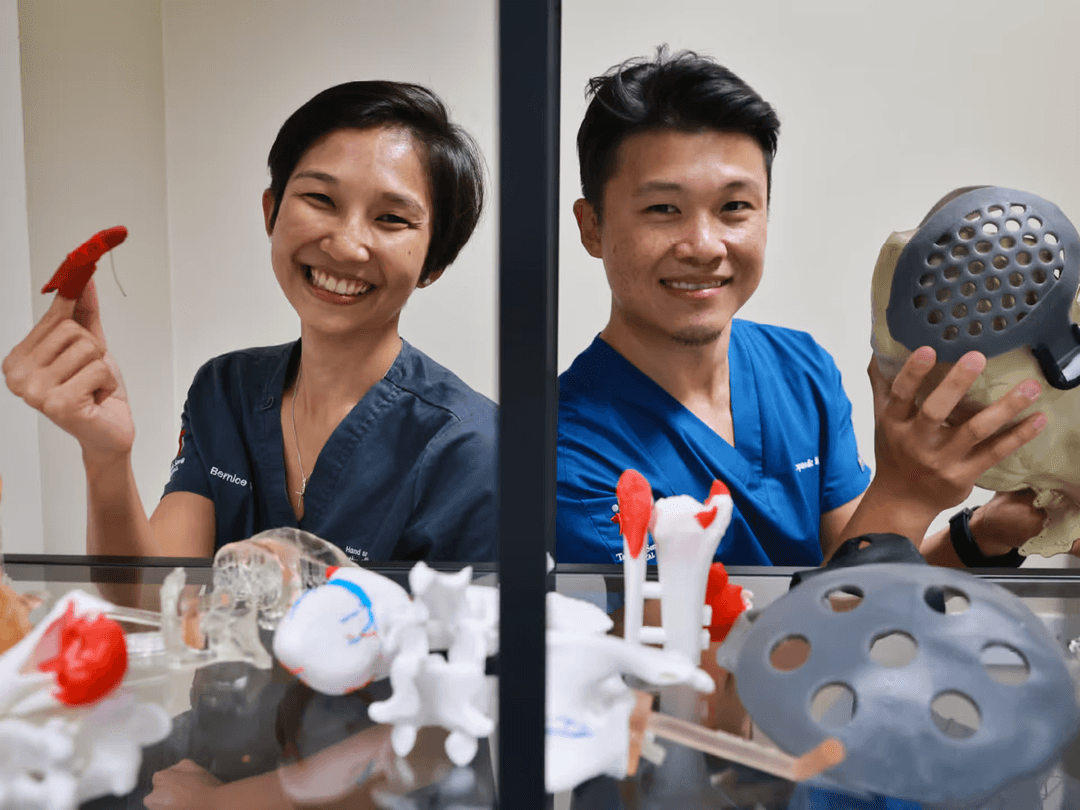

Luiz Maracaja worked with his colleagues at Yale School of Medicine

Everyone has been impacted by the COVID-19 crisis. Hospital staff are among those hit hardest, dealing with shortages of items such as nasopharyngeal (NP) swabs used to collect samples for COVID-19 testing. As the crisis deepened, the shortage of supplies expanded to include face masks, ventilator splitters, and other PPE. With medical equipment in short supply, 3D printing is being used to support healthcare providers and patients during the coronavirus.

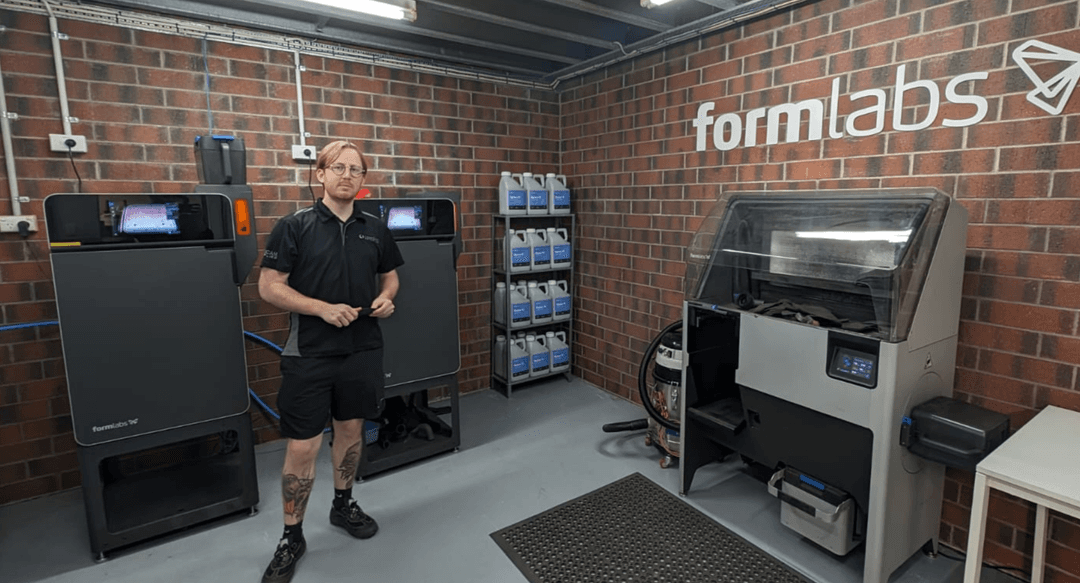

Formlabs is dedicated to helping the medical community address the COVID-19 epidemic and associated supply chain shortages. That’s why we launched the Formlabs Support Network, so anyone with a 3D printer could join us in safely printing supplies, and make sure those supplies get to the correct medical professionals. Over 3,000 people with engineering and printing capabilities have offered to volunteer as part of the Formlabs response effort.

A major obstacle to outsourcing 3D printing is that medical equipment requires specialized manufacturing environments, formal documentation processes, and numerous regulatory requirements. While Formlabs has been printing medical devices including swabs, we know many in our support network cannot. To help activate our network, Formlabs has created a new COVID-19 community part library of non-medical but still vital parts for users to print at home.

Read on to learn more about the Formlabs COVID-19 community part library, and how you can help.

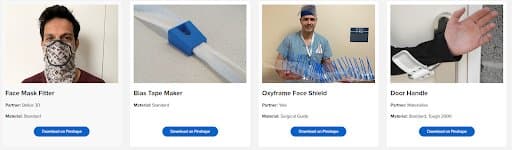

Parts Ready to Print

Formlabs has curated parts from hundreds of designs and concepts currently being explored to support COVID-19 response efforts. We’ve carefully vetted these prints with our internal team of healthcare experts and engineers, as well as clinicians when possible, and optimized the files and materials for stereolithography 3D printers such as the Form 3. From mask components to door handle add-ons, this small but impactful collection can help alleviate supply-chain shortages around the world.

Functional prototype of OxyFrame printed in Draft Resin. End-use devices printed in Dental SG Resin.

Formlabs user Luiz Maracaja worked with his colleagues at Yale School of Medicine and University of Mississippi to devise a novel face shield frame called OxyFrame. The 3D printed device combines a traditional face shield framework with a novel air channel system that allows inflow of oxygen or compressed air behind the ear and outflow above the nose-bridge.

According to the researchers, healthcare providers at their institutions taking care of a patient with suspected or proven infection must wear a gown, gloves, a mask (such as a N95 respirator), and an eye shield or face mask. Healthcare providers engaged in procedures involving the nose, mouth, or airway need even more aggressive protection from airborne viral particles, in the form of powered air purifying respirators, or similar devices.

Using OxyFrame, continuous air flow allows the provider to breathe comfortably inside a plastic hood, while simultaneously defogging the clear shield film. The device was validated for use inside of a plastic hood using compressed air or oxygen flowing at 10-15 liters per minute. Under these conditions, positive pressure was observed inside the hood, as well as active defogging of the face shield.

The design is specifically optimized to print vertically on an SLA printer with minimal supports, enabling users to tile 24 frames onto one build plate. Each frame uses only 9.7 mL of the resin material, so one liter of the resin can generate approximately 100 frames.

Luiz Maracaja and his colleagues prototyped their design using Draft Resin. Prints in Draft Resin provided sufficient surface quality while printing with remarkable speed and efficiency; the team was able to print ten prototype frames in three and a half hours.

Testimonial

“[Draft Resin] is a game changer for prototyping, testing and reaching the final design.” - Luiz Maracaja

For end-use parts with prolonged skin contact, Formlabs recommends using biocompatible Surgical Guide Resin or applying a skin-safe coating to cured parts printed with other resins. Formlabs Surgical Guide Resin, indented for printing endosseous implant accessories, is biocompatible for short term surface contact (ex: face shields) and may be steam sterilized (autoclaved).

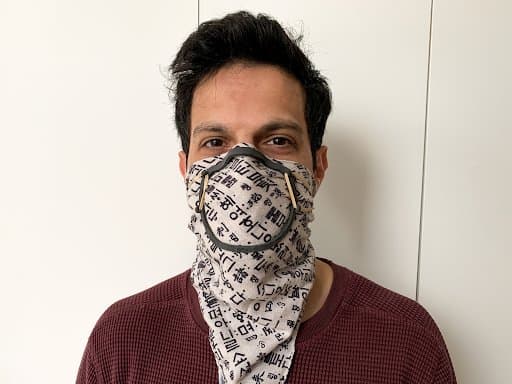

Bellus3D has integrated a Face Mask Fitter into their phone-based scanning software. The novel device is a plastic frame that helps to improve the fit of a surgical mask or a homemade fabric covering by contouring precisely to the wearer’s facial geometry.

To create your own face mask rim, download the Bellus3D app on a compatible iOS device (iPhone X, Xs, Xs Max, XR, 11, 11 Pro or 11 Pro Max). Within the app, the face scanning process takes about 30 seconds from start to finish. From here, simply export a custom frame using the “Mask Frame” button inside the application. Bellus3D provides STL exports of your custom face mask rim free of charge.

Formlabs recommends using any Standard Resin to print the face mask rim. When ready, this attachment is worn by linking rubber bands through the hooks on either side of the rim, and mounting it outside your nose and mouth covering.

Bellus3D has guaranteed us that face scans are not saved or uploaded to any cloud device; no name or personal information is required in order to generate a face mask rim. The STL file that is generated for the user can be stored or saved in where the user pleases.

While the fitter seems to improve the seal of a face mask, it has not been tested for effectiveness in preventing COVID-19. Bellus3D has been working with a research hospital to demonstrate that the custom rim is an improvement over non-custom masks. The company hopes to publish a paper soon to share their test results with the public.

Future Updates

Formlabs will continue to add new items to the community part library in the future.

Have you designed or found a valuable SLA optimized COVID-19 solution? If so, please submit your part for our team of engineers and medical experts to review for potential to include it in our library.

National Institute of Health Library

These are just some of the many designs that the 3D printing community has been developing. In addition to these prints we recommend the new library offered by the National Institute of Health (NIH). The NIH is compiling COVID-19 response designs that are evaluated by healthcare professionals. Printable files that work on machines outside of stereolithography 3D printers such as the Form 3 are available. If you have parts that are similar to parts already in our library, please share them to include in their expansive 3D printing library.

OxyFrame Authors:

-

Luiz Maracaja, MD and Daina Blitz, MD: Department of Anesthesiology at Yale School of Medicine, New Haven, CT, USA.

-

Danielle L. V. Maracaja MD -- Department of Laboratory Medicine at Yale School of Medicine, New Haven, CT, USA

-

Caroline Walker, MD -- Department of Anesthesiology at University of Mississippi, MS, USA