最新ニュース

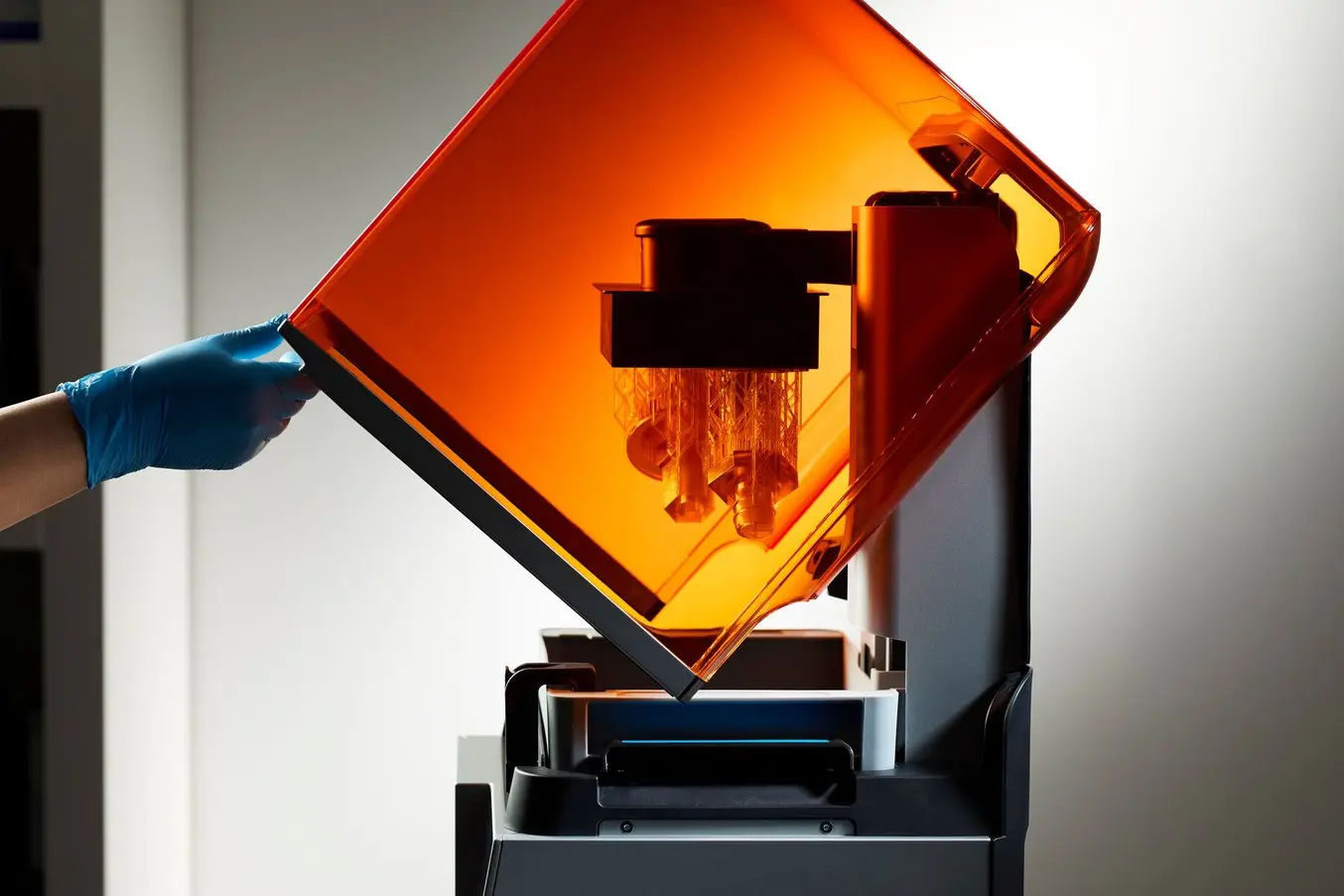

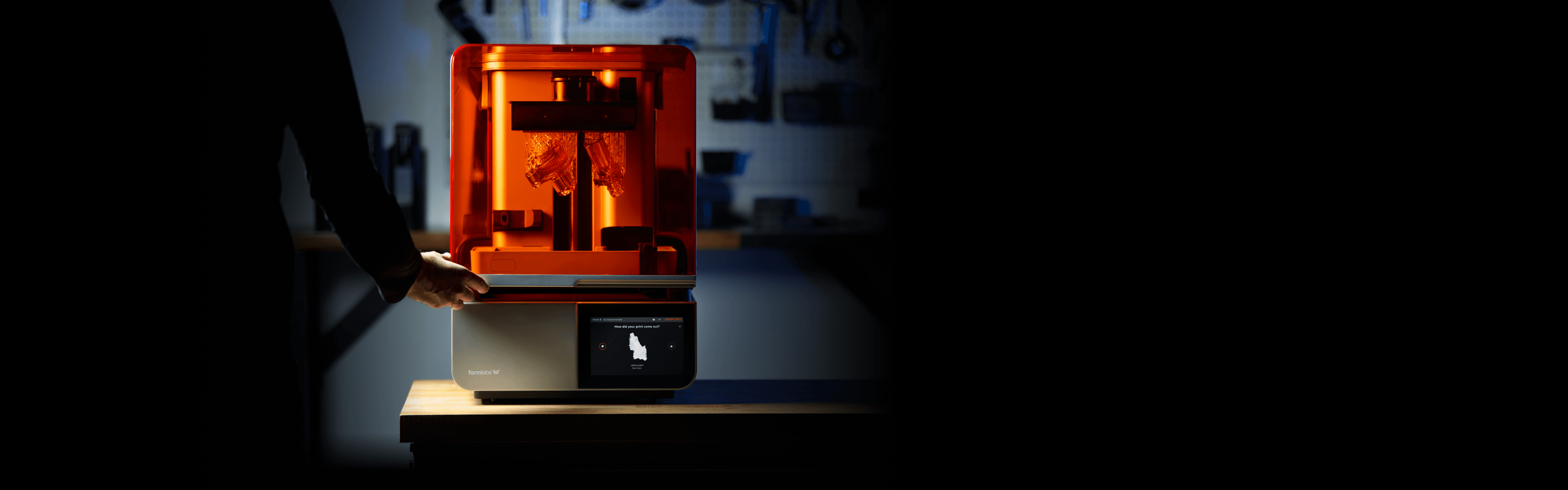

SLA光造形方式3Dプリンタ

FormシリーズSLA光造形3Dプリンタは、優れた表面品質と造形精度、豊富な高機能材料で、高い信頼性と安定性を備えた工業品質の3Dプリントが求められる業界で広く選ばれています。

SLS方式3Dプリンタ

工業品質のSLS方式3Dプリントを初めてベンチトップサイズで実現したFuseシリーズは、高品質な実製品用部品や各種治具のバッチ生産・連続生産を可能にします。包括的でシンプルな作業手順により、従来の工業用SLS 3Dプリンタの数分の一という低コストで、高い生産性を実現します。

Formlabsの3Dプリンタで、誰もが簡単にものづくりができる世界へ

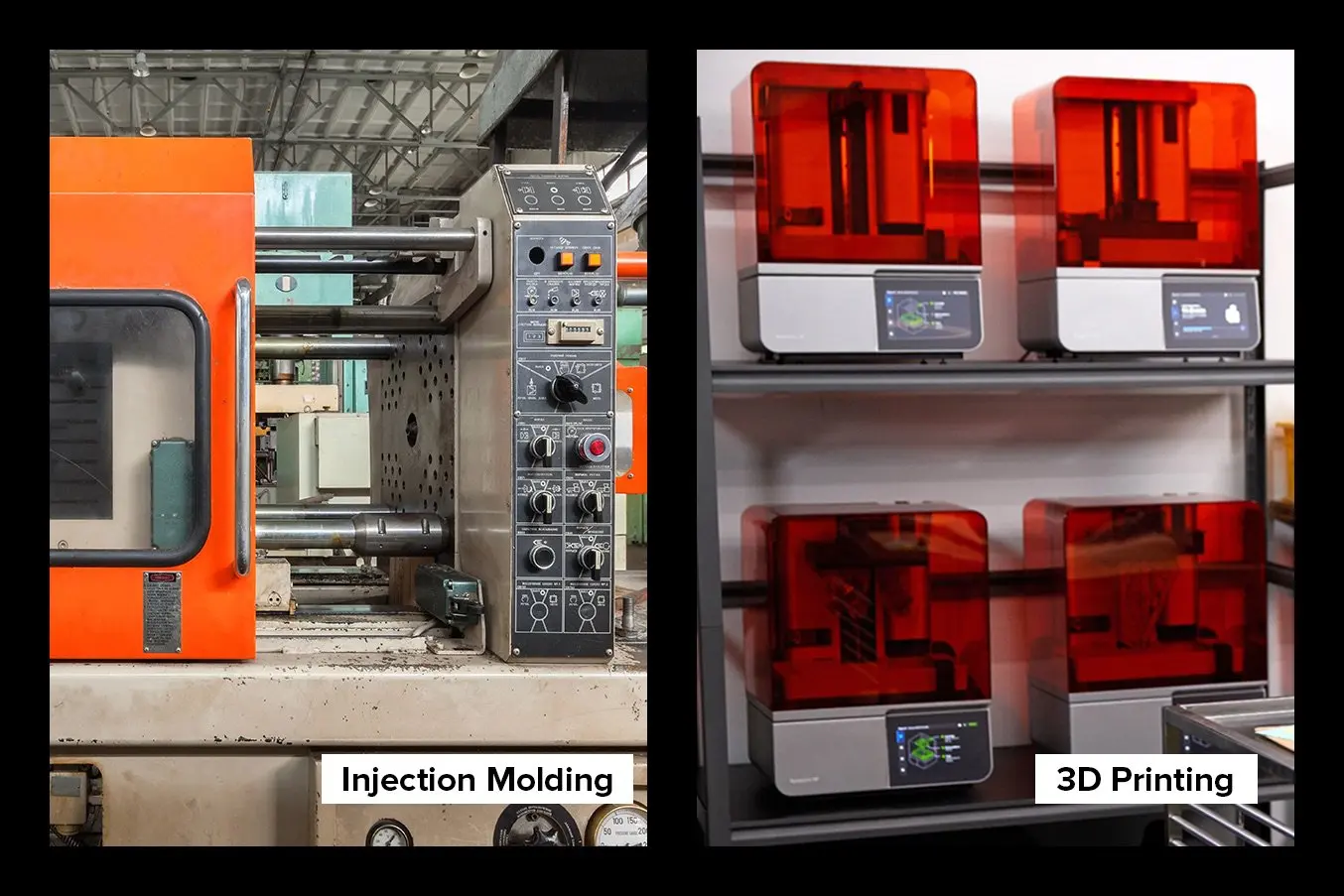

ラピッドプロトタイピング

浮かんだアイデアをその日のうちに、実製品のような外観と機能を備えた再現性の高いプロトタイプとして具現化。より高品質な新製品を、いち早く市場に。

ラピッドプロトタイピング

浮かんだアイデアをその日のうちに、実製品のような外観と機能を備えた再現性の高いプロトタイプとして具現化。より高品質な新製品を、いち早く市場に。