Filter|

Materials

Tough 1500 Resin V2 (Form 4)

Lead time: 7 day

Tough 2000 Resin V2 (Form 4)

Lead time: 21 day

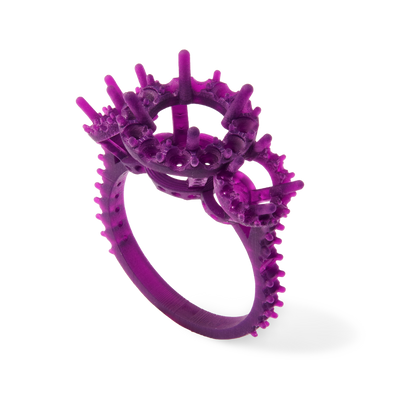

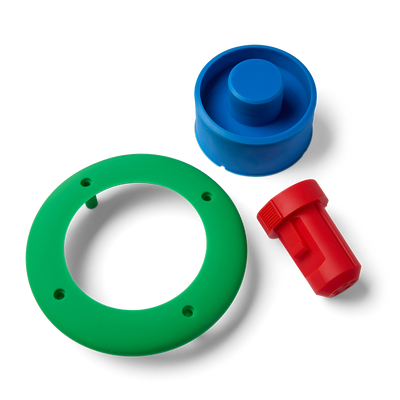

Color Resin (Form 4)

Lead time: 7 day

Alumina 4N Resin

Lead time: 28 day

BioMed Black Resin

Lead time: 21 day

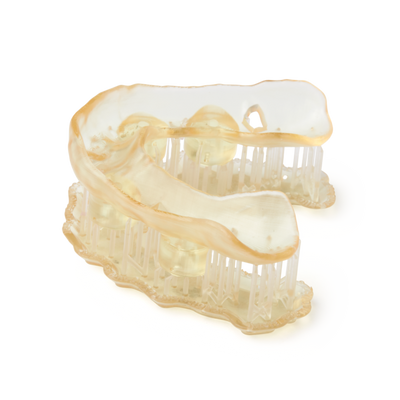

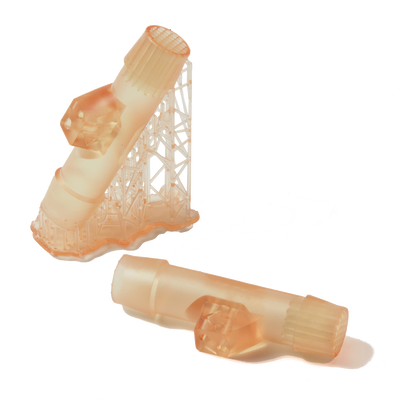

BioMed Clear Resin

Lead time: 14 day