Manufacture Custom End-Use Parts and Complex Designs Without Tooling With 3D Printing

An end-use part is a good that is sold as a product, used as a sub-assembly in a product, or used as a component in a product. With 3D printing, you can create end-use parts without tooling, making it possible to create custom parts and complex designs in a cost-efficient manner.

From Bridge Manufacturing to Mass Customization, 3D Print End-Use Parts for a Wide Variety of Applications

Eliminate high tooling costs and months-long lead times, revise products quickly to accelerate time to market, and manufacture parts that used to be too complex, prohibitively expensive, or impractical to produce with traditional methods.

Low Volume Production

3D print production runs of one to 10,000+ end-use parts with high flexibility, high speed, and the ability to quickly scale up to meet demand.

See Also

How to Unlock Low Volume Production and Custom Manufacturing with 3D Printed End-Use Parts

SLS 3D Printing vs. Injection Molding: When to Replace Molded Parts With 3D Printing?

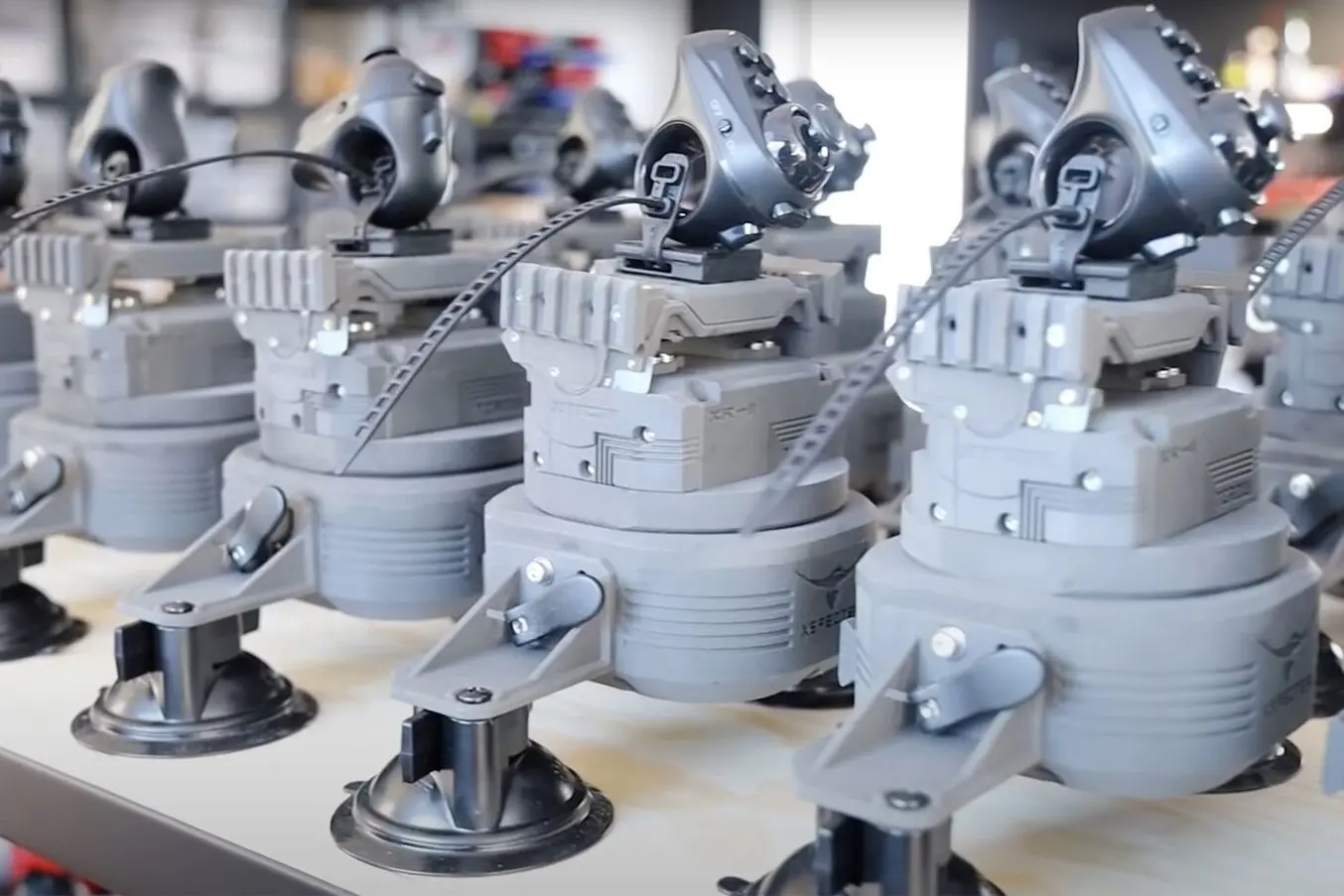

How XSPECTER Combines SLA and SLS 3D Printed End Use Parts to Manufacture Its Outdoor Camera Tripod

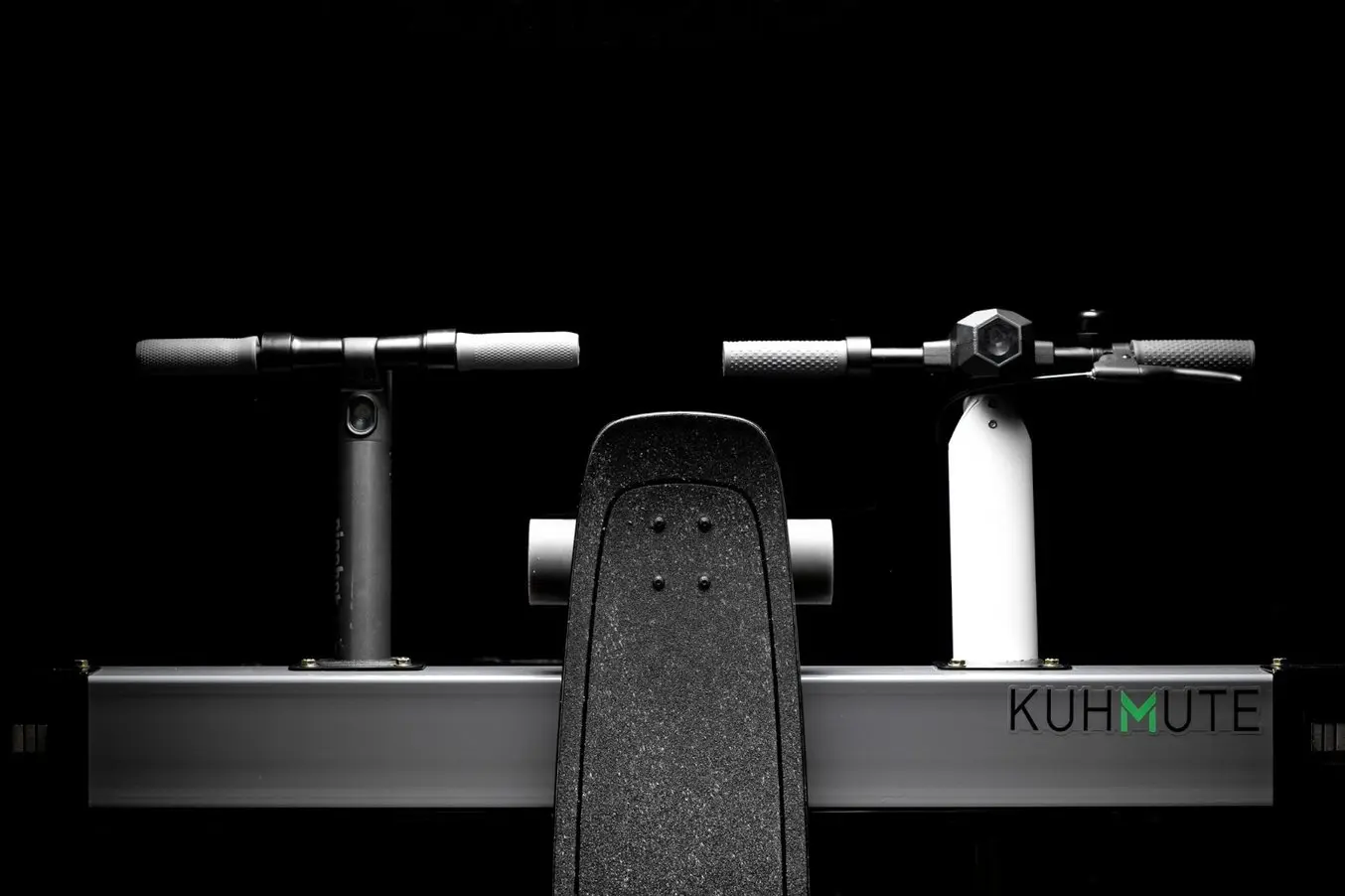

Producing Custom Control Systems for Machines and Vehicles Using SLS 3D Printing

Production of 3D Printed Eyewear on the Formlabs Fuse Series SLS Ecosystem

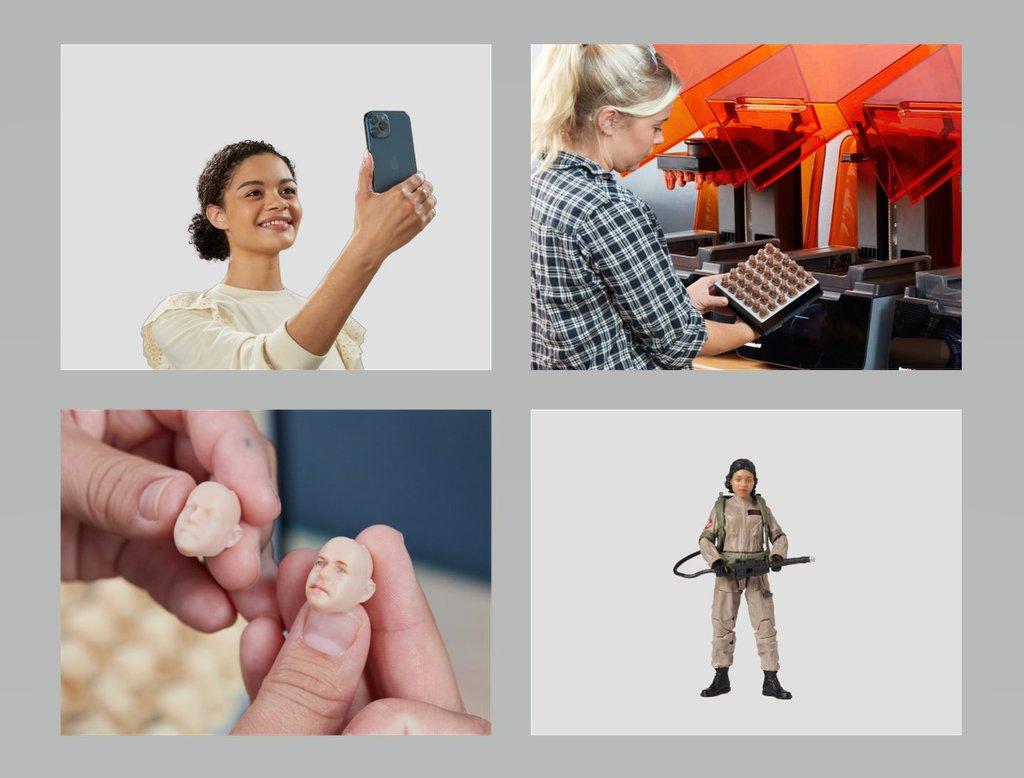

Mass Customization

The holy grail of producing customized products in large volumes is now a reality. With 3D printing, you can scale personalized products for mass-market opportunities without drastically increasing operational costs and delivery timelines.

See Also

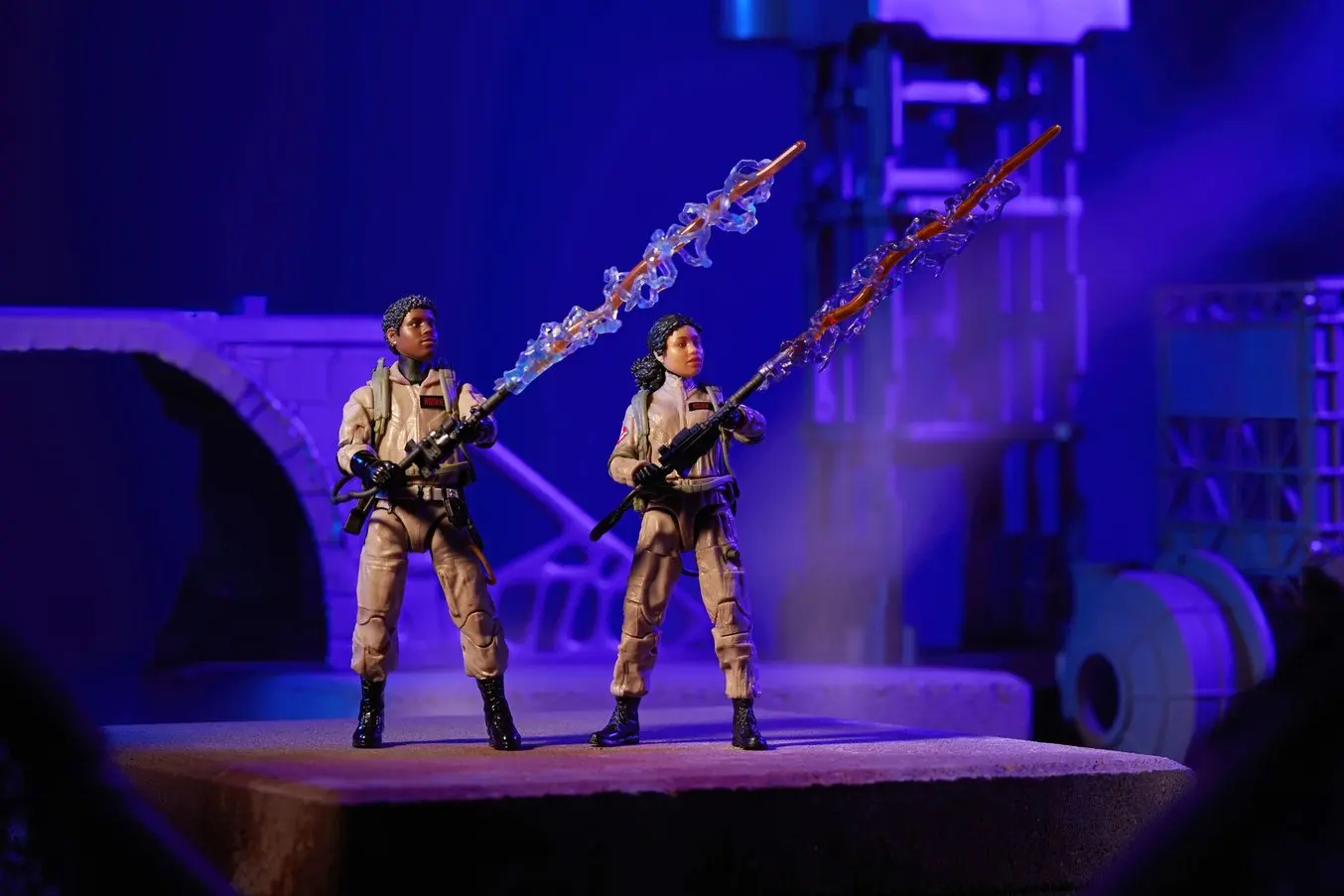

Product Innovation

Push the boundaries of design complexity, optimize structures, and customize parts at no extra cost to develop unique and innovative products. Leverage the flexibility of 3D printing to explore new business models that bring you closer to your customers’ needs.

See Also

How a Swiss Eyewear Manufacturer Uses SLS 3D Printing to Produce High-Quality Eyewear

Aftermarket Parts

Beat your competition to market. By eliminating tooling, 3D printing improves the agility of your process, both in product design and production. Adjust your products to ensure continued compatibility through the original equipment manufacturer’s updates. Reduce inventory and scrap by 3D printing parts on demand. Build complex geometries to produce more advanced forms and product performance tailored to your customer niche.

See Also

How Police and Special Vehicles Are Produced With SLS 3D Printing

Agile Manufacturing: How JetBoatPilot Responds to the Market With SLS 3D Printing

Spare and Replacement Parts

Shift from a physical to a digital inventory with 3D printed spare parts on-demand. Improve your supply chain management, mitigate risks of overproduction, reduce waste, and decrease storage costs. Upgrade your service and ensure customers’ satisfaction by providing repair parts quickly and affordably.

See Also

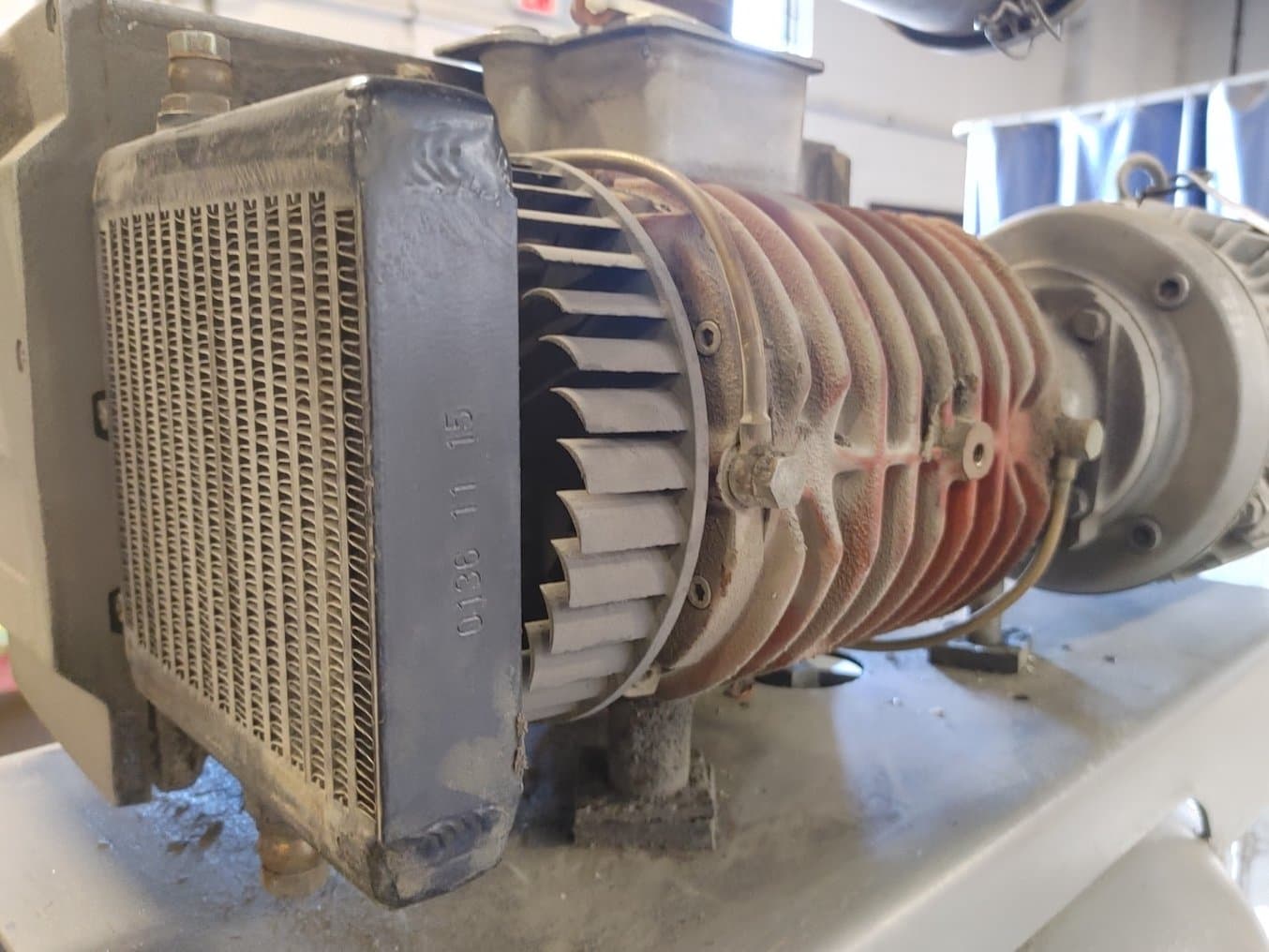

Using 3D Printing to Make Heat-Resistant End Use Parts and Spares for Motorsport

Bridge Manufacturing

Leverage 3D printing as a bridge-to-production method to quickly and affordably produce low-volume of parts before transitioning to mass manufacturing. 3D print pilot runs for product testing, market validation, and pre-sales before committing to mass production.

See Also

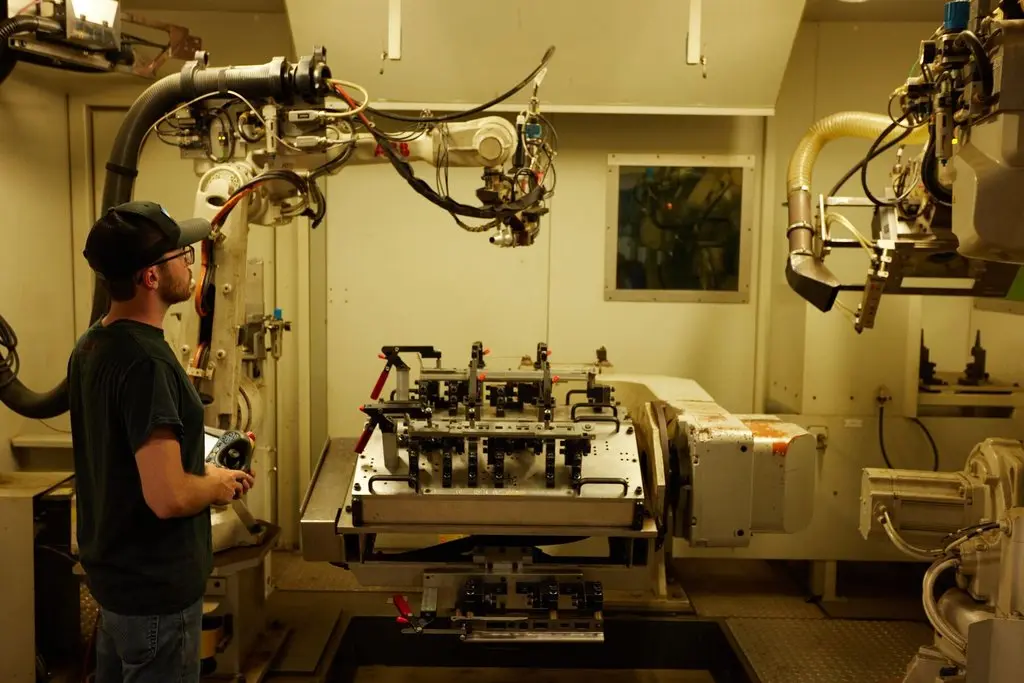

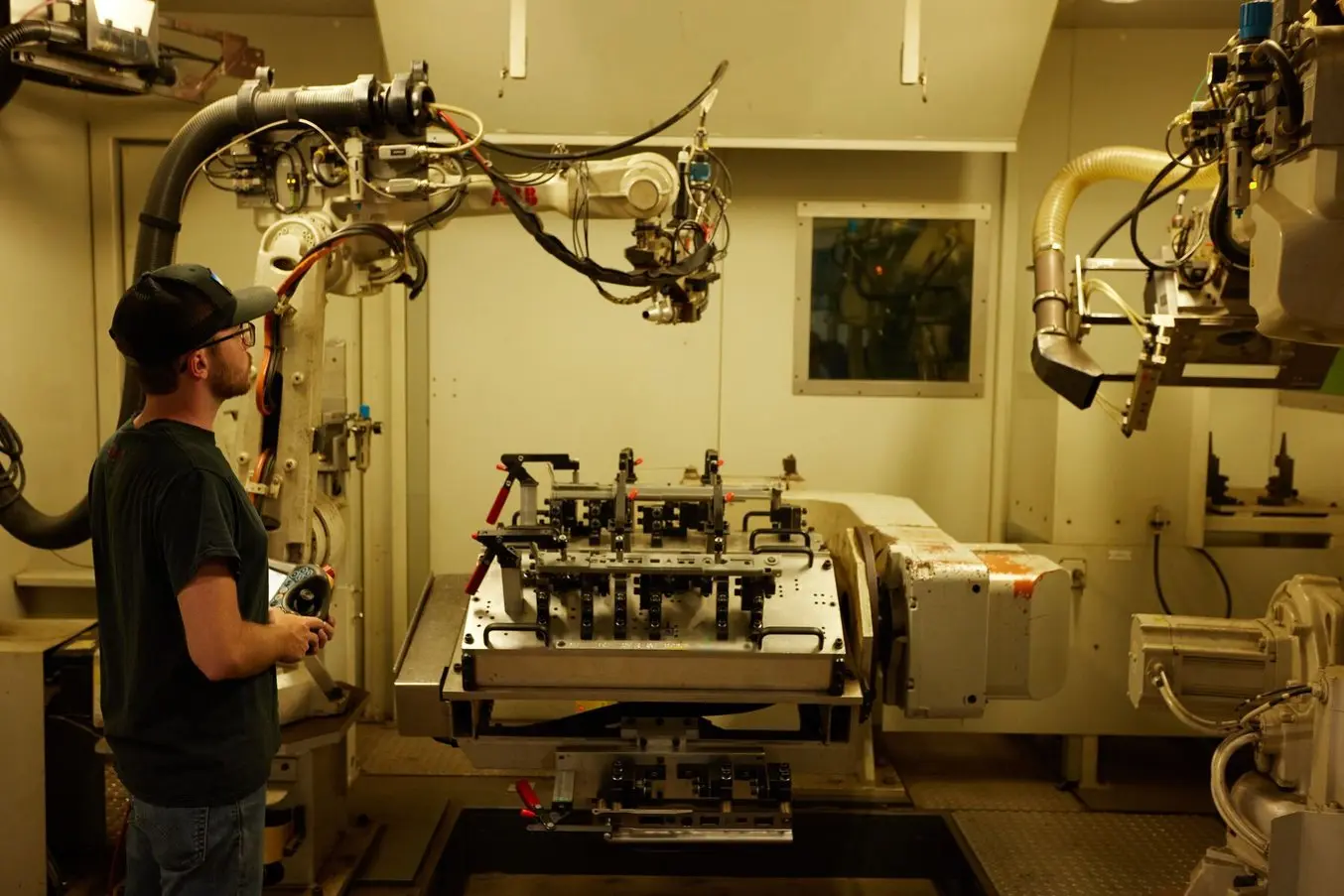

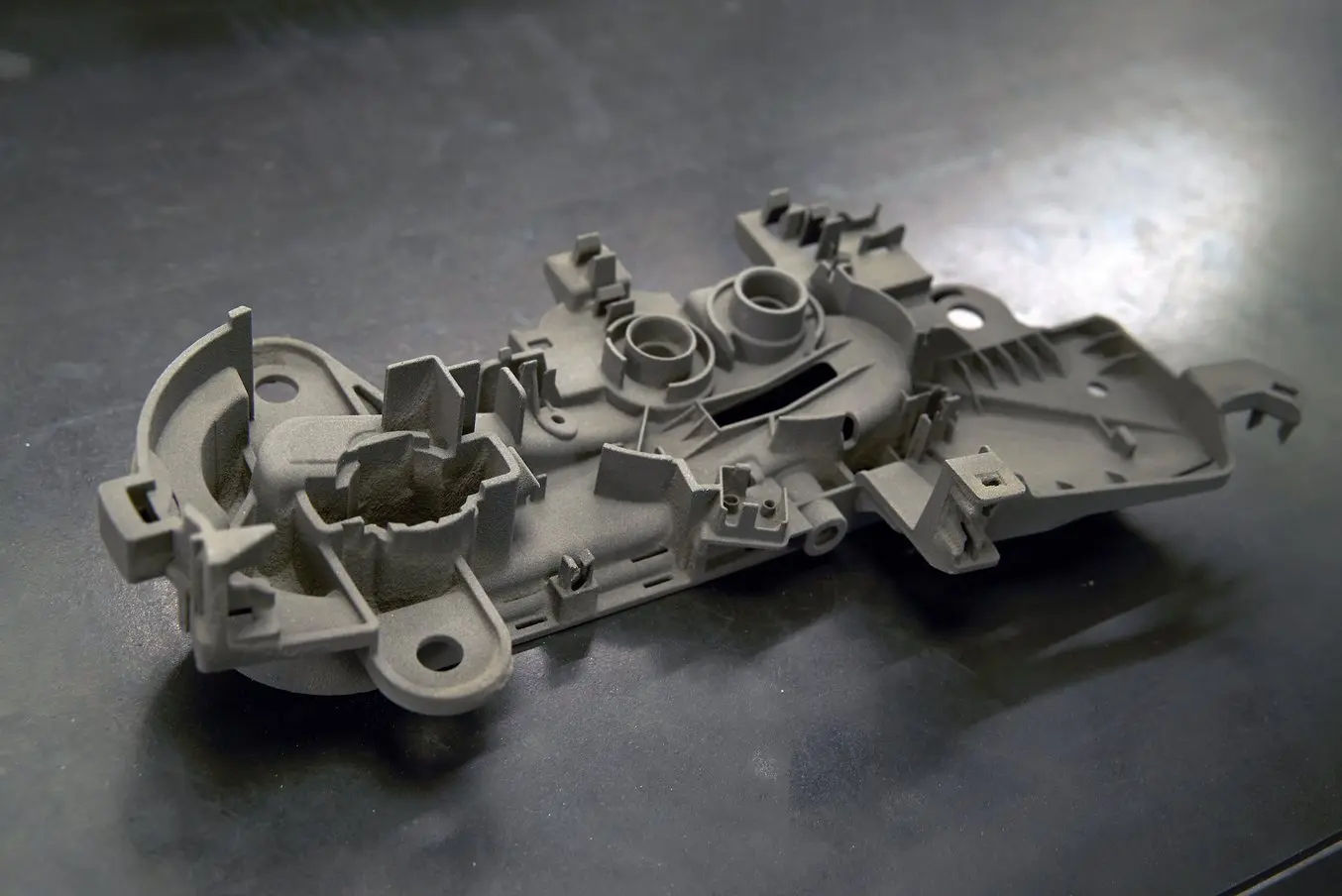

How Brose Leverages SLA and SLS Technology to Bolster Automotive Production

Veteran and Paramedic Develops 3D Printed Device that Prevents Collapsed Lung Complications

Supply Chain Resilience

Reduce your reliance on suppliers, withstand logistics disruptions, geopolitical issues, and market changes by bringing manufacturing capabilities in house. Leverage 3D printing to quickly and affordably produce low-volume of parts during times of shortage. Tighten your supply chain and shorten lead times with 3D printing stopgap parts on demand.

See Also

Reduce Costs and Improve Stability by Bringing 3D Printing In-House

Calculate how much you would save by producing end use parts in-house with 3D printing, rather than outsourcing or using an alternative production method.

| Fuse 1+ 30W In-House | Service Bureau SLS | |

| Time | 16h 57m | 7-10 business days |

| Cost | $4.42 | $47.72 |

A Full Suite of 3D Printing Solutions for End-Use Parts

Form 4 & Form 4B

Clear details and smooth surface finish

Biocompatible parts

Custom materials

Form 4L & Form 4BL

Clear details and smooth surface finish

Biocompatible parts

Large parts

Fuse 1+ 30W

Print large batches without supports

Industrial grade materials

High throughput and low cost per part

High-Performance Materials for End-Use Parts

Formlabs has an extensive library of proprietary 3D printing materials suitable for even the most demanding applications.

Nylon 12 Powder

TPU 90A Powder

Tough 1500 Resin

BioMed Resins

Formlabs is Open

Maximize your 3D printer’s potential with Formlabs Developer Platform. Unlock the possibility of printing with any 405 nm photopolymer resin or 1064 nm powder on Formlabs 3D printers, customize your print settings, or build software integrations.

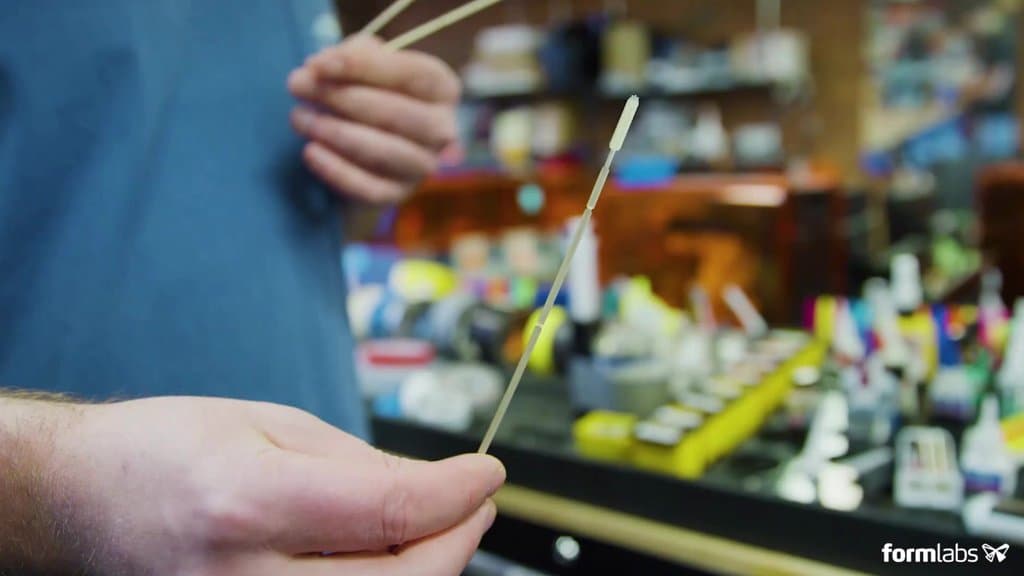

Get Started 3D Printing End-Use Parts

Contact a Formlabs Solution Specialist to get started with end-use parts production.