For over a century, the world’s largest lens was a lighthouse on Oahu, Hawaii. The Fresnel lens at Makapu’u Point, 12 feet tall, 8 feet wide, and painstakingly crafted out of of glass, has held the title since 1893.

This February, the title transitioned to a new lens: a 10-by-12-foot Fresnel lens made of interlocking 3D printed bricks. The installation, Window to the Heart, is a collaboration between Formlabs head of design Marcelo Coelho and design studio Aranda\Lasch, and is the winner of the 2018 Times Square Valentine Heart Design Competition. Previous winners include The Office for Creative Research, Collective-LOK, Stereotank, Young Projects, and Situ Studio.

Window to the Heart is designed and 3D printed specifically to distort and capture the image of Times Square, optically bending light—and attention—to a heart-shaped window at its center. Visitors can look through the window or photograph themselves within it, completing the loop between the lens of the eye and the lens of the camera.

A Lens that Reflects Culture

“Marcelo and I walked around Times Square and noticed that everyone has their camera out, photographing themselves in the light of the media around them. In this sense, Times Square is a symbol for how we experience our world,” Aranda said. “It is a physical manifestation of our culture, one dispersed and absorbed through cameras and screens.”

“The lens is what makes it all possible so we decided to design our own at the scale Times Square demands,” Coelho said.

Coelho and Aranda\Lasch chose a Fresnel lens design for the installation. Originally developed for lighthouses, Fresnel lenses are made of a set of concentric annular sections, enabling a large aperture and short focal length without the mass and volume required by a conventional lens design.

Window to the Heart’s Fresnel design is a diffusing lens, rather than a focusing lens like that of a lighthouse or magnifying glass. Instead of projecting light, it captures it.

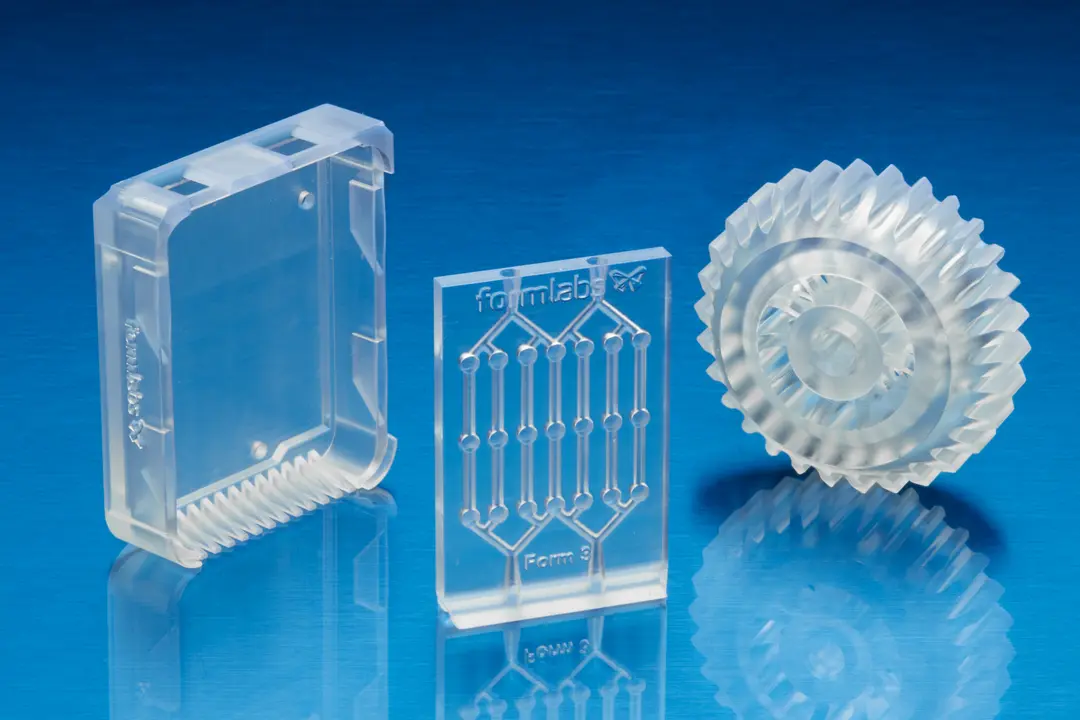

The installation is segmented into concentric rings that flatten a large spherical curvature while retaining its optical effect. Each individual lens is uniquely designed to act as both a brick and optical element.

3D Printing a 12-Foot Lens

Lens making has traditionally involved tedious labor and precision, requiring a series of steps of casting, cutting, and repeatedly polishing glass.

“Previously, a lens of this scale would have been impossible to create,” Coelho said. “Window to the Heart serves as an example of what’s possible with the latest advances in design, materials, and fabrication.”

The lens is composed of 98 concentric rings, and each circle is made of a series of bricks 3D printed with Formlabs’ Clear Resin, which is capable of the resolution and clarity that optical elements require. The entire sculpture is composed of nearly one thousand bricks.

Once printed, the individual bricks required cleaning and post-curing, but did not require the laborious polishing process required from traditional lens making.

Fabricating the lens’ bricks required running approximately 50 3D printers for two weeks. To minimize labor, some pieces were printed on Form Cell, an automated production system powered by Form 2 stereolithography 3D printers.

Visit Window to the Heart in Times Square

See the lens for yourself: the installation is open in Times Square from Feb. 1, 2018 to the end of the month.

“On the 10th anniversary of the Times Square Valentine Heart competition, what better place to host the world's largest lens than the Crossroads of the World–one of the most photographed places in the world and a hub for innovative technology and design?” said Times Square Alliance president Tim Tompkins.

More 3D Printing and Design Stories

Interested in how 3D printing can impact your design process? Learn more about how stereolithography works, and how designers like Philip Beesley, Zaha Hadid, and Britto Charette use the Form 2. Sign up for our newsletter to keep up with the latest in 3D printing design and production.