Ultimate Tensile Strength (MPa)

Tensile Modulus (MPa)

Flexural Modulus (MPa)

Heat Deflection Temp @0.45 MPa (°C)

Elongation at Break (%)

Notched IZOD (J/m)

Prefer spreadsheets? See all material datasheets in one place with a live updating spreadsheet here.

Sort by:

Featured

Price (lowest)

A-Z

Ultimate Tensile Strength (highest)

Elongation at Break (highest)

Flexural Strength (highest)

Heat Deflection Temp. @ 1.8 MPa (highest)

Heat Deflection Temp. @ 0.45 MPa (highest)

Tensile Modulus (highest)

Flexural Modulus (highest)

Shore Hardness (highest)

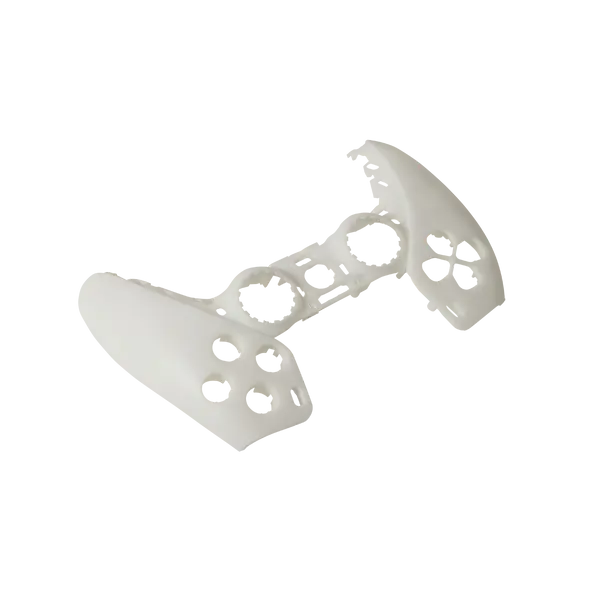

Tough 2000 Resin V2

SLAStiff & StrongImpact ResistantABS-LikeWear Resistant

SLAStiff & StrongImpact ResistantABS-LikeWear Resistant

Tough 2000 Resin V2 is a rugged material with strength and stiffness comparable to acrylonitrile butadiene styrene (ABS), combining toughness with high temperature and creep resistance.

Color Resin

SLAMatteCustom ColorsHigh StrengthHigh AccuracyFine Details

SLAMatteCustom ColorsHigh StrengthHigh AccuracyFine Details

3D print parts in colors that represent your brand, product line, or creative vision with accuracy and consistency. Choose any color to closely match final parts without painting, coating, or pigment mixing.

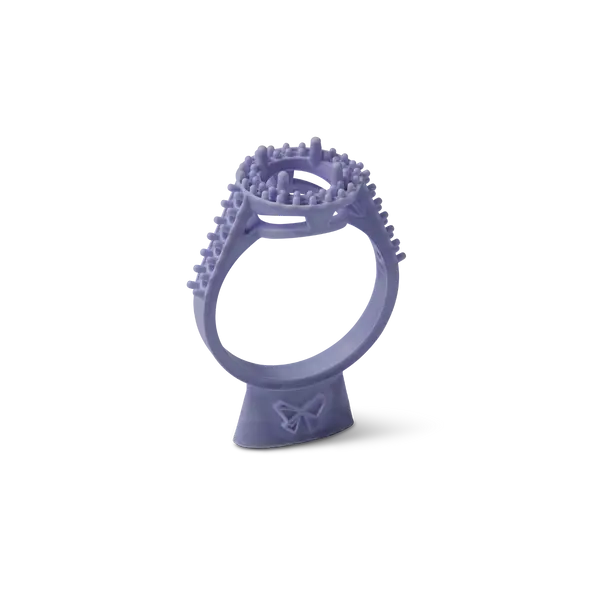

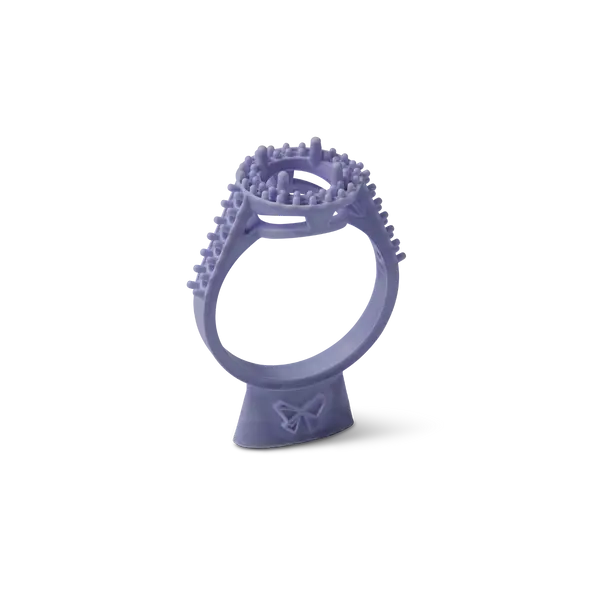

True Cast Resin

SLAPatterns for Casting & PressingHigh AccuracyFine DetailsClean BurnoutCasting

SLAPatterns for Casting & PressingHigh AccuracyFine DetailsClean BurnoutCasting

True Cast Resin is a wax-filled 3D printing material, designed for precision casting of intricate jewelry and complex engineering components up to 5 mm.

Temporary CB Resin 1 kg (0.7 L)

SLAMultiple ShadesHigh StrengthCeramic FilledBiocompatibilityTemporary Restorations

SLAMultiple ShadesHigh StrengthCeramic FilledBiocompatibilityTemporary Restorations

Temporary CB Resin is a tooth-colored resin for 3D printing of temporary crown and bridge restorations, inlays, onlays, and veneers. Indicated for up to seven-unit bridges and available in five shades, this material provides excellent marginal adaptation, strength, and aesthetics.

Black Resin V4.1

SLAStiff & StrongMatteHigh StrengthHigh AccuracyFine Details

SLAStiff & StrongMatteHigh StrengthHigh AccuracyFine Details

Black Resin is perfect for general-purpose prototyping and design, and models with intricate details. Black Resin V4.1 is compatible with Form 3 Series printers, produces deeper black parts, and offers improved print reliability compared to Black Resin V4.0. Choose Black Resin V5 on the Form 4 Series for three times faster print speed and improved mechanical properties.

Clear Resin V4.1

SLAStiff & StrongHigh StrengthTransparentHigh AccuracyFine Details

SLAStiff & StrongHigh StrengthTransparentHigh AccuracyFine Details

Clear Resin is a rigid material that polishes to near optical transparency. Clear Resin V4.1 is compatible with Form 3 Series printers and creates more color-neutral and transparent parts compared to Clear Resin V4.0. Choose Clear Resin V5 on the Form 4 Series for three times faster print speed and improved mechanical properties.

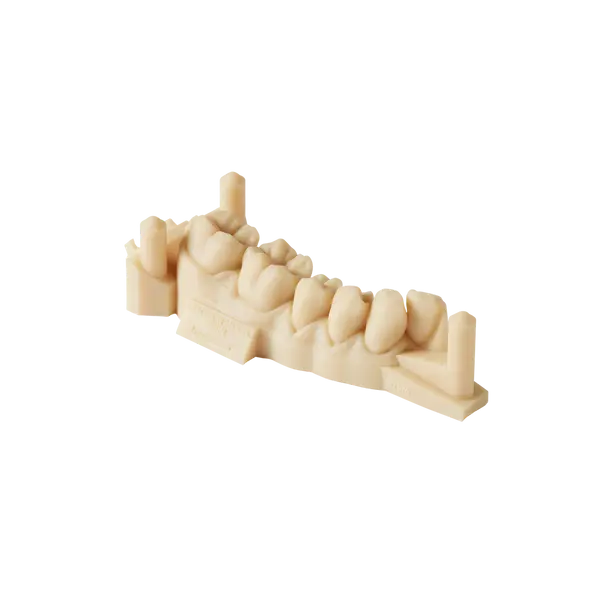

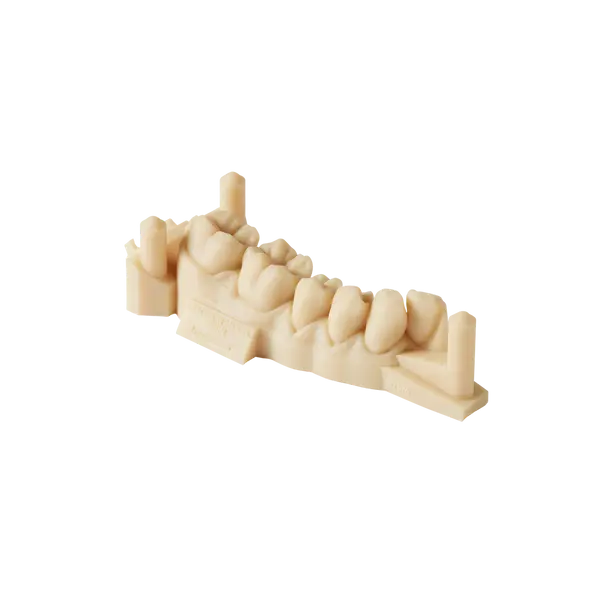

Premium Teeth Resin

SLAMultiple ShadesWear ResistantDenture TeethBiocompatibilityTemporary Full-Arch Implant-Supported Restorations (All-on-X)

SLAMultiple ShadesWear ResistantDenture TeethBiocompatibilityTemporary Full-Arch Implant-Supported Restorations (All-on-X)

Premium Teeth Resin is a nano-ceramic-filled biocompatible material with enhanced aesthetics, mechanical properties, and validated longevity to guarantee optimal clinical performance. 3D print denture teeth, temporary full-arch implant-supported restorations (All-on-X appliances), temporary single units (crowns, inlays, onlays, and veneers), and up to seven-unit bridges.

BEGO™ VarseoSmile® TriniQ® Resin

SLAMultiple ShadesCeramic FilledWear ResistantBiocompatibilityPermanent Restorations

SLAMultiple ShadesCeramic FilledWear ResistantBiocompatibilityPermanent Restorations

BEGO™ VarseoSmile® TriniQ® Resin is a versatile ceramic-filled biocompatible material, indicated for temporary and permanent single units (crowns, inlays, onlays, and veneers) and bridges, and denture teeth.

Nylon 12 White Powder 10 kg

SLSRobustHigh StrengthWear ResistantUV ResistantBiocompatibility

SLSRobustHigh StrengthWear ResistantUV ResistantBiocompatibility

Nylon 12 White Powder combines all of the great qualities of the general purpose and biocompatible Nylon 12 Powder with the customizability of white parts. Create functional prototypes and end-use customer-facing parts that can be easily dyed to match brand aesthetics as well as medical devices and models with high contrast and detail.

White Resin V5

SLAStiff & StrongMatteHigh StrengthHigh AccuracyFine DetailsPost-Curing Optional

SLAStiff & StrongMatteHigh StrengthHigh AccuracyFine DetailsPost-Curing Optional

White Resin is a versatile General Purpose Resin, offering an optimal balance of speed, accuracy, aesthetics, and mechanical properties to create parts that rival injection molding. Formulated specifically for the Form 4 Series, White Resin V5 prints three times faster than the previous version.

Fast Model Resin

SLAPost-Curing OptionalHigh ThroughputFast PrintingHigh Strength

SLAPost-Curing OptionalHigh ThroughputFast PrintingHigh Strength

Fast Model Resin is Formlabs’ fastest resin, capable of printing at speeds of over 100 mm per hour. Print dental models in minutes or large prototypes in less than two hours. Formulated specifically for the Form 4 ecosystem, this material prints three times faster than the previous version.

Black Resin V5

SLAStiff & StrongMatteHigh StrengthHigh AccuracyFine DetailsPost-Curing Optional

SLAStiff & StrongMatteHigh StrengthHigh AccuracyFine DetailsPost-Curing Optional

Black Resin is a versatile General Purpose Resin, offering an optimal balance of speed, accuracy, aesthetics, and mechanical properties to create parts that rival injection molding. Formulated specifically for the Form 4 ecosystem, Black Resin V5 prints 3 times faster than the previous version.

Color Kit (Form 4)

Color Kit is the first integrated color mixing solution for resin 3D printing. It enables 3D printing in a range of colors without the manual work of finishing, dying, or painting.

Color Kit contains a Color Base cartridge and all five Color Pigments. Use Color Kit to mix and print matte, opaque parts in a range of colors without the manual work of finishing and painting.

Color Kit contains a Color Base cartridge and all five Color Pigments. Use Color Kit to mix and print matte, opaque parts in a range of colors without the manual work of finishing and painting.

Alumina 4N Resin

SLAHeat ResistantComplex WorkflowUltra StiffUltra High StrengthCeramic

SLAHeat ResistantComplex WorkflowUltra StiffUltra High StrengthCeramic

Alumina 4N Resin is the first accessible high-density and high-purity technical ceramic 3D printing material with exceptional performance in extreme environments: thermally resistant, hard, abrasion resistant, mechanically strong, and chemically inert. Alumina 4N is a Form X material with an advanced workflow suited for expert users.

Rigid 10K Resin

SLAHeat ResistantHigh StrengthGlass FilledUltra StiffFine Details

SLAHeat ResistantHigh StrengthGlass FilledUltra StiffFine Details

Rigid 10K Resin is highly glass-filled and extremely stiff material that is similar to glass and fiber-filled thermoplastics. Use Rigid 10K Resin to rapidly produce molds, jigs, dies, and other tools, as well as functional prototypes and end use parts requiring dimensional accuracy and stability under high temperatures and pressures.

BioMed Flex 80A Resin

SLATranslucentElastomericHard Rubber-LikeBiocompatibility

SLATranslucentElastomericHard Rubber-LikeBiocompatibility

BioMed Flex 80A Resin is a firm, flexible, and transparent material for biocompatible applications requiring durability and long-term skin (>30 days) or short-term mucosal membrane contact (<24 hours). BioMed Flex 80A Resin is manufactured in our ISO 13485 certified facility.

IBT Flex Resin

SLAElastomericBiocompatibilityIndirect Bonding Trays

SLAElastomericBiocompatibilityIndirect Bonding Trays

IBT Flex Resin is a biocompatible material for indirect bonding trays and direct composite restoration guides with enhanced flexibility, strength, translucency, and color to guarantee optimal clinical outcomes, a seamless transfer of orthodontic brackets and restorative composite materials, and provide a great patient experience.

BioMed Durable Resin

SLABiocompatibilityImpact ResistantWear ResistantTransparent

SLABiocompatibilityImpact ResistantWear ResistantTransparent

BioMed Durable Resin is a transparent 3D printing material for biocompatible applications requiring impact, shatter, and abrasion resistance, as well as long-term skin (>30 days) and mucosal membrane (>30 hours) or short-term tissue, bone, and dentin contact (<24 hours).

BioMed Black Resin

SLASterilizableMatteBiocompatibility

SLASterilizableMatteBiocompatibility

BioMed Black Resin is a rigid, matte material for biocompatible applications requiring long-term skin (>30 days) or short-term mucosal membrane contact (<24 hours). Parts printed with BioMed Black Resin are compatible with common solvent disinfection and sterilization methods. BioMed Black Resin is manufactured in our ISO 13485 facility.

BioMed Amber Resin

SLAStiff & StrongTranslucentSterilizableBiocompatibilityUltra High Strength

SLAStiff & StrongTranslucentSterilizableBiocompatibilityUltra High Strength

BioMed Amber Resin is a strong, stiff material for biocompatible applications requiring long-term skin (>30 days) or short-term bone, tissue, dentin, and mucosal membrane contact (<24 hours). Parts printed with BioMed Amber Resin are compatible with common solvent disinfection and sterilization methods.

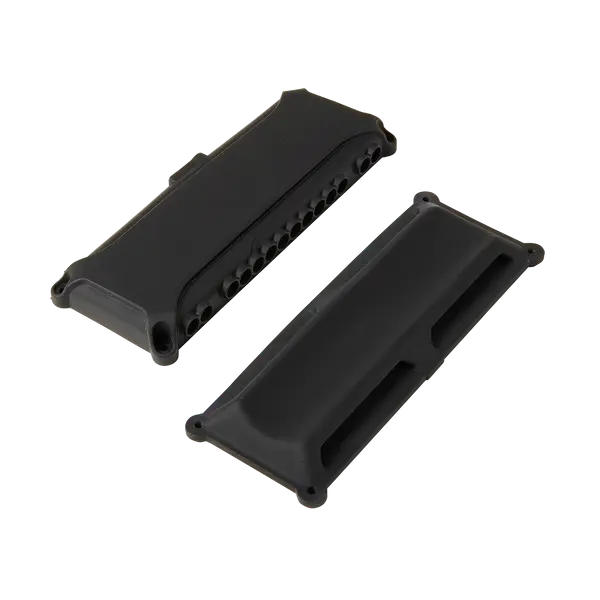

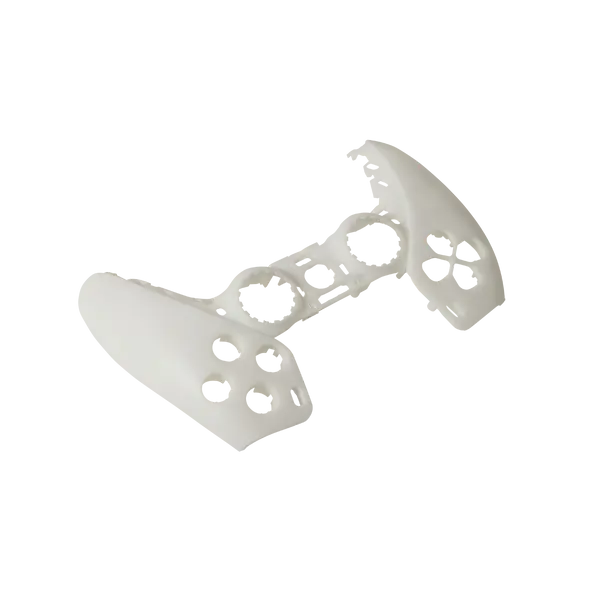

ESD Resin

SLAStiff & StrongABS-LikeESD-SafeRobust

SLAStiff & StrongABS-LikeESD-SafeRobust

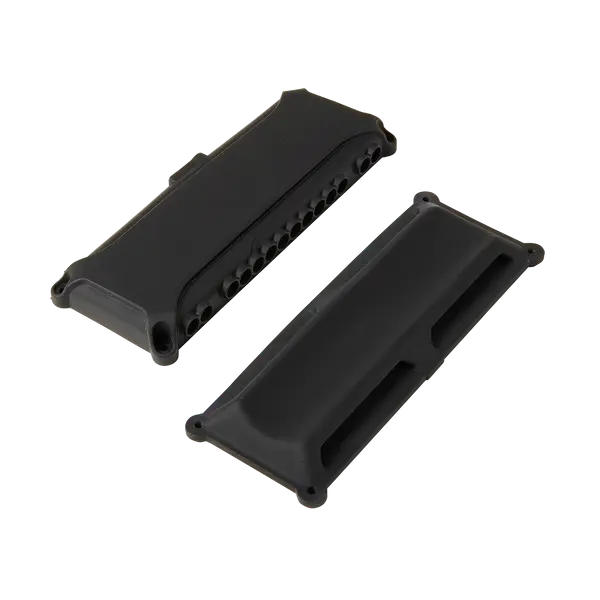

ESD Resin is a specialty material for producing custom ESD-safe prototypes and production tooling to increase operational efficiency and improve the yield of electronics manufacturing lines. Parts printed in ESD Resin are static-dissipative, repel dust and powder, and have high modulus and impact strength similar to ABS.

Castable Wax Resin

SLAFine DetailsWax FilledInvestment Casting

SLAFine DetailsWax FilledInvestment Casting

Castable Wax Resin is a 20% wax-filled material for casting that can capture intricate features and offers a smooth surface finish for accurate castings with zero ash content and clean burnout. It is ideal for ultrafine structures in jewelry, as well as highly accurate patterns for casting and pressing dental prosthetics.

BioMed Clear Resin

SLASterilizableRobustHigh StrengthBiocompatibilityTransparent

SLASterilizableRobustHigh StrengthBiocompatibilityTransparent

BioMed Clear Resin is a hard, strong, and wear-resistant material for biocompatible applications requiring long-term skin (>30 days), breathing gas pathways, and mucosal membrane contact (>30 hours) or short-term bone, tissue, and dentin (<24 hours). Parts printed with BioMed Clear Resin are compatible with common sterilization methods.

Flexible 80A Resin

SLATranslucentHard Rubber-LikeElastomericWear Resistant

SLATranslucentHard Rubber-LikeElastomericWear Resistant

Flexible 80A Resin a stiff, soft-touch, translucent elastomer with an 80A Shore durometer that is ideal for prototyping rubber-like parts with the flexibility of harder rubber or TPU. Parts printed in Flexible 80A Resin can withstand bending, flexing, and compression, even through repeated cycles.

Rigid 4000 Resin

SLAHigh StrengthGlass FilledUltra StiffPEEK-LikeFine Details

SLAHigh StrengthGlass FilledUltra StiffPEEK-LikeFine Details

Rigid 4000 Resin is a glass-filled resin that is stiff, precise, and offers high thermal and chemical resistance. It prints with a smooth, polished finish and is ideal for industrial parts that need to withstand significant load without bending. Parts printed in Rigid 4000 have similar stiffness to PEEK and PEKK thermoplastics.

Grey Pro Resin

SLAFine DetailsMatteLow CreepHigh Strength

SLAFine DetailsMatteLow CreepHigh Strength

Grey Pro Resin is a tough and heat-resistant material with a low creep, offering improved performance compared to Formlabs General Purpose Resins. Grey Pro Resin is compatible with Form 2 and Form 3 Series printers, while Grey Resin V5 for the Form 4 Series offers improved mechanical properties and faster speed, replacing Grey Pro Resin.

Tough 2000 Resin

SLAStiff & StrongABS-LikeHigh StrengthWear ResistantImpact Resistant

SLAStiff & StrongABS-LikeHigh StrengthWear ResistantImpact Resistant

Tough 2000 Resin has similar strength and stiffness to ABS plastics, making it ideal for functional parts that are difficult to bend and will hold up with extended use. Choose Tough 2000 Resin for prototyping strong and sturdy parts that should not bend easily, as well as jigs and fixtures requiring minimal deflection.

Draft Resin

SLAFine DetailsHigh AccuracyHigh ThroughputFast Printing

SLAFine DetailsHigh AccuracyHigh ThroughputFast Printing

Draft Resin prints up to four times faster than Formlabs' General Purpose Resins on Form 3 and Form 2 Series printers, and is perfect for initial prototypes, rapid iterations, and orthodontic models. Fast Model Resin for the Form 4 Series offers even faster speed and improved mechanical properties.

TPU 90A Powder 6 kg

SLSElastomericImpact ResistantTear ResistantSkin ContactHard Rubber-Like

SLSElastomericImpact ResistantTear ResistantSkin ContactHard Rubber-Like

TPU 90A Powder is a tough elastomer with high elongation at break and superior tear strength for flexible, resilient, and skin-safe prototypes and end-use parts. It is ideal for flexible functional parts that withstand the demands of everyday use.

Nylon 12 GF Powder 6 kg

SLSStiff & StrongHeat ResistantLow CreepGlass FilledUV Resistant

SLSStiff & StrongHeat ResistantLow CreepGlass FilledUV Resistant

Nylon 12 GF Powder is a glass-filled, biocompatible material with enhanced stiffness and heat resistance for demanding industrial environments. Choose this material to produce stiff functional prototypes or end-use parts for applications where structural rigidity and thermal stability are critical.

Soft Tissue Starter Pack

Gingiva MasksMultiple ShadesFlexible

Gingiva MasksMultiple ShadesFlexible

Soft Tissue Starter Pack enables you to create your own Soft Tissue Resin in customizable dark, medium, and light pink shades to 3D print flexible gingiva masks for use in combination with rigid dental models to confidently check implant prosthetics by adding removable soft tissue components to your model production.

Black Pigment

SLACustom Colors

SLACustom Colors

Black Pigment creates darker shades of Color Resin when mixed with Color Base Resin. Color Kit is the first integrated color mixing solution for resin 3D printing. It enables 3D printing in a range of colors without the manual work of finishing, dying, or painting.

Magenta Pigment

SLACustom Colors

SLACustom Colors

Magenta Pigment adds pink hues to Color Resin when mixed with Color Base Resin. Color Kit is the first integrated color mixing solution for resin 3D printing. It enables 3D printing in a range of colors without the manual work of finishing, dying, or painting.

Yellow Pigment

SLACustom Colors

SLACustom Colors

Yellow Pigment adds yellow hues to Color Resin when mixed with Color Base Resin. Color Kit is the first integrated color mixing solution for resin 3D printing. It enables 3D printing in a range of colors without the manual work of finishing, dying, or painting.

Tough 1000 Resin

SLAImpact ResistantWear ResistantHDPE-like

SLAImpact ResistantWear ResistantHDPE-like

Tough 1000 Resin is a ductile, impact-resistant material with comparable strength, stiffness, and toughness to high-density

polyethylene (HDPE), designed with exceptional wear and fatigue resistance for long-term toughness and utility.

Tough 1500 Resin V2

SLAPliablePP-LikeWear Resistant

SLAPliablePP-LikeWear Resistant

Tough 1500 Resin V2 is a resilient material with strength, stiffness, and toughness comparable to polypropylene (PP), offering exceptional resistance to fractures, impacts, and shattering.

Permanent Crown Resin 1kg (0.7 L)

SLAMultiple ShadesHigh StrengthCeramic FilledBiocompatibilityPermanent Restorations

SLAMultiple ShadesHigh StrengthCeramic FilledBiocompatibilityPermanent Restorations

Permanent Crown Resin is a tooth-colored, ceramic-filled resin for 3D printing permanent single crowns, inlays, onlays, and veneers. Permanent Crown Resin produces high strength, long term restorations with an accurate and precise fit. Available in four VITA* shades (A2, A3, B1, C2).

Grey Resin V4.1

SLAStiff & StrongMatteFast PrintingHigh AccuracyFine Details

SLAStiff & StrongMatteFast PrintingHigh AccuracyFine Details

Grey Resin is ideal for general-purpose prototyping and detailed models, offering a matte finish, opaque appearance, and precise details. Grey Resin V4 is compatible with Form 3 and Form 2 Series printers, while Grey Resin V5 for the Form 4 Series offers faster speed and improved mechanical properties.

White Resin V4.1

SLAStiff & StrongFine DetailsHigh StrengthHigh Accuracy

SLAStiff & StrongFine DetailsHigh StrengthHigh Accuracy

White Resin is perfect for general-purpose prototyping and design, and models with intricate details. White Resin V4.1 is compatible with Form 3 Series printers and produces brighter white parts compared to White Resin V4. Choose White Resin V5 on the Form 4 Series for three times faster print speed and improved mechanical properties.

Nylon 12 Tough Powder 10 kg

SLSRobustHigh StrengthWear ResistantUV ResistantBiocompatibility

SLSRobustHigh StrengthWear ResistantUV ResistantBiocompatibility

Nylon 12 Tough Powder offers the best-in-class refresh rate among Nylon powders, high ductility, and great dimensional accuracy across the build chamber. Print more durable parts for prototyping and small batch production that have reduced warpage without sacrificing strength.

Denture Base Resin

SLAMultiple ShadesDenture BasesWear ResistantBiocompatibility

SLAMultiple ShadesDenture BasesWear ResistantBiocompatibility

Denture Base Resin is a biocompatible material for producing long-lasting, wear-resistant denture bases and try-in dentures at a fraction of the cost of traditional methods. With four semi-translucent shades available, technicians can achieve lifelike gingiva with natural margins, whether with 3D printed denture teeth or acrylic cards.

Clear Cast Resin

SLAFine DetailsInvestment CastingTransparentHigh Accuracy

SLAFine DetailsInvestment CastingTransparentHigh Accuracy

Clear Cast Resin is a resin designed for investment casting, to directly print patterns that can be invested and cast. It has an extremely low thermal expansion, low ash, and no trace heavy metals.

Nylon 12 Powder 10 kg

SLSRobustHigh StrengthWear ResistantUV ResistantBiocompatibility

SLSRobustHigh StrengthWear ResistantUV ResistantBiocompatibility

Nylon 12 Powder is a general purpose, versatile, and biocompatible material with high detail and great dimensional accuracy. As the go-to material for SLS 3D printing, it is ideal for both functional prototyping and end-use production of complex assemblies and durable parts with high environmental stability.

Grey Resin V5

SLAStiff & StrongMatteFast PrintingHigh AccuracyFine DetailsPost-Curing Optional

SLAStiff & StrongMatteFast PrintingHigh AccuracyFine DetailsPost-Curing Optional

Grey Resin is a versatile General Purpose Resin, offering an optimal balance of speed, accuracy, aesthetics, and mechanical properties to create parts that rival injection molding. Formulated specifically for the Form 4 Series, Grey Resin V5 prints three times faster than the previous version.

Clear Resin V5

SLAStiff & StrongHigh StrengthTransparentHigh AccuracyFine DetailsPost-Curing Optional

SLAStiff & StrongHigh StrengthTransparentHigh AccuracyFine DetailsPost-Curing Optional

Clear Resin is an exceptionally clear 3D printing resin formulated to leverage the new Form 4 ecosystem, offering an optimal balance of fast print speed, high accuracy, transparency, and strong mechanical properties to create parts that can be coated or polished to rival acrylic.

Precision Model Resin

SLAMatteHigh AccuracyFine Details

SLAMatteHigh AccuracyFine Details

Precision Model Resin is a high-accuracy material for creating restorative models with high opacity, beige color, and a smooth, matte finish to capture fine details and create crisp margin lines. Formulated specifically for the Form 4 ecosystem, this material prints three times faster than the previous version.

Flame Retardant Resin

SLAStiff & StrongHeat ResistantRobustLow CreepUL94 V0 Certified

SLAStiff & StrongHeat ResistantRobustLow CreepUL94 V0 Certified

Flame Retardant Resin is a UL 94 V-0 certified, halogen-free material with favorable flame, smoke, and toxicity (FST) ratings for creating self-extinguishing parts. Parts printed in FR Resin are stiff and creep-resistant, and will perform well long-term in indoor and industrial environments with high temperatures or ignition sources.

Color Base Resin

SLAFine DetailsCustom ColorsMatte

SLAFine DetailsCustom ColorsMatte

Color Kit is the first integrated color mixing solution for resin 3D printing. It enables 3D printing in a range of colors without the manual work of finishing, dying, or painting. Color Base Resin is the foundation to mix with any Color Kit pigment and create Color Resin.

Elastic 50A Resin V2

SLATranslucentElastomericSoft Silicone-like

SLATranslucentElastomericSoft Silicone-like

Elastic 50A Resin V2 is a soft, translucent elastomer with a 50A Shore durometer that is ideal for prototyping parts normally produced with softer rubbers and silicones. Parts printed in Elastic 50A Resin will bend, stretch, compress, and hold up to repeated cycles without tearing, and spring back quickly to their original shape.

BioMed Elastic 50A Resin

SLAElastomericSoft Silicone-likeBiocompatibilityTranslucent

SLAElastomericSoft Silicone-likeBiocompatibilityTranslucent

BioMed Elastic 50A Resin is a soft, elastic, and transparent material for biocompatible applications requiring comfort and long-term skin (>30 days) or short-term mucosal membrane contact (<24 hours). BioMed Elastic 50A Resin is manufactured in our ISO 13485 certified facility.

Dental LT Comfort Resin

SLAFlexibleWear ResistantBiocompatibilityFlexible Splints and Occlusal GuardsTransparent

SLAFlexibleWear ResistantBiocompatibilityFlexible Splints and Occlusal GuardsTransparent

Dental LT Comfort Resin is a long-term biocompatible material for directly 3D printing flexible occlusal splints and night guards in-house, more easily than ever. Printed appliances are easily polished to high optical transparency, and offer enhanced comfort and durability that boosts patient adoption and compliance.

Silicone 40A Resin

SLAElastomericSoft100% SiliconeWear ResistantTear Resistant

SLAElastomericSoft100% SiliconeWear ResistantTear Resistant

Silicone 40A Resin is the first accessible 100% silicone 3D printing material, using Formlabs’ patent-pending Pure Silicone Technology™. Eliminate molding and labor-intensive casting processes by directly printing soft, pliable, and durable silicone parts in house in a matter of hours.

BioMed White Resin

SLASterilizableMatteBiocompatibility

SLASterilizableMatteBiocompatibility

BioMed White Resin is a rigid material for biocompatible applications requiring long-term skin (>30 days) or short-term bone, tissue, dentin, and mucosal membrane contact (<24 hours). BioMed White Resin is manufactured in our ISO 13485 facility.

Dental LT Clear V2 Resin

SLARobustWear ResistantBiocompatibilityHard Splints and Occlusal GuardsTransparent

SLARobustWear ResistantBiocompatibilityHard Splints and Occlusal GuardsTransparent

Dental LT Clear Resin V2 is a long-term biocompatible material for directly printing affordable, high-quality hard splints and occlusal guards in-house. Highly durable and resistant to fracture, this color-corrected material prints clear, polishes to high optical transparency, and resists discoloration over time.

Custom Tray Resin

SLACustom Impression TraysBiocompatibilityTranslucent

SLACustom Impression TraysBiocompatibilityTranslucent

Custom Tray Resin is a fast-printing biocompatible material used to directly print custom impression trays for implants, dentures, crowns and bridges, and other comprehensive cases. Digitally manufactured impression trays provide consistent, accurate impressions for high-quality dentistry.

Surgical Guide Resin

SLASterilizableTranslucentBiocompatibilitySurgical Guides

SLASterilizableTranslucentBiocompatibilitySurgical Guides

Surgical Guide Resin is an autoclavable, biocompatible resin for 3D printing dental surgical guides, drilling templates, pilot drill guides, and device sizing templates for implant placement. Surgical Guide Resin was rigorously tested to meet solvent disinfection and autoclave sterilization standards for implant systems.

Durable Resin

SLAPliableLow FrictionWear ResistantImpact ResistantPE-Like

SLAPliableLow FrictionWear ResistantImpact ResistantPE-Like

Durable Resin is a pliable, impact-resistant, and lubricious material for squeezable parts and low-friction assemblies. Parts printed in Durable Resin are robust and have low friction, with similar strength and stiffness to polyethylene (PE) and a coefficient of friction is comparable to Delrin® (POM).

High Temp Resin

SLATranslucentFine DetailsHeat ResistantUltra Stiff

SLATranslucentFine DetailsHeat ResistantUltra Stiff

High Temp Resin has a heat deflection temperature (HDT) of 238 °C @ 0.45 MPa — the highest among Formlabs resins. Choose it to print detailed, precise prototypes and end use parts with high thermal stability, such as molds and inserts, parts exposed to hot air, gas, and fluid flow, as well as heat-resistant mounts, housings, and fixtures.

Tough 1500 Resin V1

SLAPP-LikePliableWear ResistantImpact ResistantSkin Contact

SLAPP-LikePliableWear ResistantImpact ResistantSkin Contact

Tough 1500 Resin is a resilient, skin-safe material that offers similar strength and stiffness to polypropylene (PP). Choose Tough 1500 Resin for stiff and pliable parts that bend and spring back quickly, prototypes that repeatedly bend and quickly return to shape, and jigs and fixtures requiring repeated deflection.

Model V2 Resin

SLAMatteFine DetailsHigh Accuracy

SLAMatteFine DetailsHigh Accuracy

Model Resin V2 is the legacy formulation of Model Resin V3. It offers good aesthetics and accuracy, but prints more slowly than Model Resin V3. Model Resin V2 is compatible with Form 3 and Form 2 Series printers, while Precision Model Resin for the Form 4 Series offers better accuracy, faster speed, and improved aesthetics.

Model V3 Resin

SLAFine DetailsMatteFast PrintingHigh Accuracy

SLAFine DetailsMatteFast PrintingHigh Accuracy

Model Resin is a fast-printing material for the production of accurate restorative models. Model Resin V3 is compatible with Form 3 and Form 2 Series printers, while Precision Model Resin for the Form 4 Series offers better accuracy, faster speed, and improved aesthetics.

Grey Resin V4

SLAStiff & StrongMatteFast PrintingHigh AccuracyFine Details

SLAStiff & StrongMatteFast PrintingHigh AccuracyFine Details

Grey Resin is ideal for general-purpose prototyping and detailed models, offering a matte finish, opaque appearance, and precise details. Grey Resin V4 is compatible with Form 3 and Form 2 Series printers, while Grey Resin V5 for the Form 4 Series offers faster speed and improved mechanical properties.

Nylon 11 CF Powder 6 kg

SLSHeat ResistantCarbon Fiber FilledUltra StiffImpact ResistantUltra High Strength

SLSHeat ResistantCarbon Fiber FilledUltra StiffImpact ResistantUltra High Strength

Nylon 11 CF Powder is a carbon fiber-filled material, perfect for applications that require both superior stiffness and strength. Produce lightweight, rigid parts that remain structurally and thermally stable and can sustain repeated impact. Nylon 11 CF Powder requires to be printed on Fuse 1+ 30W with inert atmospheric control.

Nylon 11 Powder 6 kg

SLSHigh StrengthWear ResistantImpact ResistantUV ResistantSkin Contact

SLSHigh StrengthWear ResistantImpact ResistantUV ResistantSkin Contact

Nylon 11 Powder is a strong and highly ductile bio-based material. It is ideal for robust biocompatible parts, functional prototyping, and producing custom or low volume end-use parts that need to bend or take impact. For best results, print Nylon 11 Powder using the Fuse 1+ 30W and optional inert atmospheric control.

Color Kit (Form 3)

SLAFine DetailsMatteCustom Colors

SLAFine DetailsMatteCustom Colors

Color Kit is the first integrated color mixing solution for resin 3D printing. It enables 3D printing in a range of colors without the manual work of finishing, dying, or painting. Color Kit contains a Color Base cartridge and all five Color Pigments to mix and print matte, opaque parts in a range of colors.

Cyan Pigment

SLACustom Colors

SLACustom Colors

Cyan Pigment adds blue hues to Color Resin when mixed with Color Base Resin. Color Kit is the first integrated color mixing solution for resin 3D printing. It enables 3D printing in a range of colors without the manual work of finishing, dying, or painting.

White Pigment

SLACustom Colors

SLACustom Colors

White Pigment creates lighter shades of Color Resin when mixed with Color Base Resin. Color Kit is the first integrated color mixing solution for resin 3D printing. It enables 3D printing in a range of colors without the manual work of finishing, dying, or painting.

Tough 2000 Resin V2

SLAStiff & StrongImpact ResistantABS-LikeWear Resistant

SLAStiff & StrongImpact ResistantABS-LikeWear Resistant

Tough 2000 Resin V2 is a rugged material with strength and stiffness comparable to acrylonitrile butadiene styrene (ABS), combining toughness with high temperature and creep resistance.

Tough 1000 Resin

SLAImpact ResistantWear ResistantHDPE-like

SLAImpact ResistantWear ResistantHDPE-like

Tough 1000 Resin is a ductile, impact-resistant material with comparable strength, stiffness, and toughness to high-density

polyethylene (HDPE), designed with exceptional wear and fatigue resistance for long-term toughness and utility.

Color Resin

SLAMatteCustom ColorsHigh StrengthHigh AccuracyFine Details

SLAMatteCustom ColorsHigh StrengthHigh AccuracyFine Details

3D print parts in colors that represent your brand, product line, or creative vision with accuracy and consistency. Choose any color to closely match final parts without painting, coating, or pigment mixing.

Tough 1500 Resin V2

SLAPliablePP-LikeWear Resistant

SLAPliablePP-LikeWear Resistant

Tough 1500 Resin V2 is a resilient material with strength, stiffness, and toughness comparable to polypropylene (PP), offering exceptional resistance to fractures, impacts, and shattering.

True Cast Resin

SLAPatterns for Casting & PressingHigh AccuracyFine DetailsClean BurnoutCasting

SLAPatterns for Casting & PressingHigh AccuracyFine DetailsClean BurnoutCasting

True Cast Resin is a wax-filled 3D printing material, designed for precision casting of intricate jewelry and complex engineering components up to 5 mm.

Permanent Crown Resin 1kg (0.7 L)

SLAMultiple ShadesHigh StrengthCeramic FilledBiocompatibilityPermanent Restorations

SLAMultiple ShadesHigh StrengthCeramic FilledBiocompatibilityPermanent Restorations

Permanent Crown Resin is a tooth-colored, ceramic-filled resin for 3D printing permanent single crowns, inlays, onlays, and veneers. Permanent Crown Resin produces high strength, long term restorations with an accurate and precise fit. Available in four VITA* shades (A2, A3, B1, C2).

Temporary CB Resin 1 kg (0.7 L)

SLAMultiple ShadesHigh StrengthCeramic FilledBiocompatibilityTemporary Restorations

SLAMultiple ShadesHigh StrengthCeramic FilledBiocompatibilityTemporary Restorations

Temporary CB Resin is a tooth-colored resin for 3D printing of temporary crown and bridge restorations, inlays, onlays, and veneers. Indicated for up to seven-unit bridges and available in five shades, this material provides excellent marginal adaptation, strength, and aesthetics.

Grey Resin V4.1

SLAStiff & StrongMatteFast PrintingHigh AccuracyFine Details

SLAStiff & StrongMatteFast PrintingHigh AccuracyFine Details

Grey Resin is ideal for general-purpose prototyping and detailed models, offering a matte finish, opaque appearance, and precise details. Grey Resin V4 is compatible with Form 3 and Form 2 Series printers, while Grey Resin V5 for the Form 4 Series offers faster speed and improved mechanical properties.

Black Resin V4.1

SLAStiff & StrongMatteHigh StrengthHigh AccuracyFine Details

SLAStiff & StrongMatteHigh StrengthHigh AccuracyFine Details

Black Resin is perfect for general-purpose prototyping and design, and models with intricate details. Black Resin V4.1 is compatible with Form 3 Series printers, produces deeper black parts, and offers improved print reliability compared to Black Resin V4.0. Choose Black Resin V5 on the Form 4 Series for three times faster print speed and improved mechanical properties.

White Resin V4.1

SLAStiff & StrongFine DetailsHigh StrengthHigh Accuracy

SLAStiff & StrongFine DetailsHigh StrengthHigh Accuracy

White Resin is perfect for general-purpose prototyping and design, and models with intricate details. White Resin V4.1 is compatible with Form 3 Series printers and produces brighter white parts compared to White Resin V4. Choose White Resin V5 on the Form 4 Series for three times faster print speed and improved mechanical properties.

Clear Resin V4.1

SLAStiff & StrongHigh StrengthTransparentHigh AccuracyFine Details

SLAStiff & StrongHigh StrengthTransparentHigh AccuracyFine Details

Clear Resin is a rigid material that polishes to near optical transparency. Clear Resin V4.1 is compatible with Form 3 Series printers and creates more color-neutral and transparent parts compared to Clear Resin V4.0. Choose Clear Resin V5 on the Form 4 Series for three times faster print speed and improved mechanical properties.

Nylon 12 Tough Powder 10 kg

SLSRobustHigh StrengthWear ResistantUV ResistantBiocompatibility

SLSRobustHigh StrengthWear ResistantUV ResistantBiocompatibility

Nylon 12 Tough Powder offers the best-in-class refresh rate among Nylon powders, high ductility, and great dimensional accuracy across the build chamber. Print more durable parts for prototyping and small batch production that have reduced warpage without sacrificing strength.

Premium Teeth Resin

SLAMultiple ShadesWear ResistantDenture TeethBiocompatibilityTemporary Full-Arch Implant-Supported Restorations (All-on-X)

SLAMultiple ShadesWear ResistantDenture TeethBiocompatibilityTemporary Full-Arch Implant-Supported Restorations (All-on-X)

Premium Teeth Resin is a nano-ceramic-filled biocompatible material with enhanced aesthetics, mechanical properties, and validated longevity to guarantee optimal clinical performance. 3D print denture teeth, temporary full-arch implant-supported restorations (All-on-X appliances), temporary single units (crowns, inlays, onlays, and veneers), and up to seven-unit bridges.

Denture Base Resin

SLAMultiple ShadesDenture BasesWear ResistantBiocompatibility

SLAMultiple ShadesDenture BasesWear ResistantBiocompatibility

Denture Base Resin is a biocompatible material for producing long-lasting, wear-resistant denture bases and try-in dentures at a fraction of the cost of traditional methods. With four semi-translucent shades available, technicians can achieve lifelike gingiva with natural margins, whether with 3D printed denture teeth or acrylic cards.

BEGO™ VarseoSmile® TriniQ® Resin

SLAMultiple ShadesCeramic FilledWear ResistantBiocompatibilityPermanent Restorations

SLAMultiple ShadesCeramic FilledWear ResistantBiocompatibilityPermanent Restorations

BEGO™ VarseoSmile® TriniQ® Resin is a versatile ceramic-filled biocompatible material, indicated for temporary and permanent single units (crowns, inlays, onlays, and veneers) and bridges, and denture teeth.

Clear Cast Resin

SLAFine DetailsInvestment CastingTransparentHigh Accuracy

SLAFine DetailsInvestment CastingTransparentHigh Accuracy

Clear Cast Resin is a resin designed for investment casting, to directly print patterns that can be invested and cast. It has an extremely low thermal expansion, low ash, and no trace heavy metals.

Nylon 12 White Powder 10 kg

SLSRobustHigh StrengthWear ResistantUV ResistantBiocompatibility

SLSRobustHigh StrengthWear ResistantUV ResistantBiocompatibility

Nylon 12 White Powder combines all of the great qualities of the general purpose and biocompatible Nylon 12 Powder with the customizability of white parts. Create functional prototypes and end-use customer-facing parts that can be easily dyed to match brand aesthetics as well as medical devices and models with high contrast and detail.

Nylon 12 Powder 10 kg

SLSRobustHigh StrengthWear ResistantUV ResistantBiocompatibility

SLSRobustHigh StrengthWear ResistantUV ResistantBiocompatibility

Nylon 12 Powder is a general purpose, versatile, and biocompatible material with high detail and great dimensional accuracy. As the go-to material for SLS 3D printing, it is ideal for both functional prototyping and end-use production of complex assemblies and durable parts with high environmental stability.

White Resin V5

SLAStiff & StrongMatteHigh StrengthHigh AccuracyFine DetailsPost-Curing Optional

SLAStiff & StrongMatteHigh StrengthHigh AccuracyFine DetailsPost-Curing Optional

White Resin is a versatile General Purpose Resin, offering an optimal balance of speed, accuracy, aesthetics, and mechanical properties to create parts that rival injection molding. Formulated specifically for the Form 4 Series, White Resin V5 prints three times faster than the previous version.

Grey Resin V5

SLAStiff & StrongMatteFast PrintingHigh AccuracyFine DetailsPost-Curing Optional

SLAStiff & StrongMatteFast PrintingHigh AccuracyFine DetailsPost-Curing Optional

Grey Resin is a versatile General Purpose Resin, offering an optimal balance of speed, accuracy, aesthetics, and mechanical properties to create parts that rival injection molding. Formulated specifically for the Form 4 Series, Grey Resin V5 prints three times faster than the previous version.

Fast Model Resin

SLAPost-Curing OptionalHigh ThroughputFast PrintingHigh Strength

SLAPost-Curing OptionalHigh ThroughputFast PrintingHigh Strength

Fast Model Resin is Formlabs’ fastest resin, capable of printing at speeds of over 100 mm per hour. Print dental models in minutes or large prototypes in less than two hours. Formulated specifically for the Form 4 ecosystem, this material prints three times faster than the previous version.

Clear Resin V5

SLAStiff & StrongHigh StrengthTransparentHigh AccuracyFine DetailsPost-Curing Optional

SLAStiff & StrongHigh StrengthTransparentHigh AccuracyFine DetailsPost-Curing Optional

Clear Resin is an exceptionally clear 3D printing resin formulated to leverage the new Form 4 ecosystem, offering an optimal balance of fast print speed, high accuracy, transparency, and strong mechanical properties to create parts that can be coated or polished to rival acrylic.

Black Resin V5

SLAStiff & StrongMatteHigh StrengthHigh AccuracyFine DetailsPost-Curing Optional

SLAStiff & StrongMatteHigh StrengthHigh AccuracyFine DetailsPost-Curing Optional

Black Resin is a versatile General Purpose Resin, offering an optimal balance of speed, accuracy, aesthetics, and mechanical properties to create parts that rival injection molding. Formulated specifically for the Form 4 ecosystem, Black Resin V5 prints 3 times faster than the previous version.

Precision Model Resin

SLAMatteHigh AccuracyFine Details

SLAMatteHigh AccuracyFine Details

Precision Model Resin is a high-accuracy material for creating restorative models with high opacity, beige color, and a smooth, matte finish to capture fine details and create crisp margin lines. Formulated specifically for the Form 4 ecosystem, this material prints three times faster than the previous version.

Color Kit (Form 4)

Color Kit is the first integrated color mixing solution for resin 3D printing. It enables 3D printing in a range of colors without the manual work of finishing, dying, or painting.

Color Kit contains a Color Base cartridge and all five Color Pigments. Use Color Kit to mix and print matte, opaque parts in a range of colors without the manual work of finishing and painting.

Color Kit contains a Color Base cartridge and all five Color Pigments. Use Color Kit to mix and print matte, opaque parts in a range of colors without the manual work of finishing and painting.

Flame Retardant Resin

SLAStiff & StrongHeat ResistantRobustLow CreepUL94 V0 Certified

SLAStiff & StrongHeat ResistantRobustLow CreepUL94 V0 Certified

Flame Retardant Resin is a UL 94 V-0 certified, halogen-free material with favorable flame, smoke, and toxicity (FST) ratings for creating self-extinguishing parts. Parts printed in FR Resin are stiff and creep-resistant, and will perform well long-term in indoor and industrial environments with high temperatures or ignition sources.

Alumina 4N Resin

SLAHeat ResistantComplex WorkflowUltra StiffUltra High StrengthCeramic

SLAHeat ResistantComplex WorkflowUltra StiffUltra High StrengthCeramic

Alumina 4N Resin is the first accessible high-density and high-purity technical ceramic 3D printing material with exceptional performance in extreme environments: thermally resistant, hard, abrasion resistant, mechanically strong, and chemically inert. Alumina 4N is a Form X material with an advanced workflow suited for expert users.

Color Base Resin

SLAFine DetailsCustom ColorsMatte

SLAFine DetailsCustom ColorsMatte

Color Kit is the first integrated color mixing solution for resin 3D printing. It enables 3D printing in a range of colors without the manual work of finishing, dying, or painting. Color Base Resin is the foundation to mix with any Color Kit pigment and create Color Resin.

Rigid 10K Resin

SLAHeat ResistantHigh StrengthGlass FilledUltra StiffFine Details

SLAHeat ResistantHigh StrengthGlass FilledUltra StiffFine Details

Rigid 10K Resin is highly glass-filled and extremely stiff material that is similar to glass and fiber-filled thermoplastics. Use Rigid 10K Resin to rapidly produce molds, jigs, dies, and other tools, as well as functional prototypes and end use parts requiring dimensional accuracy and stability under high temperatures and pressures.

Elastic 50A Resin V2

SLATranslucentElastomericSoft Silicone-like

SLATranslucentElastomericSoft Silicone-like

Elastic 50A Resin V2 is a soft, translucent elastomer with a 50A Shore durometer that is ideal for prototyping parts normally produced with softer rubbers and silicones. Parts printed in Elastic 50A Resin will bend, stretch, compress, and hold up to repeated cycles without tearing, and spring back quickly to their original shape.

BioMed Flex 80A Resin

SLATranslucentElastomericHard Rubber-LikeBiocompatibility

SLATranslucentElastomericHard Rubber-LikeBiocompatibility

BioMed Flex 80A Resin is a firm, flexible, and transparent material for biocompatible applications requiring durability and long-term skin (>30 days) or short-term mucosal membrane contact (<24 hours). BioMed Flex 80A Resin is manufactured in our ISO 13485 certified facility.

BioMed Elastic 50A Resin

SLAElastomericSoft Silicone-likeBiocompatibilityTranslucent

SLAElastomericSoft Silicone-likeBiocompatibilityTranslucent

BioMed Elastic 50A Resin is a soft, elastic, and transparent material for biocompatible applications requiring comfort and long-term skin (>30 days) or short-term mucosal membrane contact (<24 hours). BioMed Elastic 50A Resin is manufactured in our ISO 13485 certified facility.

IBT Flex Resin

SLAElastomericBiocompatibilityIndirect Bonding Trays

SLAElastomericBiocompatibilityIndirect Bonding Trays

IBT Flex Resin is a biocompatible material for indirect bonding trays and direct composite restoration guides with enhanced flexibility, strength, translucency, and color to guarantee optimal clinical outcomes, a seamless transfer of orthodontic brackets and restorative composite materials, and provide a great patient experience.

Dental LT Comfort Resin

SLAFlexibleWear ResistantBiocompatibilityFlexible Splints and Occlusal GuardsTransparent

SLAFlexibleWear ResistantBiocompatibilityFlexible Splints and Occlusal GuardsTransparent

Dental LT Comfort Resin is a long-term biocompatible material for directly 3D printing flexible occlusal splints and night guards in-house, more easily than ever. Printed appliances are easily polished to high optical transparency, and offer enhanced comfort and durability that boosts patient adoption and compliance.

BioMed Durable Resin

SLABiocompatibilityImpact ResistantWear ResistantTransparent

SLABiocompatibilityImpact ResistantWear ResistantTransparent

BioMed Durable Resin is a transparent 3D printing material for biocompatible applications requiring impact, shatter, and abrasion resistance, as well as long-term skin (>30 days) and mucosal membrane (>30 hours) or short-term tissue, bone, and dentin contact (<24 hours).

Silicone 40A Resin

SLAElastomericSoft100% SiliconeWear ResistantTear Resistant

SLAElastomericSoft100% SiliconeWear ResistantTear Resistant

Silicone 40A Resin is the first accessible 100% silicone 3D printing material, using Formlabs’ patent-pending Pure Silicone Technology™. Eliminate molding and labor-intensive casting processes by directly printing soft, pliable, and durable silicone parts in house in a matter of hours.

BioMed Black Resin

SLASterilizableMatteBiocompatibility

SLASterilizableMatteBiocompatibility

BioMed Black Resin is a rigid, matte material for biocompatible applications requiring long-term skin (>30 days) or short-term mucosal membrane contact (<24 hours). Parts printed with BioMed Black Resin are compatible with common solvent disinfection and sterilization methods. BioMed Black Resin is manufactured in our ISO 13485 facility.

BioMed White Resin

SLASterilizableMatteBiocompatibility

SLASterilizableMatteBiocompatibility

BioMed White Resin is a rigid material for biocompatible applications requiring long-term skin (>30 days) or short-term bone, tissue, dentin, and mucosal membrane contact (<24 hours). BioMed White Resin is manufactured in our ISO 13485 facility.

BioMed Amber Resin

SLAStiff & StrongTranslucentSterilizableBiocompatibilityUltra High Strength

SLAStiff & StrongTranslucentSterilizableBiocompatibilityUltra High Strength

BioMed Amber Resin is a strong, stiff material for biocompatible applications requiring long-term skin (>30 days) or short-term bone, tissue, dentin, and mucosal membrane contact (<24 hours). Parts printed with BioMed Amber Resin are compatible with common solvent disinfection and sterilization methods.

Dental LT Clear V2 Resin

SLARobustWear ResistantBiocompatibilityHard Splints and Occlusal GuardsTransparent

SLARobustWear ResistantBiocompatibilityHard Splints and Occlusal GuardsTransparent

Dental LT Clear Resin V2 is a long-term biocompatible material for directly printing affordable, high-quality hard splints and occlusal guards in-house. Highly durable and resistant to fracture, this color-corrected material prints clear, polishes to high optical transparency, and resists discoloration over time.

ESD Resin

SLAStiff & StrongABS-LikeESD-SafeRobust

SLAStiff & StrongABS-LikeESD-SafeRobust

ESD Resin is a specialty material for producing custom ESD-safe prototypes and production tooling to increase operational efficiency and improve the yield of electronics manufacturing lines. Parts printed in ESD Resin are static-dissipative, repel dust and powder, and have high modulus and impact strength similar to ABS.

Custom Tray Resin

SLACustom Impression TraysBiocompatibilityTranslucent

SLACustom Impression TraysBiocompatibilityTranslucent

Custom Tray Resin is a fast-printing biocompatible material used to directly print custom impression trays for implants, dentures, crowns and bridges, and other comprehensive cases. Digitally manufactured impression trays provide consistent, accurate impressions for high-quality dentistry.

Castable Wax Resin

SLAFine DetailsWax FilledInvestment Casting

SLAFine DetailsWax FilledInvestment Casting

Castable Wax Resin is a 20% wax-filled material for casting that can capture intricate features and offers a smooth surface finish for accurate castings with zero ash content and clean burnout. It is ideal for ultrafine structures in jewelry, as well as highly accurate patterns for casting and pressing dental prosthetics.

Surgical Guide Resin

SLASterilizableTranslucentBiocompatibilitySurgical Guides

SLASterilizableTranslucentBiocompatibilitySurgical Guides

Surgical Guide Resin is an autoclavable, biocompatible resin for 3D printing dental surgical guides, drilling templates, pilot drill guides, and device sizing templates for implant placement. Surgical Guide Resin was rigorously tested to meet solvent disinfection and autoclave sterilization standards for implant systems.

BioMed Clear Resin

SLASterilizableRobustHigh StrengthBiocompatibilityTransparent

SLASterilizableRobustHigh StrengthBiocompatibilityTransparent

BioMed Clear Resin is a hard, strong, and wear-resistant material for biocompatible applications requiring long-term skin (>30 days), breathing gas pathways, and mucosal membrane contact (>30 hours) or short-term bone, tissue, and dentin (<24 hours). Parts printed with BioMed Clear Resin are compatible with common sterilization methods.

Durable Resin

SLAPliableLow FrictionWear ResistantImpact ResistantPE-Like

SLAPliableLow FrictionWear ResistantImpact ResistantPE-Like

Durable Resin is a pliable, impact-resistant, and lubricious material for squeezable parts and low-friction assemblies. Parts printed in Durable Resin are robust and have low friction, with similar strength and stiffness to polyethylene (PE) and a coefficient of friction is comparable to Delrin® (POM).

Flexible 80A Resin

SLATranslucentHard Rubber-LikeElastomericWear Resistant

SLATranslucentHard Rubber-LikeElastomericWear Resistant

Flexible 80A Resin a stiff, soft-touch, translucent elastomer with an 80A Shore durometer that is ideal for prototyping rubber-like parts with the flexibility of harder rubber or TPU. Parts printed in Flexible 80A Resin can withstand bending, flexing, and compression, even through repeated cycles.

High Temp Resin

SLATranslucentFine DetailsHeat ResistantUltra Stiff

SLATranslucentFine DetailsHeat ResistantUltra Stiff

High Temp Resin has a heat deflection temperature (HDT) of 238 °C @ 0.45 MPa — the highest among Formlabs resins. Choose it to print detailed, precise prototypes and end use parts with high thermal stability, such as molds and inserts, parts exposed to hot air, gas, and fluid flow, as well as heat-resistant mounts, housings, and fixtures.

Rigid 4000 Resin

SLAHigh StrengthGlass FilledUltra StiffPEEK-LikeFine Details

SLAHigh StrengthGlass FilledUltra StiffPEEK-LikeFine Details

Rigid 4000 Resin is a glass-filled resin that is stiff, precise, and offers high thermal and chemical resistance. It prints with a smooth, polished finish and is ideal for industrial parts that need to withstand significant load without bending. Parts printed in Rigid 4000 have similar stiffness to PEEK and PEKK thermoplastics.

Tough 1500 Resin V1

SLAPP-LikePliableWear ResistantImpact ResistantSkin Contact

SLAPP-LikePliableWear ResistantImpact ResistantSkin Contact

Tough 1500 Resin is a resilient, skin-safe material that offers similar strength and stiffness to polypropylene (PP). Choose Tough 1500 Resin for stiff and pliable parts that bend and spring back quickly, prototypes that repeatedly bend and quickly return to shape, and jigs and fixtures requiring repeated deflection.

Grey Pro Resin

SLAFine DetailsMatteLow CreepHigh Strength

SLAFine DetailsMatteLow CreepHigh Strength

Grey Pro Resin is a tough and heat-resistant material with a low creep, offering improved performance compared to Formlabs General Purpose Resins. Grey Pro Resin is compatible with Form 2 and Form 3 Series printers, while Grey Resin V5 for the Form 4 Series offers improved mechanical properties and faster speed, replacing Grey Pro Resin.

Model V2 Resin

SLAMatteFine DetailsHigh Accuracy

SLAMatteFine DetailsHigh Accuracy

Model Resin V2 is the legacy formulation of Model Resin V3. It offers good aesthetics and accuracy, but prints more slowly than Model Resin V3. Model Resin V2 is compatible with Form 3 and Form 2 Series printers, while Precision Model Resin for the Form 4 Series offers better accuracy, faster speed, and improved aesthetics.

Tough 2000 Resin

SLAStiff & StrongABS-LikeHigh StrengthWear ResistantImpact Resistant

SLAStiff & StrongABS-LikeHigh StrengthWear ResistantImpact Resistant

Tough 2000 Resin has similar strength and stiffness to ABS plastics, making it ideal for functional parts that are difficult to bend and will hold up with extended use. Choose Tough 2000 Resin for prototyping strong and sturdy parts that should not bend easily, as well as jigs and fixtures requiring minimal deflection.

Model V3 Resin

SLAFine DetailsMatteFast PrintingHigh Accuracy

SLAFine DetailsMatteFast PrintingHigh Accuracy

Model Resin is a fast-printing material for the production of accurate restorative models. Model Resin V3 is compatible with Form 3 and Form 2 Series printers, while Precision Model Resin for the Form 4 Series offers better accuracy, faster speed, and improved aesthetics.

Draft Resin

SLAFine DetailsHigh AccuracyHigh ThroughputFast Printing

SLAFine DetailsHigh AccuracyHigh ThroughputFast Printing

Draft Resin prints up to four times faster than Formlabs' General Purpose Resins on Form 3 and Form 2 Series printers, and is perfect for initial prototypes, rapid iterations, and orthodontic models. Fast Model Resin for the Form 4 Series offers even faster speed and improved mechanical properties.

Grey Resin V4

SLAStiff & StrongMatteFast PrintingHigh AccuracyFine Details

SLAStiff & StrongMatteFast PrintingHigh AccuracyFine Details

Grey Resin is ideal for general-purpose prototyping and detailed models, offering a matte finish, opaque appearance, and precise details. Grey Resin V4 is compatible with Form 3 and Form 2 Series printers, while Grey Resin V5 for the Form 4 Series offers faster speed and improved mechanical properties.

TPU 90A Powder 6 kg

SLSElastomericImpact ResistantTear ResistantSkin ContactHard Rubber-Like

SLSElastomericImpact ResistantTear ResistantSkin ContactHard Rubber-Like

TPU 90A Powder is a tough elastomer with high elongation at break and superior tear strength for flexible, resilient, and skin-safe prototypes and end-use parts. It is ideal for flexible functional parts that withstand the demands of everyday use.

Nylon 11 CF Powder 6 kg

SLSHeat ResistantCarbon Fiber FilledUltra StiffImpact ResistantUltra High Strength

SLSHeat ResistantCarbon Fiber FilledUltra StiffImpact ResistantUltra High Strength

Nylon 11 CF Powder is a carbon fiber-filled material, perfect for applications that require both superior stiffness and strength. Produce lightweight, rigid parts that remain structurally and thermally stable and can sustain repeated impact. Nylon 11 CF Powder requires to be printed on Fuse 1+ 30W with inert atmospheric control.

Nylon 12 GF Powder 6 kg

SLSStiff & StrongHeat ResistantLow CreepGlass FilledUV Resistant

SLSStiff & StrongHeat ResistantLow CreepGlass FilledUV Resistant

Nylon 12 GF Powder is a glass-filled, biocompatible material with enhanced stiffness and heat resistance for demanding industrial environments. Choose this material to produce stiff functional prototypes or end-use parts for applications where structural rigidity and thermal stability are critical.

Nylon 11 Powder 6 kg

SLSHigh StrengthWear ResistantImpact ResistantUV ResistantSkin Contact

SLSHigh StrengthWear ResistantImpact ResistantUV ResistantSkin Contact

Nylon 11 Powder is a strong and highly ductile bio-based material. It is ideal for robust biocompatible parts, functional prototyping, and producing custom or low volume end-use parts that need to bend or take impact. For best results, print Nylon 11 Powder using the Fuse 1+ 30W and optional inert atmospheric control.

Soft Tissue Starter Pack

Gingiva MasksMultiple ShadesFlexible

Gingiva MasksMultiple ShadesFlexible

Soft Tissue Starter Pack enables you to create your own Soft Tissue Resin in customizable dark, medium, and light pink shades to 3D print flexible gingiva masks for use in combination with rigid dental models to confidently check implant prosthetics by adding removable soft tissue components to your model production.

Color Kit (Form 3)

SLAFine DetailsMatteCustom Colors

SLAFine DetailsMatteCustom Colors

Color Kit is the first integrated color mixing solution for resin 3D printing. It enables 3D printing in a range of colors without the manual work of finishing, dying, or painting. Color Kit contains a Color Base cartridge and all five Color Pigments to mix and print matte, opaque parts in a range of colors.

Black Pigment

SLACustom Colors

SLACustom Colors

Black Pigment creates darker shades of Color Resin when mixed with Color Base Resin. Color Kit is the first integrated color mixing solution for resin 3D printing. It enables 3D printing in a range of colors without the manual work of finishing, dying, or painting.

Cyan Pigment

SLACustom Colors

SLACustom Colors

Cyan Pigment adds blue hues to Color Resin when mixed with Color Base Resin. Color Kit is the first integrated color mixing solution for resin 3D printing. It enables 3D printing in a range of colors without the manual work of finishing, dying, or painting.

Magenta Pigment

SLACustom Colors

SLACustom Colors

Magenta Pigment adds pink hues to Color Resin when mixed with Color Base Resin. Color Kit is the first integrated color mixing solution for resin 3D printing. It enables 3D printing in a range of colors without the manual work of finishing, dying, or painting.

White Pigment

SLACustom Colors

SLACustom Colors

White Pigment creates lighter shades of Color Resin when mixed with Color Base Resin. Color Kit is the first integrated color mixing solution for resin 3D printing. It enables 3D printing in a range of colors without the manual work of finishing, dying, or painting.

Yellow Pigment

SLACustom Colors

SLACustom Colors

Yellow Pigment adds yellow hues to Color Resin when mixed with Color Base Resin. Color Kit is the first integrated color mixing solution for resin 3D printing. It enables 3D printing in a range of colors without the manual work of finishing, dying, or painting.

What Material is Right for You?

Compare All MaterialsSLA

Alumina 4N Resin

BioMed Amber Resin

BioMed Black Resin

BioMed Clear Resin

BioMed Durable Resin

BioMed Elastic 50A Resin

BioMed Flex 80A Resin

BioMed White Resin

Black Resin V4.1

Black Resin V5

Clear Resin V4.1

Clear Resin V5

Color Kit

Color Resin

Custom Tray Resin

Dental LT Clear V2 Resin

Dental LT Comfort Resin

Denture Base Resin

Draft Resin

Durable Resin

ESD Resin

Elastic 50A Resin V2

Fast Model Resin

Flame Retardant Resin

Flexible 80A Resin

Grey Pro Resin

Grey Resin V4

Grey Resin V5

High Temp Resin

IBT Flex Resin

Model V2 Resin

Model V3 Resin

Permanent Crown Resin

Precision Model Resin

Premium Teeth Resin

Rigid 10K Resin

Rigid 4000 Resin

Silicone 40A Resin

Surgical Guide Resin

Temporary CB Resin

Tough 1000 Resin

Tough 1500 Resin

Tough 1500 Resin V2

Tough 2000 Resin

Tough 2000 Resin V2

White Resin V4.1

White Resin V5

SLS

Nylon 11 CF Powder

Nylon 11 Powder

Nylon 12 GF Powder

Nylon 12 Powder

Nylon 12 Tough Powder

Nylon 12 White Powder

TPU 90A Powder

SLA

Alumina 4N Resin

BioMed Amber Resin

BioMed Black Resin

BioMed Clear Resin

BioMed Durable Resin

BioMed Elastic 50A Resin

BioMed Flex 80A Resin

BioMed White Resin

Black Resin V4.1

Black Resin V5

Clear Resin V4.1

Clear Resin V5

Color Kit

Color Resin

Custom Tray Resin

Dental LT Clear V2 Resin

Dental LT Comfort Resin

Denture Base Resin

Draft Resin

Durable Resin

ESD Resin

Elastic 50A Resin V2

Fast Model Resin

Flame Retardant Resin

Flexible 80A Resin

Grey Pro Resin

Grey Resin V4

Grey Resin V5

High Temp Resin

IBT Flex Resin

Model V2 Resin

Model V3 Resin

Permanent Crown Resin

Precision Model Resin

Premium Teeth Resin

Rigid 10K Resin

Rigid 4000 Resin

Silicone 40A Resin

Surgical Guide Resin

Temporary CB Resin

Tough 1000 Resin

Tough 1500 Resin

Tough 1500 Resin V2

Tough 2000 Resin

Tough 2000 Resin V2

White Resin V4.1

White Resin V5

SLS

Nylon 11 CF Powder

Nylon 11 Powder

Nylon 12 GF Powder

Nylon 12 Powder

Nylon 12 Tough Powder

Nylon 12 White Powder

TPU 90A Powder

Overview

Tough 1500 Resin V2 is a resilient material with strength, stiffness, and toughness comparable to polypropylene (PP), offering exceptional resistance to fractures, impacts, and shattering.

Fast Model Resin is Formlabs’ fastest resin, capable of printing at speeds of over 100 mm per hour. Print dental models in minutes or large prototypes in less than two hours. Formulated specifically for the Form 4 ecosystem, this material prints three times faster than the previous version.

Material properties1

34 MPa

Ultimate Tensile Strength

62 MPa

Ultimate Tensile Strength

41 MPa

Flexural Strength

106 MPa

Flexural Strength

1,370 MPa

Flexural Modulus

2,740 MPa

Flexural Modulus

42 J/m

Notched Izod

37 J/m

Notched Izod

155 %

Elongation at Break

11 %

Elongation at Break

53 °C

Heat Deflection Temp. @ 1.8 MPa

61 °C

Heat Deflection Temp. @ 1.8 MPa

66 °C

Heat Deflection Temp. @ 0.45 MPa

76 °C

Heat Deflection Temp. @ 0.45 MPa

1,460 MPa

Tensile Modulus

2,670 MPa

Tensile Modulus

910 J/m

Unnotched Izod

—

Unnotched Izod

1,090 J/m

Work of Fracture (Wf)

—

Work of Fracture (Wf)

1.7 MPa-m1/2

Maximum Stress Intensity Factor (Kmax)

—

Maximum Stress Intensity Factor (Kmax)

5.9 J

Gardner at 1/32" (0.97 mm) thickness

—

Gardner at 1/32" (0.97 mm) thickness

11.1 J

Gardner at 1/16" (1.9 mm) thickness

—

Gardner at 1/16" (1.9 mm) thickness

8,000 cycles

Ross Flexing Fatigue

—

Ross Flexing Fatigue

Tough 1500 Resin V2

Fast Model Resin

Ultimate Tensile Strength (MPa)

34

62

0

16

31

47

62

Flexural Strength (MPa)

41

106

0

27

53

80

106

Flexural Modulus (MPa)

1370

2740

0

685

1370

2055

2740

Notched Izod (J/m)

42

37

0

11

21

32

42

Unnotched Izod (J/m)

910

No Measurement

0

228

455

683

910

Elongation at Break (%)

155

11

0

39

78

117

155

Heat Deflection Temp. @ 1.8 MPa (°C)

53

61

0

16

31

46

61

Heat Deflection Temp. @ 0.45 MPa (°C)

66

76

0

19

38

57

76

Work of Fracture (Wf) (J/m)

1090

No Measurement

0

273

545

818

1090

Maximum Stress Intensity Factor (Kmax) (MPa-m1/2)

1.7

No Measurement

0.00

0.42

0.85

1.27

1.70

Tensile Modulus (MPa)

1460

2670

0

668

1335

2003

2670

Gardner at 1/32" (0.97 mm) thickness (J)

5.9

No Measurement

0.0

1.5

3.0

4.4

5.9

Gardner at 1/16" (1.9 mm) thickness (J)

11.1

No Measurement

0

3

6

9

12

Ross Flexing Fatigue (cycles)

8000

No Measurement

0

2000

4000

6000

8000

1: Post-cured measurements. See more details in material properties data