 3D Facility Technician

Learn more about our service plan offerings, including medical and dental-specific service plans, here.

Set Higher Safety and Quality Standards

Features of the Form 4 ecosystem were designed to improve the safety and experience of users.

Ease of use should never come with a trade-off for increased risk of exposure to harmful chemicals, which is often the case with low-cost resin 3D printers. Lack of documentation and dedicated support leaves many low-cost resin 3D printer users facing challenges without recourse.

“At Formlabs, we are dedicated to maintaining and setting higher standards of safety and quality in the resin 3D printing industry. We prioritize providing comprehensive information, proper safety guidelines, and reliable documentation to ensure that our users can print with confidence and peace of mind.”

Dávid Lakatos, Chief Product Officer, Formlabs

We’re excited by the increased accessibility of 3D printing, but access should not come at the price of your health. While nothing is entirely without risk, by designing with safety as a priority and providing ample information and documentation, Formlabs users can have peace of mind. Still curious? Read more from Formlabs’ Chief Product Officer Dávid Lakatos in his essay.

Leave the mess behind and start printing with Formlabs resin 3D printers or contact sales to learn more.